Preparation method for cured tobacco leaves

A technology for tobacco leaves and flue-cured tobacco, which is applied in the field of preparation of flue-cured tobacco leaves, can solve the problems of increasing the difficulty of formulating leaf groups for formulators, affecting the quality and characteristics of cigarette products, and the single style of tobacco leaf raw materials, thereby reducing energy and labor input and enriching the quality of tobacco leaves. Style, the effect of widening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Flue-cured tobacco Yunyan 87 was selected as the implementation object.

[0020] The first step: planting. The planting was carried out in Fangxian County, Shiyan City, Hubei China Tobacco's tobacco raw material base. The specific planting site was selected at Xiping Experimental Station in Fangxian County.

[0021] The second step: harvest. Flue-cured tobacco reaches maturity standards (the main veins of the lower leaves are all white and shiny, 1 / 3 of the branch veins are white, the leaf surface is yellow-green, the leaf tips are drooping, the leaf margins are slightly withered, and the hairs are less lost; the main veins of the middle leaves are all white and shiny, and the branch veins are 1 / 3 ~2 / 3 turns white, with yellow and yellow-white patches on the leaf surface, yellow-green obvious, the leaf ears are slightly yellow to light yellow, and some hairs are off; the main veins of the upper leaf are all white and shiny, and the branch veins 2 / 3 become white, and the lea...

Embodiment 2

[0029] The flue-cured tobacco Yunyan 87 was selected as the implementation object, and the method steps were the same as those in Example 1, except that the urea sprayed on the kilogram leaf surface was 0.05 g.

Embodiment 3

[0031] The flue-cured tobacco Yunyan 87 was selected as the implementation object, and the method steps were the same as in Example 1, except that the urea sprayed on the leaf surface of kilograms was 0.2g.

[0032] The quality evaluation of the flue-cured tobacco leaves prepared in the above Examples 1-3:

[0033] Table 1 Comparison of appearance quality between the present invention and conventional flue-cured tobacco

[0034] Approach

colour

Maturity

Identity

Oil

Chroma

Structure

normal method

Orange

it is good

Moderate thickness

Foot

Strong

Still loose

Example 1

Tan-red brown

it is good

Slightly thin-moderate

More foot-foot

Strong

Looser

Example 2

Tan-red brown

it is good

Slightly thin-moderate

More foot-foot

Strong

Looser

Example 3

Tan-dark red brown

it is good

Slightly thin-moderate

More foot-foot

Strong

Looser

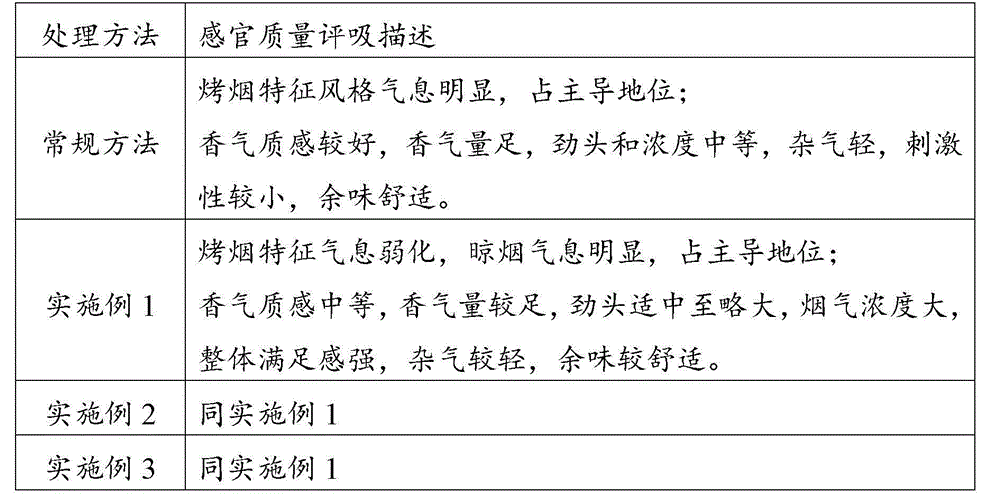

[0035] Table 2 Comparison of sensory quality between the present invention and conventional flue-cured tobacco

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com