Cigar type cigarette tobacco leaf formulation

A leaf group formula and cigar-type technology, which is applied in the field of cigar-type cigarette tobacco leaf group formulation, can solve the problems of the cigar-type cigarette smoking taste style is not stable enough, the research is not deep enough, and the industrial development is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

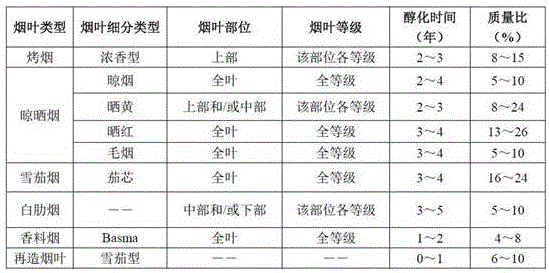

[0033] The cigar-shaped cigarette tobacco leaf group formula provided in this example is compounded by flue-cured tobacco, air-cured tobacco, cigar tobacco, burley tobacco, oriental tobacco, and reconstituted tobacco leaves. The specific requirements of various tobacco leaves are as follows:

[0034]

[0035] "——" in the table means unlimited.

Embodiment 2

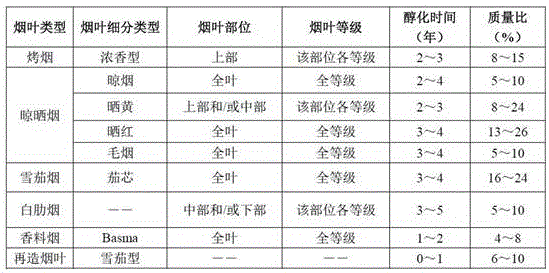

[0037]The formula of the cigar-type cigarette leaf group provided by the present embodiment is calculated by mass percentage, and the specific requirements of various tobacco leaves are as follows:

[0038] .

[0039] Test case

[0040] According to the leaf group formulations provided in Examples 1 and 2, shredded tobacco is made by using the existing production unit, rolled into finished cigarettes, and smoked. The specific evaluation results are shown in the table below:

[0041] .

[0042] At the same time, the smoke components of the prepared cigarettes were detected and analyzed, and the results were as follows:

[0043] .

[0044] According to the test results of the above-mentioned smoke components, although the formula of the leaf group has been adjusted appropriately, the consistency of the smoke components is still good.

[0045] As far as the above smoking evaluation results are concerned, the style of the cigarettes is consistent, and there is no obvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com