Tobacco moisturizer and preparation method and application thereof

A moisturizing agent, tobacco technology, applied in the direction of tobacco, tobacco preparation, tobacco treatment, etc., to achieve the effects of improving moisturizing quality and stability, reducing irritation, and improving aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

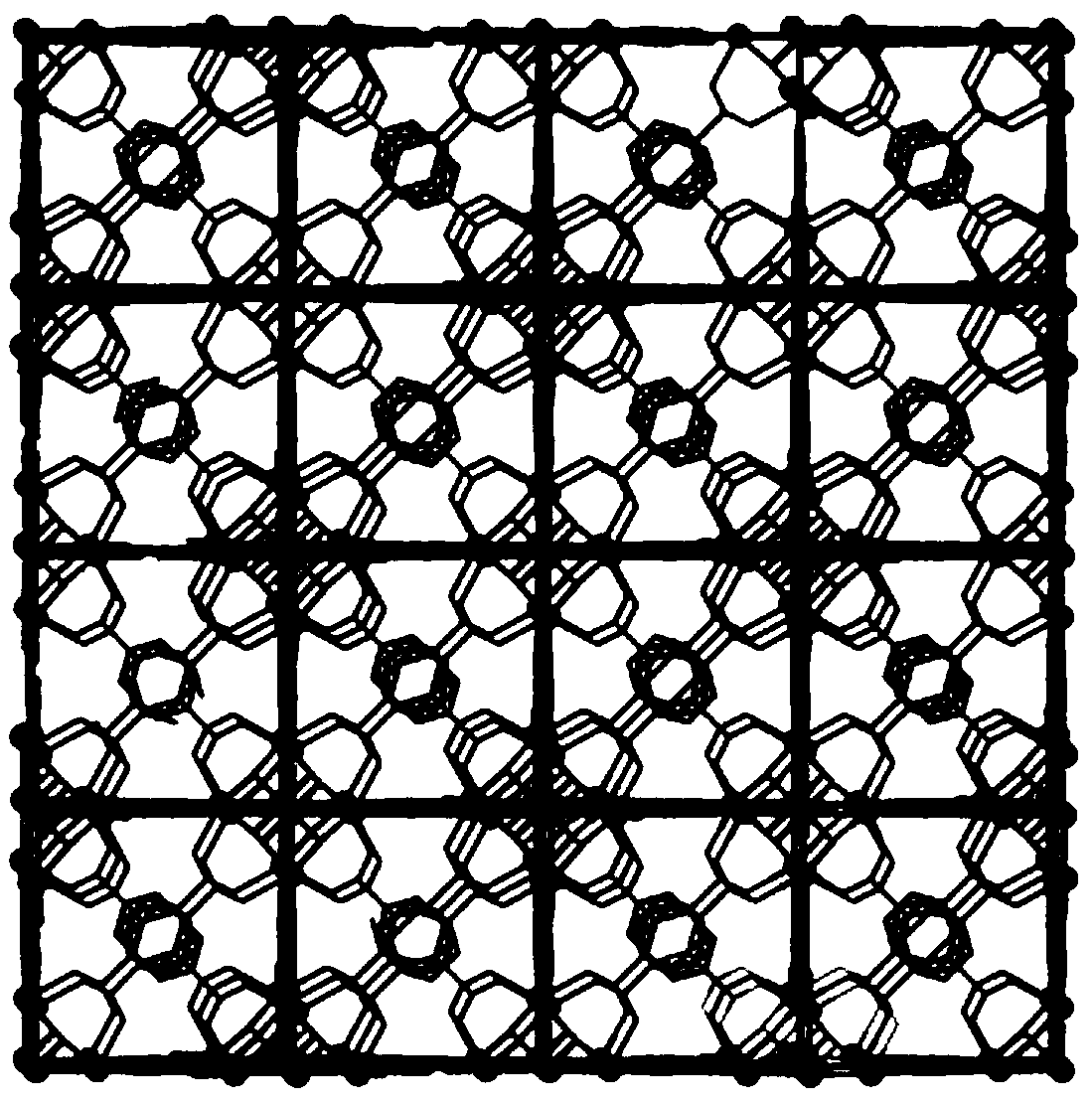

[0035] Preparation of tobacco humectant Uio-66 by solvothermal method:

[0036] 15mmol anhydrous ZrCl 4 Put it into a beaker, add 30ml of N,N'-dimethylamide, and then perform ultrasonic treatment for 30 minutes until it is completely dissolved. Add 15mmol terephthalic acid and 60ml N,N'-dimethylamide into the above solution, and continue to sonicate for 30 minutes until completely dissolved. The above mixed solution was transferred into a polytetrafluoroethylene reactor and reacted at 120°C for 24h. Filter out the solid product, wash it with 20ml of 60°C ethanol, dry it, transfer it to a conical flask, add 30ml N,N'-dimethylamide and stir to remove unreacted ligand. The above-mentioned product was filtered out, washed with 20ml of ethanol, dried and transferred to a reaction kettle, and then dried in an oven at 90°C for 12 hours. The solid product was obtained by centrifugation, and was centrifugally washed twice with 20 ml of ethanol and twice with 20 ml of acetone, and th...

Embodiment 2

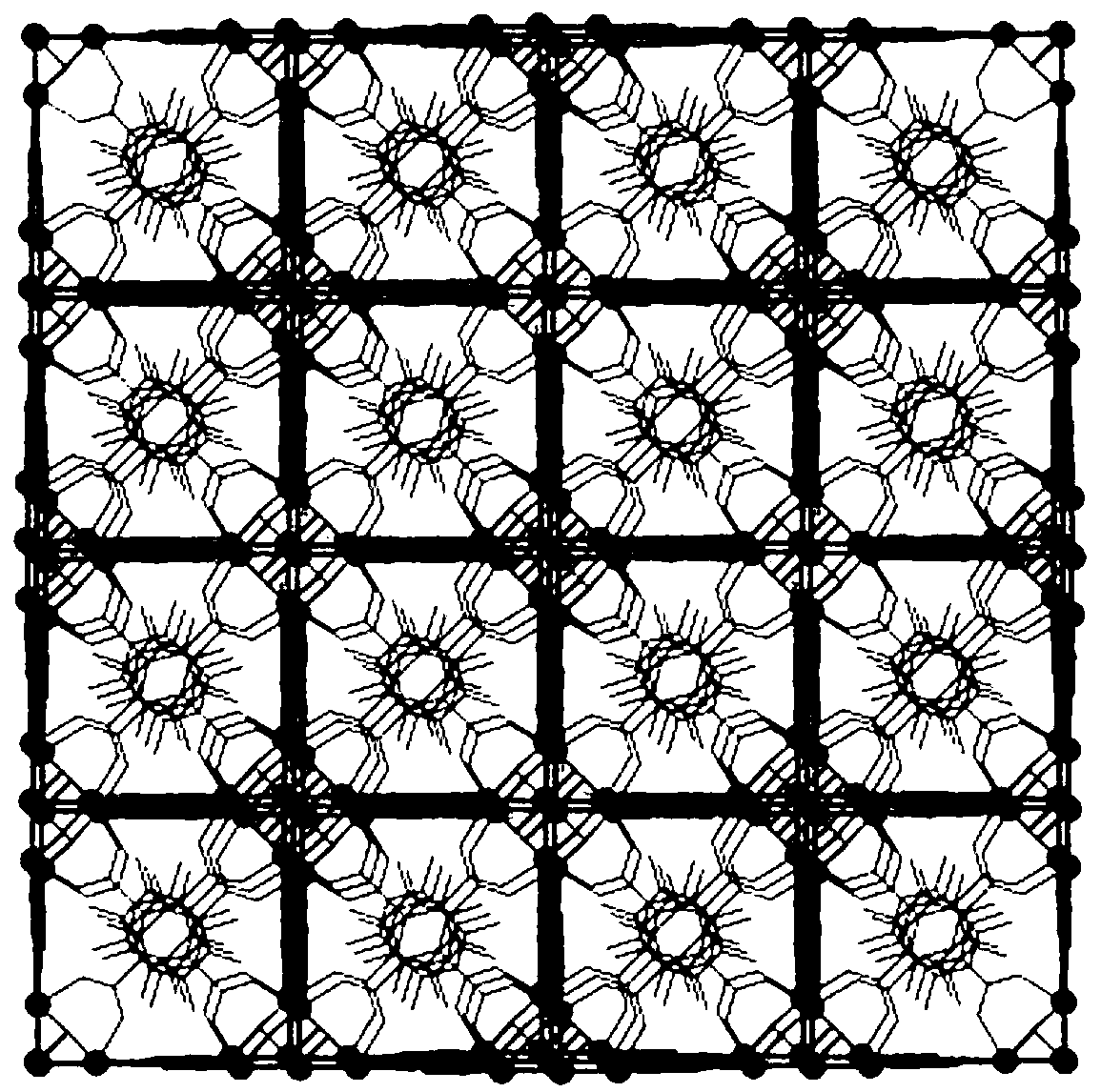

[0037] Embodiment 2: Preparation of tobacco humectant Uio-66-NH by solvothermal method 2

[0038] 18mmol anhydrous ZrCl 4Put it into a beaker, add 30ml of N,N'-dimethylamide, and then perform ultrasonic treatment for 30 minutes until it is completely dissolved. Add 14mmol of 2-amino-terephthalic acid and 50ml of N,N'-dimethylamide into the above solution, and continue ultrasonic treatment for 30 minutes. The above mixed solution was transferred into a polytetrafluoroethylene reactor and reacted at 120°C for 24h. Filter out the solid product, wash it with 20ml of 60°C ethanol, dry it, transfer it to a conical flask, add 30ml N,N'-dimethylamide and stir to remove unreacted ligand. The above-mentioned product was filtered out, washed with 20ml of ethanol, dried and transferred to a reaction kettle, and then dried in an oven at 90°C for 12 hours. The solid product was obtained by centrifugation, and was centrifugally washed twice with 20 ml of ethanol and twice with acetone, a...

Embodiment 3

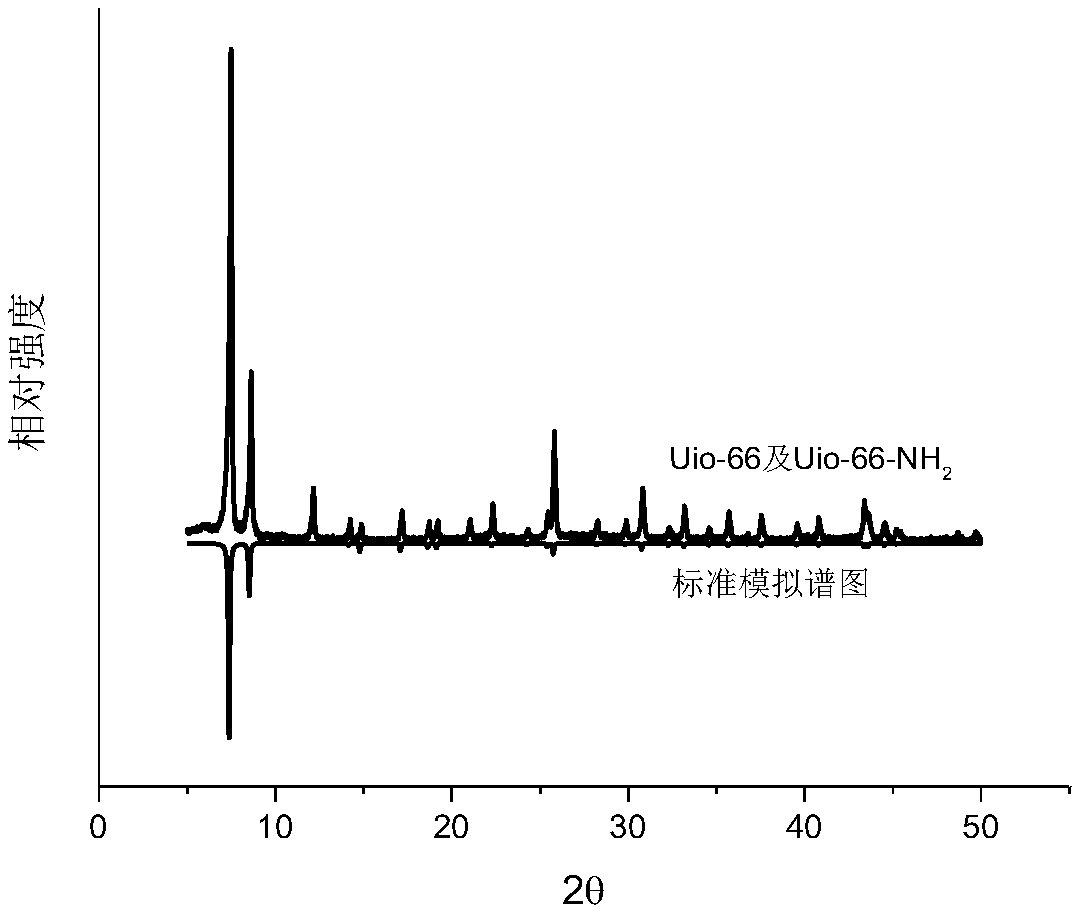

[0040] Embodiment 3: the mensuration of the dynamic content of moisture added in tobacco by tobacco humectant Uio-66

[0041] Dissolve the tobacco humectant Uio-66 prepared in Example 1 in a mixed solvent of 1,2-propanediol and glycerin, and add it to shredded tobacco according to the amount of humectant at 0.2%, so as to add an equal amount of alcohol mixed solvent but not Cut tobacco samples containing humectant Uio-66 were used as blank control. Then the shredded tobacco sample was placed in a DVS dynamic moisture adsorption instrument with a temperature of 22° C. and a relative humidity of RH46%, to measure the dynamic moisture content. The results are shown in Table 1 and Figure 4 shown. From Figure 4 It can be seen that the adsorption-desorption curve of Uio-66 has a large adsorption hysteresis. Under a certain pressure, it has a certain degree of adsorption and retention of water, and the maximum adsorption capacity can reach 14%, which has a good water adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com