CTD pneumatic drying technology for stem

An air drying and process technology, applied in the fields of application, tobacco, food science, etc., can solve the problem of low availability of cigarette filling raw materials, and achieve the effect of reducing the consumption of cut tobacco, reducing the cost of cigarettes, and increasing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A process for drying cut stems by CTD airflow, including pressing and cutting tobacco stems after warming and humidifying, shredding, heating and humidifying (HT) cut stems, and drying cut stems by CTD airflow. The cutting width is 0.12mm, the material temperature at the outlet of the cut stem heating and humidification (HT) is controlled at 93°C, the flow rate of cut stems dried by CTD airflow is 2300kg / h, and the process gas temperature of the CTD expansion joint is 235°C.

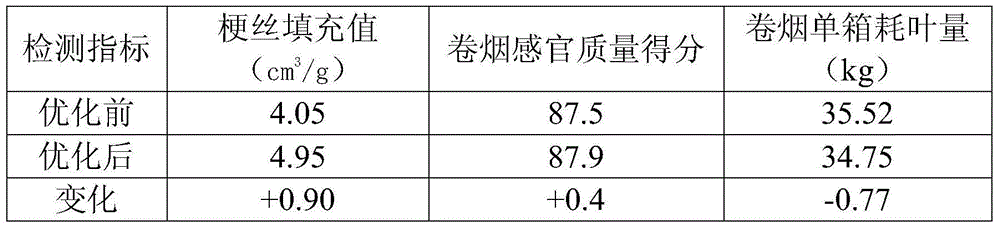

[0019] After testing, the filling value of CTD air-dried cut stems has changed from 4.05cm 3 / g increased to 4.95cm 3 / g (the weight of the force measuring head is 3kg), the expansion rate is increased by 22%. The proportion of Zhenlong Class A special stalks used in Zhenlong (Xiangyun) increased from 7% to 12%, and the sensory quality score of cigarettes increased by 0.4 points; the leaf consumption of a single box of Zhenlong (Xiangyun) decreased from 35.52kg to 34.75kg . See the table below ...

Embodiment 2

[0022] A process for drying cut stems by CTD airflow, including pressing and cutting tobacco stems after warming and humidifying, shredding, heating and humidifying (HT) cut stems, and drying cut stems by CTD airflow. The cutting width is 0.10mm, the material temperature at the outlet of the cut stem is controlled to increase temperature and humidity (HT) to 95°C, the flow rate of cut stems dried by CTD airflow is 2500kg / h, and the process gas temperature of CTD expansion joint is 230°C.

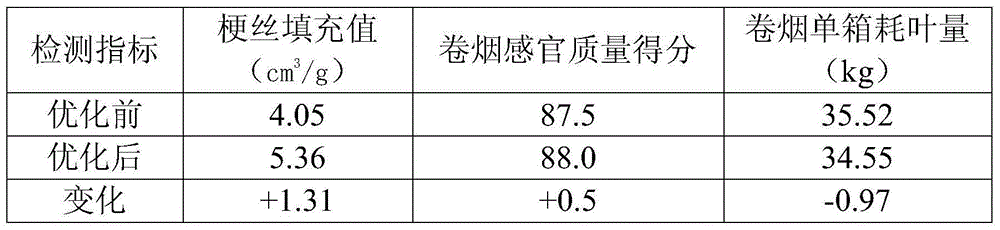

[0023] After testing, the filling value of CTD air-dried cut stems has changed from 4.05cm 3 / g increased to 5.36cm 3 / g (the weight of the force measuring head is 3kg), the expansion rate is increased by 32%. The proportion of Zhenlong Class A special stalks used in Zhenlong (Xiangyun) increased from 7% to 12%, and the sensory quality score of cigarettes increased by 0.5 points; the leaf consumption of a single box of Zhenlong (Xiangyun) decreased from 35.52kg to 34.55kg . See the table ...

Embodiment 3

[0026] A process for drying cut stems by CTD airflow, including pressing and cutting tobacco stems after warming and humidifying, shredding, heating and humidifying (HT) cut stems, and drying cut stems by CTD airflow. The cutting width is 0.08mm, the material temperature at the outlet of the cut stem heating and humidification (HT) is controlled at 90°C, the flow rate of cut stems dried by CTD airflow is 2800kg / h, and the process gas temperature of the CTD expansion joint is 225°C.

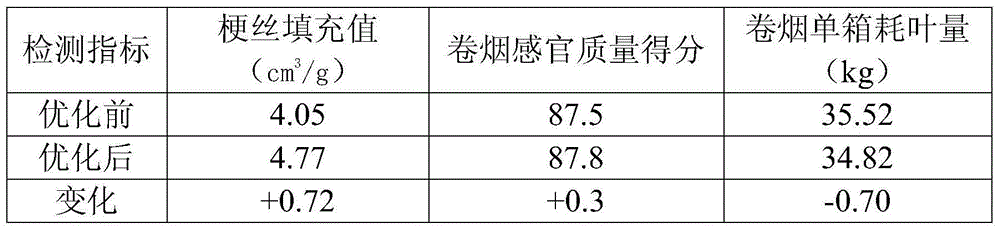

[0027] After testing, the filling value of CTD air-dried cut stems has changed from 4.05cm 3 / g increased to 4.77cm 3 / g (the weight of the force measuring head is 3kg), the expansion rate is increased by 18%. The proportion of Zhenlong Class A special stalks used in Zhenlong (Xiangyun) increased from 7% to 12%, and the sensory quality score of cigarettes increased by 0.3 points; the leaf consumption of a single box of Zhenlong (Xiangyun) decreased from 35.52kg to 34.82kg . See the table below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com