Tobacco additive for improving sensory quality of tobacco sheet and preparation method as well as application thereof

A technology of tobacco additives and tobacco flakes, which is applied in the fields of tobacco, application, and preparation of tobacco, etc., can solve the problems of consumption of long-fiber log resources, high irritation of tobacco leaves, and strong dependence on wood pulp, etc., to reduce bad smell, smoke The effect of reducing gas irritation and reducing woodiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

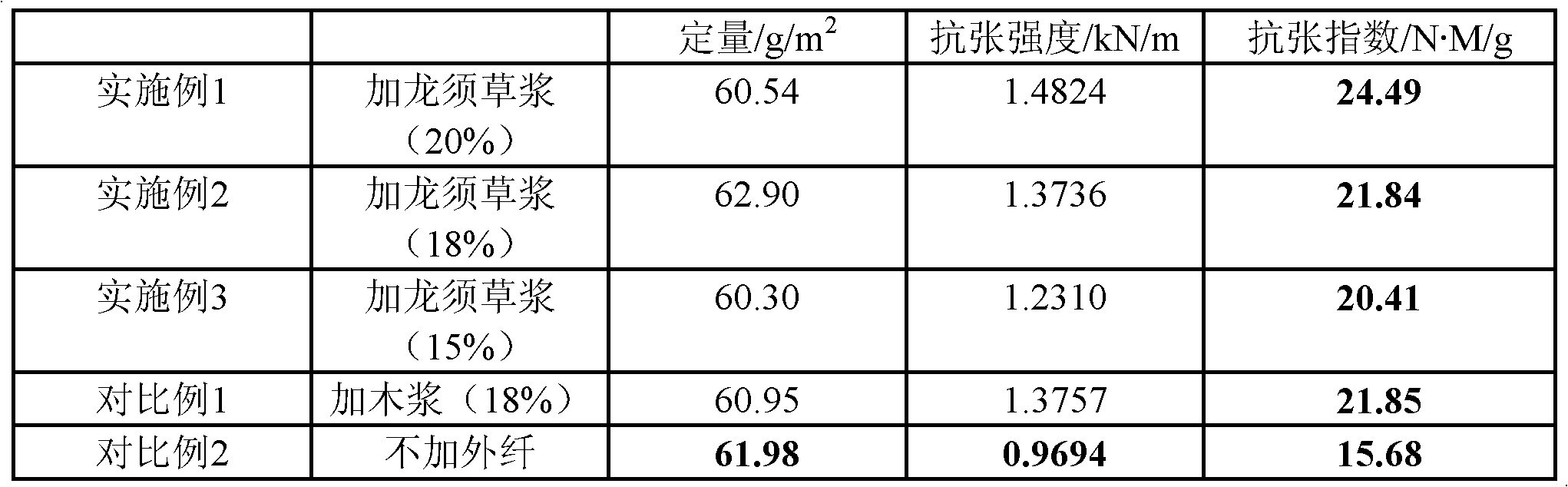

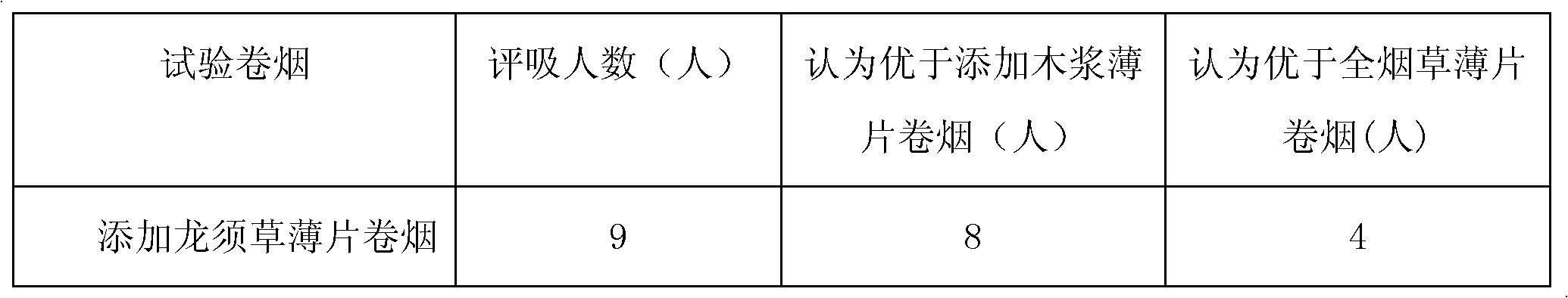

Embodiment 1

[0025] Preparation of asparagus straw pulp: The finished asparagus straw pulp board is subjected to hydraulic pulping at 40°C for 10 minutes. After the fluid slurry is obtained, it is beaten by a conical refiner, and the beating degree is 23 0 SR; fiber wet weight at 9.8g.

[0026] Preparation of tobacco pulp and tobacco extract: extract and decompose tobacco stems according to the on-site process, and prepare tobacco pulp according to the normal sample ratio, the ratio is tobacco stem: tobacco sheet: tobacco powder = 5: 4: 1 (weight ratio). Extract the mixed smoke slurry with water at 40°C, collect and concentrate the extract to prepare a coating solution. Utilize the high-consistency mill to beat the residue after the extraction of tobacco pulp to obtain tobacco pulp, and the degree of beating is determined to be 26 0 The SR and fiber wet weight was 4.5 g.

[0027] Tobacco sheet preparation: the above-mentioned asparagus pulp and tobacco pulp are mixed in proportion, wher...

Embodiment 2

[0029] Preparation of asparagus straw pulp: The finished asparagus straw pulp board is subjected to hydraulic pulping at 50°C for 15 minutes. After the fluid slurry is obtained, it is beaten by a conical refiner, and the size is 26 0 SR; fiber wet weight is 7g.

[0030] Preparation of tobacco pulp and tobacco extract: extract and decompose tobacco stems according to the on-site process, and prepare tobacco pulp according to the normal sample ratio, the ratio is tobacco stem: tobacco sheet: tobacco powder = 5: 4: 1 (weight ratio). Extract the mixed smoke slurry with water at 50°C, collect and concentrate the extract to prepare a coating solution. Use high-consistency grinding to beat the residue after the extraction of tobacco pulp to obtain tobacco pulp, and the degree of beating is determined to be 28 0 The SR and fiber wet weight was 3.6 g.

[0031] Tobacco sheet preparation: the above-mentioned asparagus pulp and tobacco pulp were mixed in proportion, wherein the asparag...

Embodiment 3

[0033] Preparation of asparagus straw pulp: The finished asparagus straw pulp board is subjected to hydraulic pulping at 60°C for 20 minutes. After the fluid slurry is obtained, it is beaten by a conical refiner to maintain the slurry at 31 0 SR; fiber wet weight at 7.1 g.

[0034] Preparation of tobacco pulp and tobacco extract: extract and decompose tobacco stems according to the on-site process, and prepare tobacco pulp according to the normal sample ratio, the ratio is tobacco stem: tobacco sheet: tobacco powder = 5: 4: 1 (weight ratio). Extract the mixed smoke slurry with water at 60°C, collect and concentrate the extract to prepare a coating solution. Use high-consistency grinding to beat the residue after extraction of tobacco pulp to obtain tobacco pulp, and the degree of beating is determined to be 34 0 The SR and fiber wet weight was 3.2 g.

[0035] Tobacco sheet preparation: the above-mentioned asparagus pulp and tobacco pulp are mixed in proportion, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com