A Chinese-style mixed cigarette and its preparation method

A technology for shredded tobacco and tobacco sheet, which is applied in the field of Chinese-style mixed cigarettes and their preparation, and the formulation of cigarette leaf groups, can solve the problems of suppressing smoking desire, re-flavoring burley tobacco, unpleasant taste, etc. Reduce the cost of cigarettes, the effect of rich and beautiful aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Preparation of Chinese-style mixed cigarettes (Sample 1)

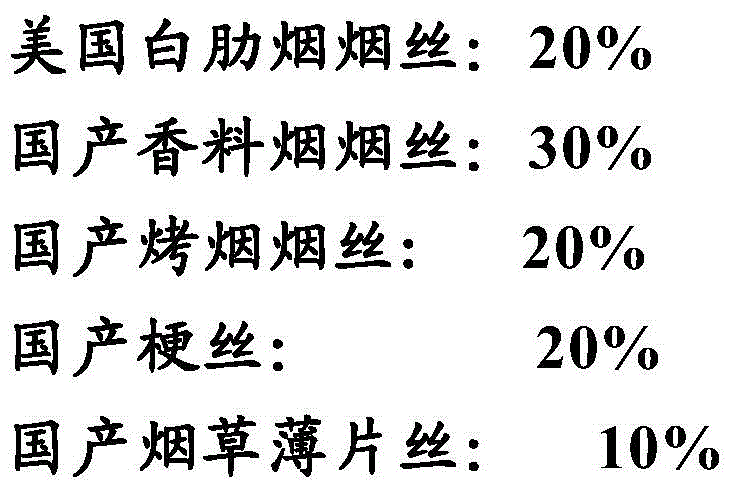

[0079] Chinese-style mixed cigarette leaf group formula:

[0080]

[0081] The percentages of the lining ingredients in the liquid ingredients of the burley tobacco adding and baking and the weight of the burley tobacco shreds are:

[0082] Propylene glycol 0.5%

[0083] Cocoa powder 0.7%,

[0084] The rest is 60% ethanol aqueous solution;

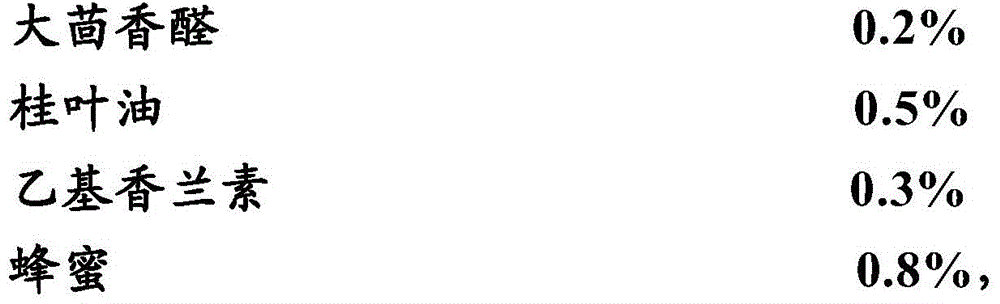

[0085] The surface aroma components and the percentage of the weight of the tobacco are:

[0086]

[0087] The rest is 60% ethanol aqueous solution.

[0088] The preparation method of roasted burley tobacco shredded tobacco is carried out according to the method of the present invention.

[0089] Other steps in the preparation of cigarettes are carried out in accordance with conventional mixed preparation methods.

Embodiment 2

[0090] Example 2: Preparation of Chinese Blended Cigarettes (Sample 2)

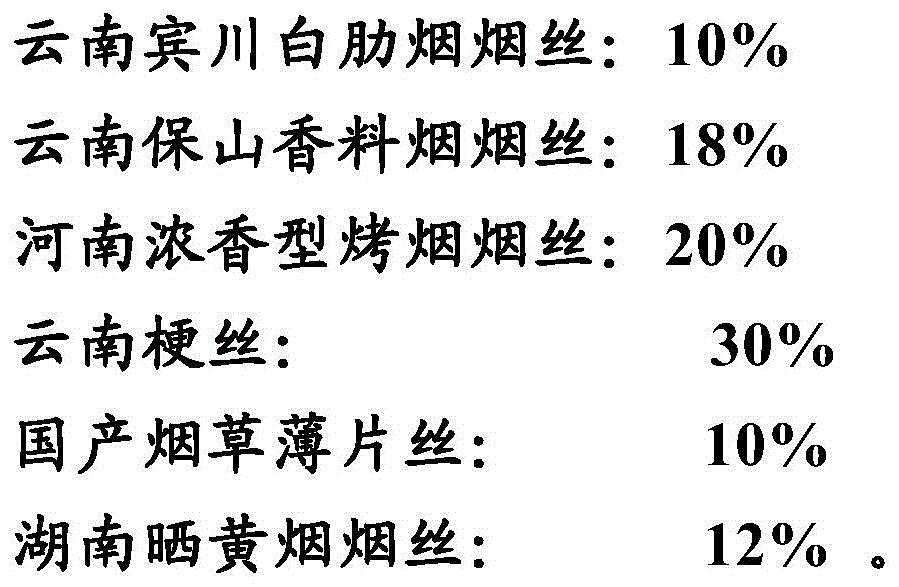

[0091] Chinese-style mixed cigarette leaf group formula:

[0092]

[0093]

[0094] The percentages of the lining ingredients in the liquid ingredients of the burley tobacco adding and baking and the weight of the burley tobacco shreds are:

[0095] Propylene glycol 0.5%

[0096] Cocoa powder 0.7%,

[0097] The rest is 60% ethanol aqueous solution;

[0098] The surface aroma components and the percentage of the weight of the tobacco are:

[0099]

[0100] The rest is 60% ethanol aqueous solution.

[0101] The preparation method of roasted burley tobacco shredded tobacco is carried out according to the method of the present invention.

[0102] Other steps in the preparation of cigarettes are carried out in accordance with conventional mixed preparation methods.

Embodiment 3

[0103] Example 3: Sensory evaluation test

[0104] 1. Comment on samples:

[0105] The reference sample prepared in Comparative Example 1; and the cigarette sample 1-2 prepared in Example 1-2.

[0106] 2. Evaluation methods and standards

[0107] The overall cycle evaluation method is specifically based on the People’s Republic of China tobacco industry standard tobacco and tobacco product sensory evaluation method YC / T138-1998.

[0108] 3. Evaluation results

[0109] As shown in Table 1 below.

[0110] Table 1: Quality evaluation results of cigarette samples

[0111] sample

[0112] The sensory evaluation results show that compared with the reference sample, the sample 1-2 of Example 1-2 has an increased aroma, rich aroma, reduced impurity, reduced irritation, and a more comfortable aftertaste. The best quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com