Application of stevia rebaudiana in aspect of preparing reconstituted tobacco and reconstituted tobacco

A technology for reconstituted tobacco leaves and stevia, applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems such as no stevia application reports, and achieve the effect of easy popularization and application and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

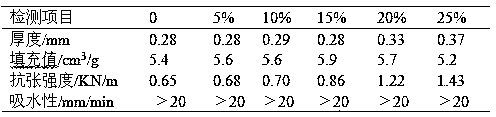

Examples

Embodiment 1

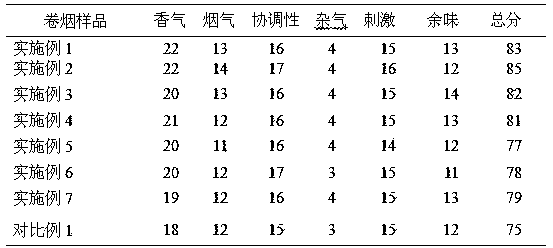

[0053] Example 1 Physical Properties of Stevia Reconstituted Tobacco Leaf and Routine Analysis of Smoke

[0054] Stevia rebaudiana (leaves) was soaked and extracted with ethanol with a concentration of 75% by volume, the ratio of solid to liquid was 1:6, the extraction temperature was 50°C, the extraction time was 40min, and the extraction was performed twice; after filtration, stevia rebaudiana fiber was obtained. The weight of papermaking is set at 55g / m 2 , the stevia fiber is mixed and refined with the extracted tobacco raw material according to the ratio of 5%, 10%, 15%, 20%, and 25%, respectively, the slurry is formed, and the sweetener with different stevia fiber content is obtained through drying. Chrysanthemum reconstituted tobacco leaf substrate. The physical properties of the substrates were determined, as shown in Table 1.

[0055] Table 1 The physical performance test results of stevia fiber sheet base with different addition amounts

[0056]

[0057] The ob...

Embodiment 2

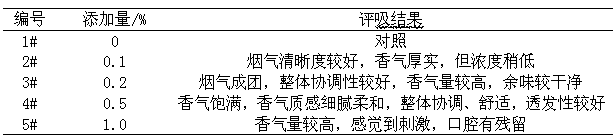

[0061] Example 2 Sensory evaluation and analysis of aroma components in reconstituted tobacco leaves

[0062] Stevia rebaudiana was soaked and extracted with ethanol with a concentration of 75% by volume, the ratio of solid to liquid was 1:6, the extraction temperature was 50°C, and the extraction time was 40 minutes, and the extraction was performed twice. The obtained extracts were combined, filtered with a 200-mesh filter cloth, and the filtrate was concentrated to 60% on a rotary evaporator to obtain stevia extract. Add stevia extract to the same coating solution in different proportions of 0%, 0.1%, 0.2%, 0.5%, and 1.0%, and coat and cut into shreds on the selected substrate blended with 15% stevia fiber , and then sensory evaluation was carried out by 7 smoking evaluation experts, and the evaluation results are shown in Table 3.

[0063] Table 3 Smoking results of reconstituted tobacco leaves with stevia extracts added in different amounts

[0064]

[0065] With the...

Embodiment 3

[0067] S1. Extraction of Stevia: Stevia was soaked and extracted with ethanol with a concentration of 50% by volume, the ratio of solid to liquid was 1:10, the extraction temperature was 40°C, and the extraction time was 50 minutes, and the extraction was performed twice. The obtained extracts were combined, filtered with a 200-mesh filter cloth, and the filtrate was concentrated to 50% on a rotary evaporator to obtain stevia extract.

[0068] S2. Prepare the reconstituted tobacco leaf base sheet and the coating solution: the present invention does not strictly limit the reconstituted tobacco leaf base sheet and the coating solution. For convenience of description, the preparation method of the reconstituted tobacco leaf base sheet and the coating solution used in this example is as follows:

[0069] Conventional tobacco stems and tobacco powder are used to extract the tobacco stems and tobacco powder by soaking them in water respectively; the conditions for the steeping and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com