Heating cigarette double-filament gathering device and cigarette core rod forming system

A technology for shredded tobacco and cigarettes, which is applied in the fields of heating cigarette double shred gathering devices and cigarette core rod forming systems, can solve the problems of uneven wrapping of outer shredded tobacco, loose combination of inner shredded tobacco and outer shredded tobacco, etc., achieves high production efficiency and reduces cigarette Cost, uniform and complete effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

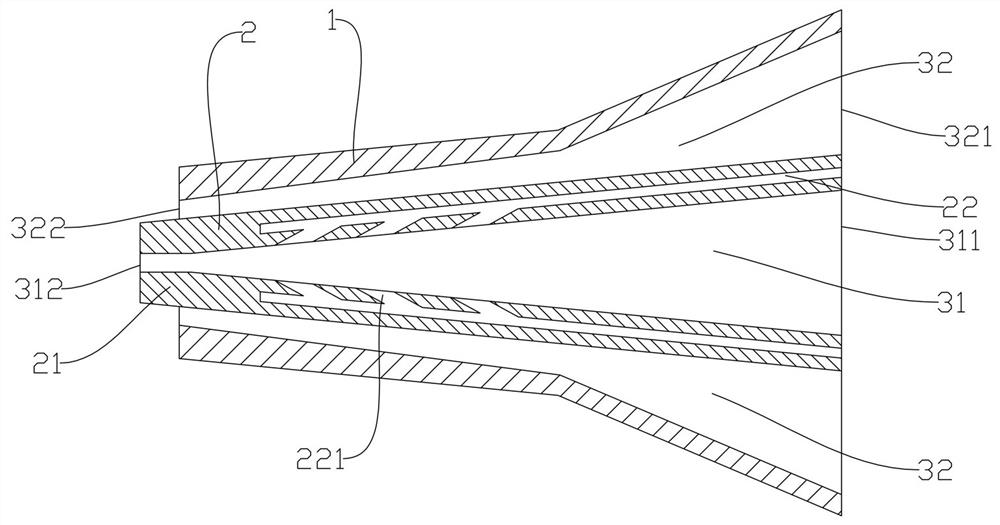

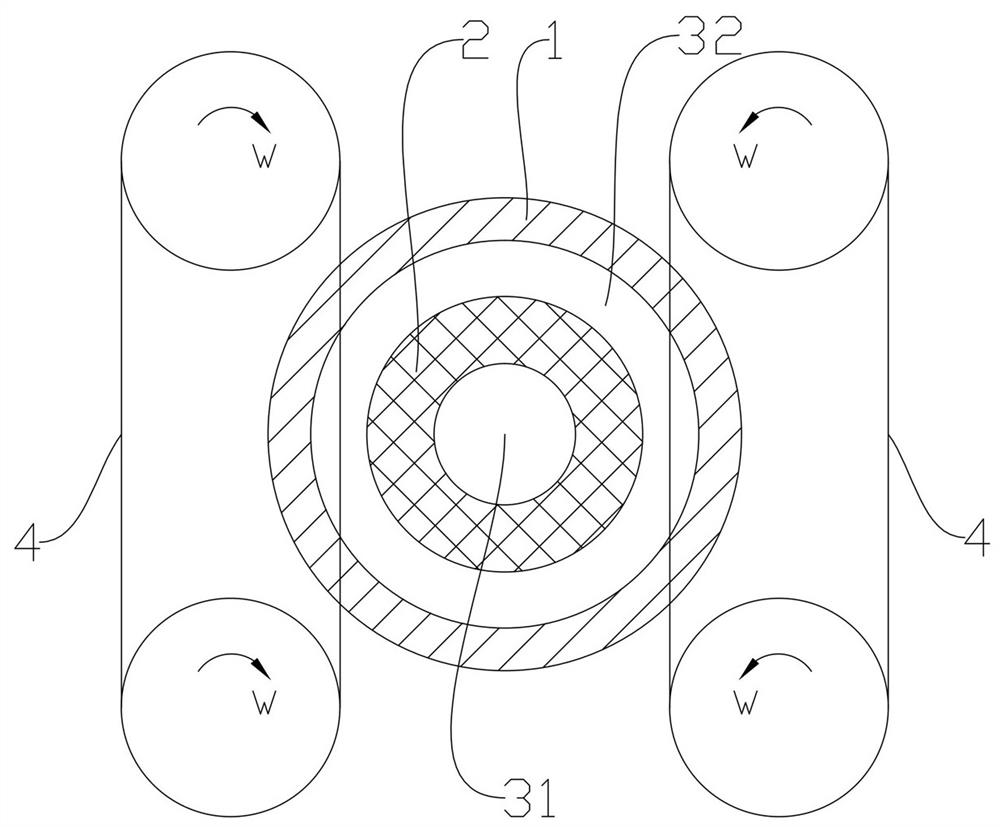

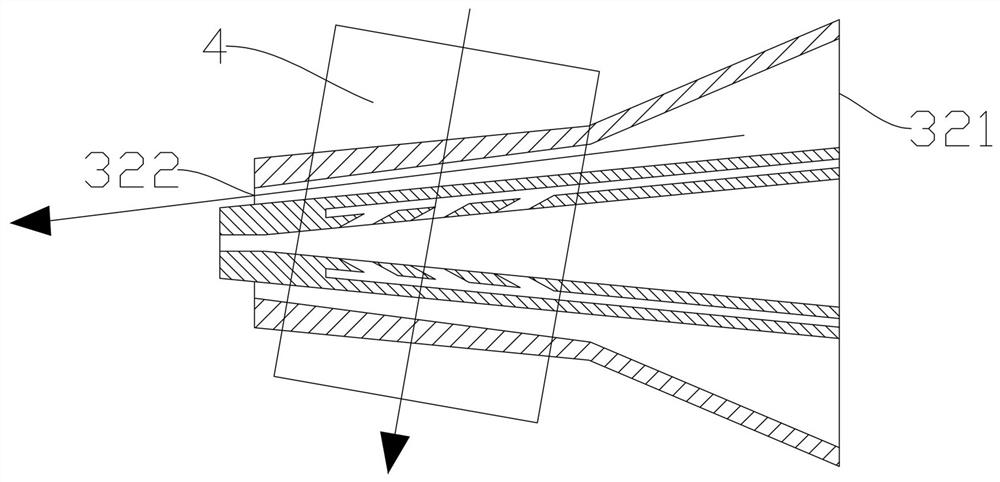

[0035] A double-filament gathering device for heated cigarettes, such as figure 1 As shown, it includes a gathering shell, and both ends of the gathering shell are open to form a shredded tobacco inlet and a shredded tobacco outlet respectively. The gathering shell includes a coaxial outer shell 1 and an inner shell 2. The inner shell 2 can be arranged in the outer shell 1 in any way, for example, connecting rods are arranged between the outer wall of the inner shell 2 and the inner wall of the outer shell 1, and the number of connecting rods is not limited. , but the less the better, it is enough to ensure the supporting connection effect, and at the same time, the end of the connecting rod connected to the inner shell 2 can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com