Technology for treating expanded stems

A processing technology and a technology for cutting stems, which are applied in the field of silk cutting by using tobacco stems and tobacco cuttings, can solve the problems of the negative impact of the uniformity of tobacco blending on the sensory quality, high safety and environmental protection requirements, and unfavorable quality stability of the cut stems. , to achieve the effect of easy physical size, reduced processing fragmentation, and high filling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The following will be further described in detail with reference to the accompanying drawings.

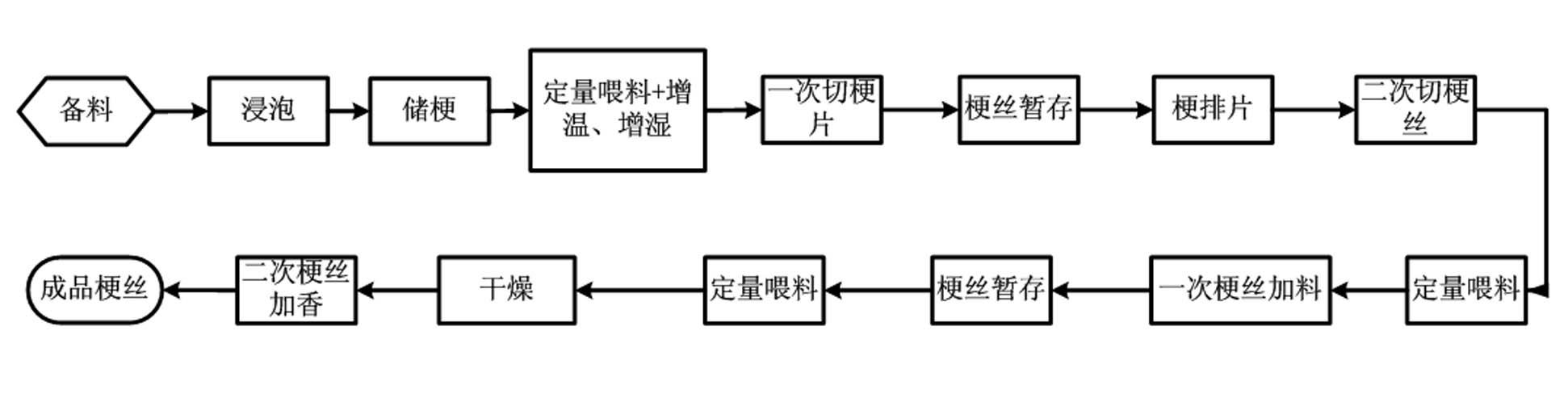

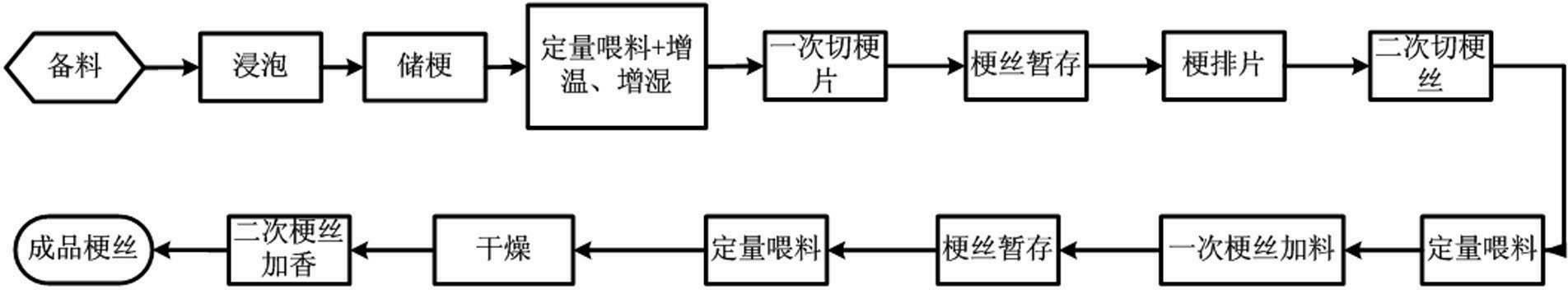

[0034] Adopt the technology of first cutting and then expansion (that is, the tobacco stems are sliced first, and then processed by puffing), the second stem cutting (through the first stem cutting, the stem slices are arranged in vibrating grooves, and the second stem shreds are cut), and the second stem cutting is adopted. Flavoring method (feeding, flavoring once, adding flavoring twice), the process is: (1) Soaking → (2) Stem storage → (3) Quantitative feeding + warming, humidification → (5) Once Sliced stems → (6) Sliced stems → (7) Secondary shredded stems → (8) Temporary storage of shredded stems → (9) Quantitative feeding → (10) One-time addition of shredded stems and flavoring → (11) Stem storage Silk → (12) Quantitative feeding → (13) Microwave expansion → (14) Secondary flavoring → (15) Finished stem shreds. Concrete process is carried out acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com