Patents

Literature

36results about How to "Improve your energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fragrance type heating nonflammable tobacco product and preparation method thereof

InactiveCN105249524AThe fragrance is remarkableImprove your energyTobacco preparationTobacco treatmentTobacco productChemistry

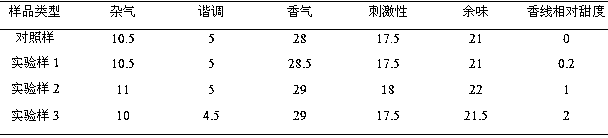

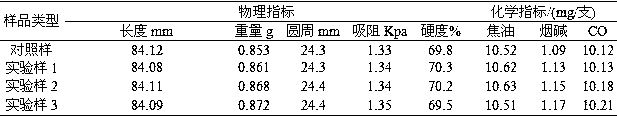

The invention relates to a fragrance type heating nonflammable tobacco product. The fragrance type heating nonflammable tobacco product includes the following materials by weight: 1 to 6 parts of tobacco extract, 0.5 to 5 parts of tobacco flavor, 0.5 to 3 parts of taste and flavor conditioning agent, 0.5 to 6 parts of fragrance type liquor, 0.5 to 15 parts of fogging agent, and 75 to 95 parts of tobacco carrier. The invention also provides a preparation method of the tobacco product. According to the invention, the tobacco product is low in danger to a human body and an environment; the tobacco extract is added to improve the tobacco flavor concentration of the tobacco product at the low temperature, and meanwhile, smoke vigor and satisfaction can be improved; the fragrance type liquor is added to allow smoke to be fragrant, prominent, elegant and exquisite, and the liquor is rich and is long in aftertaste; the content of the fogging agent is improved, so that the amount of the smoke can be assured to the greatest extent when a consumer smokes at the low temperature, and the feel more similar to the feel of the traditional cigarettes is provided.

Owner:CHINA TOBACCO GUIZHOU IND

Extracting method for radix ophiopogonis extract and dark plum extract as well as cigarette containing radix ophiopogonis extract and dark plum extract

ActiveCN102499460ASpray evenlyIncrease the sense of body fluidTobacco treatmentThroatPathogenic microorganism

The invention discloses an extracting method for a radix ophiopogonis extract and a dark plum extract as well as a cigarette containing the radix ophiopogonis extract and the dark plum extract in order to solve the technical problem on the reduction of dry sensation and harm of smoke of the cigarette. The extracting method for the radix ophiopogonis extract and the dark plum extract comprises thefollowing steps of: drying and crushing radix ophiopogonis and dark plums; adding hot water into radix ophiopogonis and dark plum powder; extracting and filtering; reducing pressure of filtrate; concentrating; adding ethanol; and stewing and filtering to obtain the ophiopogonis extract and the dark plum extract. According to the cigarette containing the radix ophiopogonis extract and the dark plum extract, disclosed by the invention, the mass of the radix ophiopogonis extract and the dark plum extract is 0.001-10% of that of cut tobacco. Compared with the prior art, the radix ophiopogonis extract and the dark plum extract are contained in the cut tobacco; during the smoking, components of the radix ophiopogonis extract and the dark plum extract can enter a human body along with mainstreamsmoke, and can be absorbed by the human body, so that the cigarette has the functions of killing bacteria, resisting pathogenic microorganisms, benefiting gallbladder, improving hypoxia tolerant capability and resisting aging; the smoke is plump and mellow, and has no foreign smells, so that secretion generation of the smoke is enhanced, and the throat is comfortable; the quality of the cigarettecan be improved; and threats of the smoke to the human body can be reduced.

Owner:SHENZHEN DABAIHUI TECH

E-cigarette nicotine liquid and preparation method thereof

ActiveCN106617265ASimple preparation processSimple and fast operationTobacco treatmentAdditive ingredientLiquid smoke

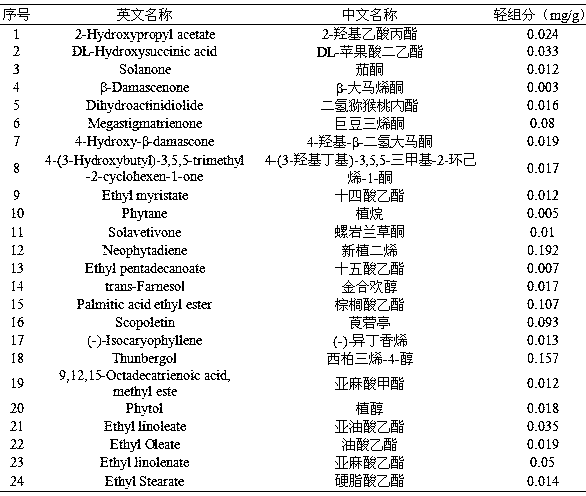

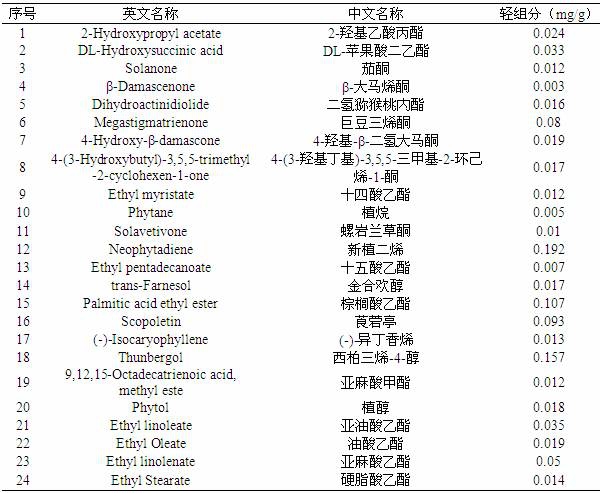

The invention discloses E-cigarette nicotine liquid and a preparation method thereof and belongs to the technical field of E-cigarette nicotine liquids. The E-cigarette nicotine liquid is made from high-nicotine tobacco extract, tobacco flavor and the like, wherein the tobacco extract has rich tobacco characteristic fragrant ingredients (such as megastigmatrienone, beta-damascone, pyrones, and furanones) and nicotine, can provide tobacco aroma and curing aroma and meet the physiological needs of consumers, and provides better satisfaction. The high-nicotine tobacco extract has very low contents of high-boiling-point ingredients and macromolecular substances (such as proteins, pectin, and polysaccharides), is free of burnt smell and low in sweetness, and can supplement aroma and cover peculiar odors, lower stimulus and improve taste strength. By being used with tobacco flavors, the E-cigarette nicotine liquid has enhanced curing aroma and tobacco aroma, and has strong aroma and good volatility. The preparation process of the E-cigarette nicotine liquid is simple, is simple and easy to perform, and is applicable to large-scale industrial production and application.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Casing flavor for expanded cut tobacco

ActiveCN103305342ARich fragranceIncrease sweetnessTobacco preparationTobacco treatmentThroat irritationMetal impurities

The invention discloses a casing flavor for an expanded cut tobacco. The casing flavor comprises the following components in parts by weight: 8-15 parts of a Zimbabwe tobacco leaf extract, 5-12 parts of a Brazil tobacco leaf extract, 3-8 parts of honey, 1-3 parts of 10% by mass of a red jujube extract, 2-5 parts of 1% by mass of phenylacetaldehyde, 5-8 parts of 1% by mass of guaiac wood oil, 0.5-2 parts of a fenugreek fluid extract, 1-3 parts of a liquorice fluid extract, 2-5 parts of maple syrup, 1-2 parts of 10% by mass of an orris root extract, 10-25 parts of water and 12-61.5 parts of propanediol. After the casing flavor is added into the expanded cut tobacco, the sensory quality shortages of insufficient fragrance, high metal impurity gas content, high irritation, metallic flavor residues and the like in the existing expanded cut tobacco are overcome, the fragrance content is increased, the expanded cut tobacco is endowed with fragrance and sweetness of a fruit and is enriched in fragrance, the throat irritation is reduced, and the sensory quality of the expanded cut tobacco is remarkably improved.

Owner:HUBEI CHINA TOBACCO IND +1

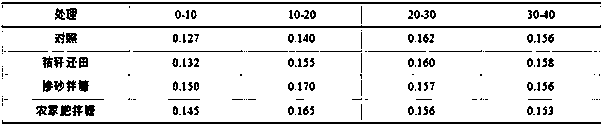

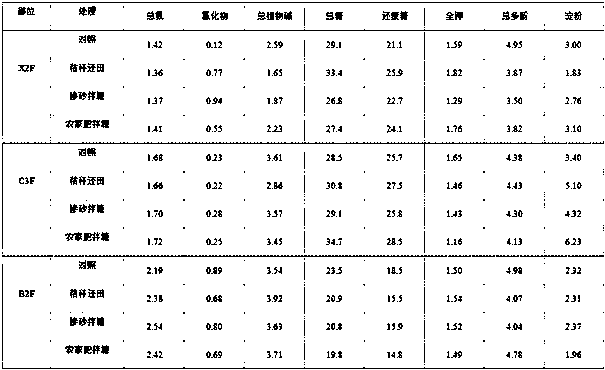

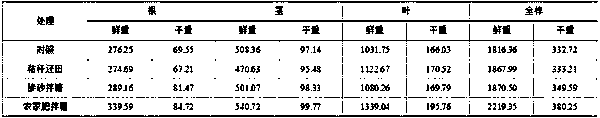

Tobacco field soil improvement method capable of effectively improving quality of tobacco leaves

ActiveCN107750506AChemical Composition HarmonizationIncrease the fragranceFertilising methodsTobacco cultivationHigh concentrationChemical composition

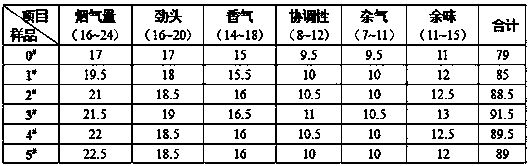

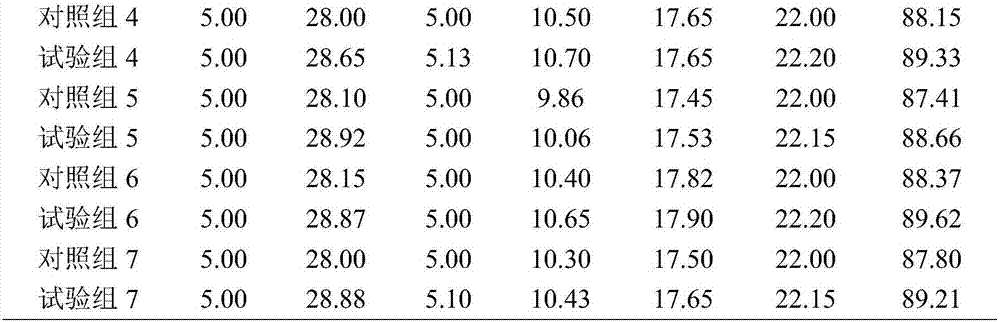

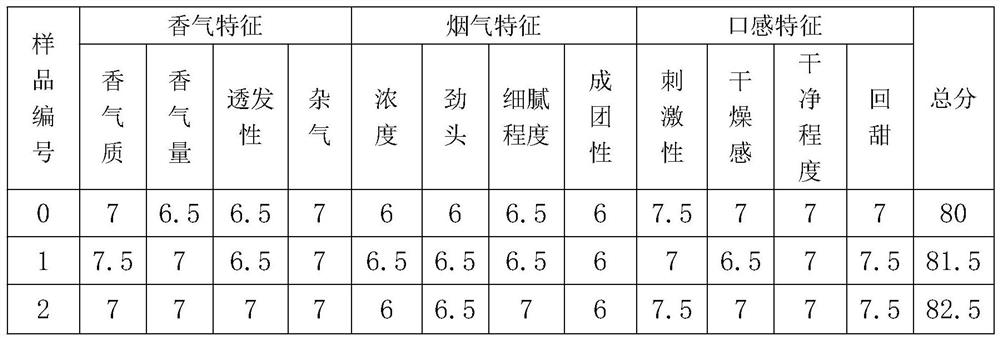

The invention discloses a tobacco field soil improvement method for effectively improving the quality of tobacco leaves. The tobacco field soil improvement method comprises the following steps: 1) selection of areas; 2) selection of tobacco fields; 3) ridges and ponds; 4) base fertilizer application ; 5) Farmyard manure mixing pond; 6) Top dressing application. The present invention treats the soil of the tobacco field through farmyard manure mixing ponds, and the chemical components of the obtained tobacco leaves are more coordinated, the tobacco leaf smoking evaluation score is as high as 82.5 or more, the aroma is more prominent, the concentration is higher, and the strength is stronger, and it can be used as a method for improving sticky soil. An effective way, while the total fertilization rate of the improved soil of the present invention is 90% of the conventional fertilization rate, which effectively reduces the fertilization rate and reduces the cost.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

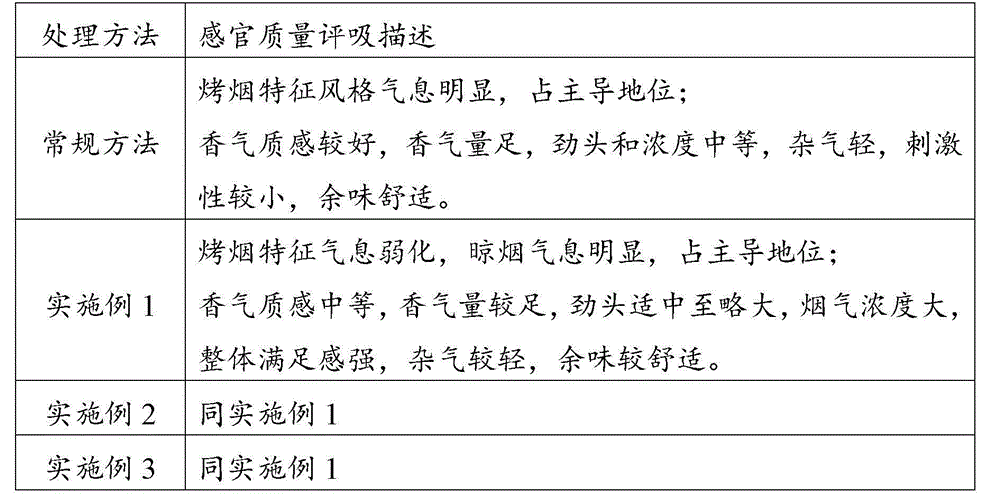

Tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes

InactiveCN110150723AIntact void structurePromote absorptionTobacco preparationTobacco treatmentHeat not burnEngineering

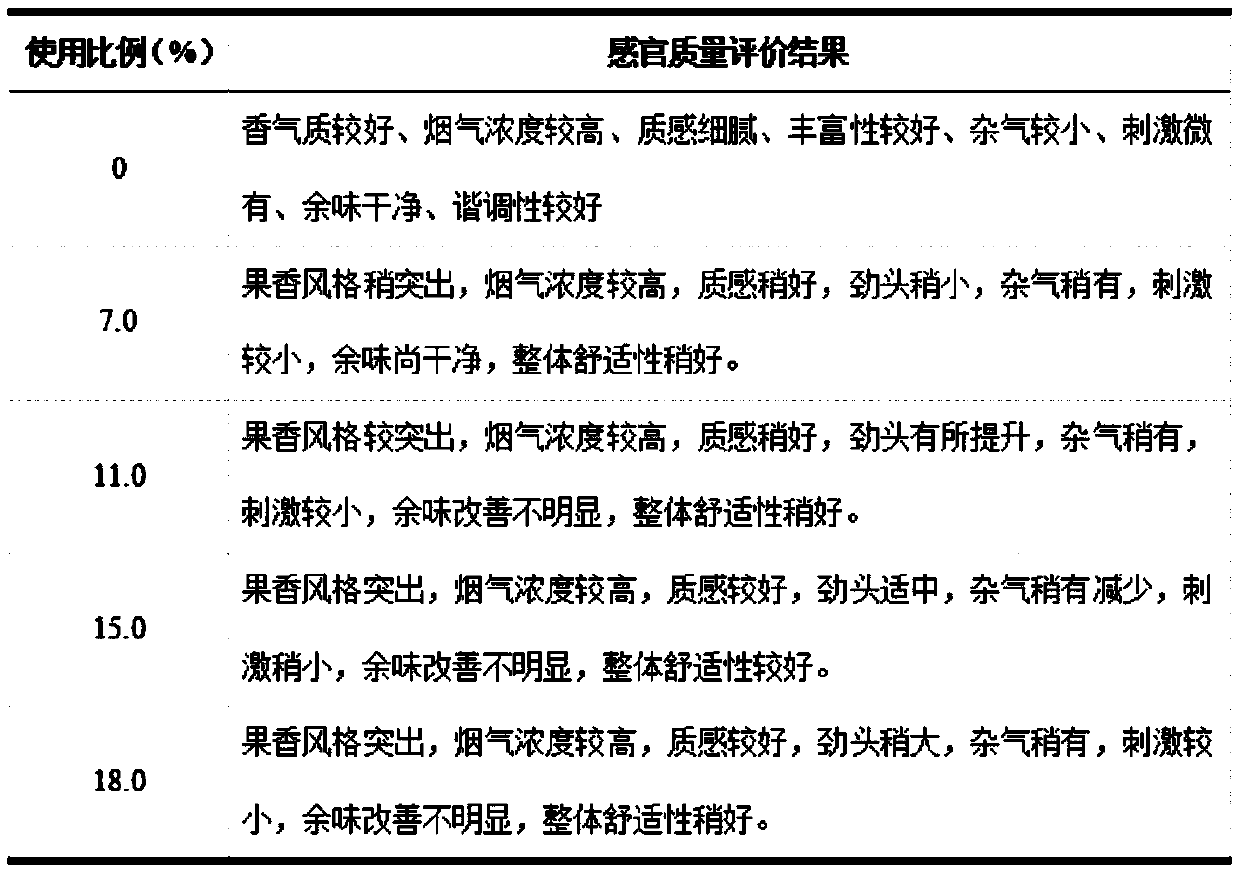

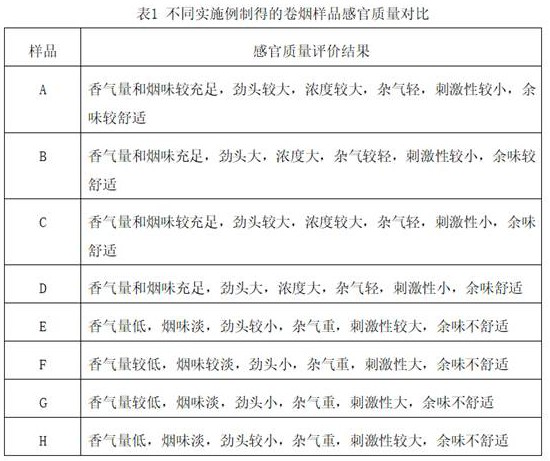

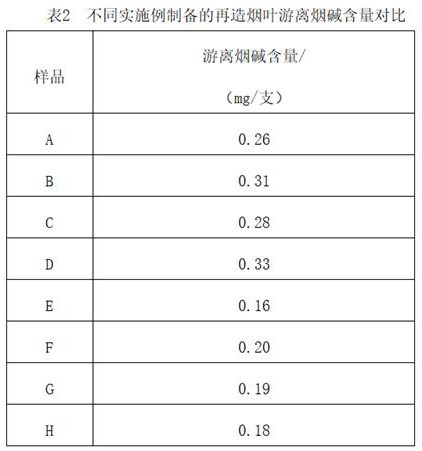

The invention discloses a tobacco composition for paper-making method reconstituted tobacco leaves and application thereof to heat-not-burn cigarettes. The tobacco composition is prepared from a stemgroup raw material and a leaf group raw material dividedly, based on a conventional paper-making reconstituted tobacco leaf process, a stem group tobacco powder wet part is added into a film base before film base forming, leaf group tobacco powder is added into coating liquid, and the core material paper-making method reconstituted tobacco leaves applied to the heat-not-burn cigarettes are prepared. By utilizing the tobacco composition, the absorption property of the film base of the paper-making method reconstituted tobacco leaves can be improved, the adding requirement of a high-content smoke agent is met, an aroma framework of the heat-not-burn cigarettes is perfected, the quality pursuit of the heat-not-burn cigarettes is reached in the aspect of sensory quality, the aroma quality is good, the smoke concentration is high, the strength is high, the texture is fine and smooth, mixed gas slightly exists, the remaining taste is clear, and harmoniousness is good.

Owner:ZHONGYAN SHIWEICE (YUNNAN) RECONSTITUTED TOBACCO CO LTD

Cigarette flavoring coating material and application thereof

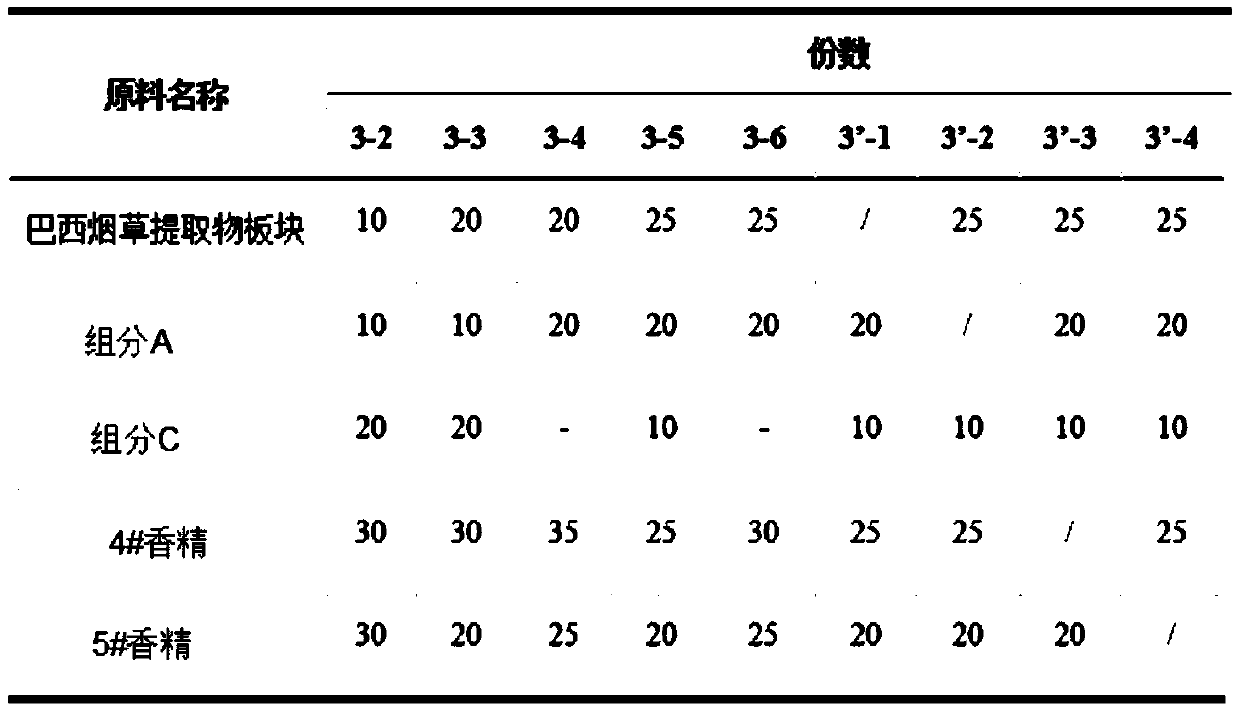

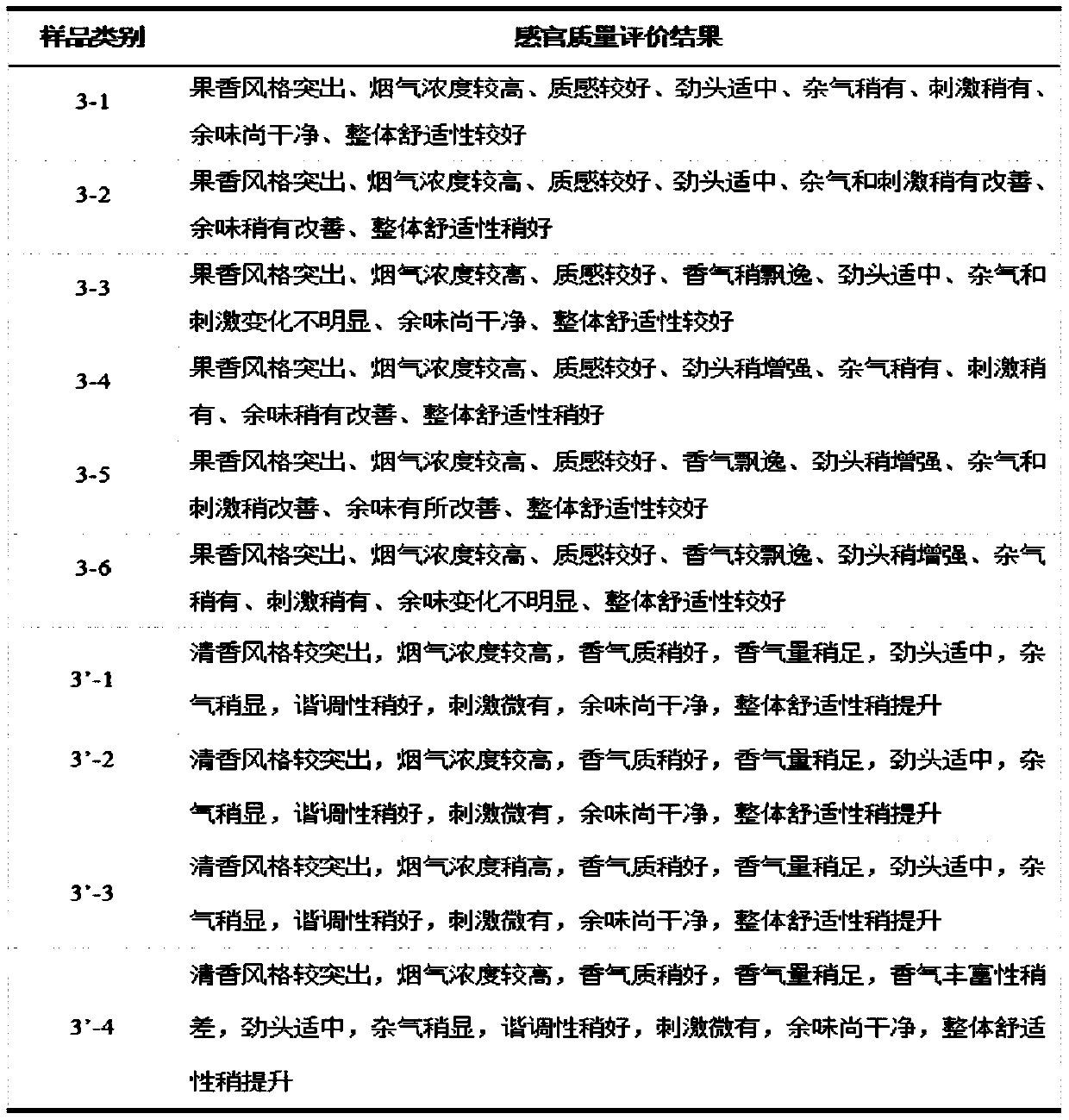

InactiveCN109875098AImprove comfortIncrease concentrationTobacco preparationTobacco treatmentFlavorHeat not burn

The invention discloses a cigarette flavoring coating material and application thereof. The cigarette flavoring coating material is prepared from, by mass, 10-40% of a component A, 0-40% of a component B, 0-30% of a component C and 0-70% of an essence. By selecting suitable essence and spice raw materials and adjusting compounding and dosage of the raw materials, the cigarette flavoring coating material which is high in overall smoke concentration, fine and soft in smoke, good in richness and harmony, moderate in strength, clean in remaining taste and good in sweet-and-moisturized feeling andoverall comfort is finally formed. The cigarette flavoring coating material is used for preparing and developing heat-not-burn cigarettes; the feasible cigarette flavoring coating material is providedfor low-temperature cigarettes, and powerful technical support is provided for conducting further development and improving the quality and mouthfeel of reconstituted tobacco.

Owner:CHINA TOBACCO GUANGDONG IND +1

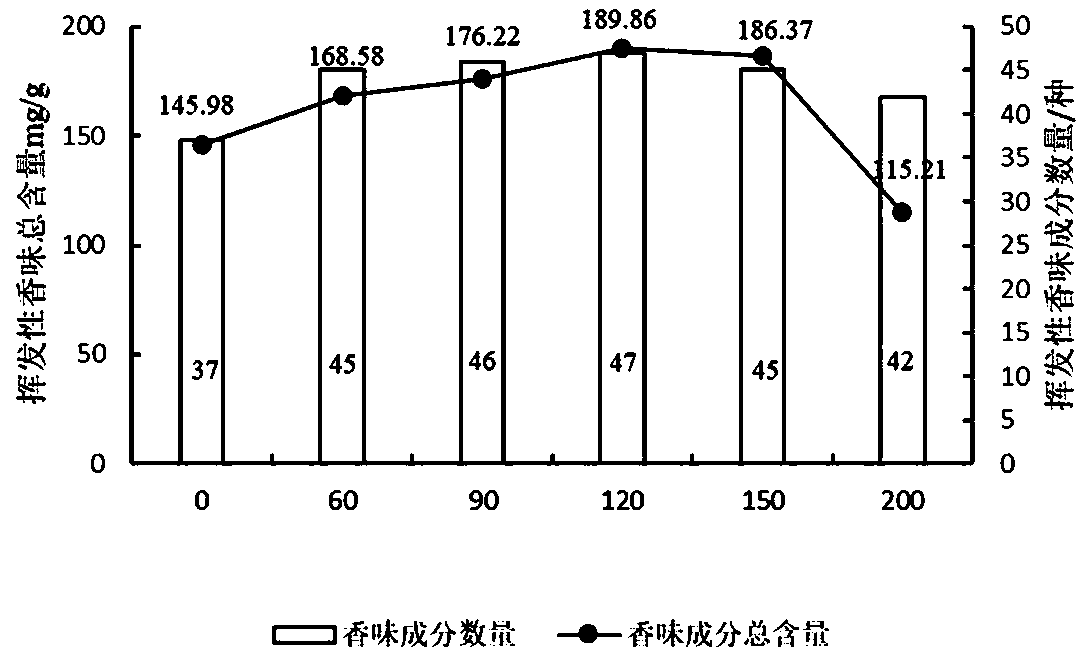

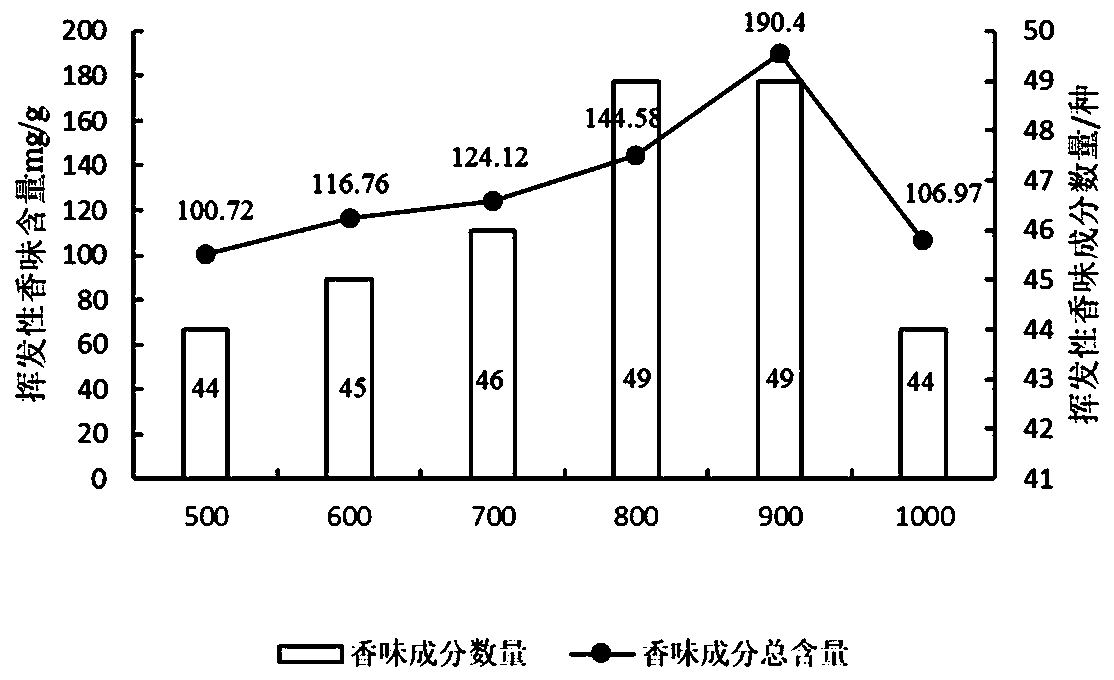

Method for preparing dark sun-cured tobacco extract and application of method

ActiveCN106174688ARealize development applicationLarge amount of applicationTobacco preparationTobacco treatmentWater bathsMaillard reaction

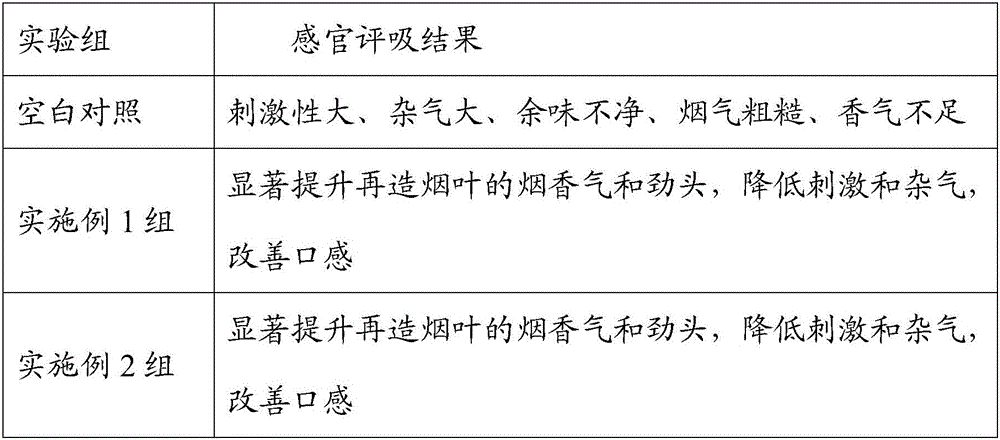

The invention provides a method for preparing dark sun-cured tobacco extract and application of the method. The method comprises the steps that firstly, dark sun-cured tobacco is subjected to enzymatic aroma enhancement and biotransformation in two steps; aroma enhancement is carried out under the acidic condition through beta-glucosidase biotransformation, and then protease and amylase are added to hydrolyze protein not beneficial to smoking in the dark sun-cured tobacco into free amino acid and decompose starch into glucose and the like; water bath stirring is carried out under the alkaline condition, self free amino acid and revertose serve as a natural nitrogen source and carbon source, a Maillard reaction is carried out, reflux extraction is carried out for 3-5 hours at the temperature of 60 DEG C to 70 DEG C, filtrate is obtained after suction filtration, macroporous resin is used for separation and purification, macromolecular impurities are further removed, and after desorption is carried out, a desorption solution is concentrated to obtain the high-purity dark tenne dark sun-cured tobacco extract. The dark sun-cured tobacco extract is applied to regenerated tobacco, the smoke aroma and strength of the regenerated tobacco can be remarkably improved, irrigation and offensive odors can be reduced, the taste can be improved, and the quality of the regenerated tobacco can be improved.

Owner:HUBEI CHINA TOBACCO IND

Sweet-scented aroma thread with tobacco aroma characteristics, preparation method and application thereof

ActiveCN109123753AKeep the tasteImprove your energyTobacco preparationTobacco treatmentBiotechnologyEngineering

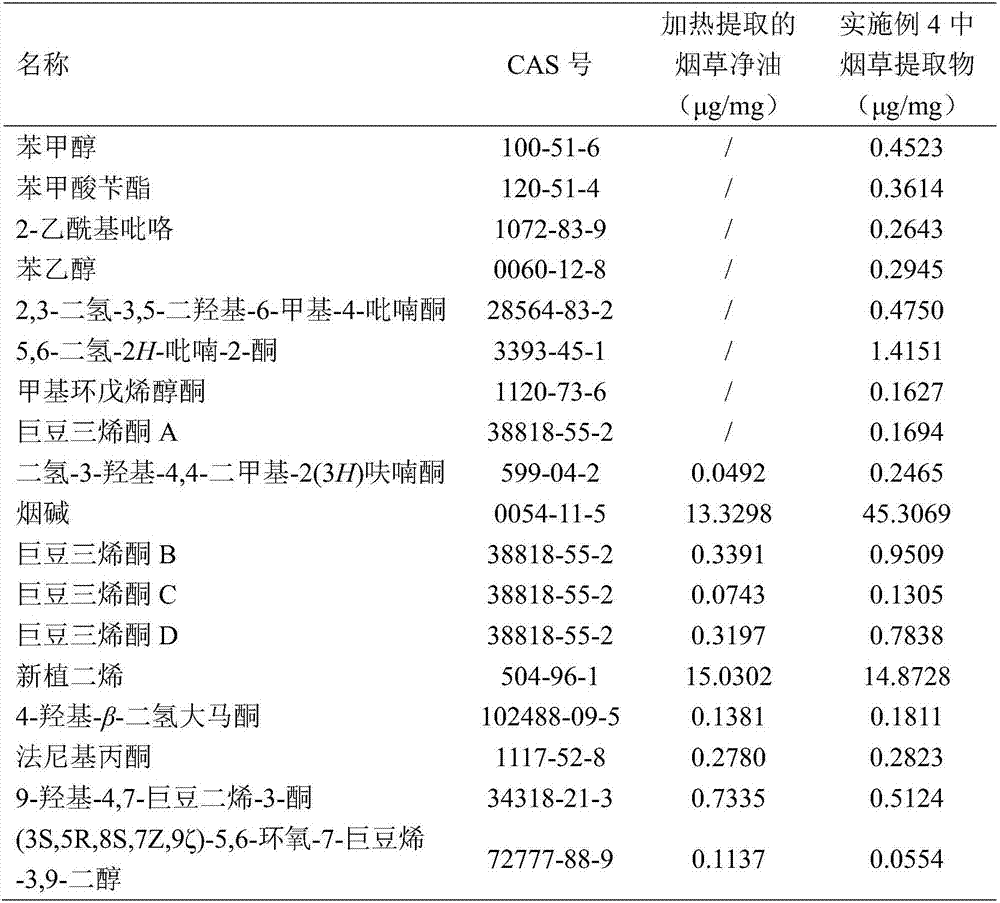

The invention discloses a sweet-scented aroma thread with tobacco aroma characteristics, a preparation method and an application in cigarettes, belonging to the technical field of cigarette materials,comprising the following steps of: (1) baking tobacco shreds; (2) preparation of tobacco extract; (3) preparation of tobacco net oil; (4) separating and preparing all kinds of components of tobacco net oil; (5) the blending of flavors with tobacco-based fragrance and sweet fragrance; and (6) preparation of filter rods with tobacco aroma and sweet aroma. The sweet-scented aroma filter rod preparedby the invention can effectively alleviate the irritation of the smoke to the throat and the mouth, increase the strength of the cigarette, increase the sweetness, improve the aftertaste, increase the smoking comfort of the cigarette and improve the compatibility of the cigarette.

Owner:CHINA TOBACCO HENAN IND

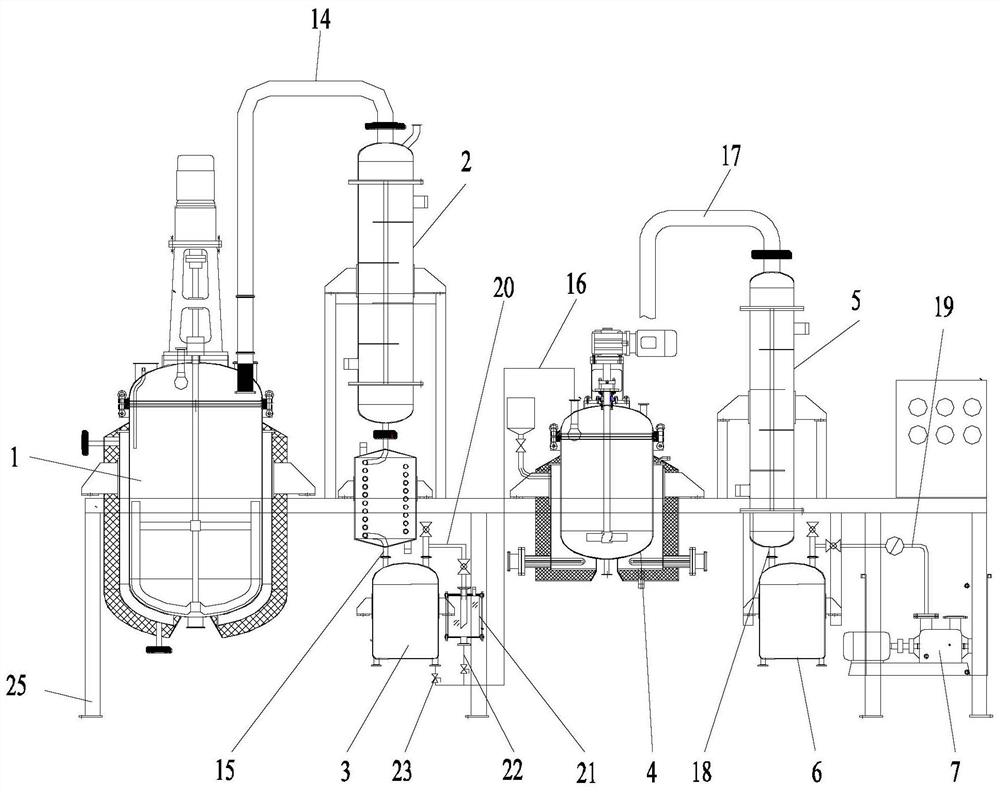

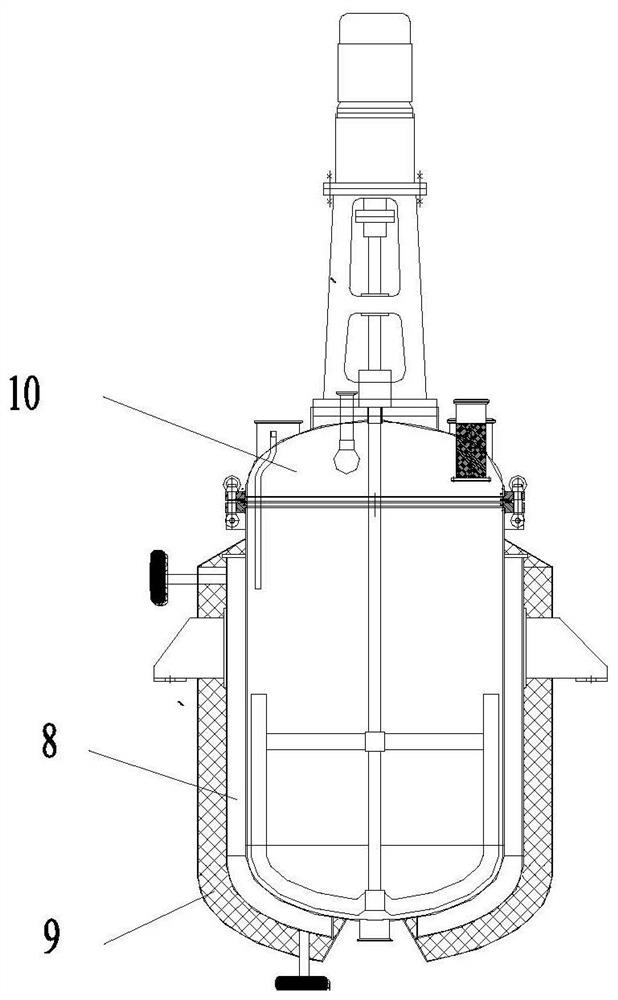

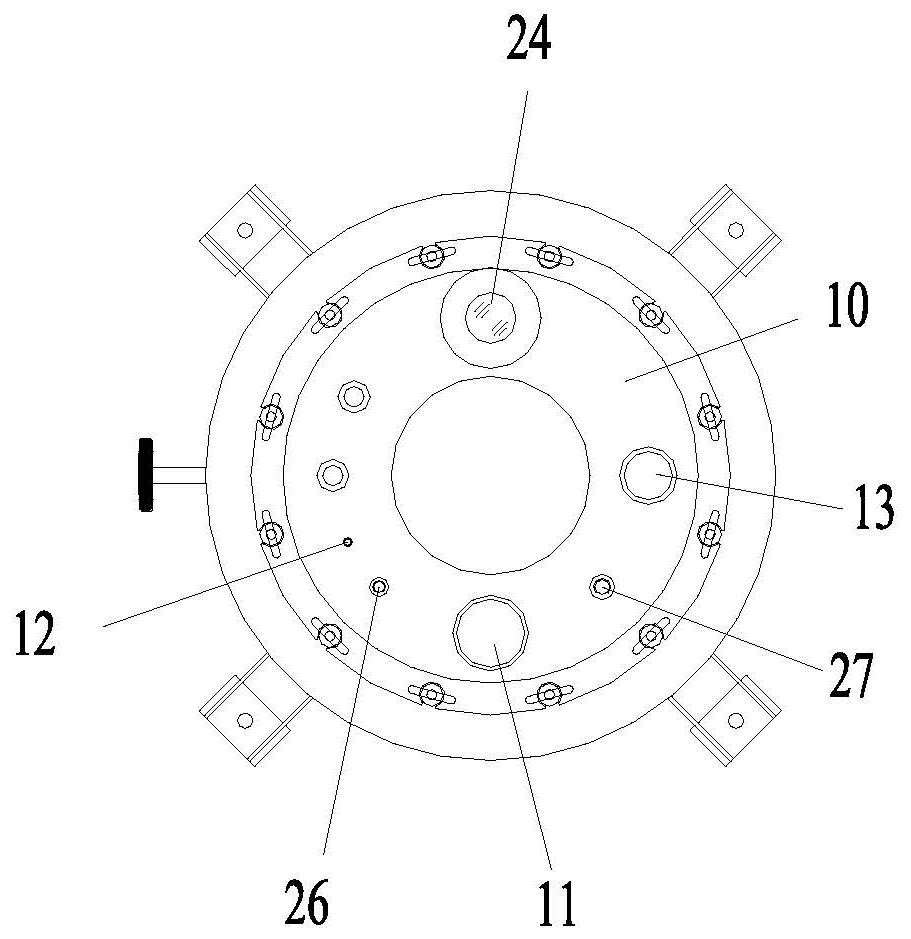

Macro preparation method of tobacco thermal reaction spice

ActiveCN112375626AHigh bulk densityLarge reaction dosageTobacco preparationBiofuelsDistillationProcess engineering

The invention discloses a macro preparation method of tobacco thermal reaction spice. The macro preparation method comprises two procedures of extraction and concentration, and comprises the followingsteps: granulating tobacco powder serving as a raw material to obtain tobacco particles, performing destructive distillation extraction on the tobacco particles under the protection of nitrogen, andperforming reduced pressure distillation and concentration on the obtained extract to obtain the tobacco thermal reaction spice. The adopted tobacco particles are large in stacking density, the reaction feeding amount is large, and the yield of the extracted thermal reaction spice is high.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Preparation method of electronic tobacco tar for microwave pyrolysis-molecular distillation combination

ActiveCN110236231AReduce tar and other harmful substancesImprove aroma qualityTobacco devicesTarChemistry

The invention belongs to the technical field of electronic cigarette, and particularly relates to a preparation method of electronic tobacco tar. The preparation method of the electronic tobacco tar comprises the steps of microwave pyrolysis, extraction, molecular distillation to obtain light components and heavy components and the like. Due to the fact that firstly pyrolysis operation is carried out, compared with a general preparation method, tar and other harmful substances can be effectively reduced when molecular distillation is carried out later; and on the other hand, the light components and the heavy components are obtained through molecular distillation treatment, after electronic cigarette liquid is prepared further, the quality of electronic cigarette fragrance can be effectively improved, so that the electronic cigarette fragrance is grace and fine, traditional cigarette characteristic fragrance is achieved, strength, satisfaction and sensory quality are improved, and thus better practical value is achieved.

Owner:CHINA TOBACCO HENAN IND

Production method of cigar tobacco leaf extract

InactiveCN113040416ATake advantage ofRich aromaTobacco preparationTobacco treatmentAqueous ethanolEngineering

The invention discloses a production method of cigar tobacco leaf extract. The production method comprises the following steps: S1, collecting tobacco stems, leftover materials or scraps; S2, adding water and enzyme into the waste tobacco powder in tobacco production, and sequentially performing enzymolysis, fermentation and drying; S3, carrying out supercritical extraction by taking carbon dioxide as a solvent and an ethanol water solution with the volume concentration of 80-90% as an entrainer to obtain an extract; and S4, carrying out ultrafiltration on the extract liquor to obtain ultrafiltrate, and repeatedly concentrating the ultrafiltrate into paste by adopting a film evaporator. According to the method, the subsequent tobacco extraction time is obviously shortened, the extraction rate of the tobacco extract is greatly increased, and the extract rate is increased; supercritical extraction is performed by taking carbon dioxide as a solvent and an ethanol water solution as an entrainer; and fragrance in the extract is effectively kept, and the extract has the effects of being sufficient in fragrance, palatable in smoke, mellow and mild in taste and enhanced in strength.

Owner:中国烟草总公司海南省公司

Tobacco strip low-temperature redrying method and prepared redried tobacco strip

InactiveCN109832654AAvoid high temperature bakingMaintain biological enzyme activityTobacco preparationRoom temperatureProcess engineering

The invention discloses a tobacco strip low-temperature redrying method. The redrying method comprises the following steps of at a freezing stage, freezing moisture in the raw material tobacco strip to a solid state; at a vacuum drying stage, performing vacuum drying on the frozen tobacco strip; realizing the tobacco strip moisture removal; at a temperature return and humidity regulation stage, continuously performing normal temperature drying on the tobacco strip subjected to vacuum drying; and realizing the temperature return and humidity regulation of the tobacco strip. At the redrying stage, the vacuum ultra-low temperature drying is performed; compared with high-temperature drying in a conventional process, the mode has the advantages that the processing intensity is greatly reduced;the operation is simple and compact; the energy consumption is low; aroma substances of tobacco raw materials are well remained; the sensory quality indexes of aroma volume and aroma quality of the redried tobacco strip are obviously improved; on the other hand, the bio-enzyme activity at the inside or on the surface of the tobacco leaves can be well maintained through low-temperature redrying; good conditions are created for the natural alcoholization in the later warehouse storage process; and the smoke strength and the smoke concentration are obviously improved.

Owner:CHINA TOBACCO GUANGDONG IND

High Nicotine Tobacco Extract and Its Application

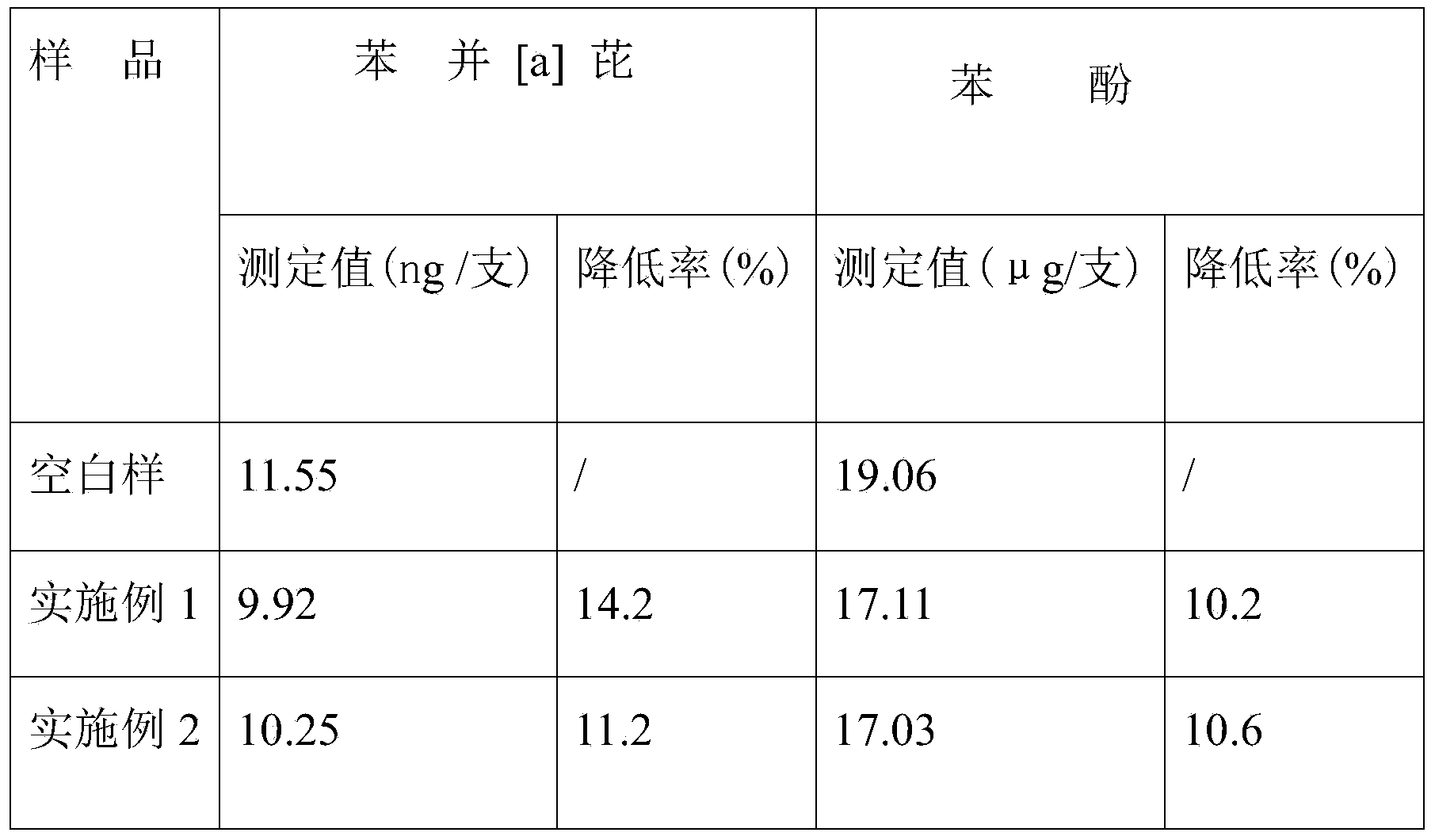

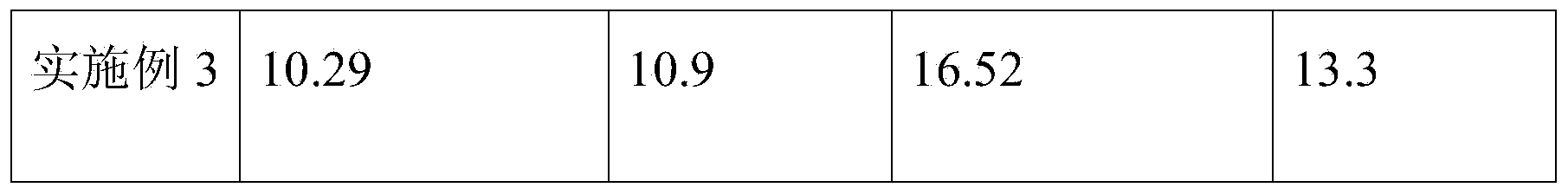

The invention discloses a high-nicotine tobacco extract and application thereof, and belongs to the field of tobacco additives. The extract is rich in aroma components such as megastigmatrienone, damascone, pyrones and furanones in tobacco, can provide tobacco aroma and roasting aroma, further contains certain nicotine, can cater for physiological needs of consumers, and improves satisfaction. Content of macromolecular substances such as proteins, pectin and polysaccharides in the extract is extremely low, solubleness is good, the high-nicotine tobacco extract can be completely dissolved into MCT (medium chain triglyceride), and can be used for perfuming a filter tip. Besides, the high-nicotine tobacco extract is added into cut stems or reconstituted tobaccos, so that stimulus can be reduced, strength is improved, a blending rate, in a tobacco group, of the cut stems or reconstituted tobaccos is increased, and content of cigarette tar is reduced while fragrance is invigorated and impurities are covered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

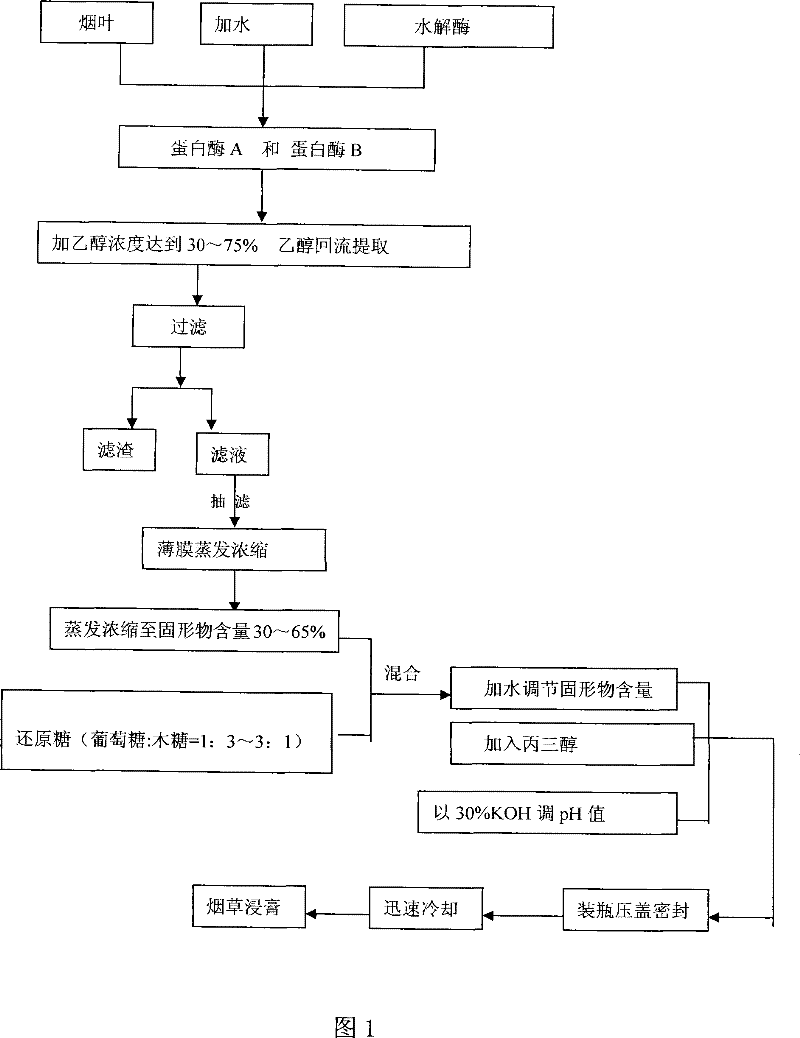

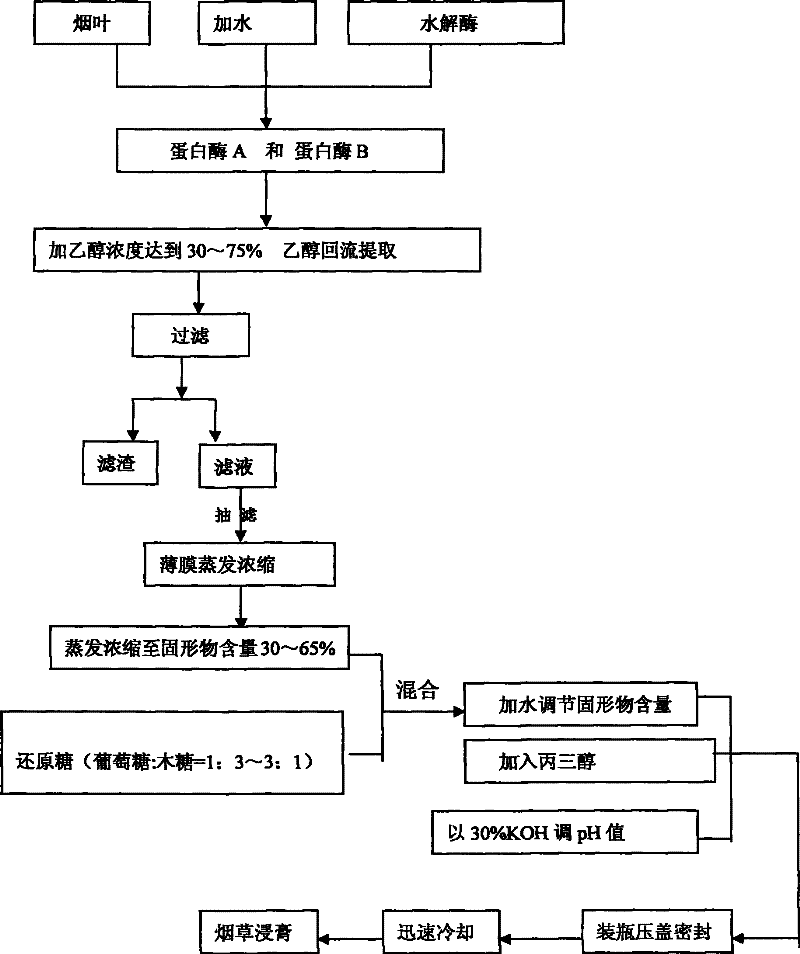

Preparation method for tobacco extract

The invention discloses a preparing method for a tobacco-made extract. The invention includes the following steps: tobacco leaves are firstly blended with water and enzyme for enzymolysis; and then ethanol is applied for extraction, filtration and concentration; and lastly the tobacco-made extract is obtained through maillard reaction. The invention utilizes the tobacco dust generated from the tobacco production, takes into full consideration the feasibility and operability of industrial production with respect to the preparing process, and furthermore, conducts a series of exploration on factors relating to the enzymolysis, extraction and maillard reaction forms the final preparing process and optimal technical parameters, and thereby the product quality reaches the requirements for adding fragrance to the tobacco-made extract with outstanding steadiness and repeatability.

Owner:CHINA TOBACCO GUANGDONG IND

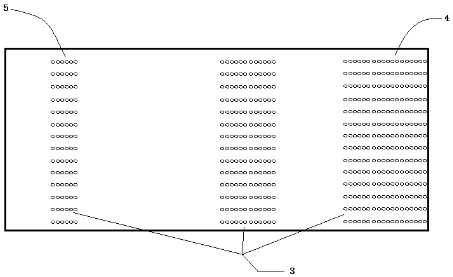

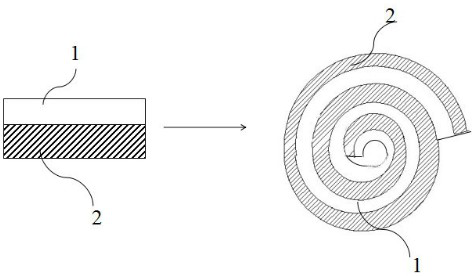

Forming paper for preparing heat-not-burn cigarette core and method for preparing cigarette core thereof

ActiveCN107361400BNo obvious irritationSufficient amount of flue gasTobacco preparationTobacco treatmentBurn cigaretteEngineering

The invention relates to a wrap paper for making a heating incombustible cigarette core and a making method of the cigarette core made of the same and belongs to the technical field of cigarettes. The method comprises the six steps of preprocessing, preparation of a first mixture, preparation of mixed pulp, preparation of perfuming material liquid, coating and cigarette core making. The made heating incombustible cigarette core can make the smoke amount sufficient and make the puff number up to 19 due to the fact that a larger number of tobacco granule materials attaches to the wrap paper, can remarkably improve smoke strength. A perfuming material can make smoke mellow, full, soft and make aroma full and compatible, no obvious irritation feeling is produced in the mouth cavity, the comfort is improved, the smoking quality and style characteristics of the cigarette core can be more greatly improved compared with existing products, accordingly the smoking quality of a heating incombustible cigarette is remarkably improved, and the wrap paper has a good application prospect.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Composite enzyme bacteria preparation for shredded tobacco production and preparation method thereof

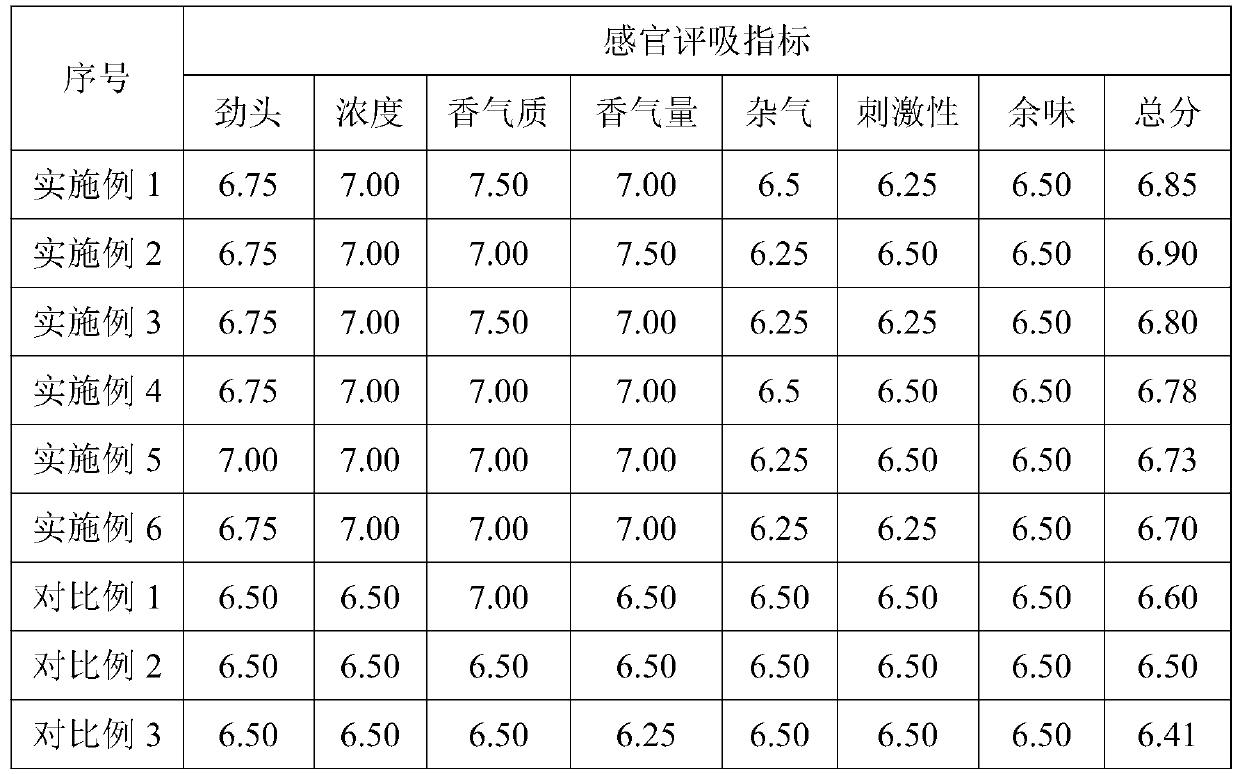

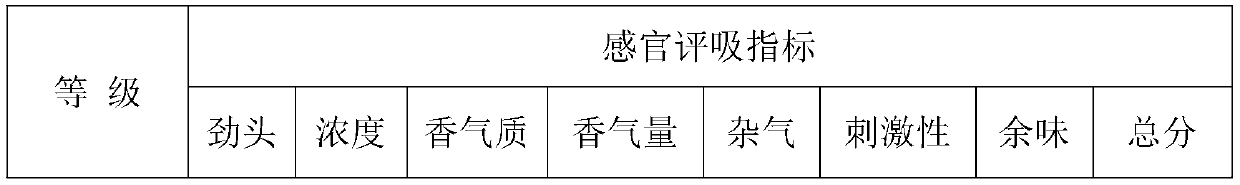

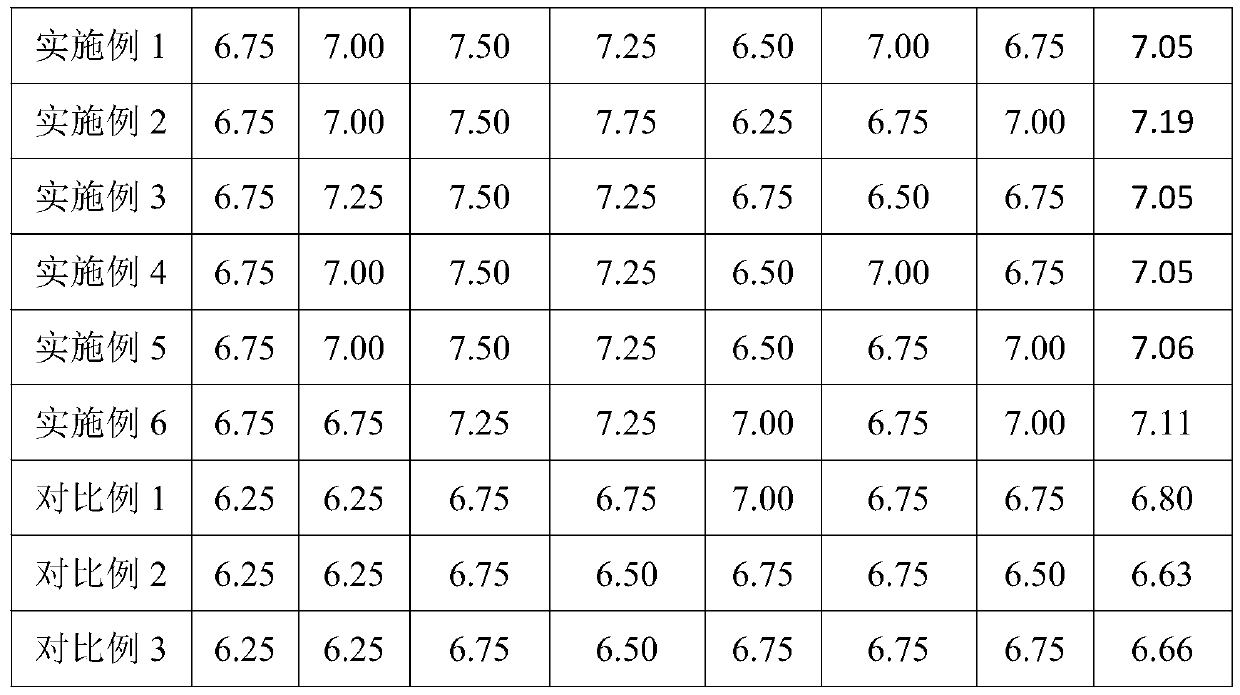

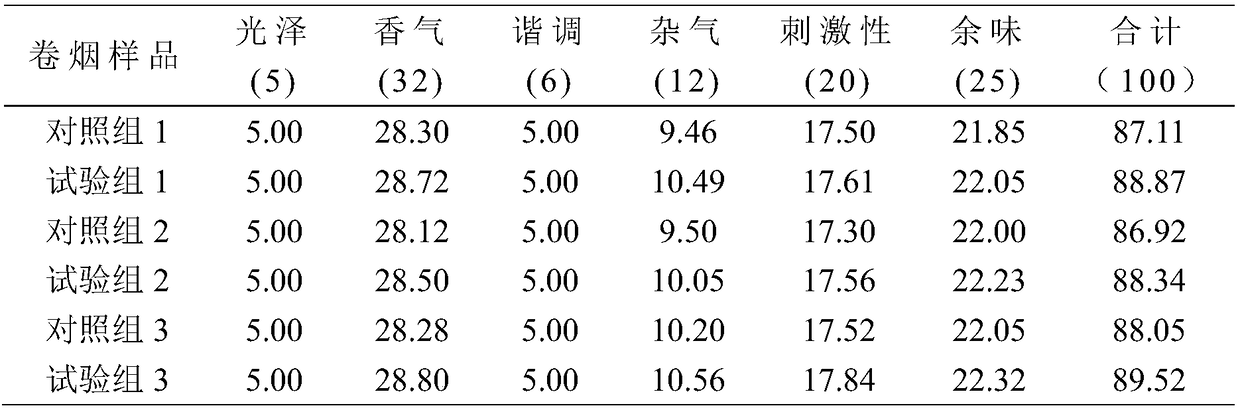

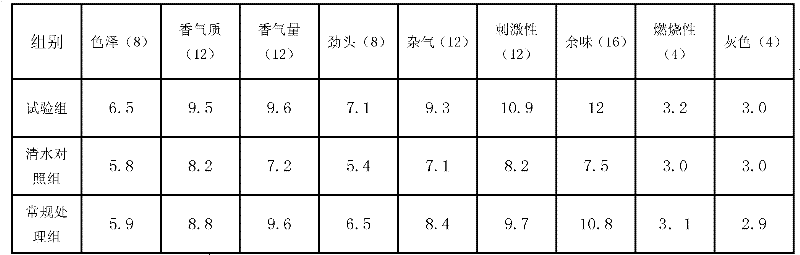

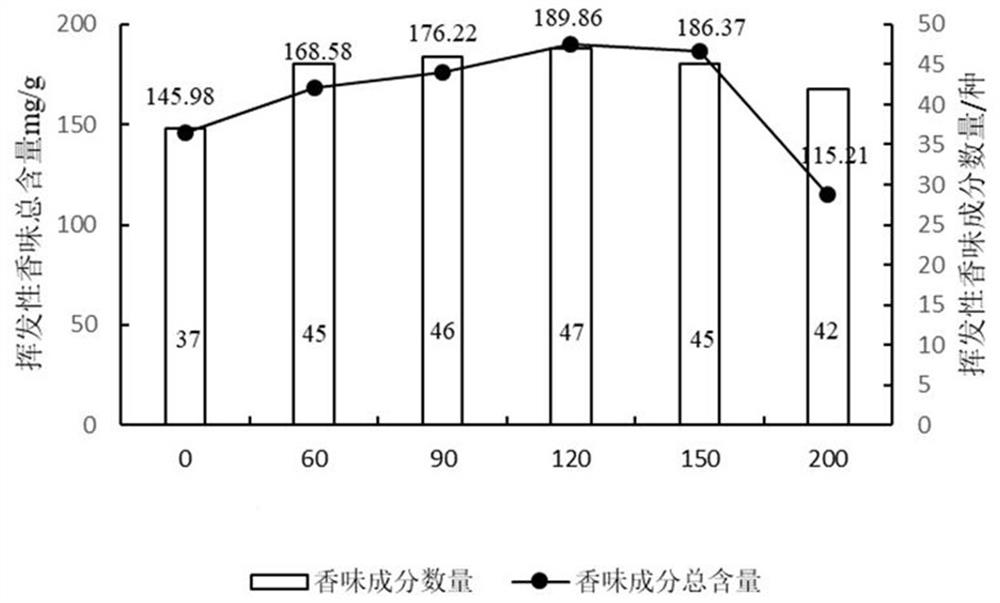

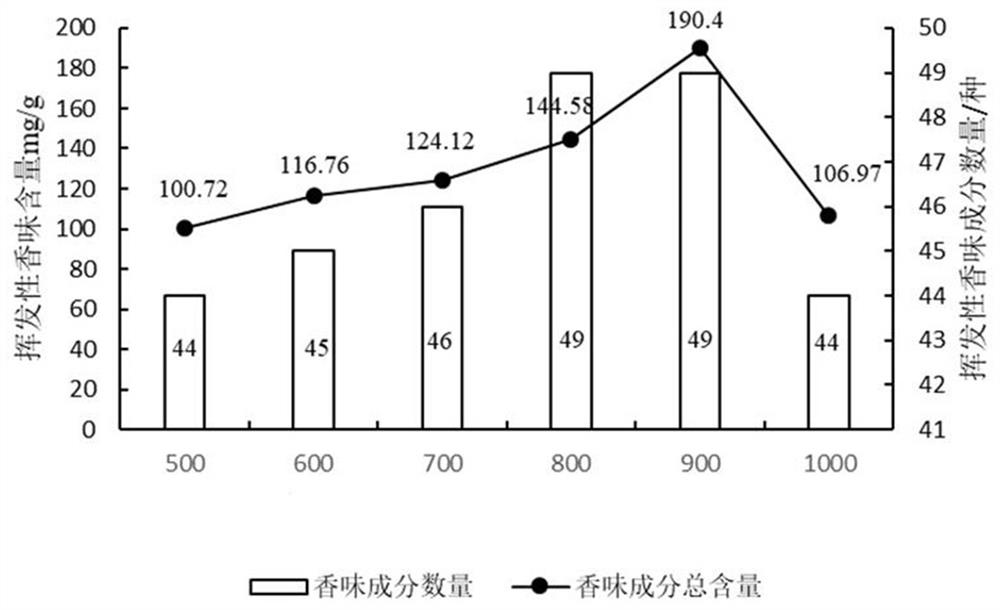

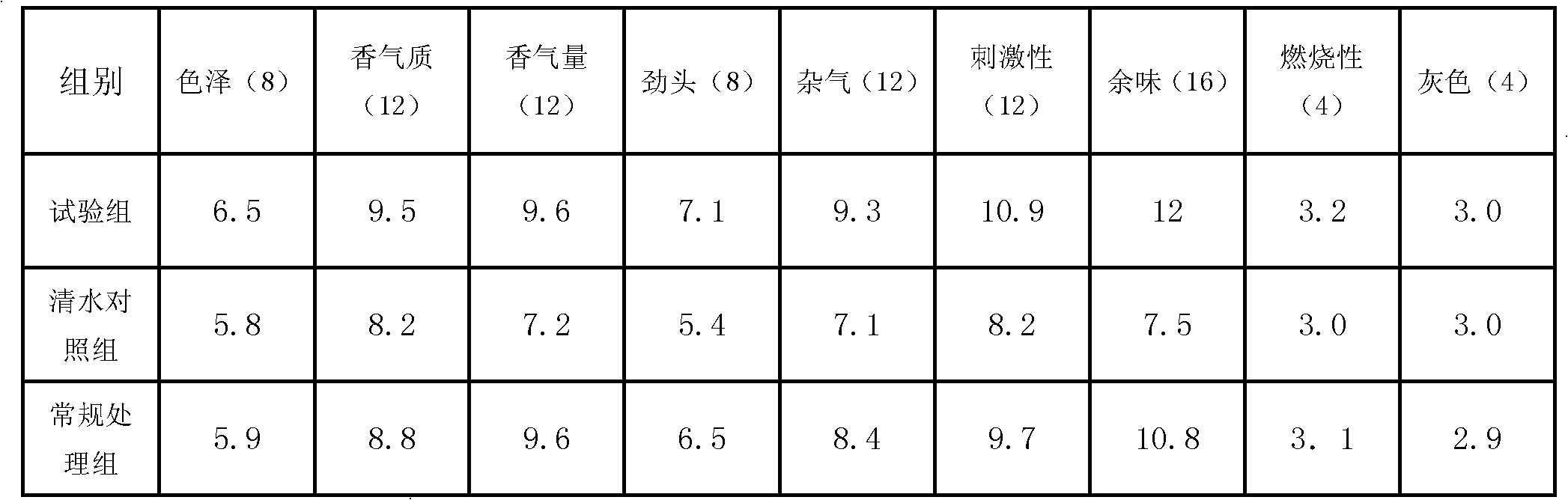

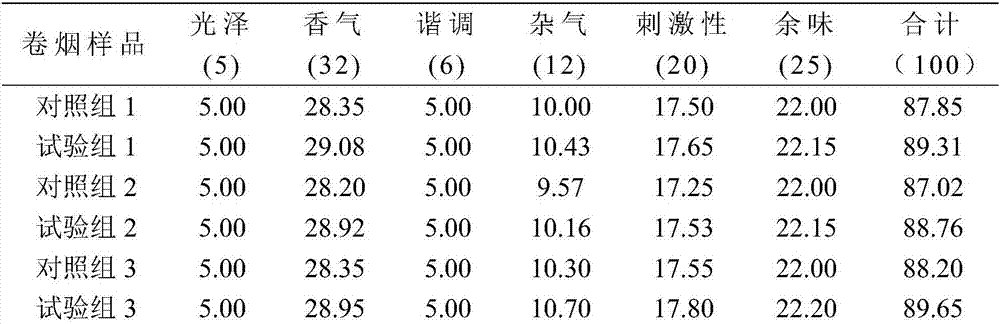

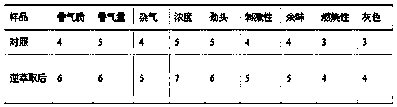

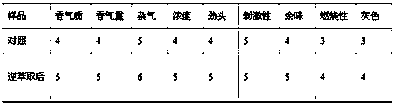

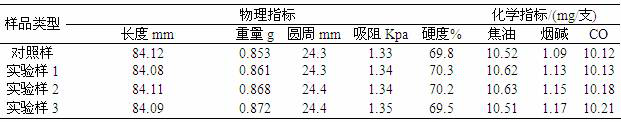

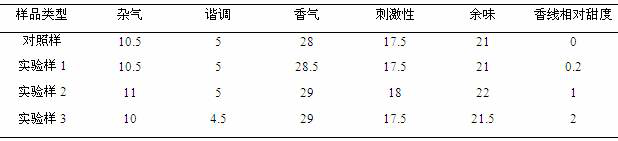

The invention discloses a complex enzyme bacterium preparation used for tobacco thread production. The complex enzyme bacterium preparation contains a liquid A and a liquid B, wherein the liquid A is preserved in CGMCC (China general microbiological culture collection center), is enrolled as a fermentation liquor clear solution after fermentation of a strain and is numbered as CGMCC No.4121, and the liquid B is preserved in CGMCC, is enrolled as a fermentation liquor clear solution after fermentation of a strain and is numbered as CGMCC No.4120. By applying the preparation provided by the invention, indexes of cigarette such as colour and lustre, fragrance quality, fragrance quantity, strength, impurity gas, irritation, aftertaste, flammability, grey and the like are obviously improved.

Owner:农博士(福建)生物技术有限公司

Cigarette containing cordyceps militaris extract

ActiveCN102499435BImprove your energyReduce drynessTobacco preparationCordyceps militarisExtraction methods

The invention discloses a cordyceps militaris extraction method and a cigarette containing the cordyceps militaris extract, which aim to solve the technical problems of increasing the cigarette aroma and reducing the objectionable constituents of the cigarette. The cordyceps militaris extraction method comprises the following steps of: drying, crushing, digesting, filtering and concentrating the cordyceps militaris, adding ethanol, standing, concentrating, and obtaining the cordyceps militaris extract. In the cigarette containing the cordyceps militaris extract, a tobacco shred contains the cordyceps militaris extract, and the weight of the cordyceps militaris extract is 0.001-10 percent of that of the tobacco shred. Compared with the prior art, the cordyceps militaris extract which is obtained after extraction is added in the tobacco shred, so the cigarette aroma can be increased, the smoke impact is improved, the smoke dryness of the cigarette is reduced, the smoke taste is improved, and the objectionable constituents of the cigarette are reduced.

Owner:SHENZHEN DABAIHUI TECH

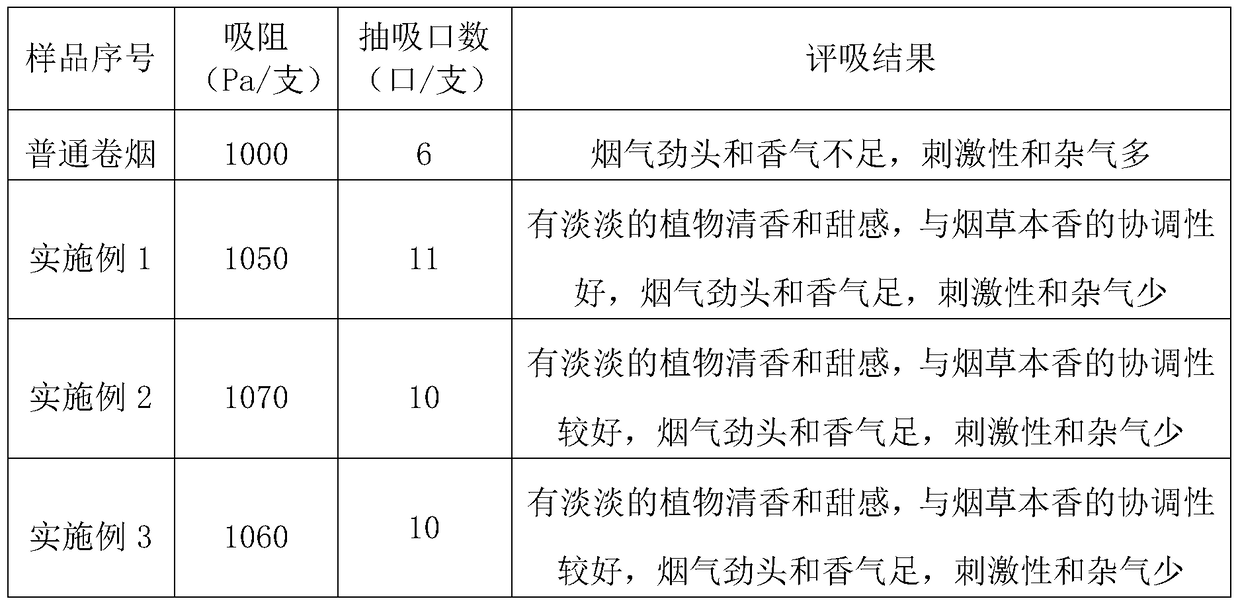

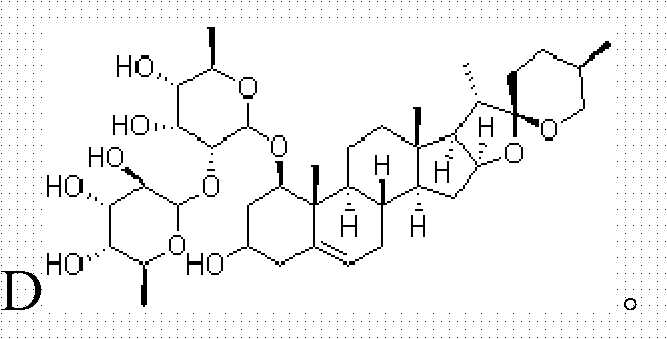

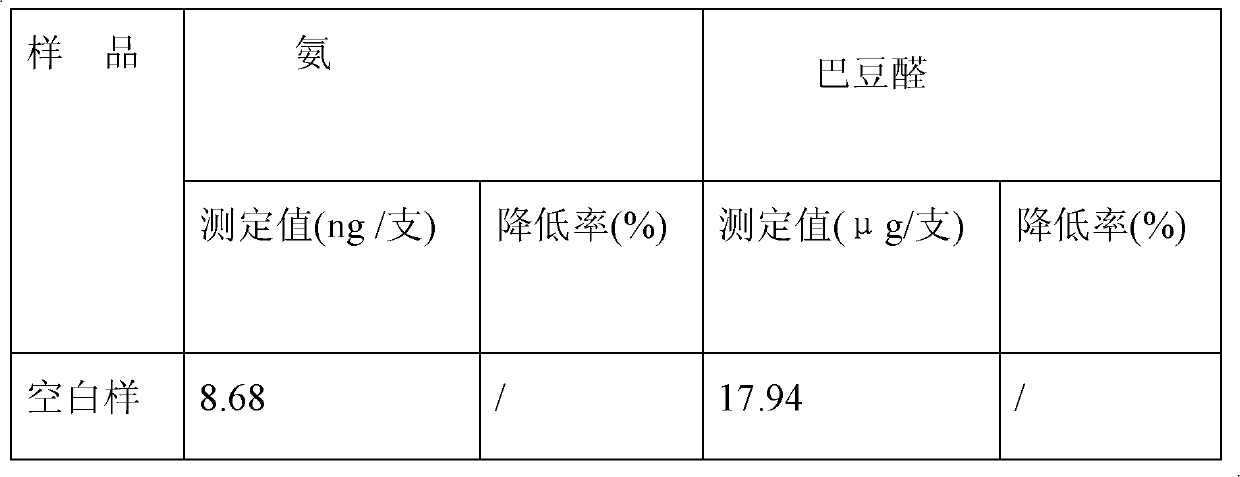

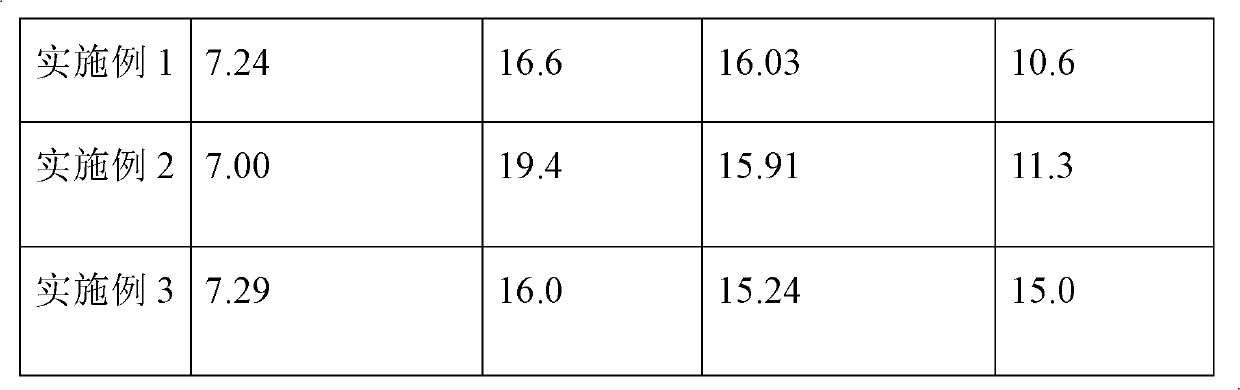

A kind of preparation method of plant fragrance type cigarette

The invention discloses a preparation method of a plant faint-scented cigarette. The preparation method comprises the following steps: crushing cyclocarya paliurus leaves and tobacco leaves into fine powder, adding with syrup to produce a soft material, processing the soft material into particles, pressing the particles into a tobacco rod, wrapping the tobacco rod by cigarette paper, connecting with a filter tip, and manufacturing the cigarette according to a conventional method. The prepared cigarette is novel is type, can bring brand-new experience to a consumer, and is uniform in component, thus the stability of the smoking quality of the cigarette is guaranteed, the burning time of the cigarette is prolonged, the smoking time is increased, and further, the consumer obtains strong satisfaction. The cigarette has faint plant scent, and the smoking is strong in strength and aroma, and low in irritation and miscellaneous smell

Owner:HUBEI CHINA TOBACCO IND

Extracting method for radix ophiopogonis extract and dark plum extract as well as cigarette containing radix ophiopogonis extract and dark plum extract

ActiveCN102499460BSpray evenlyIncrease the sense of body fluidTobacco treatmentPathogenic microorganismThroat

The invention discloses an extracting method for a radix ophiopogonis extract and a dark plum extract as well as a cigarette containing the radix ophiopogonis extract and the dark plum extract in order to solve the technical problem on the reduction of dry sensation and harm of smoke of the cigarette. The extracting method for the radix ophiopogonis extract and the dark plum extract comprises the following steps of: drying and crushing radix ophiopogonis and dark plums; adding hot water into radix ophiopogonis and dark plum powder; extracting and filtering; reducing pressure of filtrate; concentrating; adding ethanol; and stewing and filtering to obtain the ophiopogonis extract and the dark plum extract. According to the cigarette containing the radix ophiopogonis extract and the dark plum extract, disclosed by the invention, the mass of the radix ophiopogonis extract and the dark plum extract is 0.001-10% of that of cut tobacco. Compared with the prior art, the radix ophiopogonis extract and the dark plum extract are contained in the cut tobacco; during the smoking, components of the radix ophiopogonis extract and the dark plum extract can enter a human body along with mainstream smoke, and can be absorbed by the human body, so that the cigarette has the functions of killing bacteria, resisting pathogenic microorganisms, benefiting gallbladder, improving hypoxia tolerant capability and resisting aging; the smoke is plump and mellow, and has no foreign smells, so that secretion generation of the smoke is enhanced, and the throat is comfortable; the quality of the cigarette can be improved; and threats of the smoke to the human body can be reduced.

Owner:SHENZHEN DABAIHUI TECH

Preparation method for cured tobacco leaves

ActiveCN103238919BCharacteristic aroma weakenedImprove your energyTobacco preparationHarvestersIrritationBiology

The invention discloses a preparation method for cured tobacco leaves. The method comprises the steps of cured tobacco plantation, tobacco leaf harvest and curing. In the step of tobacco leaf harvest, the tobacco leaves are harvested from bottom to top one by one according to tobacco leaf growth positions, 4-5 tobacco leaves are harvested each time, urea solution is evenly sprayed onto surfaces of the tobacco leaves after harvesting, urea sprayed onto the leaf surfaces per kg is 0.05-0.2g; and the tobacco leaf curing comprises the steps of tobacco leaf withering, yellowing, browning and killing-out. Characteristic aroma of the prepared cured tobacco leaves is remarkably weakened, aroma quality style is similar to air-cured tobacco leaves, strength is slightly high, satisfaction is strong, concentration is high, the cured tobacco leaves are full and mellow, irritation is small, smoke is smooth, the application range is greatly expanded, and technical support is provided for enriching tobacco leaf quality styles and meeting diversified raw materials requirements of low-tar low-harm cigarette products.

Owner:HUBEI CHINA TOBACCO IND

Cut tobacco module of heat-not-burn cigarette and preparation method thereof

ActiveCN109567258BFaster and more even transmission toFaster and more even spread toTobacco treatmentBiotechnologyBurn cigarette

Owner:CHINA TOBACCO GUANGDONG IND

A method for preparing electronic cigarette oil by combining microwave cracking and molecular distillation

ActiveCN110236231BComplete aroma componentsImprove aroma qualityTobacco treatmentTobacco devicesHazardous substanceLiquid smoke

This application belongs to the technical field of electronic cigarettes, and specifically relates to a patent application for a method for preparing electronic cigarette oil. The method includes such steps as microwave cracking, extraction, and molecular distillation to obtain light components and heavy components. Because the present application has carried out the cracking operation at first, it can effectively reduce tar and other harmful substances in the follow-up molecular distillation compared with the conventional preparation method; After being made into e-cigarette liquid, it can effectively improve the aroma quality of e-cigarettes, make the aroma of e-cigarettes elegant and delicate, have the characteristics of traditional cigarettes, and improve the sensory qualities such as energy and satisfaction, so it has good practical value.

Owner:CHINA TOBACCO HENAN IND

Complex enzyme bacterium preparation used for tobacco thread production and preparation method thereof

Owner:农博士(福建)生物技术有限公司

Tobacco extract, extraction method and application

The invention discloses a tobacco extract, an extracting method and application and belongs to the field of tobacco additives. The tobacco extract is extracted with the method including the following steps that firstly, propylene glycol is added into tobacco raw materials, and then baking is carried out after standing; secondly, smashing is carried out, and a solvent is added into powder materials for extraction; thirdly, extract liquid passes through an ultrafiltrtion membrane, penetrating liquid is obtained and subjected to reduced pressure distillation, and concentrate is obtained; fourthly, the concentrate is subjected to secondary separation with a molecule distillation method, light components are collected, and the tobacco extract is obtained. The extract contains rich megastigmatrienone, Damascone, neophytadiene, phenylcarbinol, phenethyl alcohol, farnesylacetone and pyrone and furanone aroma components, and the tobacco extract is thick in baking aroma and tobacco aroma, good in penetration, small in irritation and miscellaneous gas, high in satisfaction, capable of improving the smoking quality of cigarettes and providing a certain amount of nicotine to meet the physiological needs of consumers when used.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

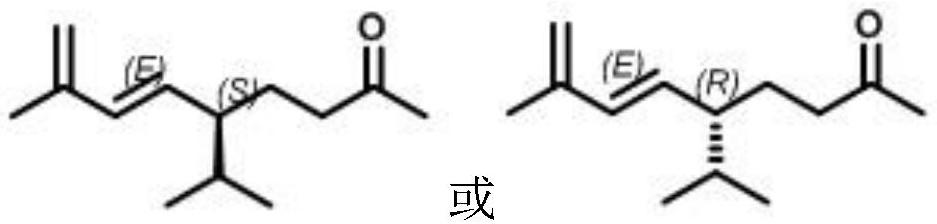

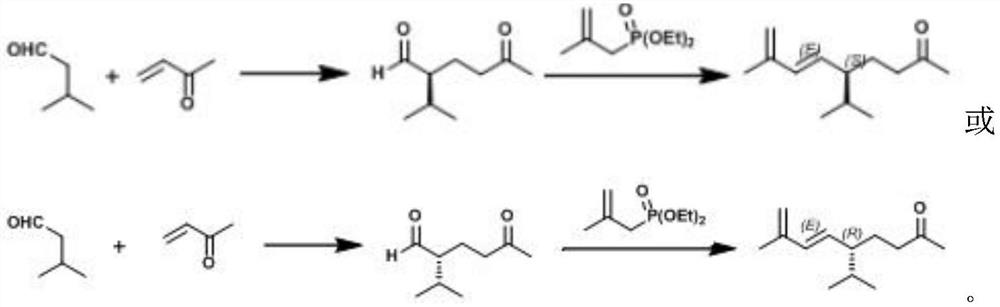

A kind of (e) type solanone, its preparation method and application

ActiveCN111039770BFew synthetic stepsFew stepsTobacco preparationOrganic compound preparationIsopropylKetone

The invention discloses an (E)-type solanone, whose three-dimensional structural formula is: or its name is: (S,E)-5-isopropyl-8-methyl-6,8-diene-2-one , or (R,E)‑5‑isopropyl‑8‑methyl‑6,8‑dien‑2‑one. The invention also discloses the preparation method of the (E) type solanone and its use for flavoring shredded tobacco of cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

Method for preparing paper-making reconstituted tobacco by using multi-component complex and reconstituted tobacco

ActiveCN112704258AIncrease concentrationFacilitated releaseTobacco preparationTobacco treatmentPtru catalystPulp and paper industry

The invention provides a method for preparing paper-making reconstituted tobaccoby using a multi-component complex and the reconstituted tobacco. According to the method for preparing the paper-making process reconstituted tobacco by using the multi-component complex, a certain amount of sodium sulfate, potassium carbonate, calcium carbonate and guar gum are added in the pulp preparing process, adsorption multi-component complex finished pulp is prepared, and after the multi-component complex is attached to the finished pulp, the concentration of free nicotine and smoke generated by product combustion can be increased; then, a certain amount of sodium sulfate, potassium carbonate and calcium carbonate are added in the tobacco stem and tobacco powder concentrated solution blending process, the multi-component complex is formed in the coating solution through the adsorption effect of the calcium carbonate, and amulti-component complex improved coating solution is obtained, so that on one hand, aroma substances can be adsorbed, and the product quality is improved, and on the other hand, a free nicotine catalyst can be formed in the combustion process, the free nicotine release amount is increased, and the feeling and satisfaction of the product during smoking are improved.

Owner:江苏鑫源烟草薄片有限公司

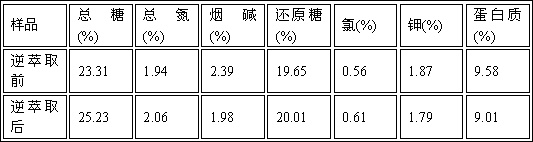

A Subcritical Back Extraction Method of Tobacco Essential Fragrance Components

The invention relates to the field of extraction and reverse extraction, and concretely relates to a subcritical reverse extraction method of a tobacco original flavor component, having a simple process and having no destroys to the activity or the structure of tobacco flavor components. The method comprises the following steps: 1, carrying out preprocessing, drying and cell wall breaking; 2, extracting: placing preprocessed tobacco leaves in a closed extraction tank, injecting a subcritical fluid as an extraction solvent, and carrying out extraction under certain extraction conditions to obtain tobacco leaf extract; 3, removing impurities to obtain purified tobacco leaf extract; and 4, reversely extracting: placing the purified tobacco leaf extract and tobacco leaves to be reversely extracted in a subcritical reverse extraction tank, injecting the subcritical fluid as a reverse extraction agent, and carrying out reverse extraction under certain reverse extraction conditions in order to obtain quality improved tobacco leaves. The tobacco leaves obtained through reverse extraction have stable quality, and have very ideal quality improvement.

Owner:CHINA TOBACCO HENAN IND +1

A kind of electronic cigarette smoke liquid and preparation method thereof

ActiveCN106617265BIncreased roasted aromaIncrease the aroma of tobaccoTobacco treatmentLiquid smokeAdditive ingredient

The invention discloses E-cigarette nicotine liquid and a preparation method thereof and belongs to the technical field of E-cigarette nicotine liquids. The E-cigarette nicotine liquid is made from high-nicotine tobacco extract, tobacco flavor and the like, wherein the tobacco extract has rich tobacco characteristic fragrant ingredients (such as megastigmatrienone, beta-damascone, pyrones, and furanones) and nicotine, can provide tobacco aroma and curing aroma and meet the physiological needs of consumers, and provides better satisfaction. The high-nicotine tobacco extract has very low contents of high-boiling-point ingredients and macromolecular substances (such as proteins, pectin, and polysaccharides), is free of burnt smell and low in sweetness, and can supplement aroma and cover peculiar odors, lower stimulus and improve taste strength. By being used with tobacco flavors, the E-cigarette nicotine liquid has enhanced curing aroma and tobacco aroma, and has strong aroma and good volatility. The preparation process of the E-cigarette nicotine liquid is simple, is simple and easy to perform, and is applicable to large-scale industrial production and application.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

A sweet-flavored incense thread with the characteristics of tobacco aroma, preparation method and application thereof

ActiveCN109123753BKeep the tasteImprove your energyTobacco preparationTobacco treatmentBiotechnologySweet flavor

This patent discloses a sweet incense thread with the characteristic of tobacco aroma, its preparation method and its application in cigarettes, which belongs to the technical field of tobacco materials and includes the following steps: (1) roasting of shredded tobacco; (2) preparation of tobacco extract ; (3) Preparation of tobacco absolute; (4) Separation and preparation of various components of tobacco absolute; (5) Blending of flavors with the aroma and sweetness of tobacco; (6) Sweet flavor with the aroma of tobacco Preparation of scented filter sticks. The sweetness filter stick prepared by the present invention has the aroma and aroma of tobacco, which can effectively alleviate the irritation of the throat and mouth caused by smoke, increase the strength of cigarettes, increase the sweetness, improve the aftertaste, and increase the smoke of cigarettes when applied to cigarettes. Improve smoking comfort and improve the compatibility of cigarettes.

Owner:CHINA TOBACCO HENAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com