Preparation method for tobaccos not combusting after being heated

A heat-not-burn and tobacco product technology, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, to achieve the effect of sufficient aroma, strong sense of satisfaction, and enhanced aroma texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

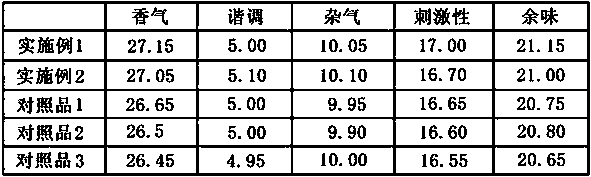

Examples

Embodiment 1

[0017] . 5 parts by weight of Zimbabwean tobacco leaves, 5 parts by weight of Brazilian tobacco leaves, 80 parts by weight of Yunnan tobacco leaves, 3 parts by weight of Fujian tobacco leaves, and 7 parts by weight of Guizhou tobacco leaves are mixed and then injected with steam for moisture regain treatment. When the moisture content of the above-mentioned mixed tobacco leaves reaches 19.5 ± 1.0 %, cut it into shreds, and the cut leaves are dried on a thin plate (the drying temperature is 130°C) to a moisture content of 13.0±0.5%, and the shredded leaves are used as raw materials for tobacco extract, and dried at 40°C for 2 hours Finally, pulverize when it reaches the balance weight, and then pass through a 40-mesh sieve to obtain smoke powder;

[0018] . Weigh 500g of the above-mentioned smoke powder, add 4500g of 95% ethanol solution by volume, stir and extract at 60°C, turn off the heating after leaching for 2 hours, let stand at room temperature and cool for 12 hours...

Embodiment 2

[0027] Example 2: The difference between this example and Example 1 is that the ratio of tobacco extract raw materials is different, the extraction temperature is different, the vacuum degree of molecular distillation is different, the distribution ratio of light and heavy is different, and the flavor and fragrance solution and the reconstituted tobacco extract The proportions are different, the raw materials of reconstituted tobacco leaves and their proportions are different, and the proportions of heat-not-burn cigarette flavors and fragrances in reconstituted tobacco leaves are different.

[0028] . 10 parts by weight of Zimbabwean tobacco leaves, 10 parts by weight of Brazilian tobacco leaves, 70 parts by weight of Yunnan tobacco leaves, 2 parts by weight of Fujian tobacco leaves and 8 parts by weight of Guizhou tobacco leaves are mixed and then injected with water vapor for moisture regain treatment. When the moisture content of the above-mentioned mixed tobacco leaf mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com