Tobacco stem cutting process by threshed tobacco stems

A technology of tobacco stems and shredded stems, which is applied in the field of shredded tobacco stems after threshing, and can solve the problems of large differences in cigarette weight, draw resistance, and density physical indicators, uneven distribution of flaky shredded stems, and large differences in shape of shredded tobacco. To improve the quality and stability of rolling, reduce the re-baking process of tobacco stems, and improve the uniformity of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

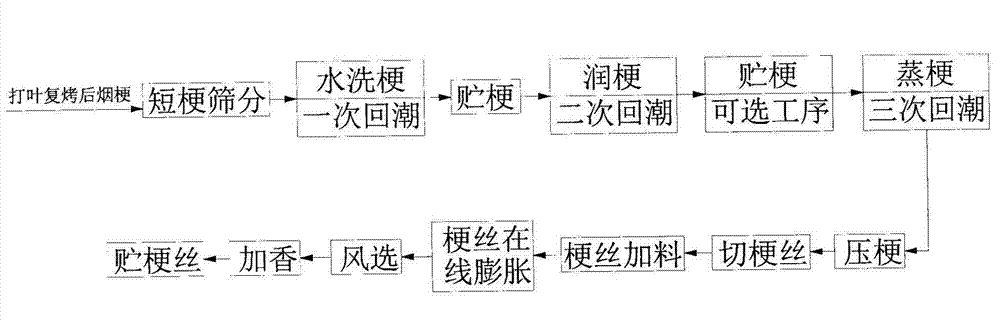

[0026] The present invention is described in detail below in conjunction with accompanying drawing technological process as follows:

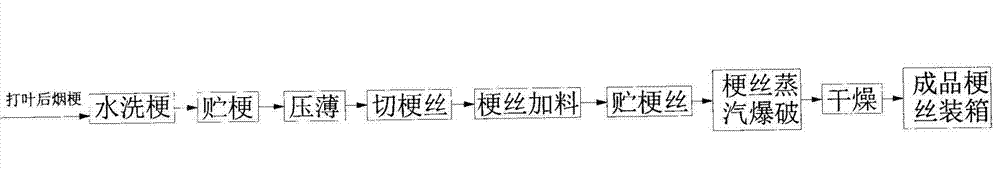

[0027] Such as figure 2 As shown, the tobacco stem shredded stem processing process after threshing leaves of the present invention is as follows:

[0028] After threshing, the tobacco stems go through the screening process, and after screening out the broken stems with a diameter of φ1.5mm and a length of less than 10mm, the tobacco stems are sent to the soaking device, and the tobacco stems are soaked in circulating hot water at 45-50°C for 3 minutes to wash off the tobacco stems Sand, colloid, hemp silk and other sundries on the surface. Send the soaked tobacco stems to the stem storage cabinet, and store the stems for 2-3 hours, so that the tobacco stems can fully absorb water and fully soften the tobacco stems; meet the needs of thin pressing in the stem pressing process (the thickness of the stems is 0.6-0.8mm ), but in order to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com