Tobacco extract pyrolysis product and application thereof in novel tobacco product

A technology for pyrolysis products and tobacco products, which is applied in the fields of tobacco, application, and tobacco processing, and can solve problems such as not being able to meet the needs of physiological and psychological behaviors, and restricting the market acceptance of new cigarettes and electronic cigarettes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

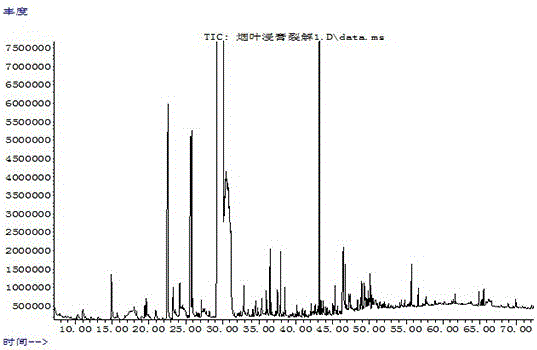

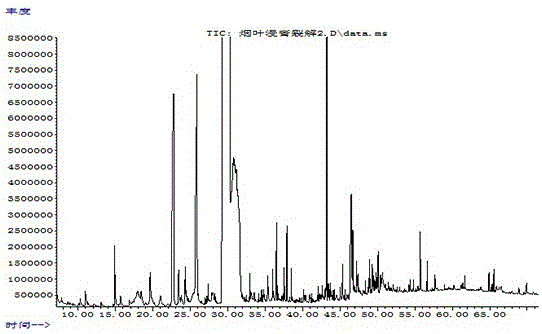

Image

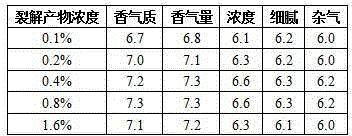

Examples

Embodiment 1

[0034] The pyrolysis product of tobacco leaf extract provided in this example is prepared by the following steps.

[0035] (1) Preparation of tobacco leaf extract

[0036] Take 30kg of tobacco leaves and grind them through a 20-mesh sieve, add 600L of extraction solvent ethanol (80% ethanol v / v), heat and reflux for 3 hours, filter, concentrate under reduced pressure until no more liquid flows out, and obtain 7.08kg of tobacco leaf extract;

[0037] The tobacco leaves are Luzhou-flavor tobacco leaves, specifically the tobacco leaves of China Tobacco 100B2F in Jiaxian County, Henan Province.

[0038] (2) cracking the tobacco leaf extract

[0039] Place the tobacco leaf extract prepared in step (1) in a cracking furnace, the side wall of the cracking furnace is connected to a receiving bottle through a connecting pipe, and the receiving bottle contains 3L of absorption solvent ethanol;

[0040] Introduce high-purity nitrogen (that is, neither oxygen nor hydrogen), adjust the n...

Embodiment 2

[0052] The pyrolysis product of tobacco leaf extract provided in this example is prepared by the following steps.

[0053] (1) Preparation of tobacco leaf extract

[0054] The prepared tobacco leaf extract is the same as in Example 1.

[0055] (2) cracking the tobacco leaf extract

[0056] The prepared tobacco leaf extract is placed in a cracking furnace, the side wall of the cracking furnace is connected with a receiving bottle through a connecting pipe, and 3L of absorption solvent n-hexane is filled in the receiving bottle;

[0057] Introduce nitrogen with an oxygen content of 10%, adjust the gas flow rate to 10L / min, and after passing the mixed gas for 5 minutes, the temperature of the cracking furnace is rapidly raised to 650°C, and the heating is stopped after 2 minutes of thermal cracking.

[0058] (3) Vacuum rotary evaporation concentration

[0059] Place the receiving bottle containing the cleavage product obtained in step (2) under vacuum at 25°C, and carry out va...

Embodiment 3

[0063] The pyrolysis product of tobacco leaf extract provided in this example is prepared by the following steps.

[0064] (1) Preparation of tobacco leaf extract

[0065] The prepared tobacco leaf extract is the same as in Example 1.

[0066] (2) cracking the tobacco leaf extract

[0067] The tobacco leaf extract is placed in the cracking furnace, the side wall of the cracking furnace is connected with a receiving bottle through a connecting pipe, and 3L of absorption solvent acetone is contained in the receiving bottle;

[0068] Introduce nitrogen gas with a hydrogen content of 8%, adjust the gas flow rate to 12L / min, and after introducing the mixed gas for 5 minutes, the temperature of the cracking furnace is rapidly raised to 750°C, and the heating is stopped after 1.5 minutes of thermal cracking.

[0069] (3) Vacuum rotary evaporation concentration

[0070] Place the receiving bottle containing the cleavage product obtained in step (2) under vacuum at 25°C, and carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com