Patents

Literature

38results about How to "Strong sense of satisfaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for remote endoscopic surgery

InactiveUS6731988B1Improve satisfactionStrong sense of satisfactionComputer controlSimulator controlControl armDisplay device

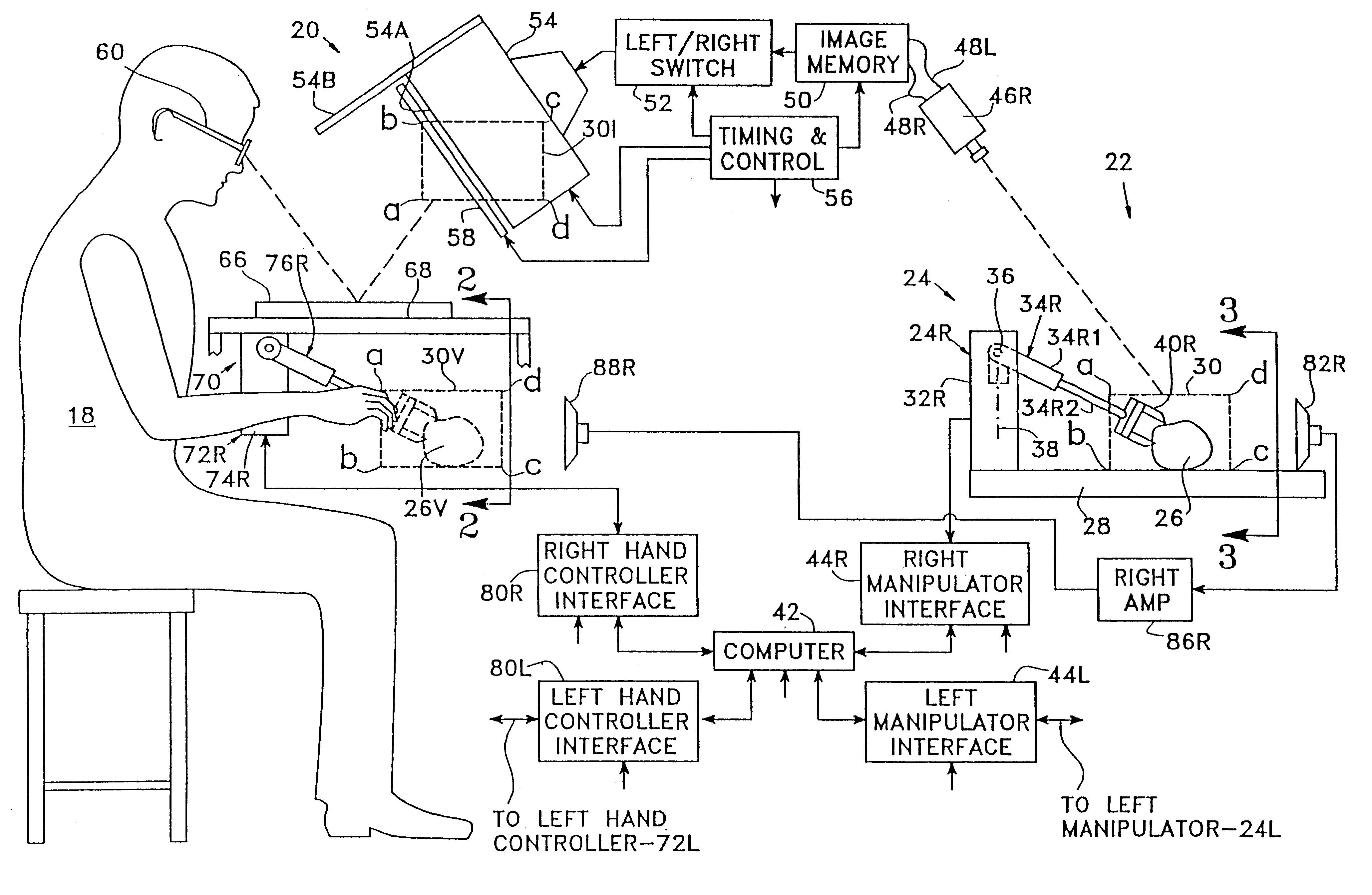

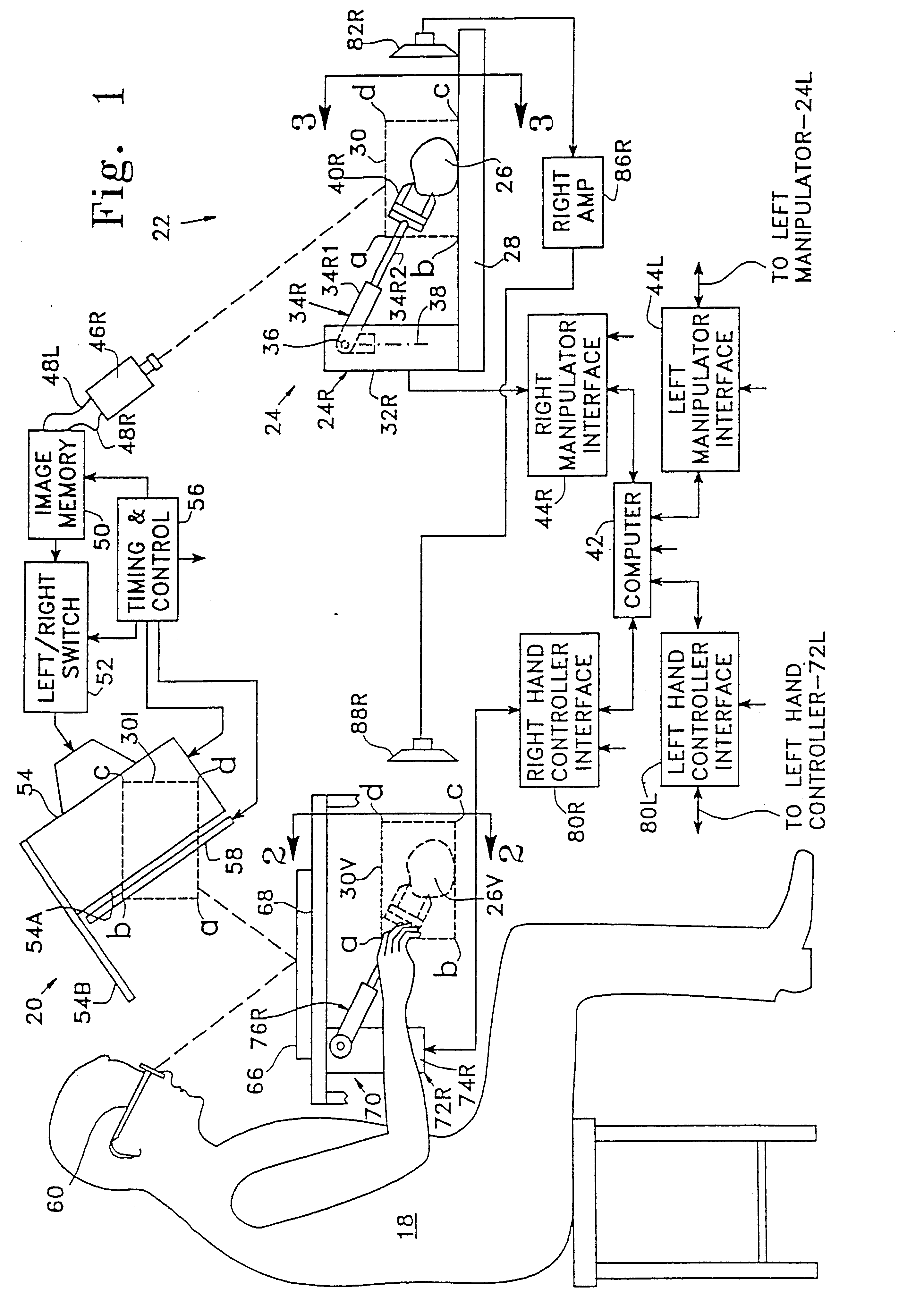

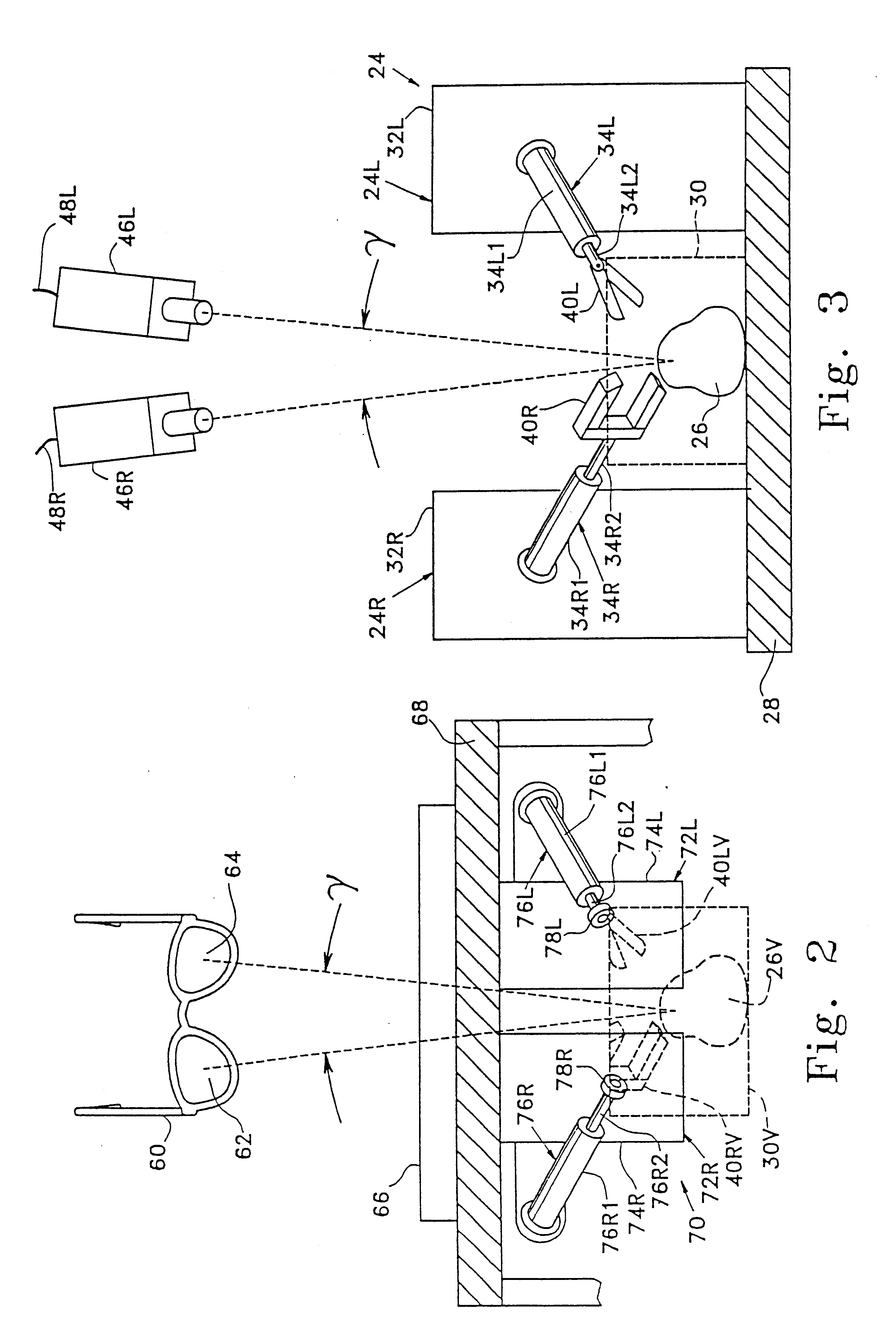

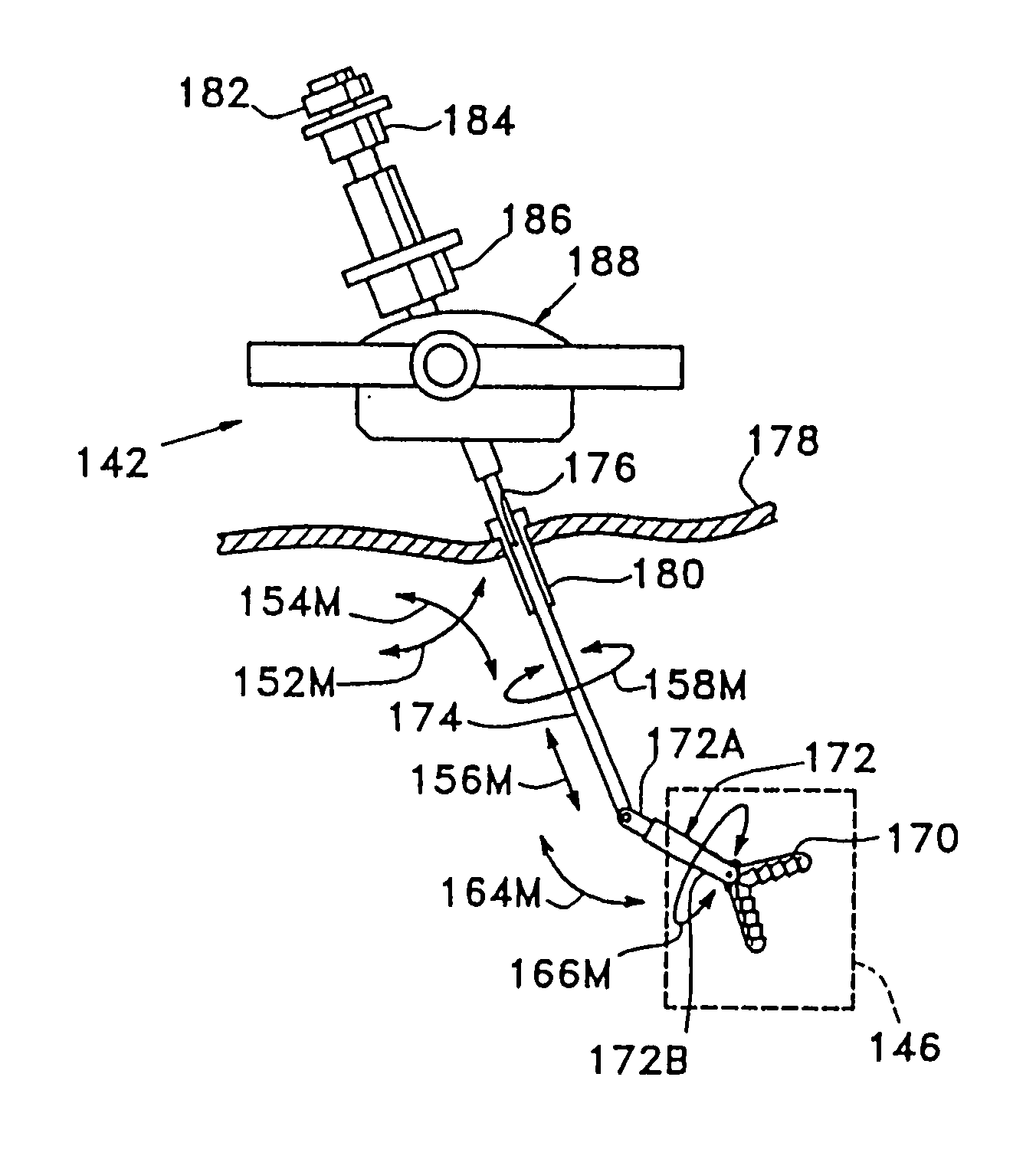

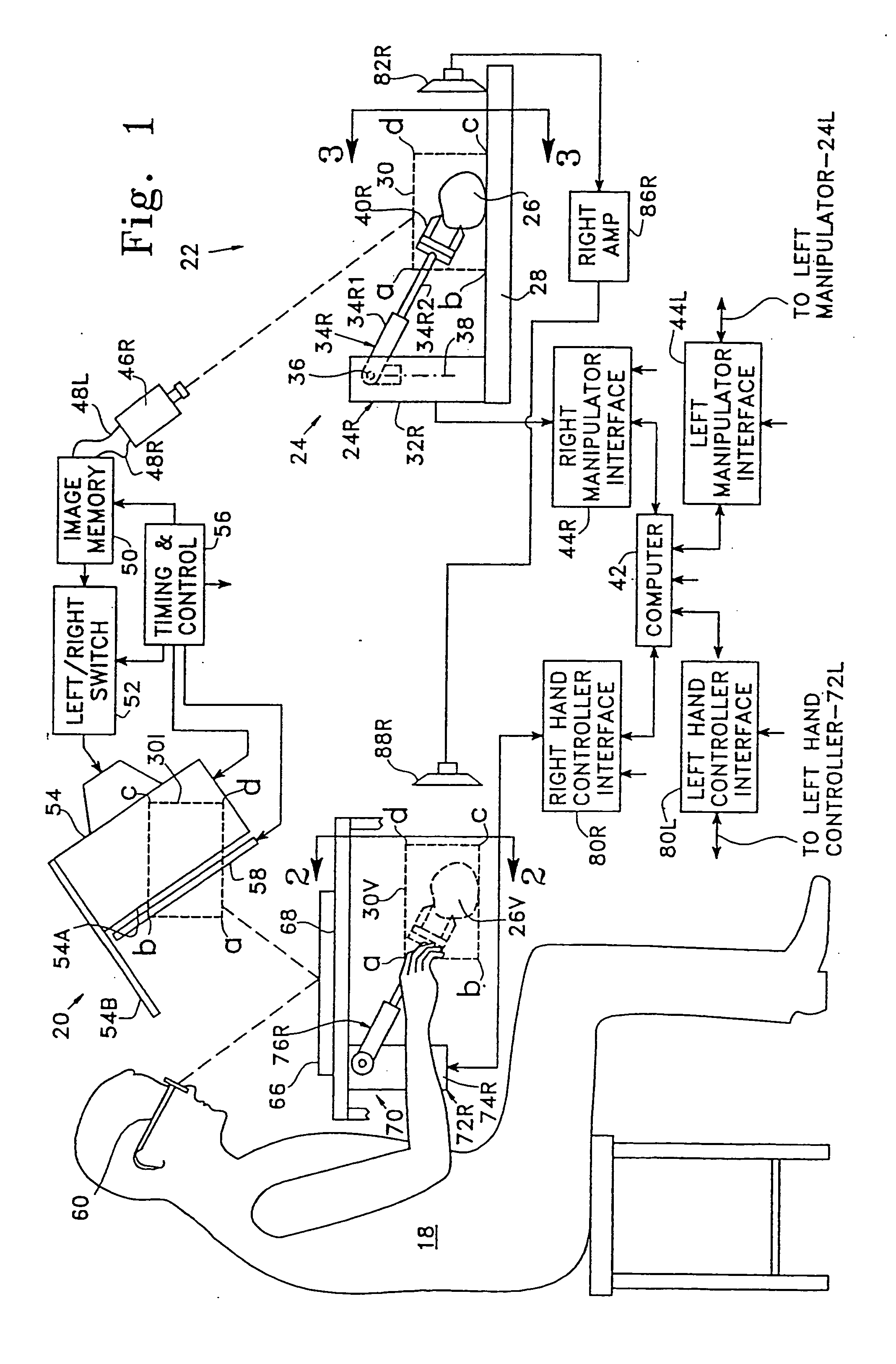

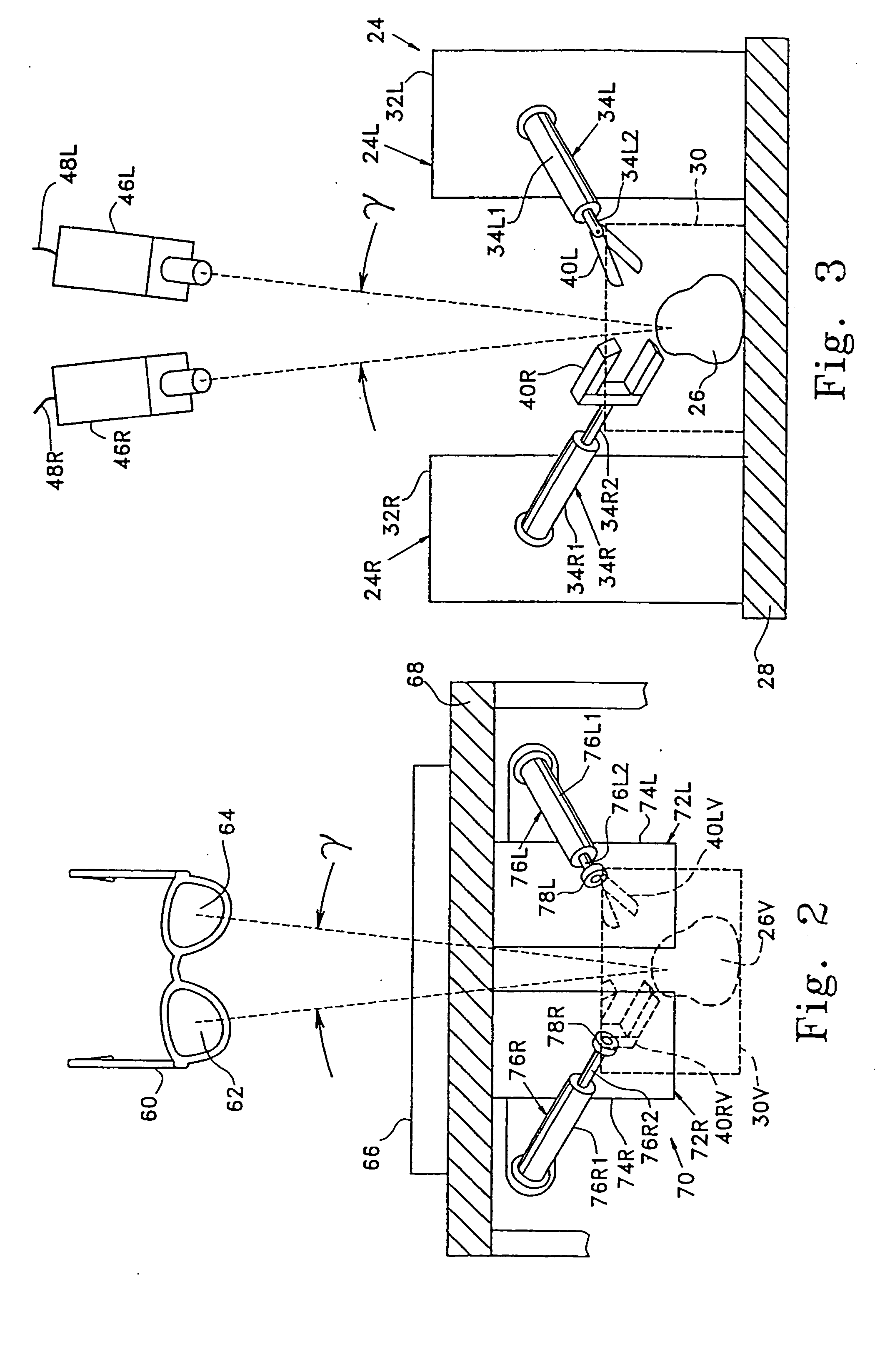

A teleoperator system with telepresence is shown which includes right and left hand controllers (72R and 72L) for control of right and left manipulators (24R and 24L) through use of a servomechanism that includes computer (42). Cameras (46R and 46L) view workspace (30) from different angles for production of stereoscopic signal outputs at lines (48R and 48L). In response to the camera outputs a 3-dimensional top-to-bottom inverted image (30I) is produced which, is reflected by mirror (66) toward the eyes of operator (18). A virtual image (30V) is produced adjacent control arms (76R and 76L) which is viewed by operator (18) looking in the direction of the control arms. By locating the workspace image (30V) adjacent the control arms (76R and 76L) the operator is provided with a sense that end effectors (40R and 40L) carried by manipulator arms (34R and 34L) and control arms (76R and 76L) are substantially integral. This sense of connection between the control arms (76R and 76L) and end effectors (40R and 40L) provide the operator with the sensation of directly controlling the end effectors by hand. By locating visual display (246) adjacent control arms (244R and 244L) image (240I) of the workspace is directly viewable by the operator (FIGS. 12 and 13). Use of the teleoperator system for surgical procedures is also disclosed (FIGS. 7-9 and 13).

Owner:SRI INTERNATIONAL

Roll-pitch-roll wrist methods for minimally invasive robotic surgery

InactiveUS20050102062A1Improve satisfactionStrong sense of satisfactionEndoscopesSurgical manipulatorsServomechanismManipulator

A teleoperator system with telepresence is shown which includes right and left hand controllers (72R and 72L) for control of right and left manipulators (24R and 24L) through use of a servomechanism that includes computer (42). Cameras (46R and 46L) view workspace (30) from different angles for production of stereoscopic signal outputs at lines (48R and 48L). In response to the camera outputs a 3-dimensional top-to-bottom inverted image (30I) is produced which, is reflected by mirror (66) toward the eyes of operator (18). A virtual image (30V) is produced adjacent control arms (76R and 76L) which is viewed by operator (18) looking in the direction of the control arms. Use of the teleoperator system for surgical procedures also is disclosed.

Owner:SRI INTERNATIONAL

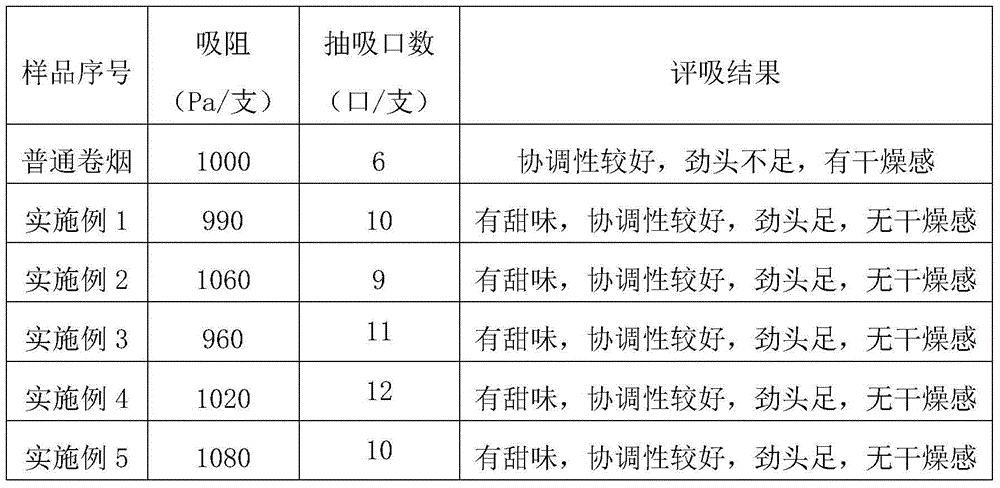

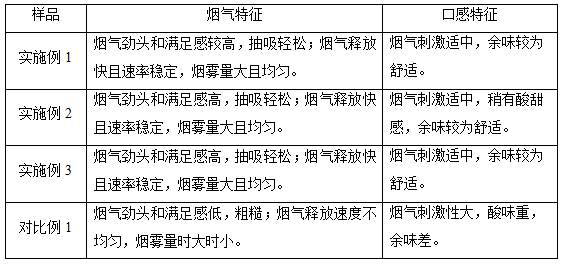

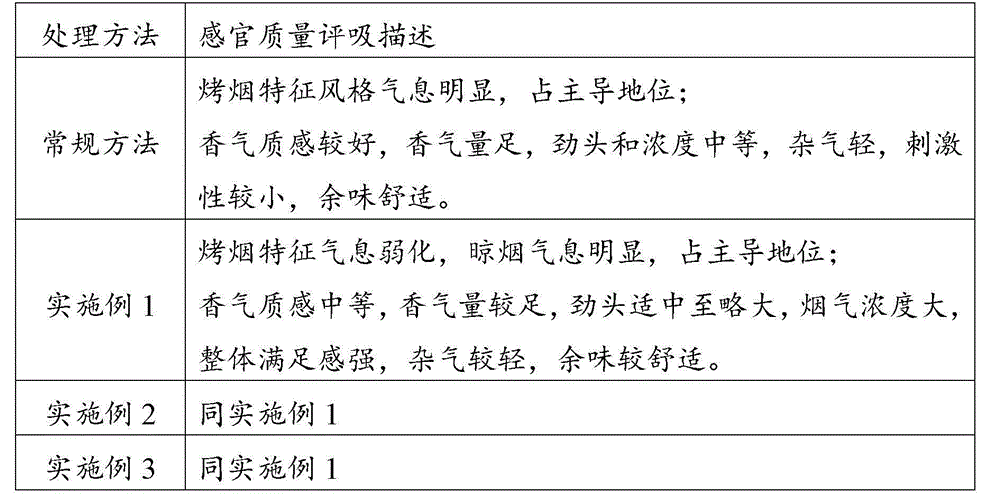

Tobacco material preparing method for heated non-combustion tobacco products

ActiveCN103462213AEfficient releaseStrong sense of satisfactionTobacco treatmentBiotechnologyFreeze-drying

A tobacco material preparing method for heated non-combustion tobacco products is characterized by sequentially comprising the following steps of (1) performing digestion on tobacco raw materials with an ethanol solution and preparing a tobacco extract; (2) after the digestion, separating the solution from the tobacco to obtain a tobacco extracting solution, evaporating the extracting solution under a decompressing condition to remove ethanol, and freezing and drying to obtain a solid tobacco extract; (3) mixing the solid tobacco extract with metal hydroxide particles with a flame retarding function, adding a solvent to disperse and form a thick mixture, drying the obtained thick mixture with a roller drying method, and crushing the dried materials to obtain the tobacco material suitable for the heated non-combustion tobacco products. Smoke released due to heating at 200 DEG C to 400 DEG C from the tobacco material prepared according to the method has good satisfying feeling in both concentration and strength, and the flavor quality and sense comfort are good, and a good flame retarding action is realized.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

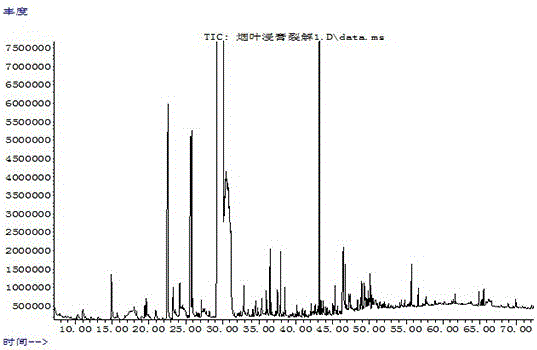

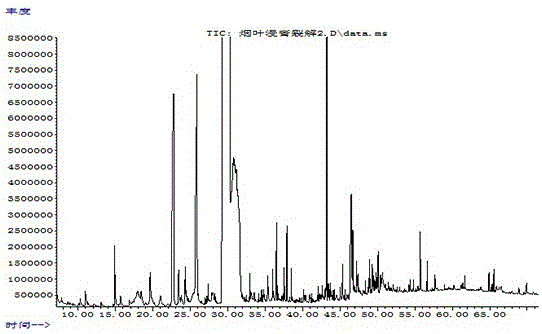

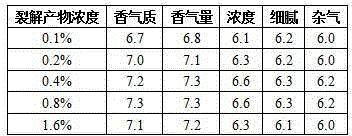

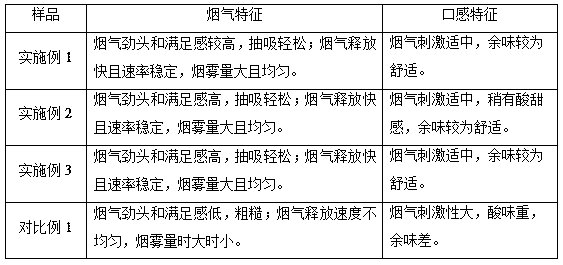

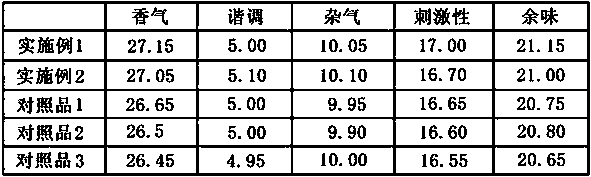

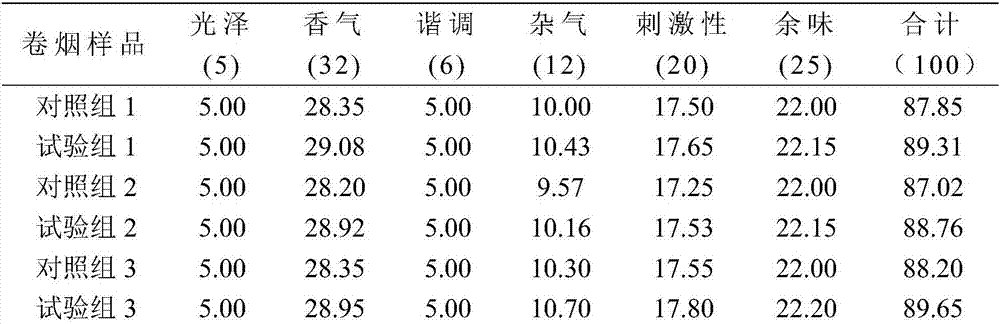

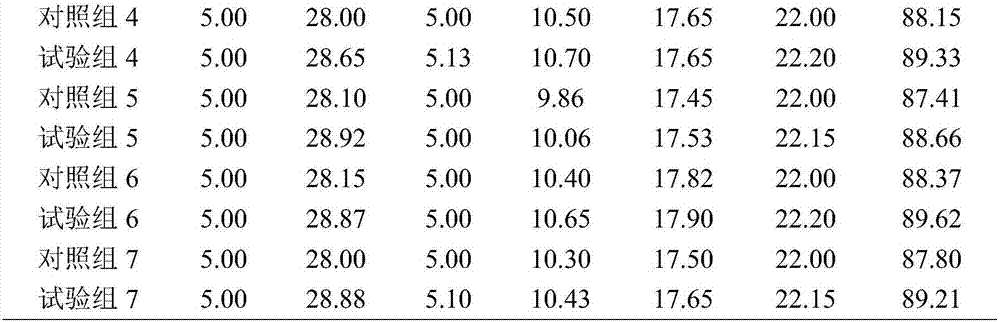

Tobacco extract pyrolysis product and application thereof in novel tobacco product

The invention belongs to the technical field of cigarette production, and particularly relates to a tobacco extract pyrolysis product and an application thereof in a novel tobacco product. The tobacco extract pyrolysis product is applied to the novel tobacco product, a preparation method comprises the steps of preparing tobacco extract, conducting pyrolysis on the tobacco extract, conducting evaporation and concentration through vacuum rotating and the like. According to the tobacco extract pyrolysis product and the application thereof in the novel tobacco product, the tobacco extract pyrolysis product is added to the novel cigarette product, the smoking quality of the novel cigarette product is better improved, the taste is close to that of a traditional cigarette, natural incense of smoke is obvious, satisfaction of the smoke is strong, the feel of engendering liquid is obviously enhanced for the novel cigarette product, the degree of comfort is improved, the smoking characteristic is almost the same as that of the traditional cigarette, the requirements of customers for smoking taste, physiology and psychology on the novel cigarette product are better met, and the novel cigarette product has better application and promotion value.

Owner:CHINA TOBACCO HENAN IND +1

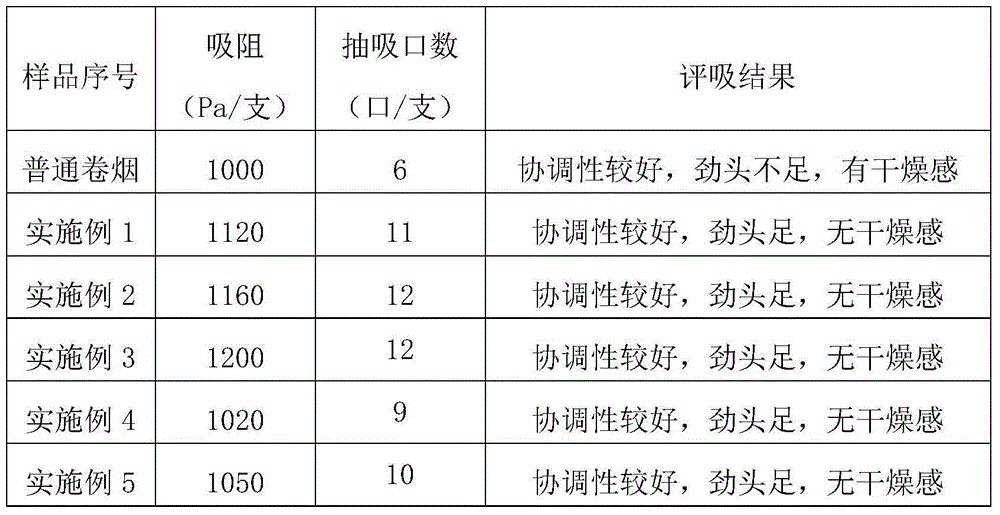

Method for preparing cigarette from tobacco beads

The invention discloses a method for preparing a cigarette from tobacco beads. The method for preparing the cigarette from the tobacco beads comprises the steps that firstly, cigarette tobacco is smashed into fine powder; secondly, adhesives are added, so that a soft material is prepared, and the cigarette beads are prepared through an extruding-rounding method; thirdly, the cigarette beads are rolled into a cigarette bar; finally, the cigarette bar is wrapped by cigarette paper, a filter tip is connected to the cigarette bar, and the cigarette is prepared according to a conventional method. The prepared cigarette is novel in form and capable of bringing brand-new experience to customers; the formula of the cigarette is even, and the stability of cigarette smoking quality is guaranteed; meanwhile, the combustion time of the cigarette is prolonged, and number of puffs is increased; the sense of satisfaction of the customer is stronger.

Owner:HUBEI CHINA TOBACCO IND +1

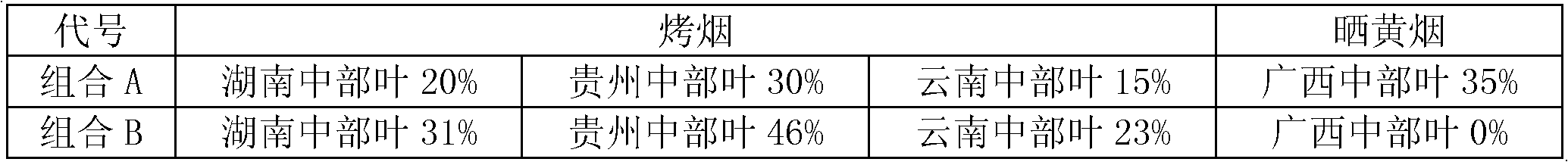

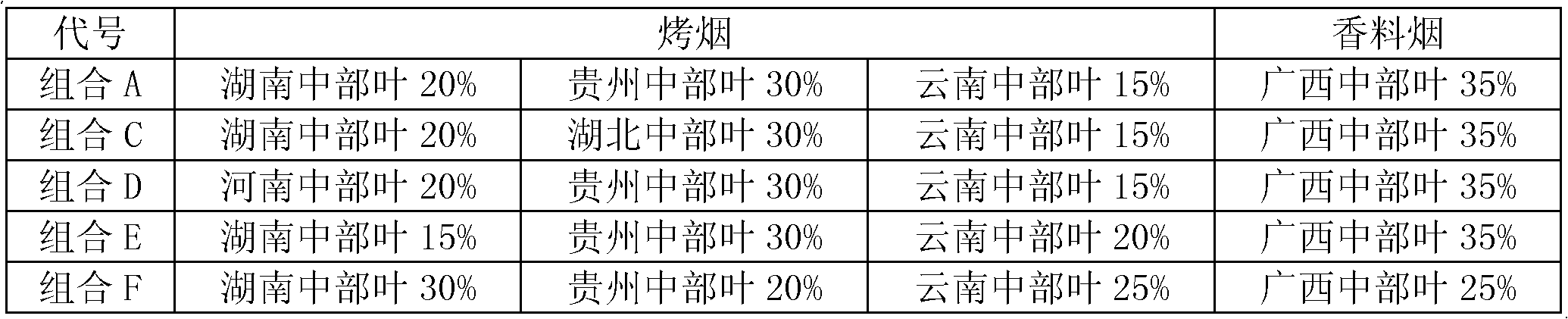

Expanded cut tobacco composition of fluecured tobacco and yellow sun-cured tobacco and low-tar cigarette

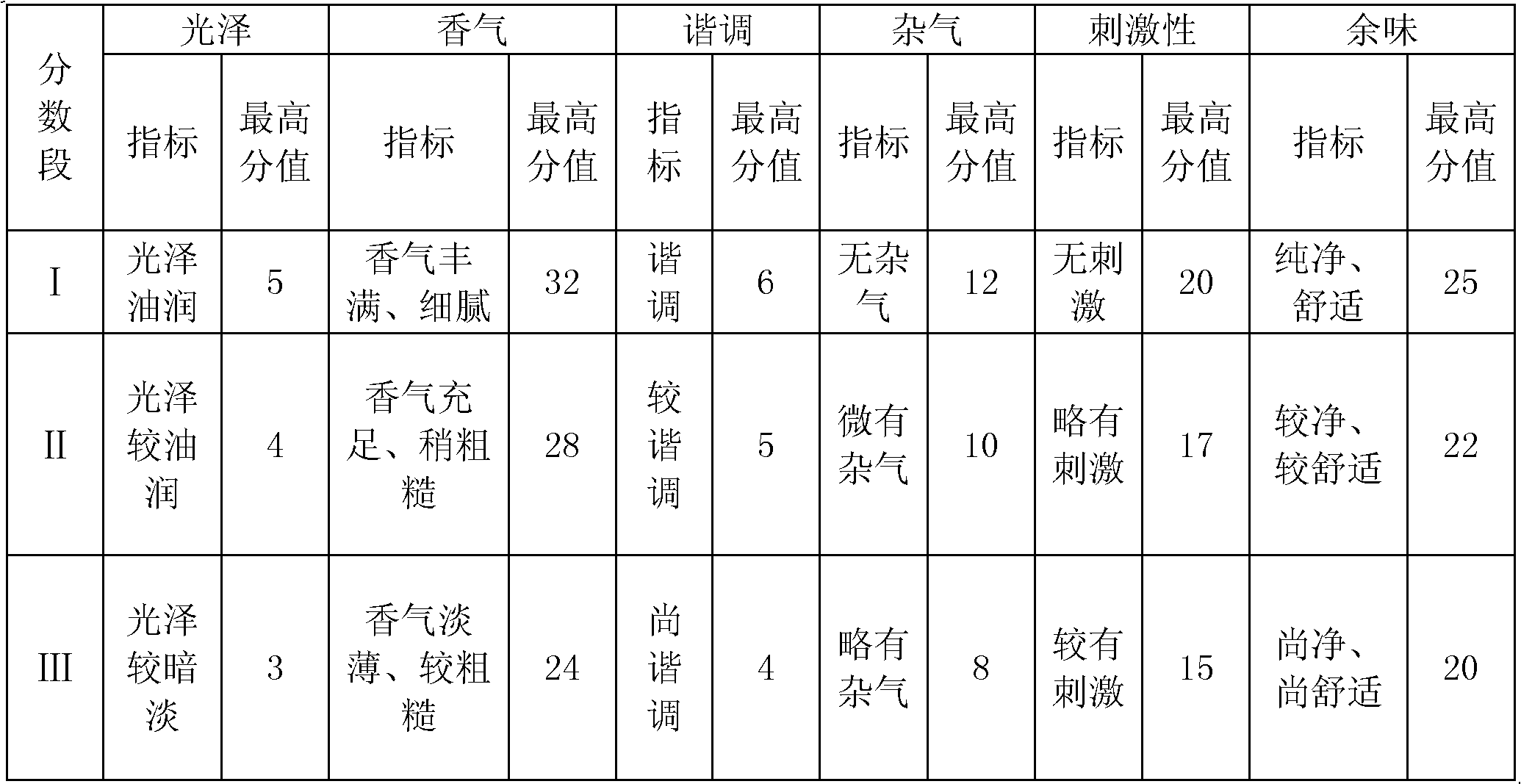

InactiveCN102423118AExpand the scope of useFull of aromaTobacco preparationCigar manufactureTaste intensityIrritation

The invention belongs to the technical field of cigarette tobacco blends, and particularly relates to an expanded cut tobacco composition of fluecured tobacco and yellow sun-cured tobacco and a low-tar cigarette added with the expanded cut tobacco composition. The expanded cut tobacco composition of the fluecured tobacco and the yellow sun-cured tobacco is blended expanded cut tobacco which is made of the fluecured tobacco and the yellow sun-cured tobacco according to the weight proportion of 5.5 to 6.5:4.5 to 3.5 by the carbon dioxide expansion technology. The delicacy of tobacco aroma can be slightly increased, the richness can be slightly decreased, aftertaste residue can be slightly reduced, the cut tobacco composition of the fluecured tobacco and the yellow sun-cured tobacco can manifest the characteristic of high characteristic tobacco aroma richness of the yellow sun-cured tobacco under low concentration and also partially improve the defects of the yellow sun-cured tobacco, such as slightly rough tobacco aroma, slightly high irritation, dry aftertaste and residue, and is blended in low-tar products according to a certain proportion in order to achieve the effect of improving taste intensity, and moreover, the intrinsic quality meets the requirement on rich, harmonious aroma, moderate tobacco aroma richness, high satisfiability, pure taste and no irritation.

Owner:CHINA TOBACCO ZHEJIANG IND

Cigarette core column for heating cigarettes and preparation method thereof

ActiveCN111011915AImprove thermal conductivityLarge specific surface areaCigar manufactureCigarette manufactureBurn cigaretteMesoporous material

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a cigarette core column for heating cigarettes and a preparation method thereof. The cigarette core column for heating cigarettes comprises the following components, by mass: 20-40 parts of tobacco powder, 5-10 parts of tobacco extract, 0.2-3 parts of essence and flavor, 2-10 parts of a smoke agent, 2-8 parts of an adhesive and 2-5 parts of a smoke auxiliary agent; a metal-mesoporous material complex is selected as the smoke auxiliary agent. The porous framework which is not prone to collapse is constructed through the metal-mesoporous material complex, heat conduction and loading of flavors, fragrances and nicotine are realized, the smoke rate and the fragrance release uniformity can be effectivelyimproved, so that the consistency of sensory quality of heated cigarettes is improved.

Owner:CHINA TOBACCO JIANGSU INDAL

Preparation method for tobaccos not combusting after being heated

InactiveCN109090699AHighlight beneficial featuresHighlight the characteristics of this fragranceTobacco preparationTobacco treatmentAlcoholDistillation

The invention discloses a preparation method for tobaccos not combusting after being heated. The preparation method comprises the steps of shredding after tobacco leaf conditioning, drying, pulverizing, alcohol dissolving, digestion, separation, distilling, mixing and the like. A tobacco extract is subjected to fragrance recombination by molecular distillation, and is separated into light components and heavy components, the tobacco extract is compounded in proportion, adverse factors caused by the raw materials of tobacco leaves are weakened by the process, the beneficial features of the rawmaterials are highlighted, an essence and flavor solution is blended by taking plant extracts as main raw materials, fragrance quality, harmony, layering, comfort level and the like of cigarette not combusting after being heated can be improved, and thus, the smoking sense of a cigarette not combusting after being heated is close to that of a real cigarette. After judges smoke the prepared tobaccos not combusting after being heated, the result shows that compared with another cigarette not combusting after being heated, the tobacco has the advantages that the fragrance, harmony, offensive odor, irritation and aftertaste are separately increased by 0.5, 0.06, 0.1, 0.2 and 0.3, and are closer to those of a traditional cigarette, the satisfaction is high, the fragrance is full, and the aftertaste is pure.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

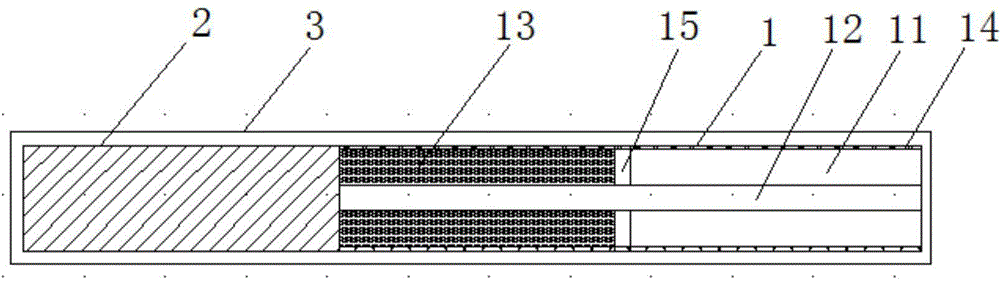

Sectional type non-combustion cigarette with self-heating material

The invention discloses a sectional type non-combustion cigarette with a self-heating material. The sectional type non-combustion cigarette with the self-heating material comprises a suction nozzle and a tobacco section, wherein the suction nozzle and the tobacco section are connected through rolling and connecting paper; the tobacco section is composed of the self-heating material, tobacco shreds and cigarette paper; the self-heating material is a cylinder the same as the tobacco shreds in diameter; the self-heating material is arranged at the front end of the tobacco shreds; the length of the self-heating material is 0.5- 2 times that of the tobacco shreds; airtight sealing layers are arranged outside the suction nozzle and the tobacco section. The sectional type non-combustion cigarette avoids high-temperature cracking of tobacco combustion, so that the release amount of harmful ingredients in main stream smoke is greatly reduced. Meanwhile, as the tobacco shreds are not combusted, the environment smoke is greatly reduced, the atomization and smoking effects of the tobacco shreds are good at a low temperature state, and satisfaction of customers is high.

Owner:HUBEI CHINA TOBACCO IND +1

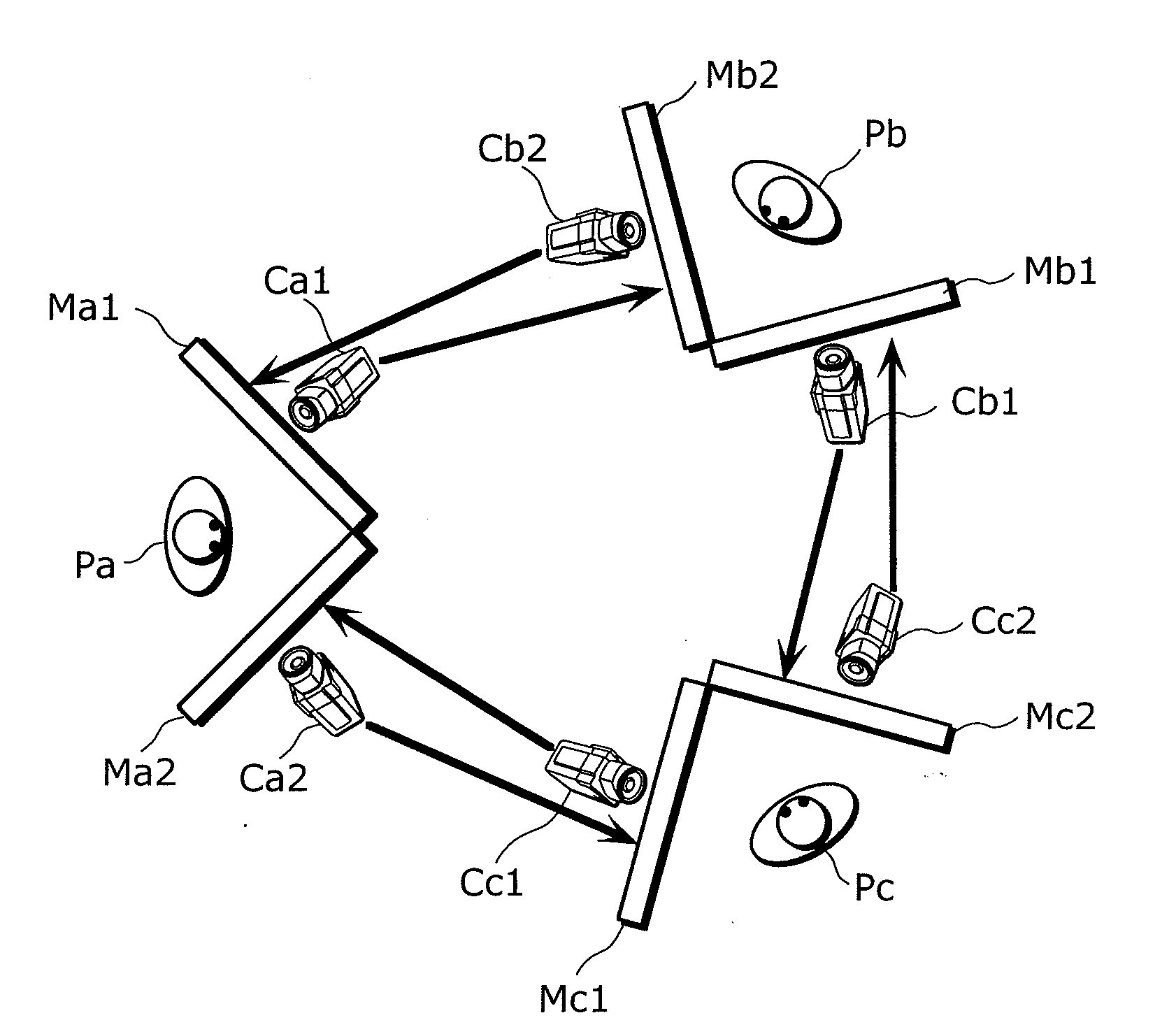

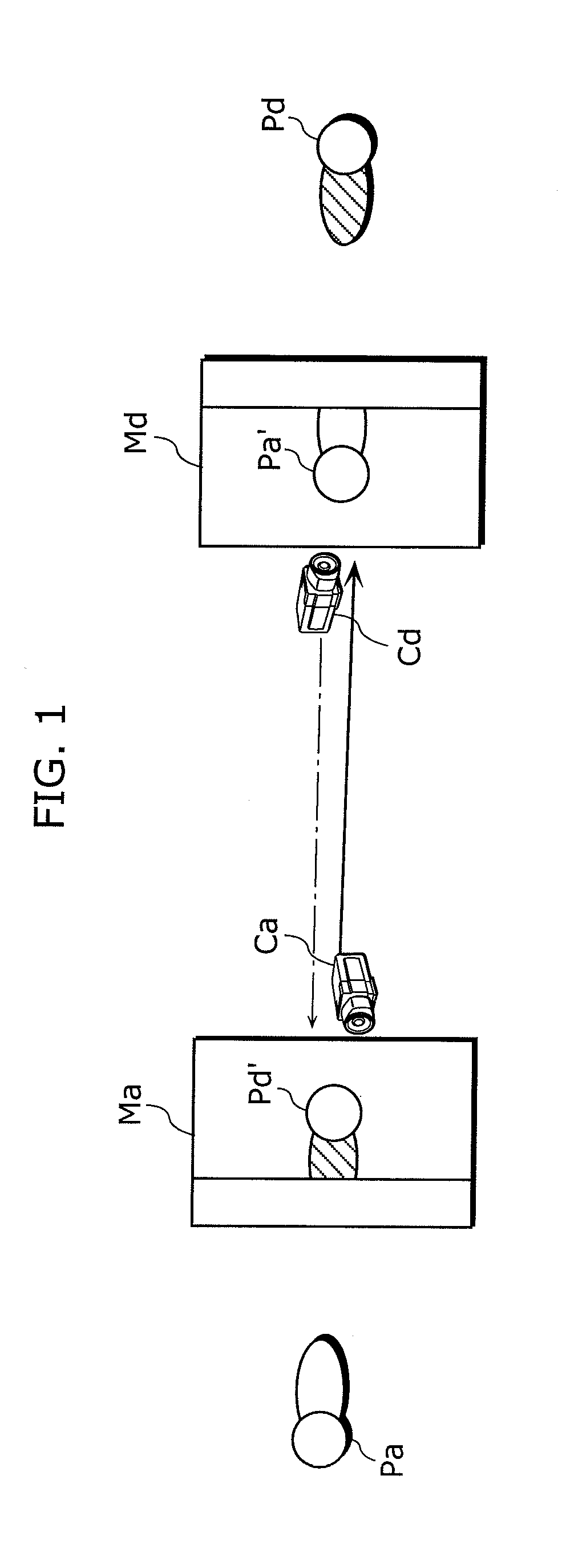

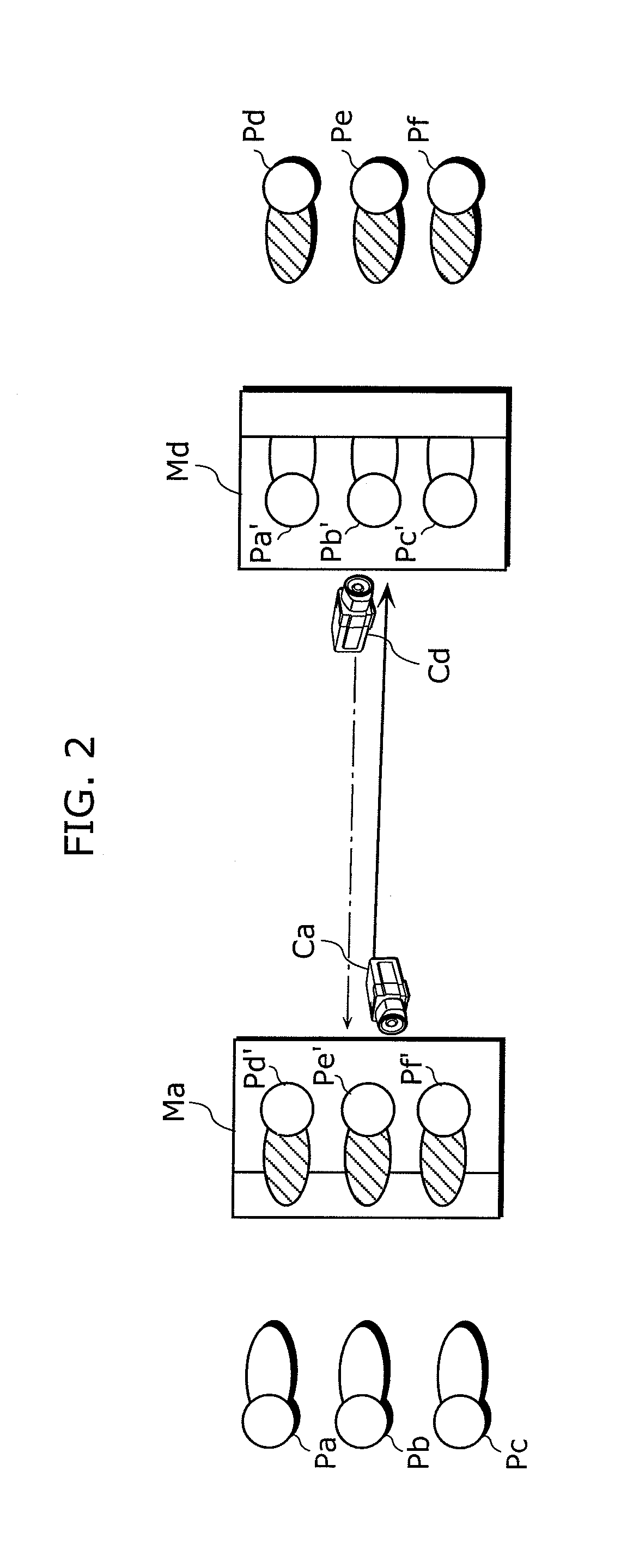

Image codec apparatus

InactiveUS20100165069A1Accurate checkStrong sense of satisfactionTwo-way working systemsDigital video signal modificationComputer graphics (images)Computer science

Provided is an image codec apparatus that allows a user to check his own-image properly while feeling a strong sense of presence. The image codec apparatus (100) includes cameras (Ca, Cb, and Cc) that generate taken-image data by shooting, monitors (Ma, Mb, and Mc) that display images, encoders (101, 102, and 103) that code taken-image data, decoders (121, 122, and 123) that decodes coded image data for generating decoded image data, and synthesizers (111, 112, and 113) that process the taken-image data generated by the cameras (Ca, Cb, and Cc) for generating processed image data and synthesizing a processed image represented by the processed image with the decoded image and output, to the monitors (Ma, Mb, and Mc), synthesized image data that represents synthesized image.

Owner:PANASONIC CORP

A method of preparing hollow cigarettes by using tobacco leaf beads

A method of preparing hollow cigarettes by using tobacco leaf beads is disclosed. The method includes smashing tobacco leaves into fine powder, adding an adhesive to prepare into a soft material, preparing tobacco leaf beads by using an extrusion-spheronization process, pressing the tobacco leaf beads into hollow cigarette sticks, wrapping the hollow cigarette sticks with cigarette paper, connecting filter tips, and preparing the cigarettes by a conventional method. The prepared cigarettes are novel in form, can bring new experience to customers and are uniform in formula. Stability of cigarette smoking quality is ensured, the combustion time of the cigarettes is prolonged, and the puff number is increased, so that customers are more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

Cigarette manufacturing method

ActiveCN104939302ANew experienceNovelty form of cigaretteTobacco treatmentCigarette manufactureEngineeringSoft materials

The invention discloses a cigarette manufacturing method. The cigarette manufacturing method includes the steps that cigarette tobacco leaves are pulverized into fine powder, syrup is added into the fine powder to obtain a soft material, particles are manufactured from the soft material and pressed into cigarette bars, and the cigarette bars are wrapped by cigarette paper, connected with filter tips and manufactured into cigarettes in a conventional method. The manufactured cigarettes are novel in style, and bran-new experience can be brought to a consumer; the cigarette formula is uniform, the stability of smoking quality of the cigarettes is ensured, the burning time of the cigarettes is prolonged, the puff number is increased, and the consumer can obtain higher satisfaction.

Owner:HUBEI CHINA TOBACCO IND

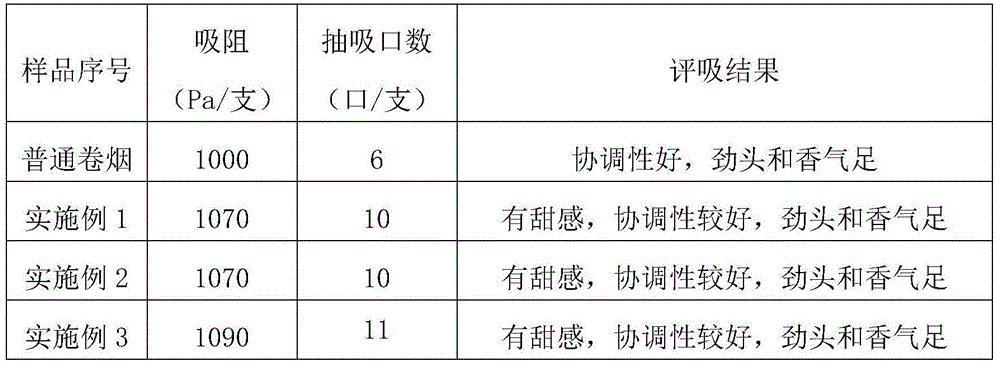

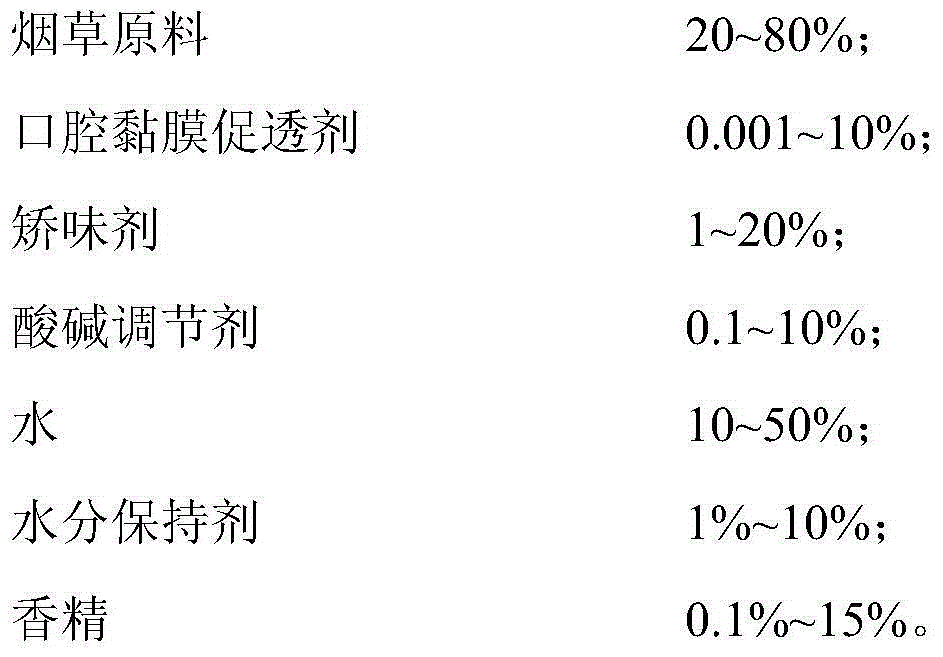

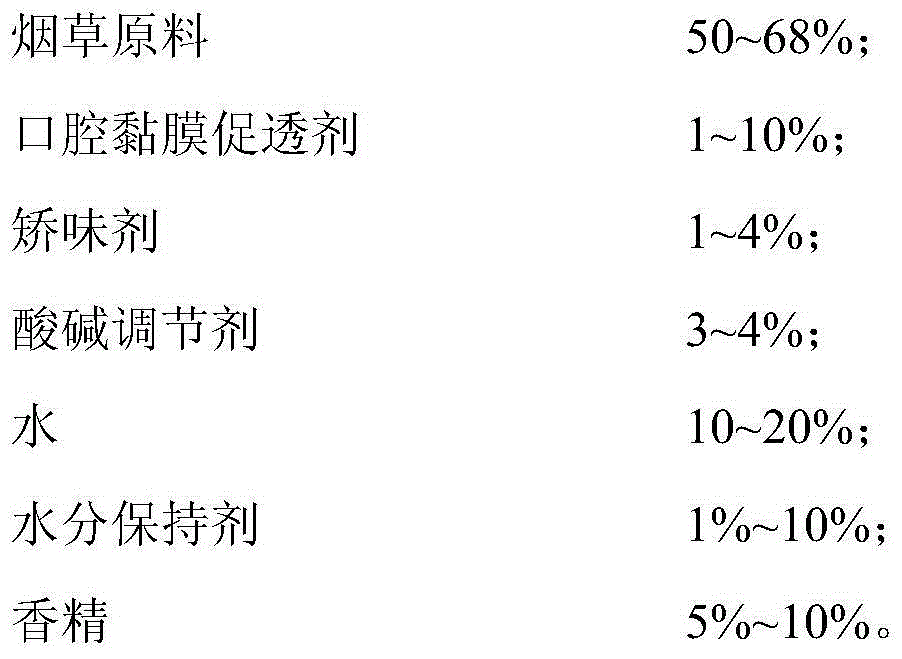

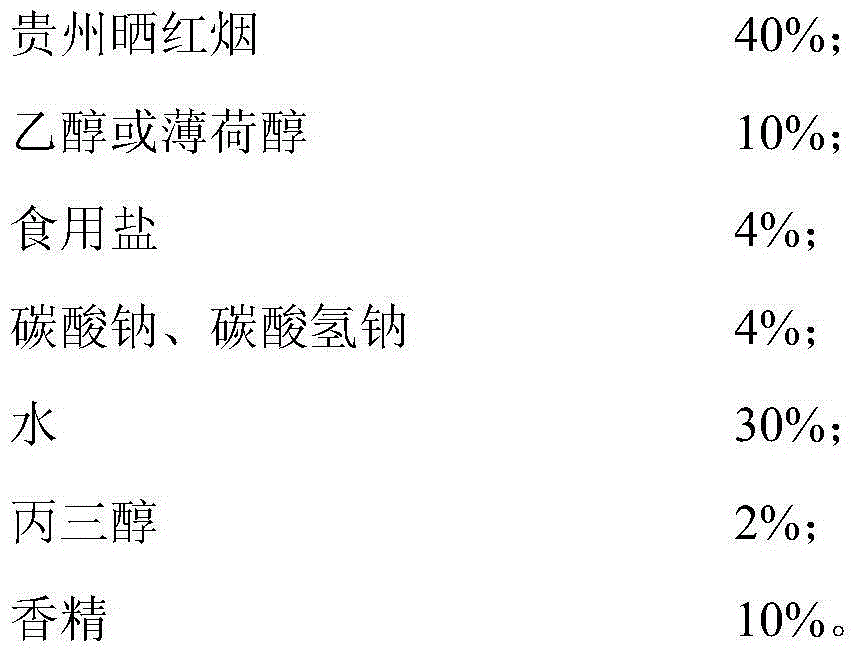

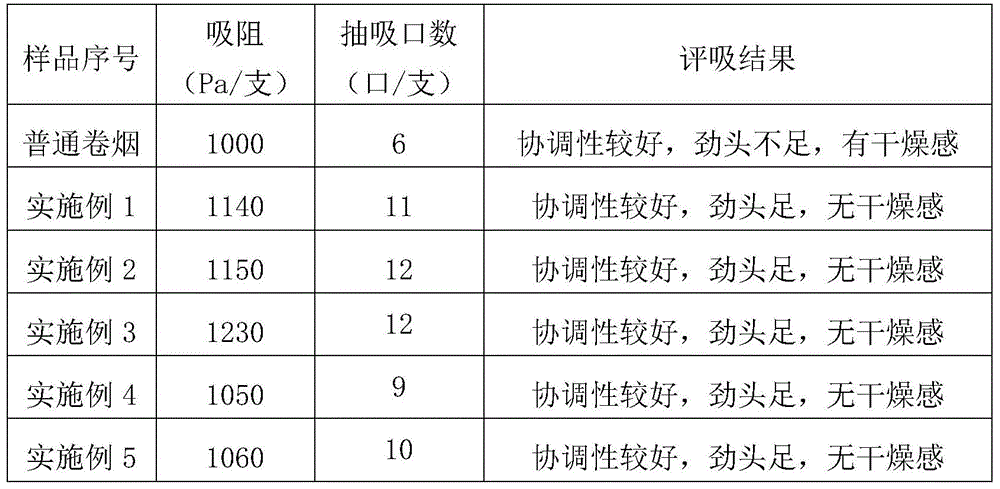

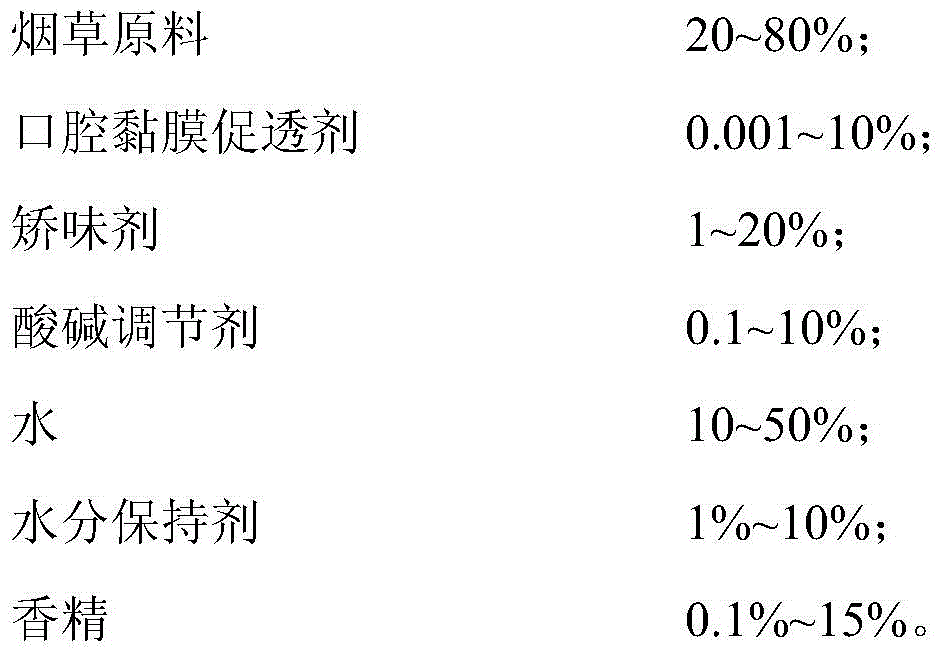

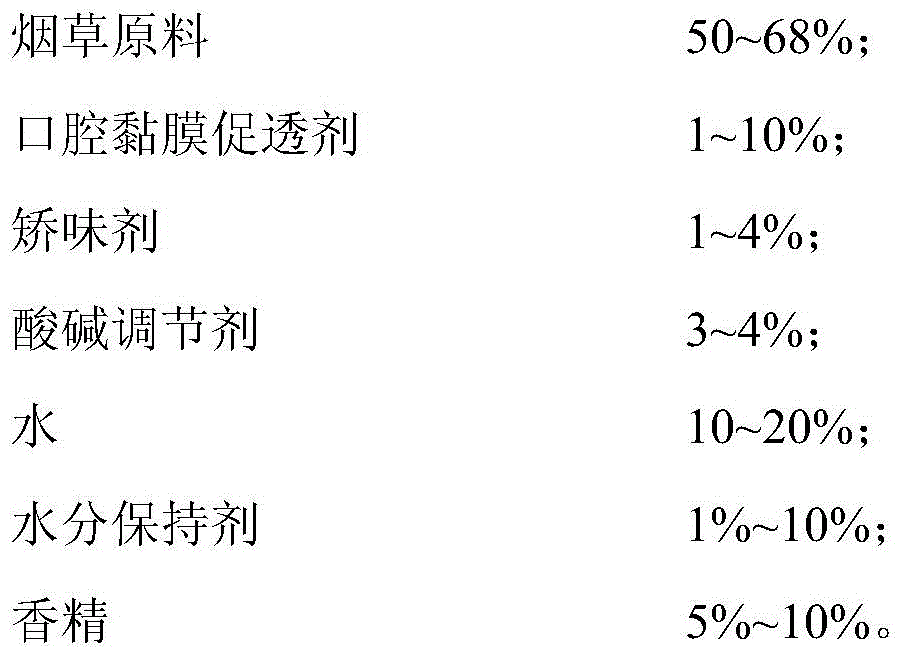

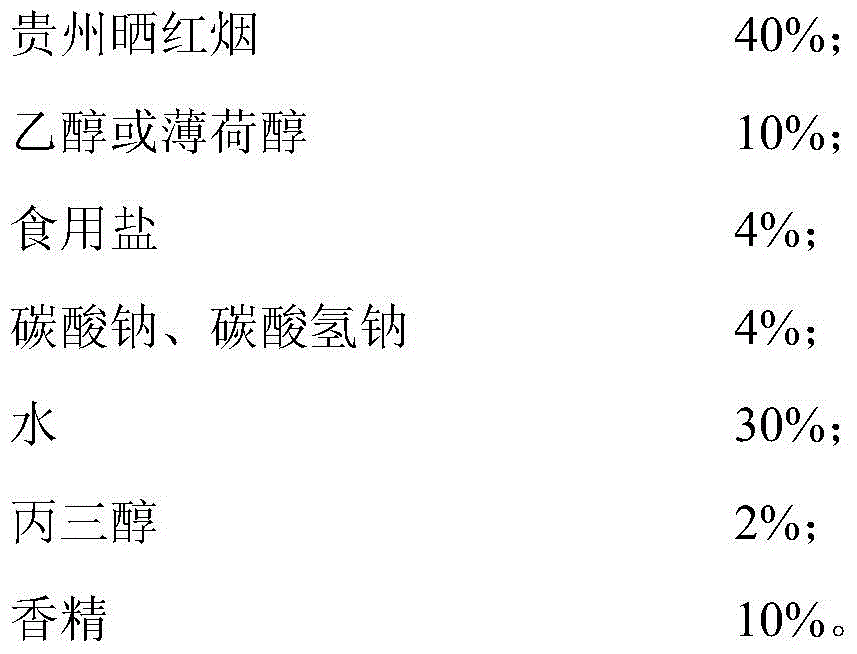

Oral tobacco product

The invention relates to the field of tobacco, in particular to an oral tobacco product. The oral tobacco product comprises components in percentage by mass as follows: 20-80% of a tobacco raw material, 0.001-10% of an oral mucosa penetration enhancer, 1-20% of a flavoring agent, 0.1-10% of a pH regulator, 10-50% of water, 1-10% of a moisture retention agent and 0.1-15% of essence. The tobacco product can promote human bodies to absorb nicotine and get the greater satisfaction under the condition that the content of the nicotine is specific, on the other hand, in order to get the same satisfaction, the tobacco amount required by the oral tobacco product is smaller, and the tobacco consumption can be reduced.

Owner:SHANGHAI TOBACCO GRP CO LTD

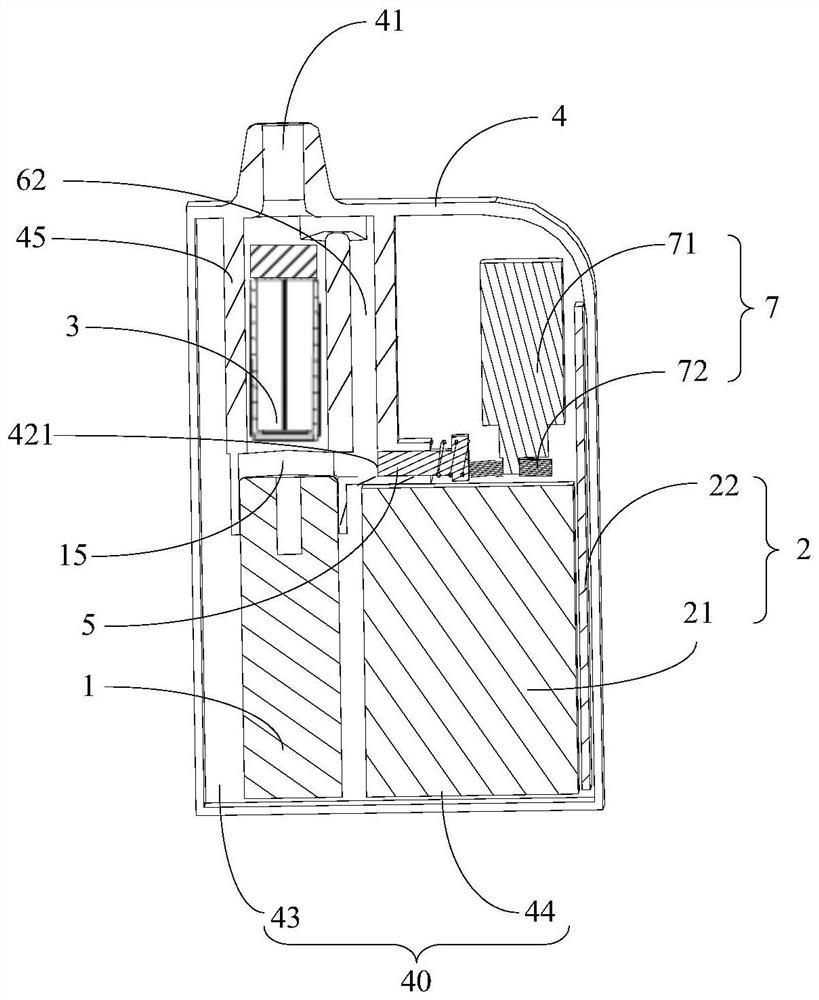

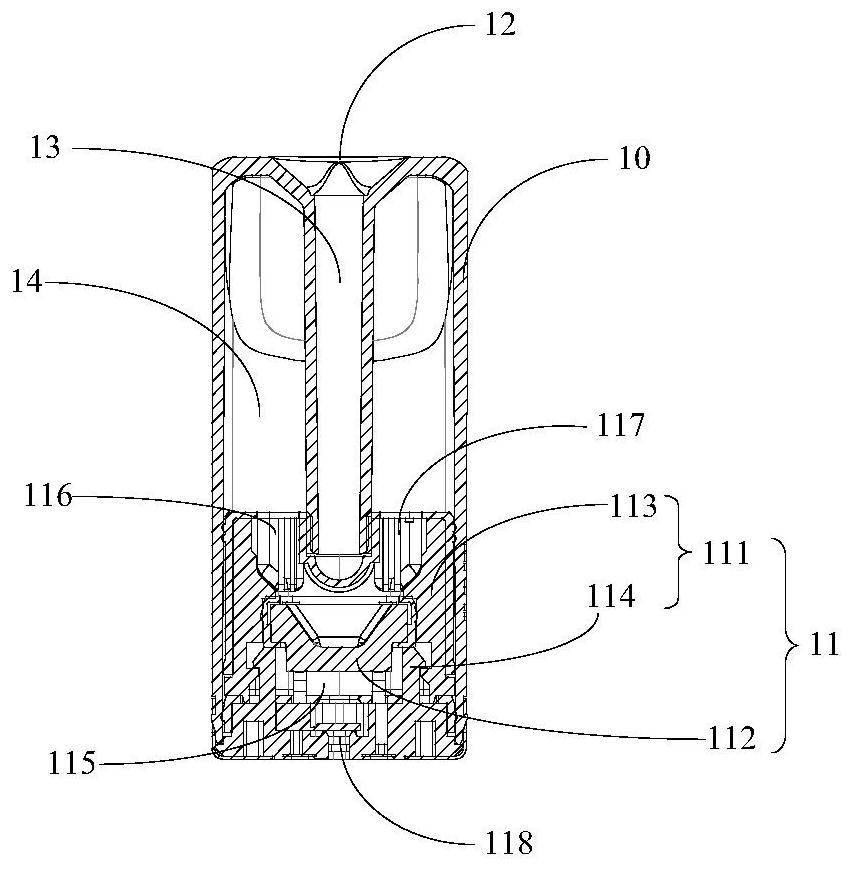

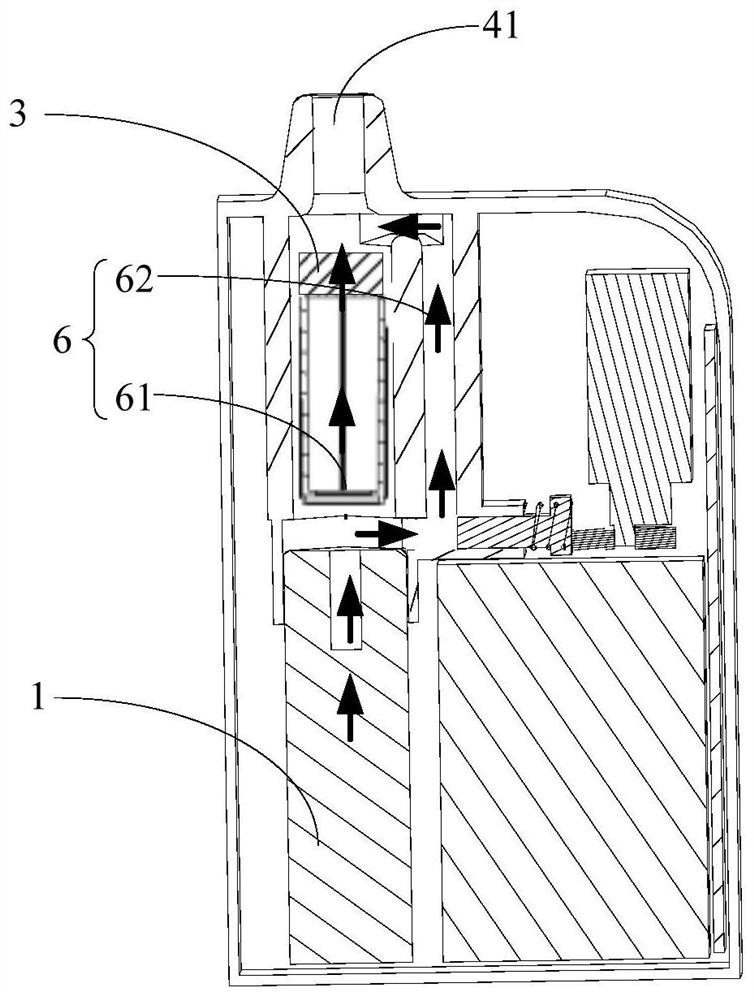

Electronic atomization device

PendingCN112493547AImprove the problem of serious attenuation of aroma releaseStrong sense of satisfactionOhmic-resistance heatingTobaccoAerosolizeEngineering

The invention discloses an electronic atomization device which comprises an air outlet part, an adjusting piece and a controller. The air outlet part is communicated with the air outlet channel through an aerosol channel, an aerosol channel is divided into a main aerosol channel and an auxiliary aerosol channel between the air outlet of the air outlet channel of the atomizer and the air outlet part, and the main aerosol channel enables aerosol generated by the atomizer to reach the air outlet part through the seasoning part; the auxiliary aerosol channel enables aerosol generated by the atomizer to directly reach the air outlet part; the adjusting piece is arranged in the aerosol channel and used for adjusting the amount of aerosol reaching the air outlet part through the auxiliary aerosolchannel. The auxiliary aerosol channel is arranged, and the amount of aerosol reaching the air outlet part through the auxiliary aerosol channel is adjusted through the adjusting piece, so that aerosol shunting is dynamically controlled, the fragrance of seasoning materials smoked by a user is stable, and the problem of serious fragrance release attenuation of the seasoning materials in the seasoning part can be solved.

Owner:SHENZHEN SMOORE TECH LTD

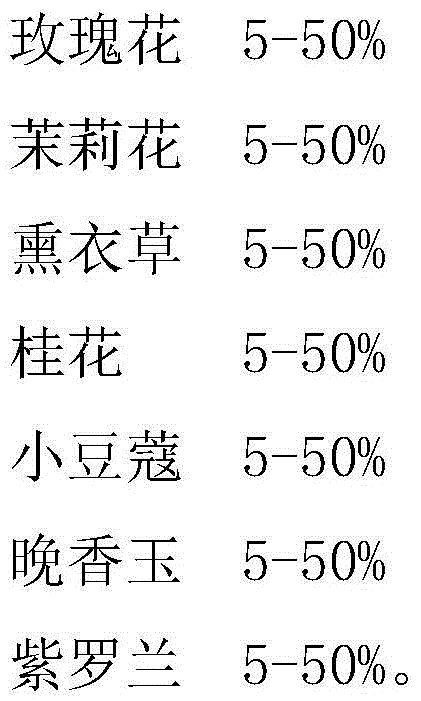

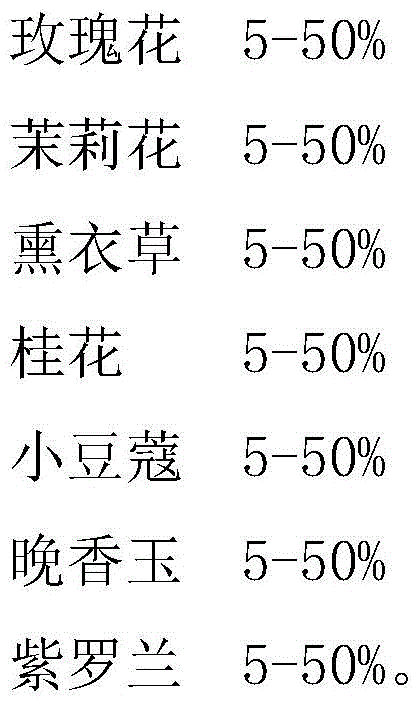

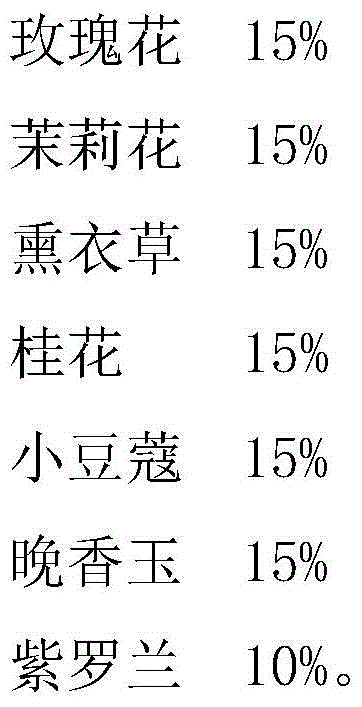

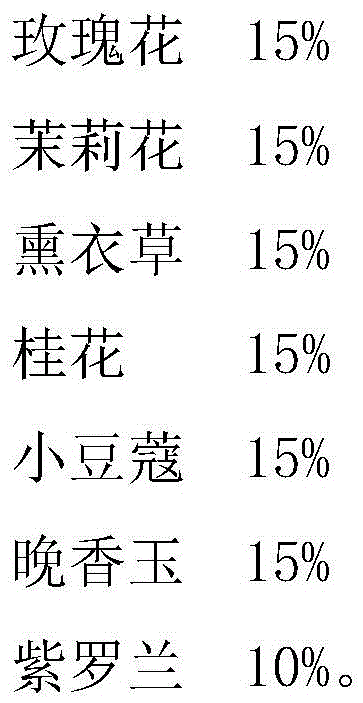

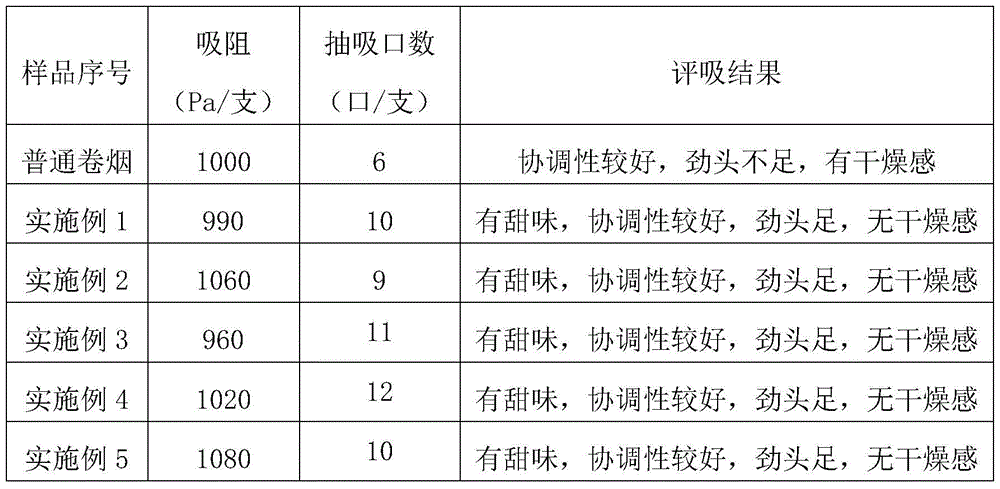

Method for preparing flowery flavor cigarette from cigarette beads

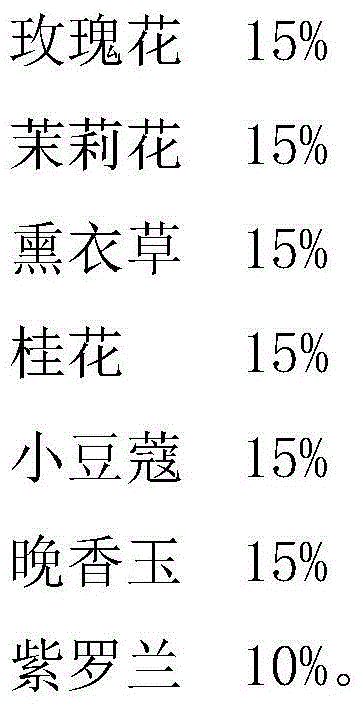

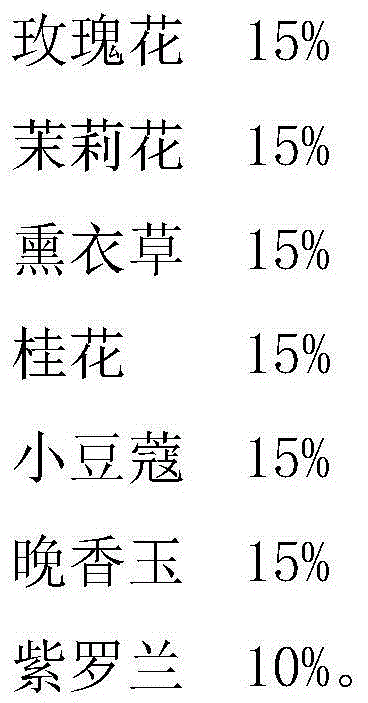

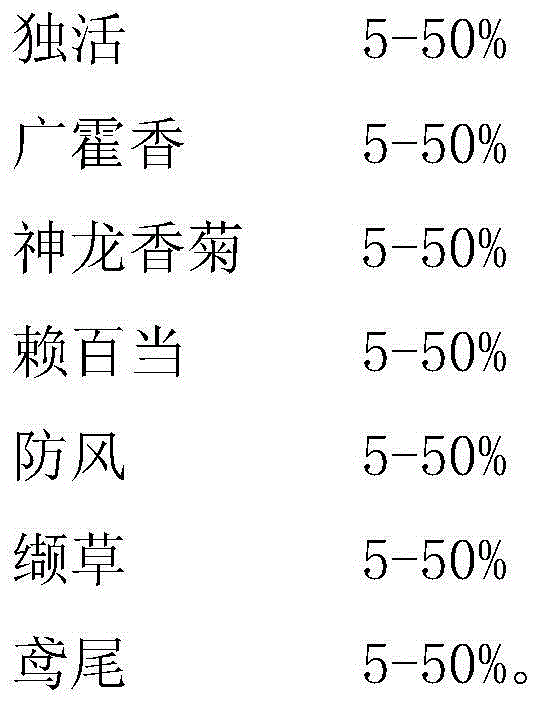

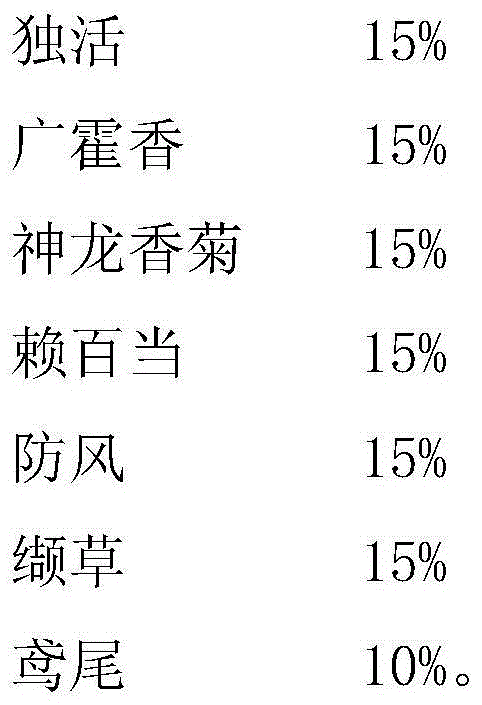

ActiveCN104921290ANew experienceNovelty form of cigaretteCigarette manufactureEssential-oils/perfumesFlavorCombustion

The invention discloses a method for preparing a flowery flavor cigarette from cigarette beads. The method comprises the following steps: firstly, crushing cigarette tobacco leaves and flowery flavor plant perfume materials into fine powder; secondly, adding an adhesive to prepare a soft material, and processing to form the cigarette beads by using an extrusion-rolling method; thirdly, pressing the cigarette beads into a cigarette stick; finally, coating the cigarette stick with cigarette paper, and connecting a filter tip to the cigarette stick to prepare the cigarette according to a conventional method. The prepared cigarette is in a novel form and can bring a brand new experience to a consumer, a cigarette prescription is uniform, and the stability of the smoking quality of the cigarette is guaranteed; meanwhile, the combustion time of the cigarette is also prolonged, the number of smoking times is increased, and the consumer feels more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

Method for preparing medicine flavor cigarette from cigarette beads

ActiveCN104921291ANew experienceNovelty form of cigaretteCigarette manufactureEssential-oils/perfumesFlavorCombustion

The invention discloses a method for preparing a medicine flavor cigarette from cigarette beads. The method comprises the following steps: firstly, crushing cigarette tobacco leaves and medicine flavor plant perfume materials into fine powder; secondly, adding an adhesive to prepare a soft material, and processing to form the cigarette beads by using an extrusion-rolling method; thirdly, pressing the cigarette beads into a cigarette stick; finally, coating the cigarette stick with cigarette paper, and connecting a filter tip to the cigarette stick to prepare the cigarette according to a conventional method. The prepared cigarette is in a novel form and can bring a brand new experience to a consumer, a cigarette prescription is uniform, and the stability of the smoking quality of the cigarette is guaranteed; meanwhile, the combustion time of the cigarette is also prolonged, the number of smoking times is increased, and the consumer feels more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

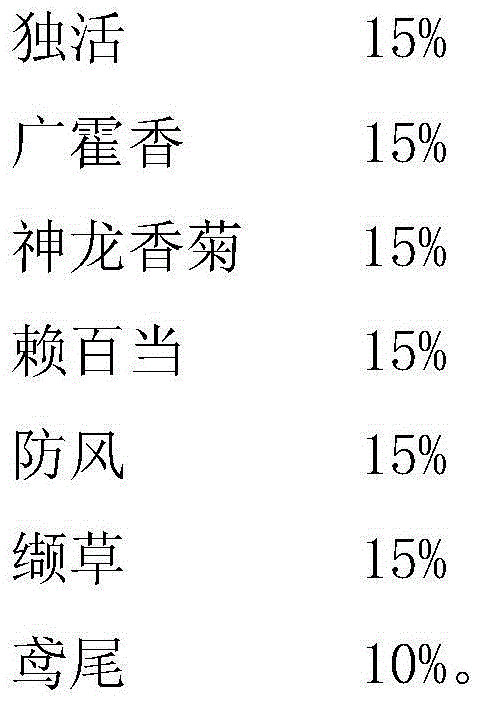

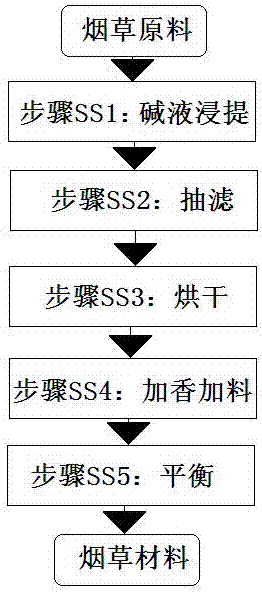

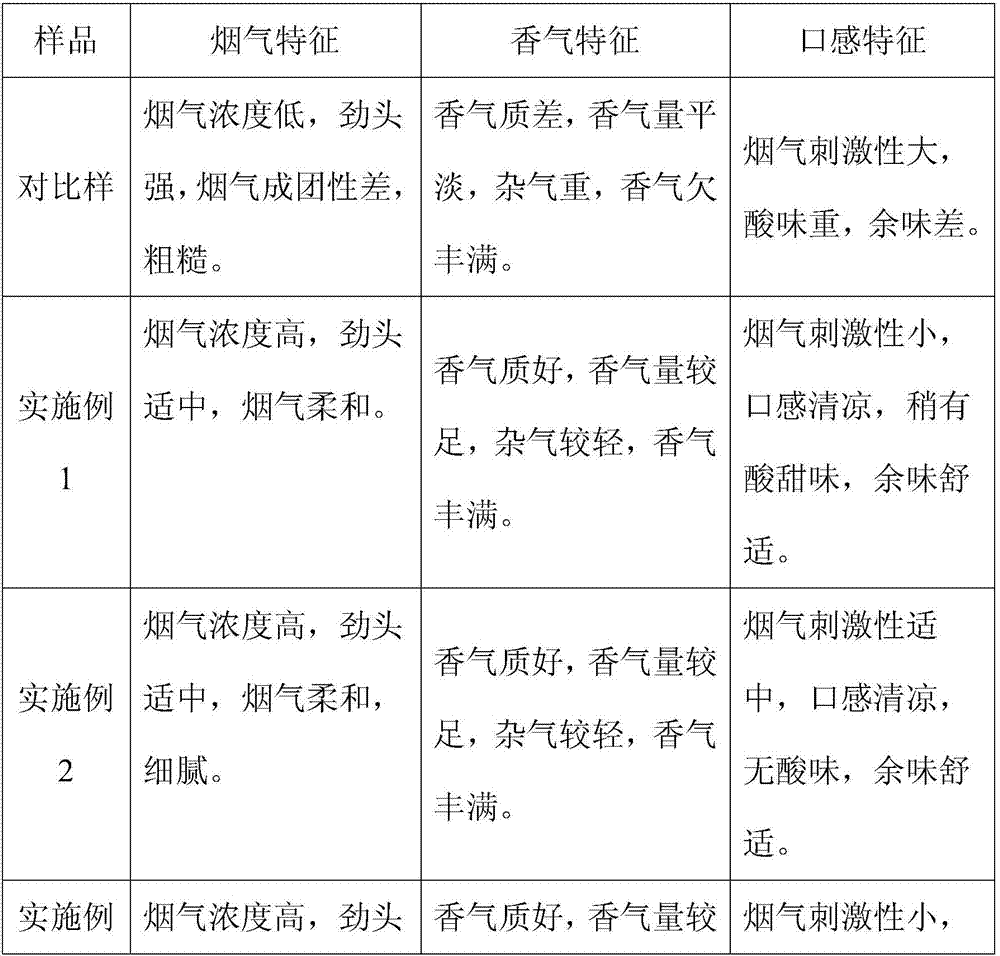

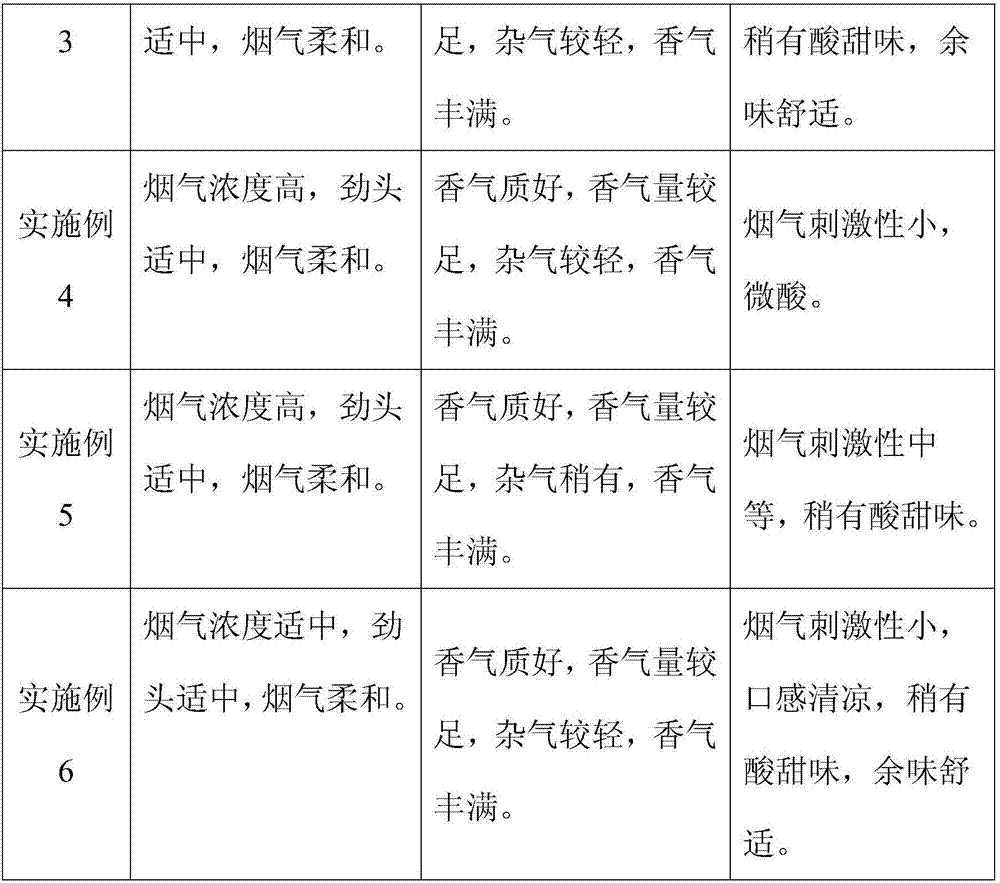

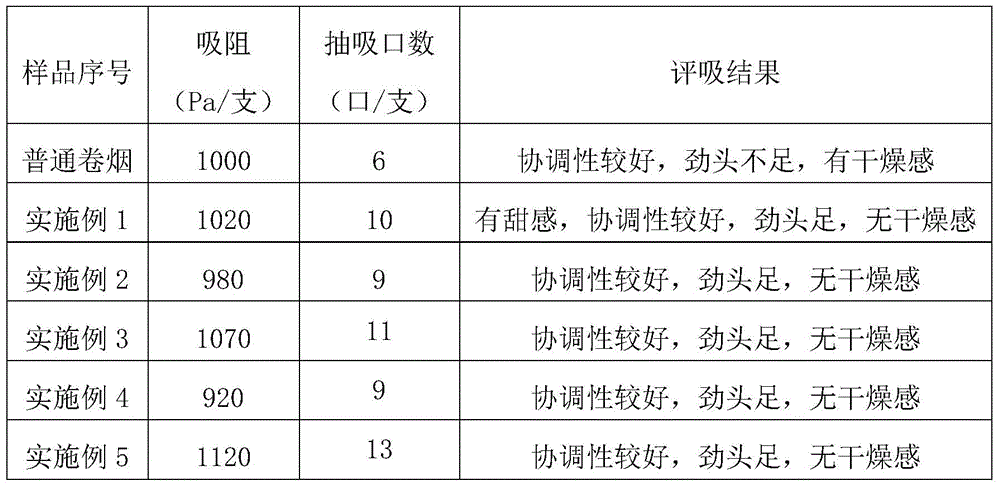

A method for processing tobacco raw materials for low-temperature cigarettes

ActiveCN106263012BImprove sensory qualityGood release effectTobacco preparationTobacco treatmentAlcoholPolyol

The invention discloses a tobacco raw material treatment method for low temperature cigarettes. The method comprises the following steps: step SS1, adding alkali liquor in tobacco raw materials for extraction, carrying out ultrasonic treatment, and executing the step SS2; step SS2, filtering for removing the extraction alkali liquor in the step SS1, adding pure water to quickly wash the tobacco raw materials, discarding the washing liquid, and executing the step SS3; step SS3, drying the tobacco raw materials prepared in the step SS2 at a low temperature, and executing the step SS4; step SS4, putting the tobacco raw materials dried in the step SS3 in a balanced environment for 24-48h, spraying an absolute ethyl alcohol solution containing tobacco essence and polyhydric alcohol to the tobacco raw materials, putting the tobacco raw materials in a sealed state for 24-48h, and executing the step SS5; and step SS5, putting the tobacco raw materials prepared in the step SS4 in the balanced environment for 48h to obtain tobacco materials suitable for heating non-combustion cigarettes. The smoke released by the tobacco raw materials treated by the method disclosed by the invention in a heating non-combustion state is large in concentration, mild and soft, small in irritation and moderate in intensity.

Owner:CHINA TOBACCO JIANGSU INDAL

A cigarette core column suitable for heating cigarettes and its preparation method

ActiveCN111011915BImprove thermal conductivityLarge specific surface areaCigar manufactureCigarette manufactureMetallurgyAdhesive

The invention relates to the technical field of heat-not-burn cigarettes, in particular to a cigarette core column suitable for heating cigarettes and a preparation method thereof. This kind of smoke core column suitable for heating cigarettes includes 20-40 parts of tobacco powder, 5-10 parts of tobacco extract, 0.2-3 parts of flavor and fragrance, 2-10 parts of smoke-generating agent, and 2 parts by mass according to parts by mass. ~8 parts, 2~5 parts of smoke-generating additive; the metal-mesoporous material composite is selected as the smoke-generating additive. This application uses a metal-mesoporous material composite to construct a porous skeleton that is not easy to collapse, and realizes heat conduction and loading of flavors, fragrances and nicotine, which can effectively improve the smoking rate and the uniformity of flavor release, thereby improving the sensory quality of heated cigarettes. consistency.

Owner:CHINA TOBACCO JIANGSU INDAL

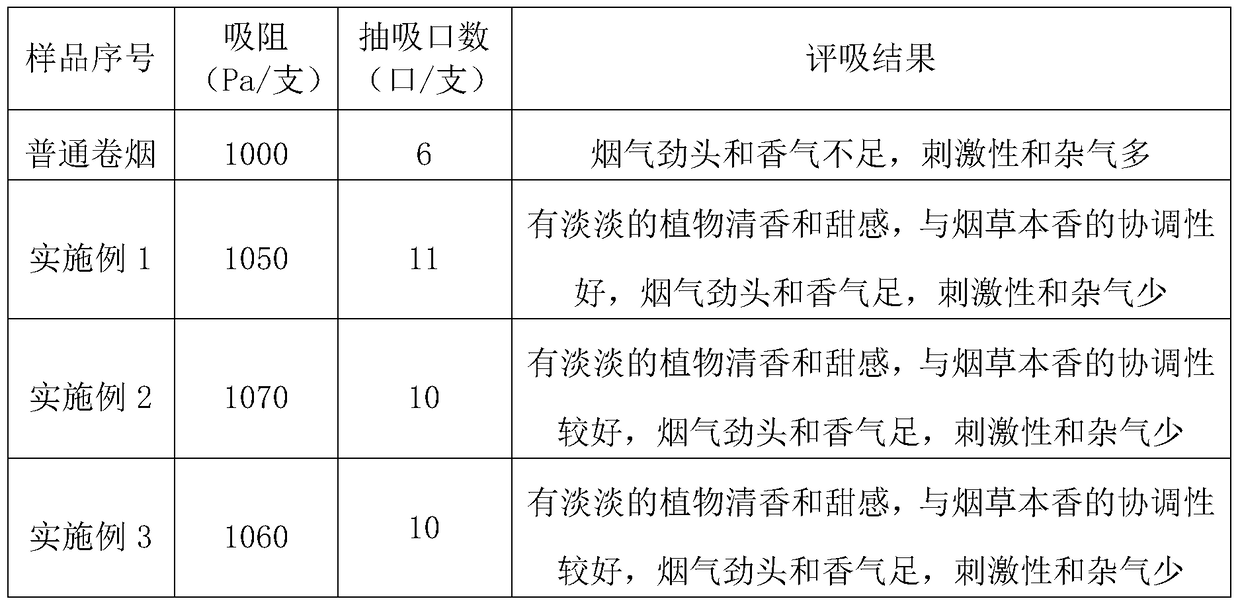

A kind of preparation method of plant fragrance type cigarette

The invention discloses a preparation method of a plant faint-scented cigarette. The preparation method comprises the following steps: crushing cyclocarya paliurus leaves and tobacco leaves into fine powder, adding with syrup to produce a soft material, processing the soft material into particles, pressing the particles into a tobacco rod, wrapping the tobacco rod by cigarette paper, connecting with a filter tip, and manufacturing the cigarette according to a conventional method. The prepared cigarette is novel is type, can bring brand-new experience to a consumer, and is uniform in component, thus the stability of the smoking quality of the cigarette is guaranteed, the burning time of the cigarette is prolonged, the smoking time is increased, and further, the consumer obtains strong satisfaction. The cigarette has faint plant scent, and the smoking is strong in strength and aroma, and low in irritation and miscellaneous smell

Owner:HUBEI CHINA TOBACCO IND

A method for preparing cigarettes by filling them with smoke beads

The invention discloses a method for preparing a cigarette from cigarette beads. The method comprises the following steps: firstly, crushing cigarette tobacco leaves into fine powder; secondly, adding an adhesive to prepare a soft material, and processing to form the cigarette beads by using an extrusion-rolling method; thirdly, putting the formed cigarette beads into a hollow smoke tube with a tip; finally, adding a small amount of adhesive slurry to the forefront end of the smoke tube, and performing drying and opening sealing to prepare the cigarette. The prepared cigarette is in a novel form and can bring a brand new experience to a consumer, a cigarette prescription is uniform, and the stability of the smoking quality of the cigarette is guaranteed; meanwhile, the combustion time of the cigarette is also prolonged, the number of smoking times is increased, and the consumer feels more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

A method for preparing cigarettes with smoke beads

The invention discloses a method for preparing a cigarette from tobacco beads. The method for preparing the cigarette from the tobacco beads comprises the steps that firstly, cigarette tobacco is smashed into fine powder; secondly, adhesives are added, so that a soft material is prepared, and the cigarette beads are prepared through an extruding-rounding method; thirdly, the cigarette beads are rolled into a cigarette bar; finally, the cigarette bar is wrapped by cigarette paper, a filter tip is connected to the cigarette bar, and the cigarette is prepared according to a conventional method. The prepared cigarette is novel in form and capable of bringing brand-new experience to customers; the formula of the cigarette is even, and the stability of cigarette smoking quality is guaranteed; meanwhile, the combustion time of the cigarette is prolonged, and number of puffs is increased; the sense of satisfaction of the customer is stronger.

Owner:HUBEI CHINA TOBACCO IND +1

Preparation method for cured tobacco leaves

ActiveCN103238919BCharacteristic aroma weakenedImprove your energyTobacco preparationHarvestersIrritationBiology

The invention discloses a preparation method for cured tobacco leaves. The method comprises the steps of cured tobacco plantation, tobacco leaf harvest and curing. In the step of tobacco leaf harvest, the tobacco leaves are harvested from bottom to top one by one according to tobacco leaf growth positions, 4-5 tobacco leaves are harvested each time, urea solution is evenly sprayed onto surfaces of the tobacco leaves after harvesting, urea sprayed onto the leaf surfaces per kg is 0.05-0.2g; and the tobacco leaf curing comprises the steps of tobacco leaf withering, yellowing, browning and killing-out. Characteristic aroma of the prepared cured tobacco leaves is remarkably weakened, aroma quality style is similar to air-cured tobacco leaves, strength is slightly high, satisfaction is strong, concentration is high, the cured tobacco leaves are full and mellow, irritation is small, smoke is smooth, the application range is greatly expanded, and technical support is provided for enriching tobacco leaf quality styles and meeting diversified raw materials requirements of low-tar low-harm cigarette products.

Owner:HUBEI CHINA TOBACCO IND

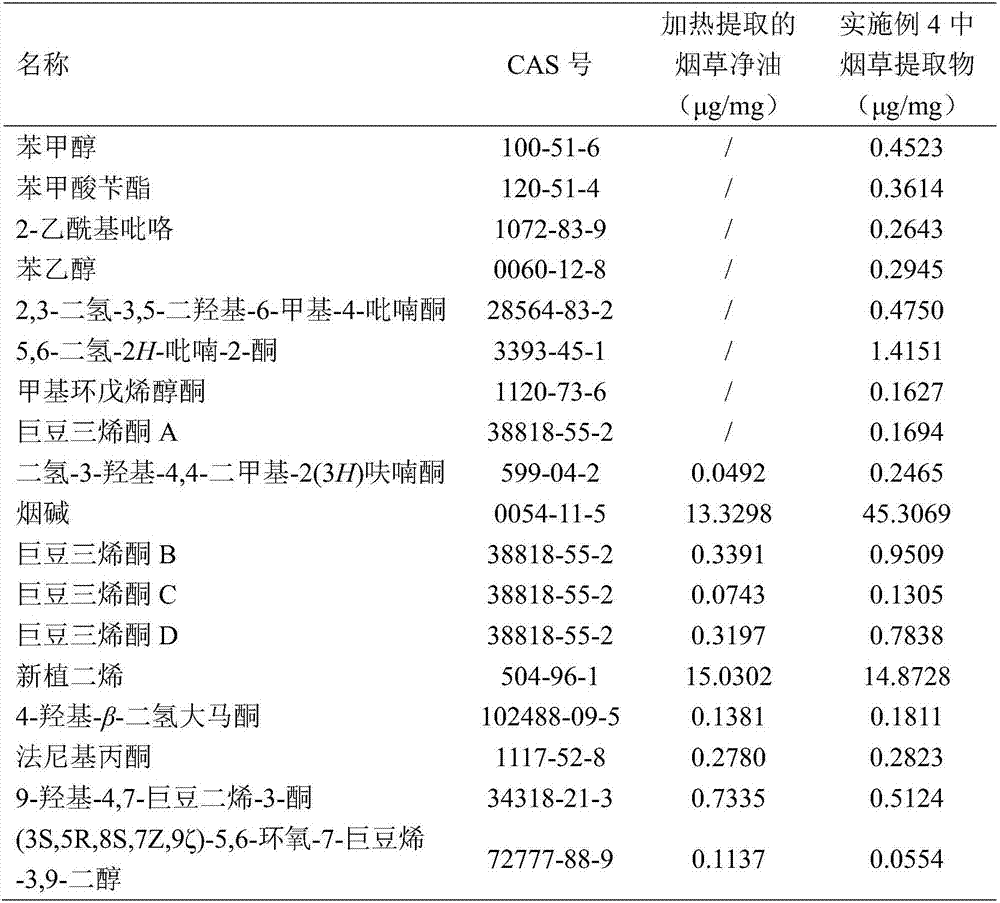

Tobacco extract, extraction method and application

The invention discloses a tobacco extract, an extracting method and application and belongs to the field of tobacco additives. The tobacco extract is extracted with the method including the following steps that firstly, propylene glycol is added into tobacco raw materials, and then baking is carried out after standing; secondly, smashing is carried out, and a solvent is added into powder materials for extraction; thirdly, extract liquid passes through an ultrafiltrtion membrane, penetrating liquid is obtained and subjected to reduced pressure distillation, and concentrate is obtained; fourthly, the concentrate is subjected to secondary separation with a molecule distillation method, light components are collected, and the tobacco extract is obtained. The extract contains rich megastigmatrienone, Damascone, neophytadiene, phenylcarbinol, phenethyl alcohol, farnesylacetone and pyrone and furanone aroma components, and the tobacco extract is thick in baking aroma and tobacco aroma, good in penetration, small in irritation and miscellaneous gas, high in satisfaction, capable of improving the smoking quality of cigarettes and providing a certain amount of nicotine to meet the physiological needs of consumers when used.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

A type of chewing tobacco wrapped in nori sheets

The invention discloses chewing tobacco. To make the chewing tobacco, tobacco powder is mixed with white granulated sugar, low-gluten flour and sesame powder evenly, then water, oil and salt are added to the mixture, then stirring is conducted to obtain dough, and the dough is diced with a die and baked to obtain cookies; then, fresh porphyra is mixed with tobacco powder, water is added, stirring is conducted to obtain pulp, the pulp is made into slices by means of the papermaking technology, and the slices are dried, sprayed with water so as to be bonded together, and then pressed to form the porphyra slices which are 1-5 mm thick; finally, the porphyra slices are placed in oil to be fried, centrifugal separation of oil is conducted, seasoner is spread on the porphyra slices, and then the cookies are wrapped with the porphyra slices. In this way, the acrid and bitter taste generated when tobacco is chewed in the mouth is completely eliminated, the irritation of tobacco is reduced, the fragrance of the chewing tobacco is improved, the taste of the chewing tobacco is improved, the satisfaction obtained by smoking a cigarette can also be obtained through chewing, and harm caused by smoking to human health is reduced.

Owner:HUBEI CHINA TOBACCO IND

A method for preparing flower-flavored cigarettes with smoke beads

ActiveCN104921290BNew experienceNovelty form of cigaretteCigarette manufactureEssential-oils/perfumesFlavorCombustion

The invention discloses a method for preparing a flowery flavor cigarette from cigarette beads. The method comprises the following steps: firstly, crushing cigarette tobacco leaves and flowery flavor plant perfume materials into fine powder; secondly, adding an adhesive to prepare a soft material, and processing to form the cigarette beads by using an extrusion-rolling method; thirdly, pressing the cigarette beads into a cigarette stick; finally, coating the cigarette stick with cigarette paper, and connecting a filter tip to the cigarette stick to prepare the cigarette according to a conventional method. The prepared cigarette is in a novel form and can bring a brand new experience to a consumer, a cigarette prescription is uniform, and the stability of the smoking quality of the cigarette is guaranteed; meanwhile, the combustion time of the cigarette is also prolonged, the number of smoking times is increased, and the consumer feels more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

A kind of method for preparing hollow cigarette with tobacco beads

A method of preparing hollow cigarettes by using tobacco leaf beads is disclosed. The method includes smashing tobacco leaves into fine powder, adding an adhesive to prepare into a soft material, preparing tobacco leaf beads by using an extrusion-spheronization process, pressing the tobacco leaf beads into hollow cigarette sticks, wrapping the hollow cigarette sticks with cigarette paper, connecting filter tips, and preparing the cigarettes by a conventional method. The prepared cigarettes are novel in form, can bring new experience to customers and are uniform in formula. Stability of cigarette smoking quality is ensured, the combustion time of the cigarettes is prolonged, and the puff number is increased, so that customers are more satisfied.

Owner:HUBEI CHINA TOBACCO IND +1

A method for preparing cigarettes with colored smoke beads

The invention discloses a method for preparing a cigarette by colored tobacco beads. The method includes the steps: firstly, crushing cigarette tobacco leaves into fine powder; secondly, adding adhesives into the fine powder to form soft materials and forming the tobacco beads by an extruding-rounding method; thirdly, covering the tobacco beads with a film coating and pressing the tobacco beads into a cigarette rod; finally, covering the cigarette rod with cigarette paper, connecting the cigarette rod with a filter tip and forming the cigarette by a conventional method. The prepared cigarette is novel in form, novel experience can be brought for consumers, the cigarette is uniform in formula, puff quality stability of the cigarette is guaranteed, burning time of the cigarette is prolonged, puff number is increased, and a consumer achieves stronger satisfaction.

Owner:HUBEI CHINA TOBACCO IND +1

an oral tobacco product

The invention relates to the field of tobacco, in particular to an oral tobacco product. The oral tobacco product comprises components in percentage by mass as follows: 20-80% of a tobacco raw material, 0.001-10% of an oral mucosa penetration enhancer, 1-20% of a flavoring agent, 0.1-10% of a pH regulator, 10-50% of water, 1-10% of a moisture retention agent and 0.1-15% of essence. The tobacco product can promote human bodies to absorb nicotine and get the greater satisfaction under the condition that the content of the nicotine is specific, on the other hand, in order to get the same satisfaction, the tobacco amount required by the oral tobacco product is smaller, and the tobacco consumption can be reduced.

Owner:SHANGHAI TOBACCO GRP CO LTD

A method for preparing tobacco material suitable for heating non-burning tobacco products

A tobacco material preparing method for heated non-combustion tobacco products is characterized by sequentially comprising the following steps of (1) performing digestion on tobacco raw materials with an ethanol solution and preparing a tobacco extract; (2) after the digestion, separating the solution from the tobacco to obtain a tobacco extracting solution, evaporating the extracting solution under a decompressing condition to remove ethanol, and freezing and drying to obtain a solid tobacco extract; (3) mixing the solid tobacco extract with metal hydroxide particles with a flame retarding function, adding a solvent to disperse and form a thick mixture, drying the obtained thick mixture with a roller drying method, and crushing the dried materials to obtain the tobacco material suitable for the heated non-combustion tobacco products. Smoke released due to heating at 200 DEG C to 400 DEG C from the tobacco material prepared according to the method has good satisfying feeling in both concentration and strength, and the flavor quality and sense comfort are good, and a good flame retarding action is realized.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

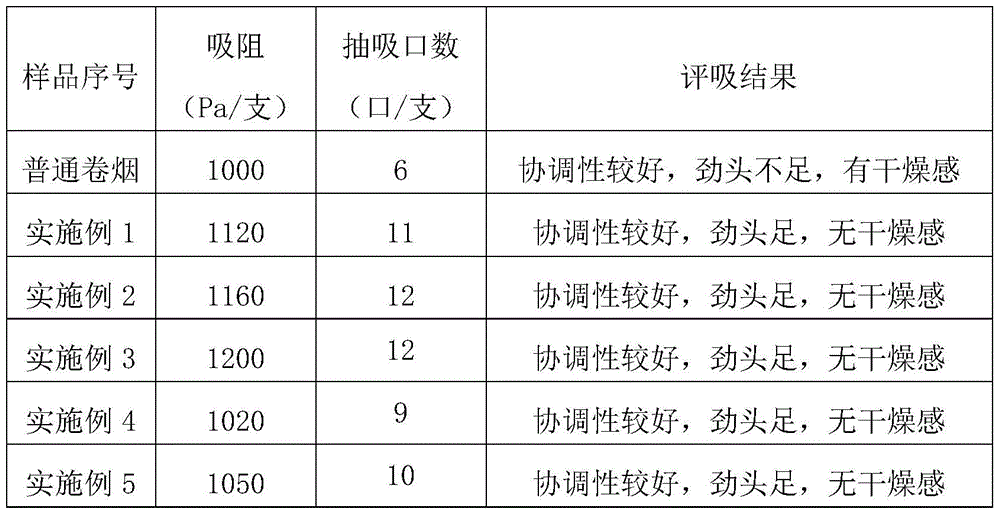

A kind of preparation method and application of cigarette aroma material for tobacco sheet

ActiveCN105754722BIncrease smoke concentrationImprove your energyTobacco preparationEssential-oils/perfumesCelluloseDistillation

The invention provides a preparation method of tobacco-aroma matters for tobacco sheets.The preparation method includes using an extraction-molecular distillation combined technology for separating purified tobacco raw materials to obtain the strongly-satisfying tobacco-aroma matters.By the extraction-molecular distillation combined technology, nicotine and characteristic tobacco aroma light constituents in tobacco extract are enriched and purified, and macromolecular substances such as cellulose, polysaccharide, pectin and protein adverse to smell absorption can be further removed.The tobacco sheets prepared from the tobacco-aroma matters are capable of remarkably increasing smoke concentration, strength and aroma of cigarette products and make smokers feel satisfied and comfortable strongly.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com