Cut tobacco fast puffing and drying process

A technology of puffing and drying and shredded leaves, which is applied in the preparation of tobacco, application, tobacco, etc., can solve the problems of incomplete puffing of shredded leaves, high manufacturing requirements and manufacturing costs, and no tobacco fragrance, so as to achieve good puffing effect and improve filling The effect of recharging and reducing the amount of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

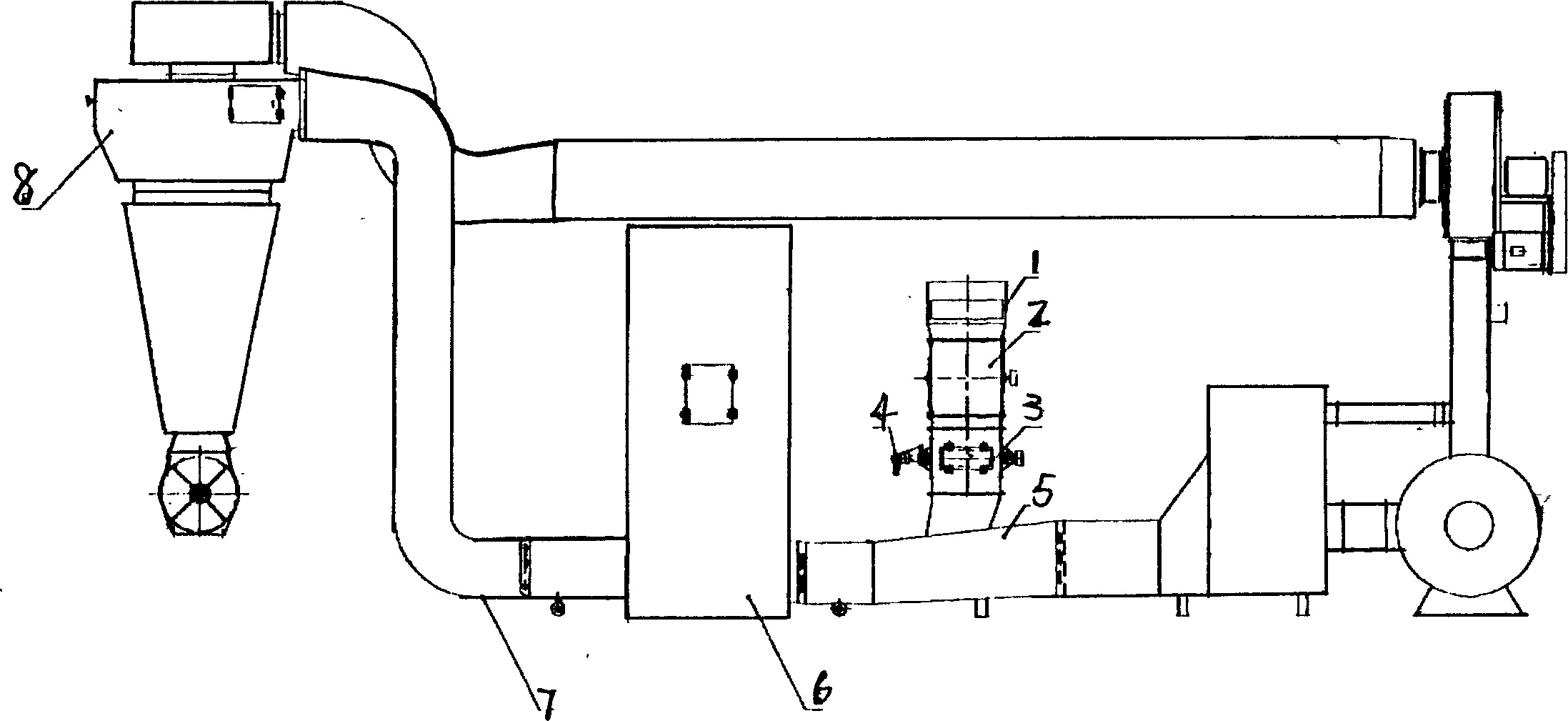

[0014] A kind of leaf shreds rapid expansion drying method (equipment such as figure 1 shown), has the following preparation process:

[0015] A. Feeding: High humidity shredded leaves (moisture content is 22-32%) enter the feed air lock 2 from the feed cover 1, and the feed air lock 2 sends the shredded leaves to the looser 3, and isolates the air ;

[0016] B. Filament heating: The leaf silk is fully mixed with the steam sprayed from the steam injection pipe 4 in the loosener 3 and heated rapidly. The leaf silk enters the hot air pipeline 5 from the looser 3, and is heated by (200-300)°C hot air ( Superheated steam) is sent into drying tower 6;

[0017] C, shredded leaf puffing: the shredded leaf is fully heat-exchanged with the hot air in the drying tower 6, and is dehydrated rapidly in about 5 seconds, and the moisture is dried from (22-32)% to 13%;

[0018] D. Discharging: The puffed shredded leaves are sent to the cyclone separator 8 by the pipeline 7. After the gas m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com