Method for preparing paper-making reconstituted tobacco by using multi-component complex and reconstituted tobacco

A technology for reconstituted tobacco leaves and composites, applied in the preparation of tobacco, tobacco, application, etc., to achieve the effects of improving strength, increasing free nicotine release, and more satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

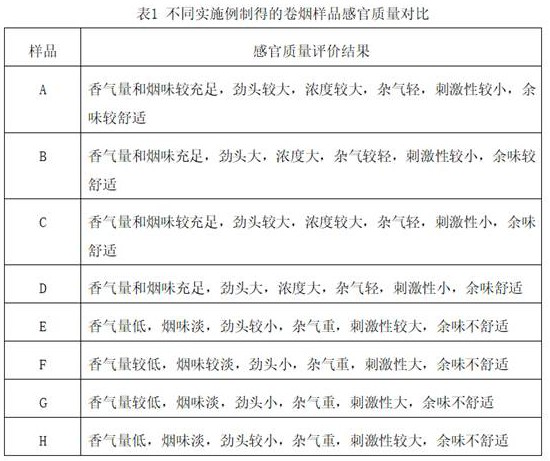

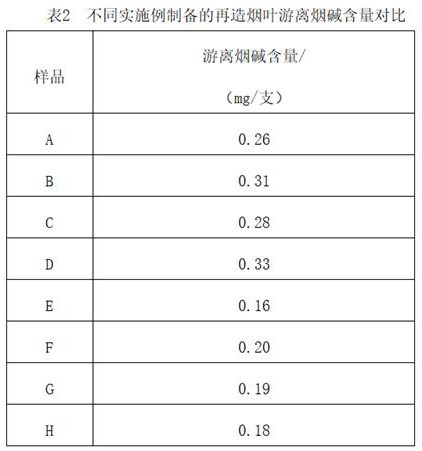

Examples

Embodiment 1

[0032] Embodiment 1 of the present invention provides a method for preparing reconstituted tobacco leaves by papermaking method and reconstituted tobacco leaves by using multi-component complex, specifically comprising the following steps:

[0033] (1) Extract the raw materials of tobacco stem and tobacco powder with clean water, the solid-liquid ratio is 1:7, the temperature is 70°C, and the time is 60 minutes; The final extract and the tobacco stem and tobacco powder after extraction;

[0034] (2) Beating the leached tobacco stems and tobacco powder obtained in step (1) respectively to obtain tobacco stem pulp and tobacco powder pulp;

[0035] (3) Centrifuge the tobacco stem extract and tobacco powder extract obtained in step (1) to remove impurities and concentrate to obtain a tobacco stem concentrate and tobacco powder concentrate with a solid content of 40%;

[0036] (4) Blend the tobacco stem pulp and tobacco powder pulp obtained in step (2) at a ratio of 3:7 to obtain ...

Embodiment 2

[0040] Embodiment 2 of the present invention provides a method for preparing reconstituted tobacco leaves by papermaking method and reconstituted tobacco leaves by using a multi-component complex, specifically comprising the following steps:

[0041] (1) Extract the raw materials of tobacco stems and tobacco powder with clean water, the solid-to-liquid ratio is 1:4, the temperature is 50°C, and the time is 70 minutes; The final extract and the tobacco stem and tobacco powder after extraction;

[0042] (2) Beating the leached tobacco stems and tobacco powder obtained in step (1) respectively to obtain tobacco stem pulp and tobacco powder pulp;

[0043] (3) Centrifuge the tobacco stem extract and tobacco powder extract obtained in step (1) to remove impurities and concentrate to obtain a tobacco stem concentrate and tobacco powder concentrate with a solid content of 40%;

[0044] (4) Blend the tobacco stem pulp and tobacco powder pulp obtained in step (2) at a ratio of 4:6 to obt...

Embodiment 3

[0048] Embodiment 3 of the present invention provides a method for preparing reconstituted tobacco leaves by the papermaking method and reconstituted tobacco leaves by using a multi-component complex, specifically comprising the following steps:

[0049] (1) Use ethanol solution with a concentration of 70% to extract the raw materials of tobacco stem and tobacco powder respectively, the solid-to-liquid ratio is 1:9, the temperature is 20°C, and the time is 90 minutes; after the extraction, the material is separated into solid and liquid , obtaining the tobacco stem extract, the tobacco powder extract, and the extracted tobacco stem and tobacco powder;

[0050] (2) Beating the leached tobacco stems and tobacco powder obtained in step (1) respectively to obtain tobacco stem pulp and tobacco powder pulp;

[0051] (3) Centrifuge the tobacco stem extract and tobacco powder extract obtained in step (1) to remove impurities and concentrate to obtain a tobacco stem concentrate and tob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com