Safe and energy-saving microwave vacuum continuous automatic drier

A microwave vacuum and dryer technology is used in drying solid materials, heating to dry solid materials, and drying. Control, rapid heating, rapid dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

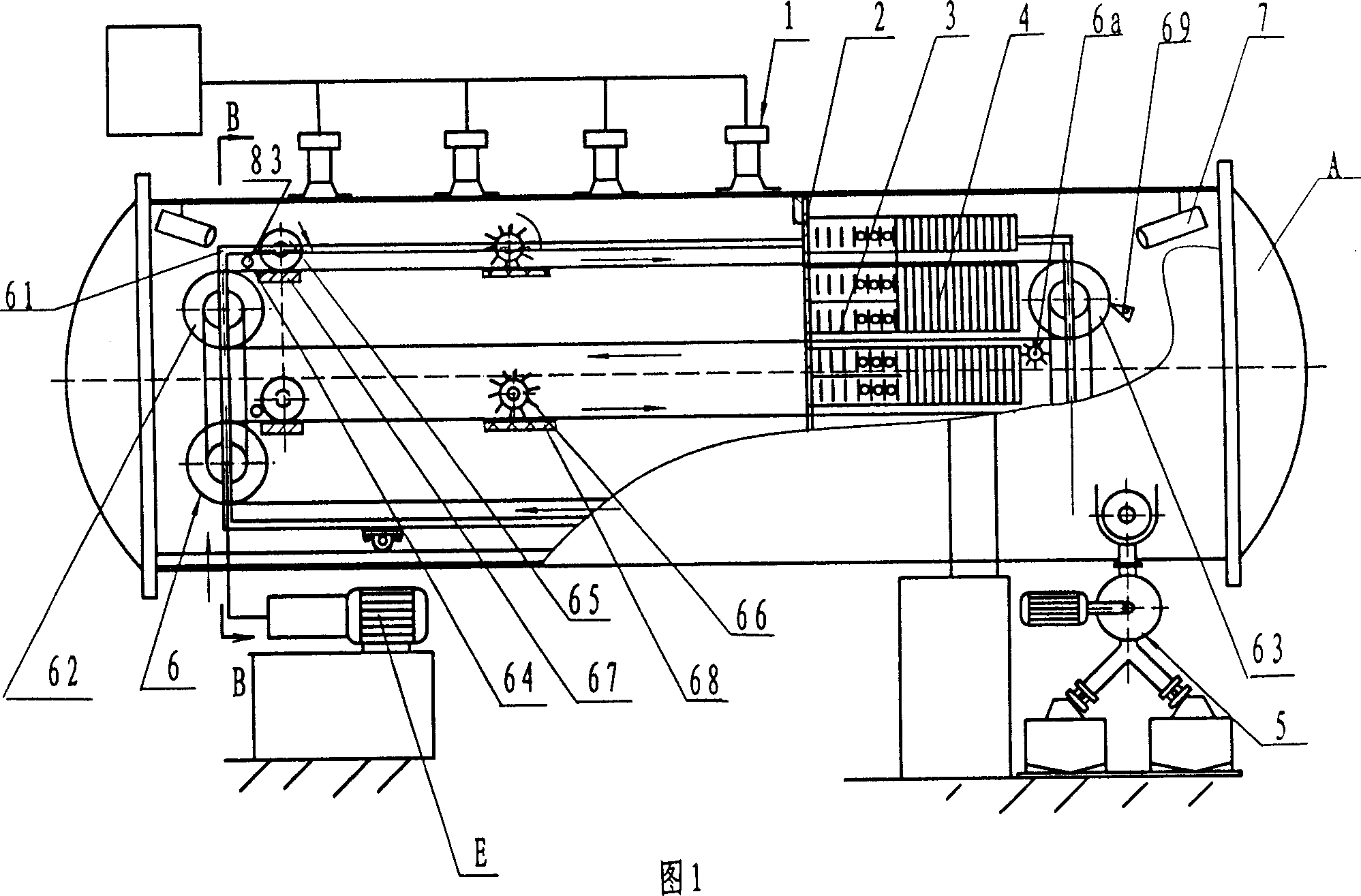

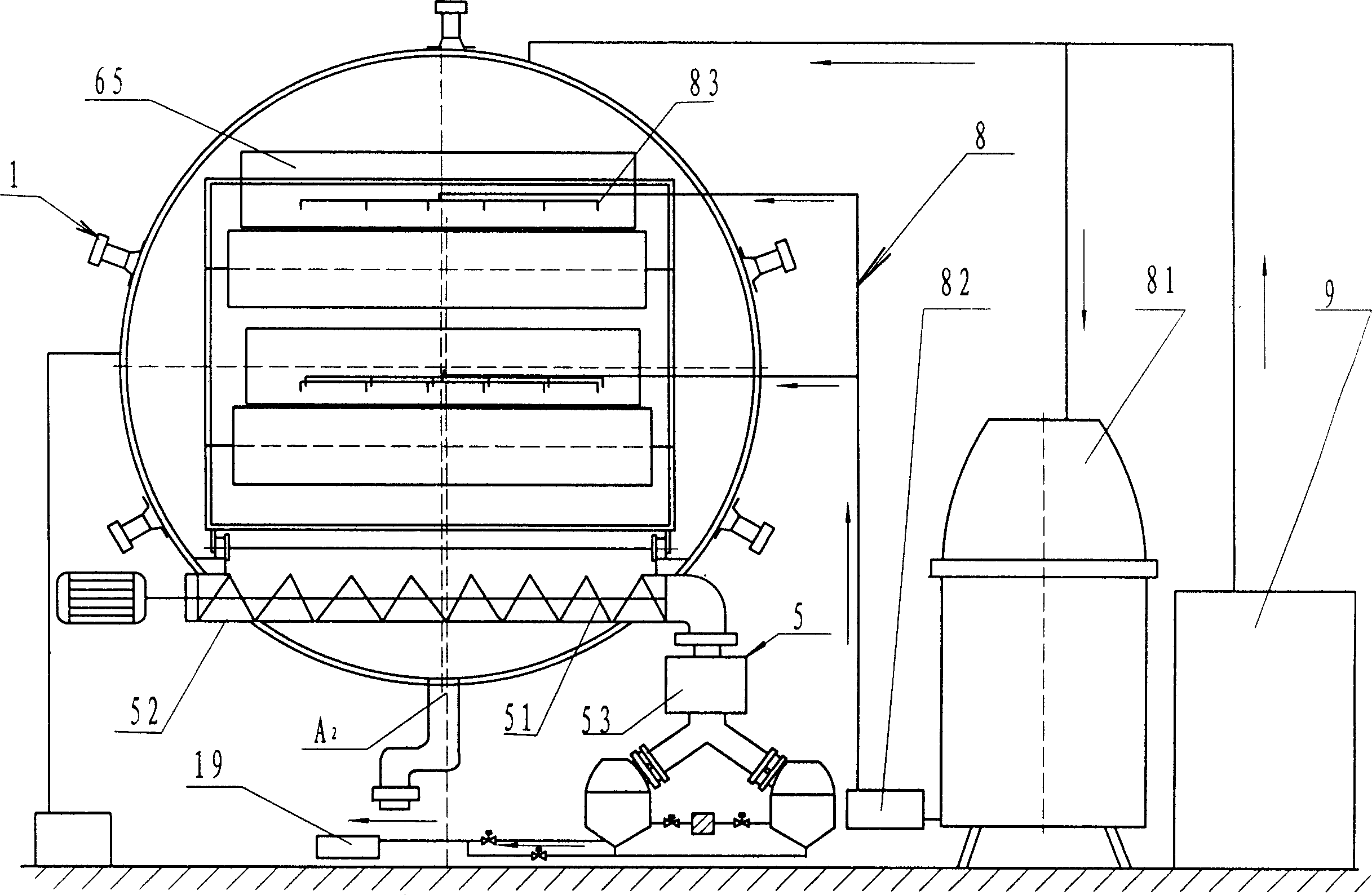

[0033] Embodiment 1: see Fig. 1, figure 2 , Figure 5 , a safe and energy-saving microwave vacuum automatic continuous dryer, including a tank body A, a feeding system 8, a vacuum system 9, a microwave heating system 1 is provided on the tank body A, and a conveying device 6 is provided in the tank body A. A discharge device 5 is arranged below the device 6; the material in the tank body A is polytetrafluoroethylene or polypropylene. The transmission device 6 includes a driving wheel 62 and a driven wheel 63 fixedly connected to the two ends of the bracket 61 respectively, and a transmission belt 64 is arranged on it, and one end of the rotating shaft on the driving wheel 62 extends out of the tank body A and the power transmission shaft through a dynamic sealing device. connected; its power shaft is driven by the reducer driven by the motor E. The end of the transmission belt 64 is provided with an elastic spatula 69; the lower end of the transmission belt 64 is provided wi...

Embodiment 2

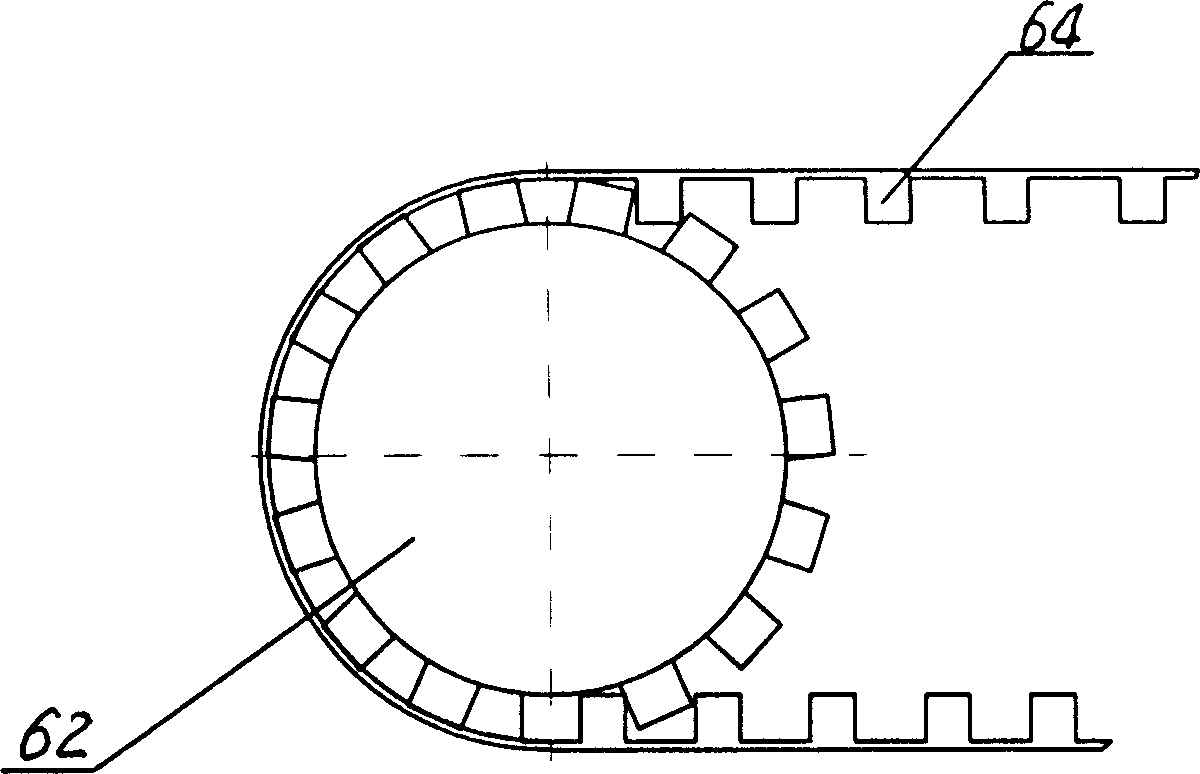

[0041] Example 2: see image 3 , the conveying device 6 is crawler belt transmission. The rest of the structure is the same as Example 1.

Embodiment 3

[0042] Embodiment 3: see Figure 4 , The conveying device 6 is set in one row in the tank body A, and each row is arranged in parallel with 8 groups. The rest of the structure is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com