Stage smoke sprayer

A smoke machine and stage technology, which is used in stage installations, entertainment, installations for theaters and circuses, etc., can solve the problems of smoke safety, reduce smoke costs, etc., so as to solve safety problems, reduce smoke costs, and reduce harm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

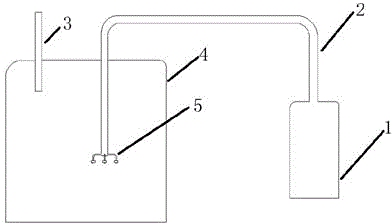

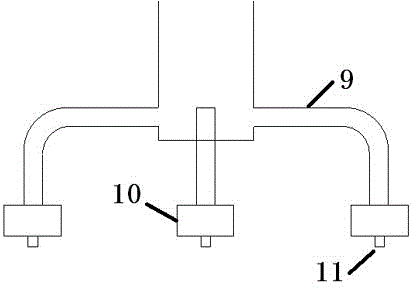

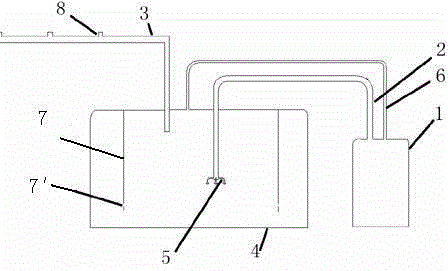

[0007] Such as figure 1 Shown is the structure diagram of the smoke machine used in the small stage of the present invention, there is a compressor 1 for providing high-pressure gas, a water storage tank 4, one end of the first high-pressure gas inlet pipe 2 is connected to the compressor 1, and the other end Insert in the storage tank 4; as figure 2 As shown, the nozzle mechanism 5 at the lower end of the first high-pressure gas inlet pipe 2 in the water storage tank 4, the nozzle mechanism 5 is composed of a shunt pipe 9, a buffer chamber 10 and a nozzle 11, wherein there are at least three shunt pipes 9, and the shunt pipe 9 The upper ends of each are respectively connected to the first high-pressure gas inlet pipe 2, and the lower ends of the shunt pipes 9 are respectively connected to a decompression chamber 10, and a nozzle 11 is respectively installed at the lower end of each decompression chamber 10, and the water level in the water storage tank 4 is higher than the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com