Electronic cigarette liquid containing polysaccharide

The technology of electronic cigarette liquid and sea buckthorn polysaccharide is applied in the field of tobacco, can solve the problems such as sea buckthorn polysaccharide that have not been seen, and achieves the effects of less solvent consumption, delicate aroma and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

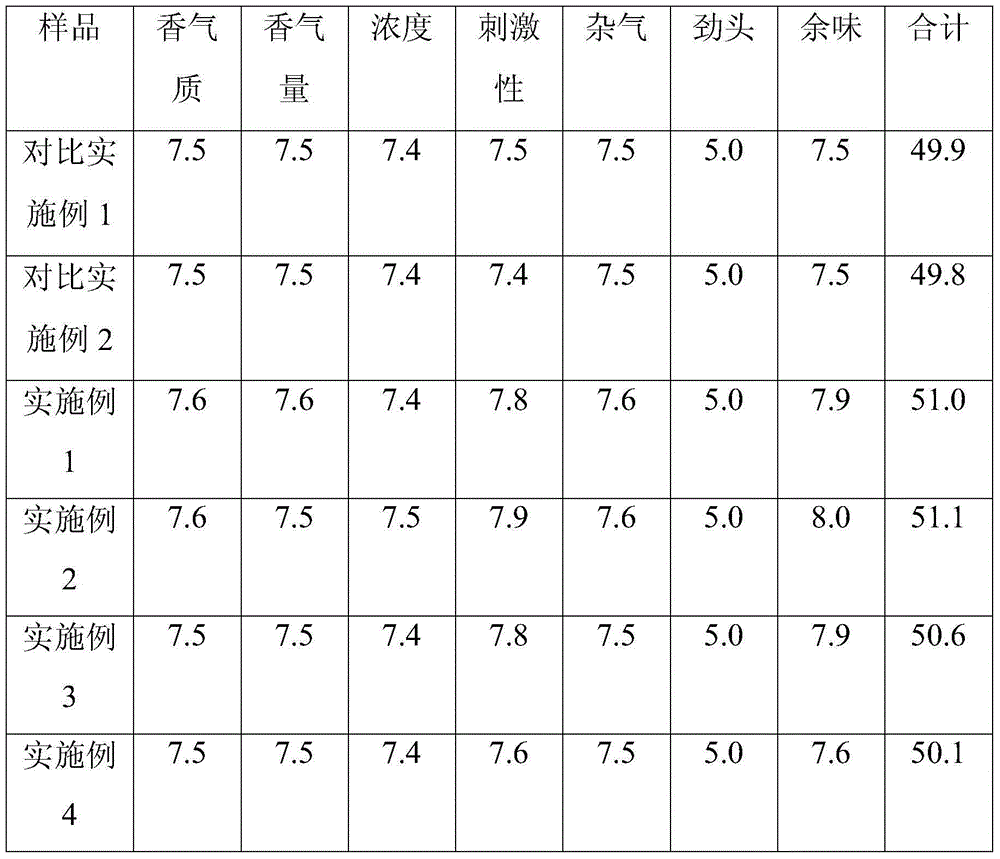

Examples

preparation example Construction

[0031] Preparation of Seabuckthorn Polysaccharide

[0032] After washing and removing impurities from seabuckthorn dried fruit, place them in an oven at 40°C to dry and crush them, then add 100g of seabuckthorn powder into the extraction pool of ASE extraction instrument, use pure water as solvent, extract at 70°C at extraction temperature, and heat for 6 minutes. The static extraction time is 12min, the extraction pressure is 1700psi, the number of extraction cycles is 3 times, the washing volume is 50%, and the nitrogen blowing time is 100s, and the extraction is heated and extracted, the extract is filtered, vacuum concentrated to 1 / 4 volume, and the Sevage method is used to remove Protein, until there is no white suspension at the interface, add ethanol with a concentration of 80%, ethanol precipitation for 10 hours, and dry to obtain 2.92g gray powder of seabuckthorn polysaccharide, with a yield of 2.92%.

[0033]The essence for tobacco is prepared by stirring and mixing ...

Embodiment 1

[0037] An electronic cigarette liquid containing seabuckthorn polysaccharide, its components include: Zimbabwean tobacco leaf extract 10%, tobacco essence 5%, tobacco flavor 2%, deionized water 15%, glycerin 10%, seabuckthorn polysaccharide 15%, and the balance is propylene glycol, and the consumption of each component is calculated by mass content.

[0038] When preparing the e-cigarette liquid, prepare the above components, then mix them, and stir at room temperature for 30 minutes to fully mix the components.

Embodiment 2

[0040] An electronic cigarette liquid containing seabuckthorn polysaccharide, its components include: Zimbabwean tobacco leaf extract 10%, tobacco essence 5%, tobacco flavor 2%, deionized water 15%, glycerin 10%, seabuckthorn polysaccharide 10%, the balance is propylene glycol, and the consumption of each component is calculated by mass content.

[0041] When preparing the e-cigarette liquid, prepare the above components, then mix them, and stir at room temperature for 30 minutes to fully mix the components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com