Working system for uniformly heating tobacco materials by induction heating mode

A tobacco material and working system technology, applied in the fields of tobacco, application, food science, etc., can solve the problems of unstable suction quality, uneven heat transfer, easy carbonization and fouling, etc., and achieve the goal of improving suction quality and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

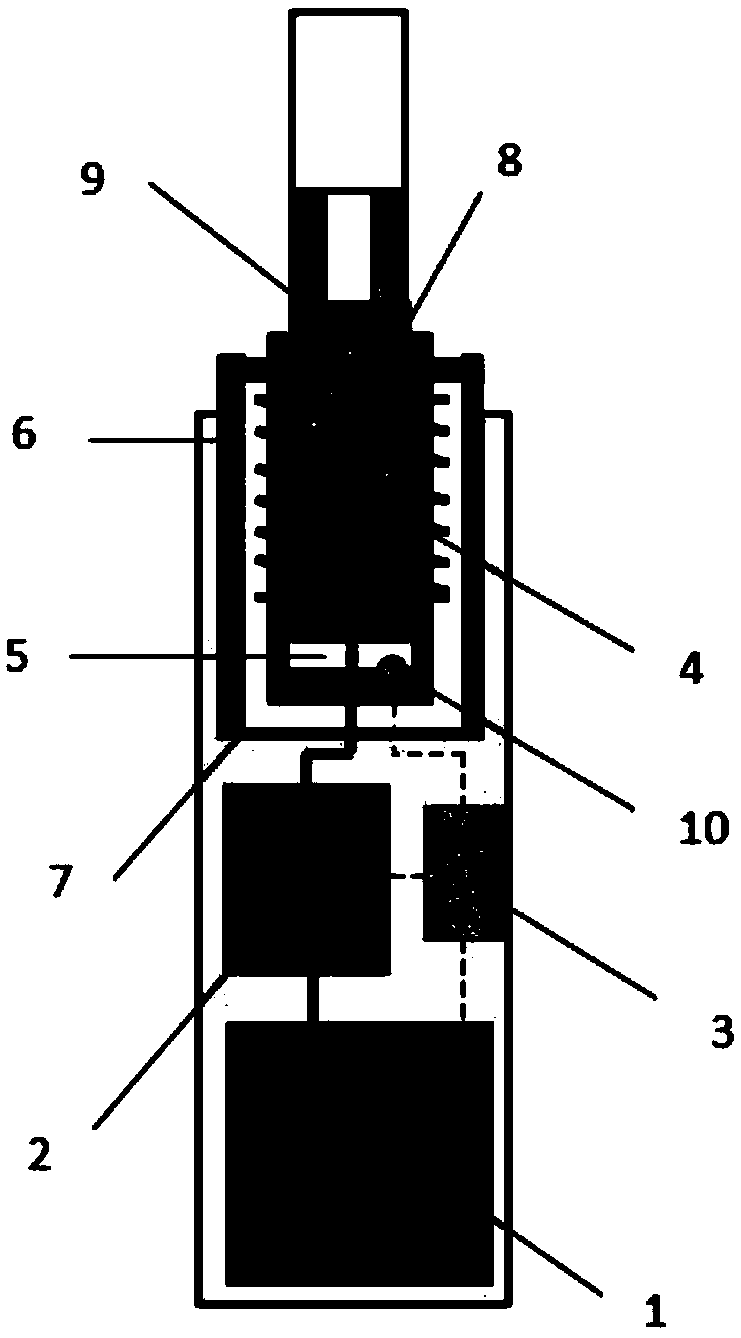

[0043] Example 1: A working system for uniformly heating tobacco materials by means of induction heating

[0044] The implementation mode of this embodiment is as follows:

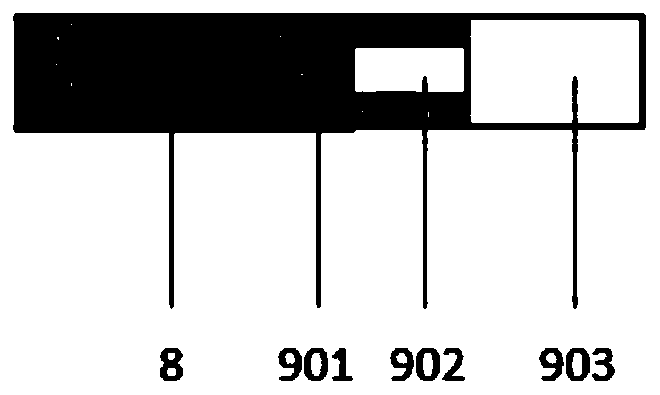

[0045] The working system includes an energy generating body, an energy accepting body and a heating temperature control system; the energy generating body is a miniaturized electromagnetic induction heating device; the energy accepting body is a cigarette containing tobacco material and an electromagnetic induction heating medium; the energy generating body The body and the energy acceptor are used together to realize the wireless energy induction transmission between the energy generator and the energy acceptor, so as to achieve uniform heating of the tobacco material in the cigarette; the heating temperature control system detects the working temperature of the working system and feeds back the temperature information in real time. To adjust the working parameters of the energy generating body to realiz...

Embodiment 2

[0050] Example 2: A working system for uniformly heating tobacco materials by means of induction heating

[0051] The implementation of this embodiment is the same as that of Embodiment 1, except that the high-frequency oscillating circuit device is an electromagnetic energy excitation device, and the electromagnetic energy excitation device includes a resonant circuit, a control circuit and an electromagnetic coil, and the operating frequency of the device is 50 ~999kHz. The heating cavity is a volume of 10cm 3 The rounded cube shape, this cavity is made of high temperature resistant engineering plastic material.

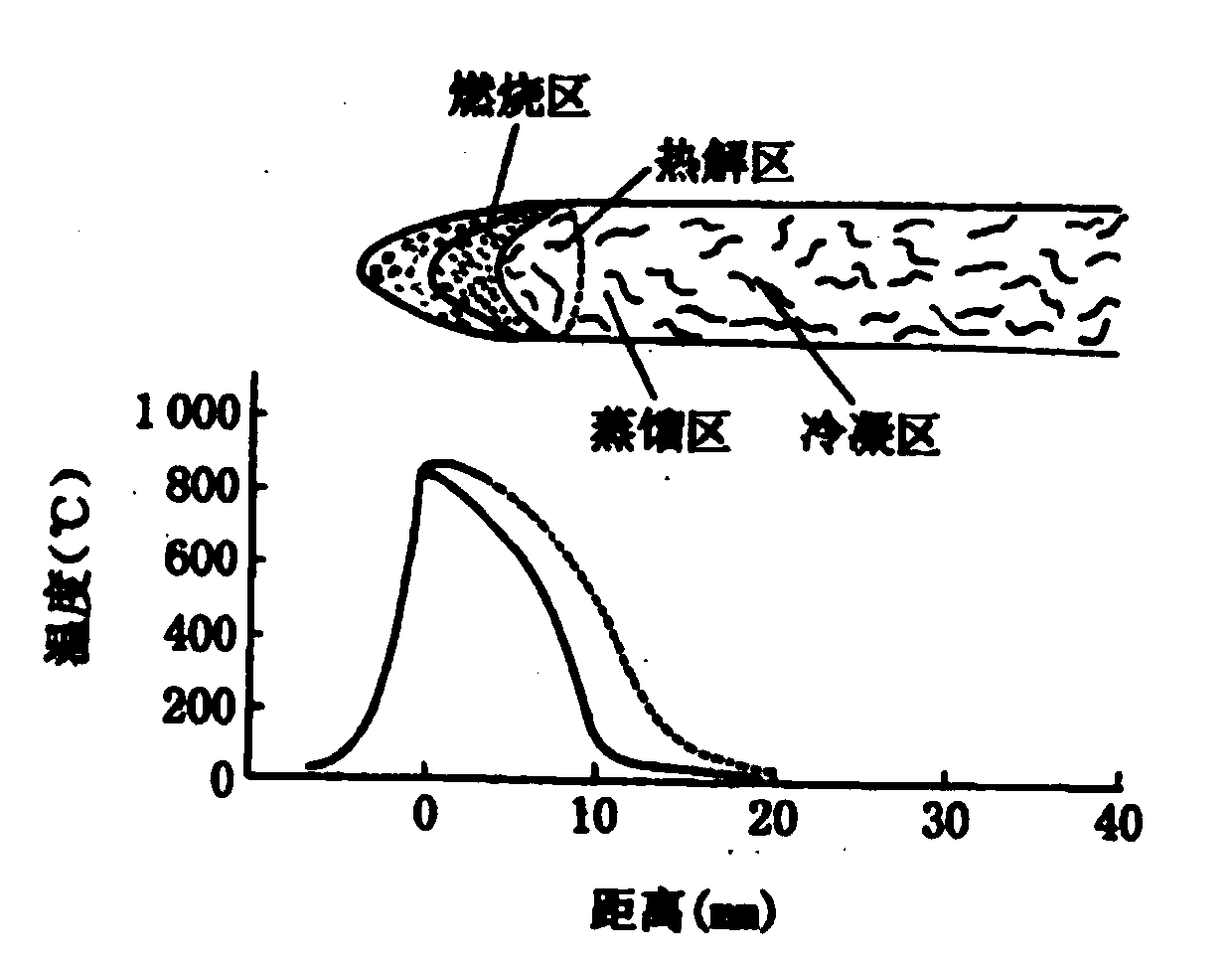

[0052] The energy acceptor is composed of tobacco material, energy conversion body, smoke cooling structure and smoke filtering structure, wherein the tobacco material is air-dried tobacco, and the tobacco material contains 8% water by weight, which is This tobacco material also contains flavoring and propylene glycol smoking agents.

[0053] The heating tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com