Cigarette core column for heating cigarettes and preparation method thereof

A cigarette core and cigarette technology, which is applied in the directions of tobacco, application, and manufacture of cigarettes, can solve the problems of easy collapse and failure of porous structures, uneven aroma release, and poor thermal conductivity, so as to be beneficial to the release of smoke and prevent porous The effect of structure collapse and smooth flue gas passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

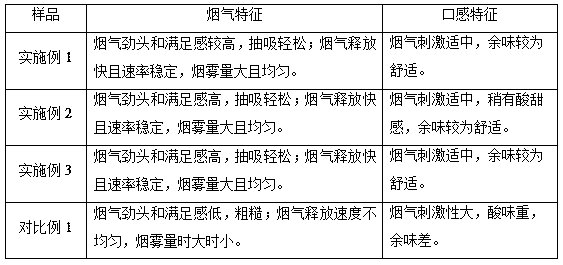

Examples

Embodiment 1

[0035] A cigarette stem suitable for heating cigarettes is prepared through the following steps:

[0036] (1) According to parts by mass, prepare 30 parts of tobacco powder, 7.5 parts of tobacco extract, 0.75 parts of flavor and fragrance, 6 parts of smoking agent, 3 parts of adhesive, and 3 parts of metal-mesoporous material composite.

[0037] Among them, the tobacco powder is obtained by crushing mixed raw materials of flue-cured tobacco, burley tobacco and oriental tobacco with a mass ratio of 5:2:3 and passing through a 100-mesh sieve. The mass fractions of flavors and fragrances are 11% β-damascenone, 16% 2,6,6-trimethyl-2-cyclohexene-1,4-dione, 6% β-ionone, 14% three Blend of glyceryl acetate, 8% furfural, 10% phenylacetaldehyde, 8% benzyl alcohol, 8% dihydroactinolactone, 3% indole, 10% 3-acetylpyridine, 6% plum extract. The fuming agent selects glycerin for use. The binder is selected from propylene glycol alginate.

[0038] Tobacco extract is extracted through the...

Embodiment 2

[0045] A cigarette stem suitable for heating cigarettes is prepared through the following steps:

[0046] (1) According to parts by mass, prepare 20 parts of tobacco powder, 5 parts of tobacco extract, 0.2 parts of flavor and fragrance, 2 parts of smoking agent, 2 parts of adhesive, and 2 parts of metal-mesoporous material composite.

[0047] Wherein, the tobacco powder is obtained by pulverizing mixed raw materials of flue-cured tobacco and oriental tobacco in an equal mass ratio and passing through an 80-mesh sieve. Flavors and fragrances are selected with mass fractions of 10% β-damascenone, 6% β-ionone, 14% glycerol triacetate, 8% furfural, 10% phenylacetaldehyde, 26% menthol, and 8% dihydrokiwi fruit Esters, 10% 3-acetylpyridine, 8% mixture of plum extract. The fuming agent is a mixture of 80% glycerin and 20% propylene glycol in mass fraction. The binder is a mixture of 50% hydroxypropyl starch and 50% corn modified starch.

[0048] Tobacco extract is extracted throug...

Embodiment 3

[0055] A cigarette stem suitable for heating cigarettes is prepared through the following steps:

[0056] (1) According to parts by mass, prepare 40 parts of tobacco powder, 10 parts of tobacco extract, 3 parts of flavor and fragrance, 10 parts of smoking agent, 8 parts of adhesive, and 5 parts of metal-mesoporous material composite.

[0057] Among them, the tobacco powder is obtained by crushing flue-cured tobacco raw materials and passing through a 200-mesh sieve. Flavors and fragrances are selected from the flavors and fragrances compound in Example 1. The smoke agent is 1,2-propanediol. The adhesive is tamarind glue.

[0058] Tobacco extract is extracted through the following steps: compound tobacco raw materials with 2.3% nicotine content; add the above-mentioned tobacco raw materials into 80% ethanol according to the solid-liquid ratio of 1:18, reflux extraction for 2.5 hours, filter and take the filtrate , Concentrate the filtrate in a water bath at 65°C to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com