Coating preparation method of cigar-flavored cigarette paper

A technology of cigarette paper and flavor, applied in the field of cigarette manufacturing, which can solve the problems affecting consumers' sensory experience, low quality of smoking cigar-shaped cigarettes, and turbid flavor, so as to enhance the flavor of cigars, increase the concentration and thickness, and optimize the sensory experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

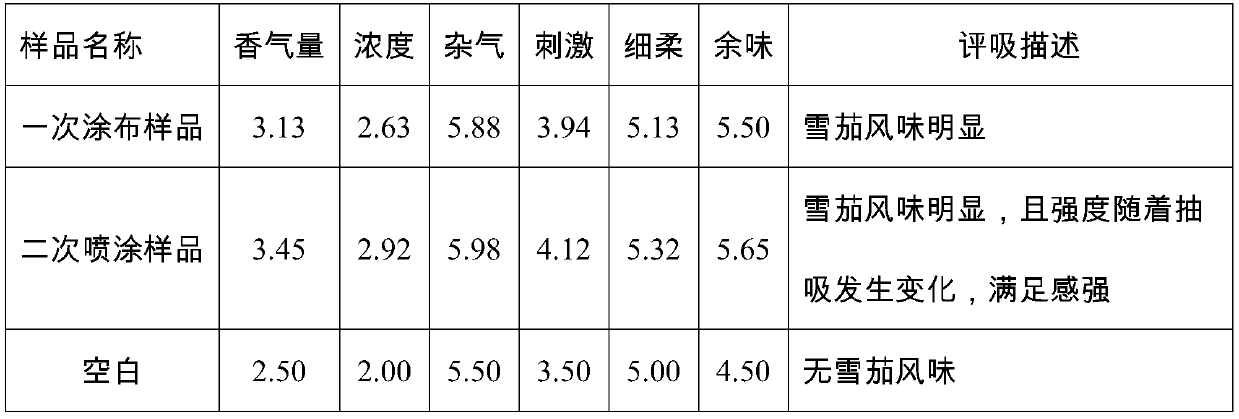

Examples

preparation example Construction

[0039] The present disclosure provides a coating preparation method for cigar-flavored cigarette paper. The coating preparation method includes the following steps:

[0040] Step (1): Concentrating under reduced pressure the supernatant liquid after dissolving the tobacco extract to obtain a tobacco concentrate. Tobacco extract can be obtained by concentrating the extract of tobacco leaves.

[0041] Step (2): Molecular distillation is carried out on the obtained tobacco concentrate, and the light components are collected to obtain the first tobacco extract. Molecular distillation treatment is beneficial to reduce the content of low-carbon alkanes and high-carbon fatty acids in tobacco concentrate.

[0042] Step (3): adding the mixture of amino acid and sugar into the tobacco leaf extract, reacting for a period of time, after the reaction is completed, filtering, diluting, membrane separation and concentrating under reduced pressure to obtain the second tobacco extract.

[00...

Embodiment 1

[0078] Crush the tobacco leaves to 100 mesh, transfer to the subcritical extraction kettle, then add dimethyl ether, the ratio of solid to liquid is 1:8, the entraining agent is 95% ethanol (5% of dimethyl ether), at 25°C Extract for 2 hours, the extraction pressure is the saturated vapor pressure of dimethyl ether at this temperature. After extraction, evaporate under reduced pressure to obtain tobacco extract.

[0079] Add 5 times the amount of 95% ethanol to the tobacco extract, heat it to 30°C and keep it for 60 minutes to fully dissolve it. It was then cooled to room temperature and transferred to a -20°C refrigerator for 8 h. The filtrate is obtained by suction filtration at low temperature, and the filtrate is concentrated under reduced pressure until ethanol-free to obtain a tobacco concentrate.

[0080] Transfer the tobacco concentrate to a molecular distillation feed tank, distill at 60°C and 0.001mbar, and collect heavy components. The heavy component was distill...

Embodiment 2

[0085] Crush the tobacco leaves to 100 mesh, transfer to the subcritical extraction kettle, then add dimethyl ether, the ratio of solid to liquid is 1:10, the entraining agent is absolute ethanol (10% of dimethyl ether), at 40°C Extract for 0.5h, and the extraction pressure is the saturated vapor pressure of dimethyl ether at this temperature. After extraction, evaporate under reduced pressure to obtain tobacco extract.

[0086] Add 10 times the amount of absolute ethanol to the tobacco extract, heat it to 50°C and keep it for 20 minutes to fully dissolve it. It was then cooled to room temperature and transferred to a -5°C refrigerator for 24 h. Centrifuge at a speed of 4000 rpm for 10 min at a low temperature, and concentrate the supernatant under reduced pressure until ethanol-free to obtain a tobacco concentrate.

[0087] Transfer the tobacco concentrate to a molecular distillation feed tank, distill at 80° C. and 0.01 mbar, and collect heavy components respectively. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com