A Subcritical Back Extraction Method of Tobacco Essential Fragrance Components

A subcritical extraction technology, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of large equipment investment, high extraction temperature, and poor effect, and achieve the effect of low equipment investment, low pressure, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

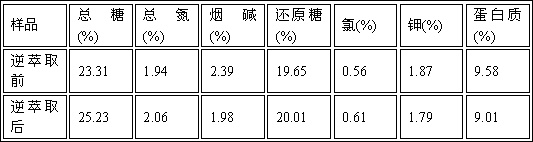

Embodiment 1

[0026]Take 500 g of Guizhou C1B1 low-grade tobacco leaves with a moisture content of less than 10%, moisten the dried tobacco leaves with 25% water by weight, seal and let stand for 40 min, and then conduct microwave treatment; the microwave conditions are power 800 W, microwave time 30 s, Repeat twice with an interval of 10 s between each time. After microwave treatment, place it in the extraction tank, vacuumize the extraction tank to -100 kPa, and inject 7.5 L of subcritical fluid butane into the extraction tank as the extraction solvent, and the sample is completely Submerge, add 800 ml of ethanol solution with a concentration of 75% entrainer for extraction, extract once for 10 minutes, at a temperature of 30°C and a pressure of 0.1 MPa; and liquid solvent were subjected to constant temperature precipitating treatment at a temperature of 30°C, and the tobacco leaf extract was obtained after the liquid solvent was precipitated; the obtained tobacco leaf extract was heated b...

Embodiment 2

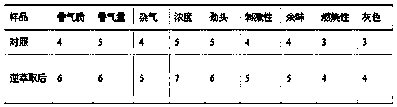

[0034] Take 30 g of Zimbabwean tobacco leaves with a water content less than 10% and put them in the extraction tank, and take 500 g of Chongqing blended CXK low-grade tobacco leaves and put them in the reverse extraction tank. The cell walls of the two types of tobacco leaves are broken by ultrasonic waves. , the dried tobacco leaves were wetted with 300% water by weight, sealed and allowed to stand for 60 minutes, and then subjected to ultrasonic treatment; the ultrasonic conditions were power 500 W, time 60 minutes.

[0035] Use a vacuum pump to make the extraction tank and reverse extraction tank meet the vacuum requirements, and inject the subcritical fluid dimethyl ether into the extraction tank for subcritical extraction. The dimethyl ether completely submerges the Zimbabwean tobacco leaves. The mass volume of the Zimbabwean tobacco leaves and dimethyl ether The ratio is 1:20, the entrainer used for extraction is 60 ml of ethanol solution with a concentration of 95%, the...

Embodiment 3

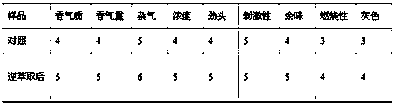

[0043] Take 10 g of Brazilian tobacco leaf extract and put it in the extraction tank, and put 200 g of Henan BK31 tobacco leaves in the reverse extraction tank. 25% water, sealed and allowed to stand for 40 minutes before terahertz treatment; the terahertz treatment conditions were temperature 30°C, distance 10cm, and time 10 minutes.

[0044] Use a vacuum pump to make the extraction tank and reverse extraction tank meet the vacuum requirements, and inject the subcritical fluid propane for extraction into the extraction tank. The propane completely submerges the Brazilian tobacco leaf extract, and the mass volume ratio of the Brazilian tobacco leaf extract and propane is 1:25 g / ml, the entrainer is 20 ml of 95% ethanol solution, the extraction time is 10 minutes, the temperature is 35°C, the pressure is 0.53 MPa, and the extraction is repeated 3 times; The paste and the liquid solvent were subjected to constant temperature precipitating treatment at a temperature of 35°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com