Method for blending tobacco materials and equipment thereof

A tobacco material and material technology, applied in the field of tobacco material blending, can solve the problems of low stability of blending amount, unstable composition of shredded tobacco, and no consideration of blending material moisture, etc., to achieve stable raw material ratio and improve blending accuracy , the effect of correct blending ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

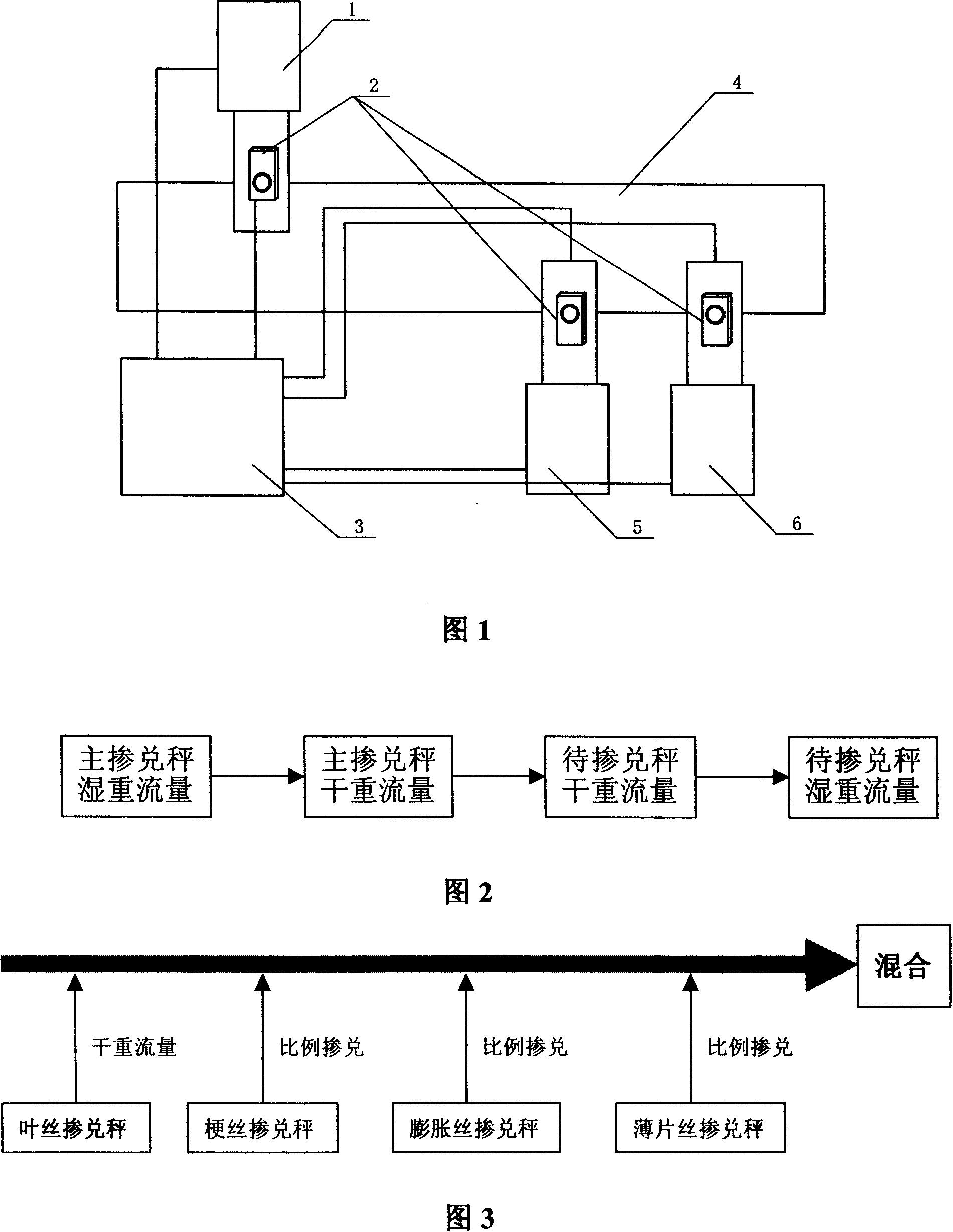

[0034] With reference to Fig. 1, the equipment provided by the present invention to realize the dry weight blending method for tobacco materials includes a conveyor belt 4, a shredded leaf blending scale 1, a cut stem blending scale 5, an expanded shredded tobacco blending scale 6 and a controller 3 , an online moisture meter 2 is installed on each blending scale, and is connected with a controller 3 .

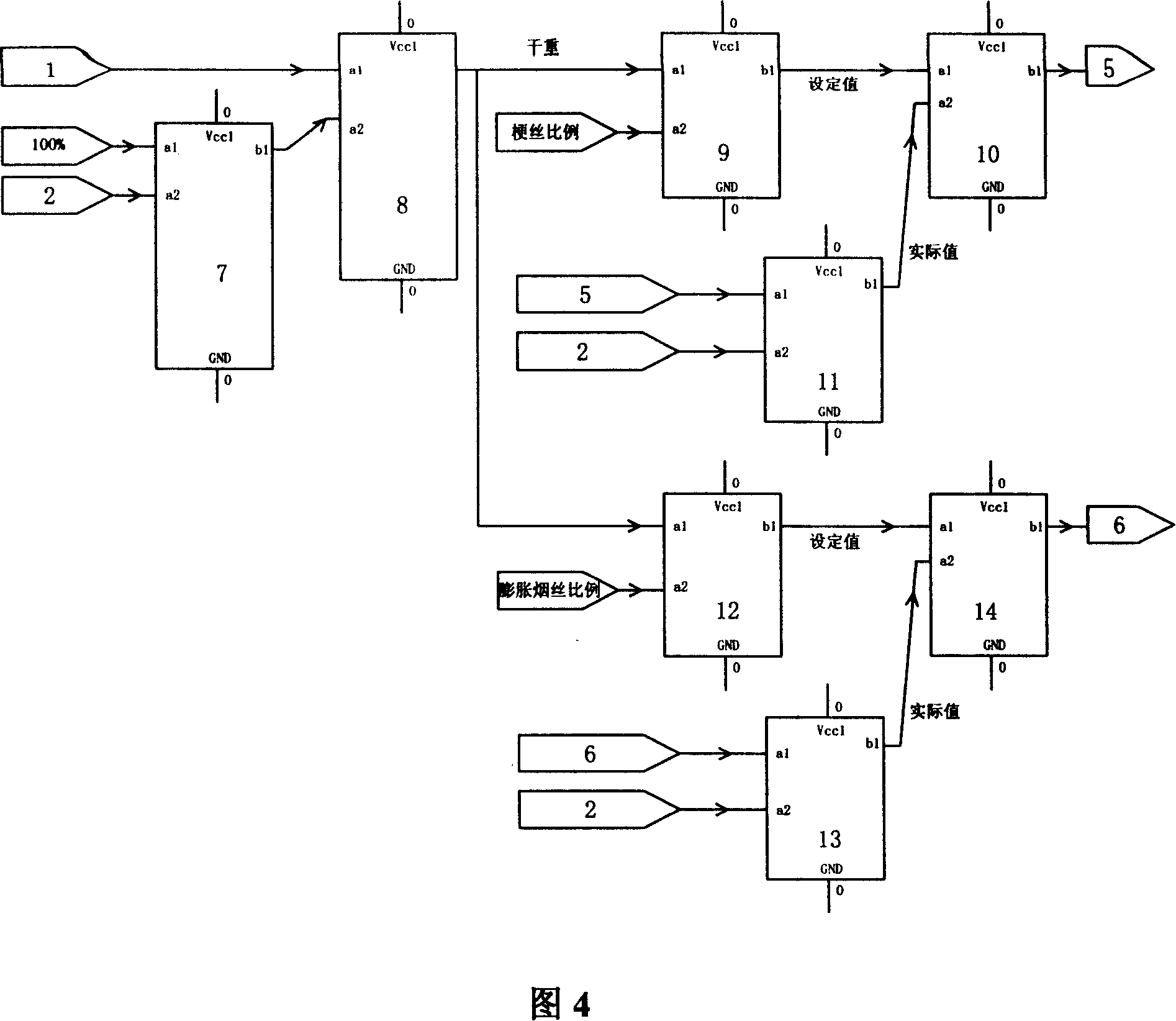

[0035] With reference to Fig. 4, take shredded leaf, shredded stem and expanded shredded tobacco formula as example, the working process of above-mentioned equipment is described as follows:

[0036] 1) Detect the moisture content of the shredded leaves on the shredded shreds blending scale by the moisture meter 2 on the shredded shreds blending scale, calculate the dry weight ratio in the shredded leaves by the subtractor 7 in the controller, and measure the total amount on the blending scale. Flow rate, use multiplier 8 to calculate the dry weight of shredded leaf according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com