Patents

Literature

149results about How to "Strong complexation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

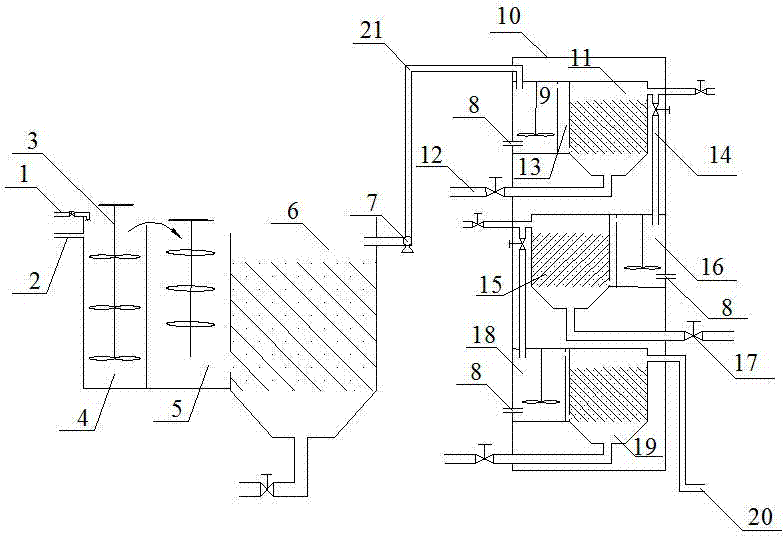

All-solid-state electrolyte membrane of lithium ion battery and preparation method thereof

ActiveCN103647107AAvoid irreversible electrochemical reactionsPrevent burningFinal product manufactureElectrolyte accumulators manufactureLithium electrodePolymer electrolytes

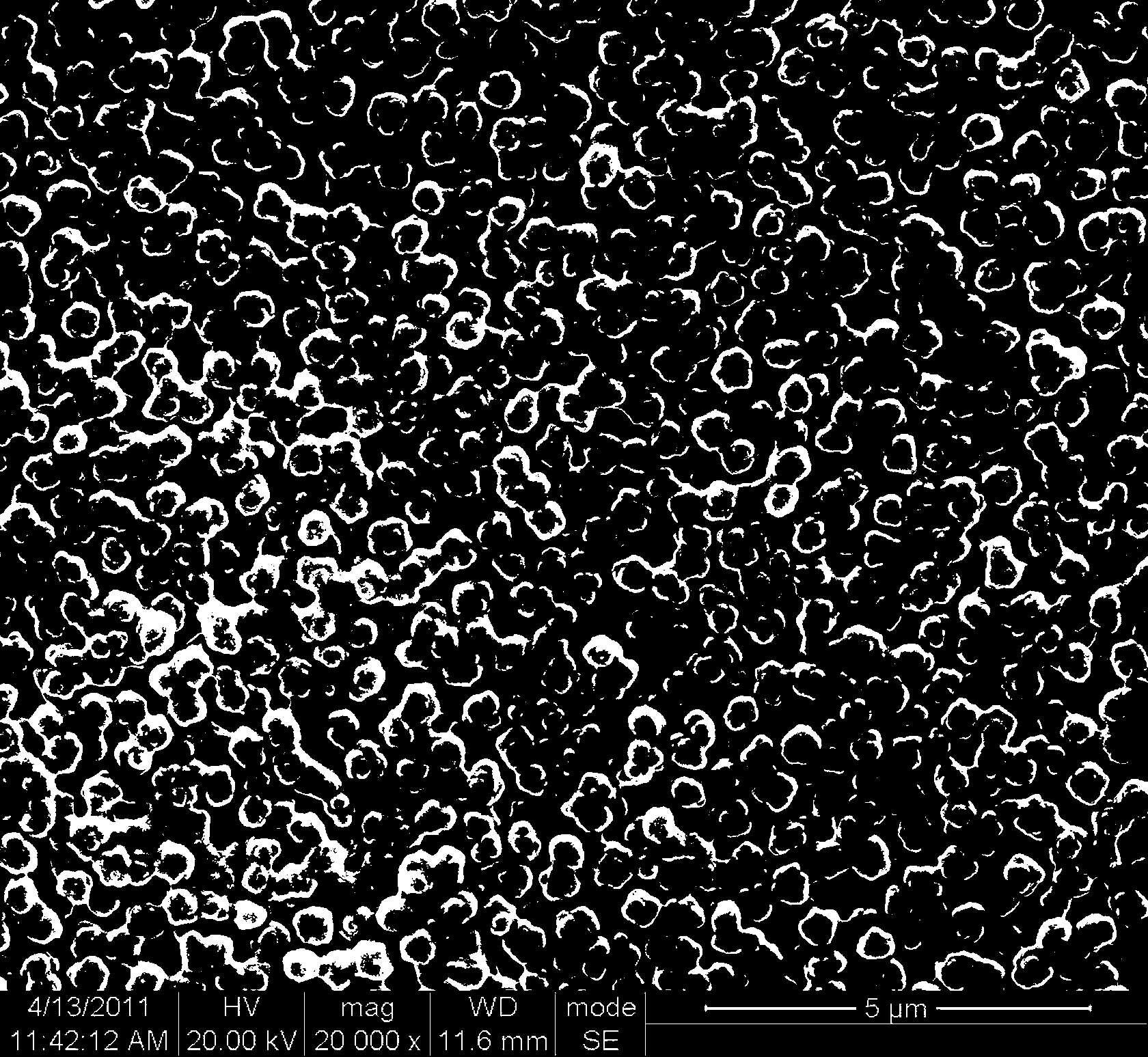

The invention relates to an all-solid-state lithium ion battery diaphragm of a microspheric structure and a preparation method thereof, belongs to the technical field of manufacturing of a lithium battery, and aims at providing a solid polymer electrolyte membrane and a modified all-solid-state polymer electrolyte membrane which are used for solving the bottleneck problem of solid polymer electrolyte, i.e. for improving the room-temperature conductivity of the all-solid-state polymer electrolyte. The spherical granularity of the polymer electrolyte membrane and the modified inorganic / organic composite electrolyte membrane is 100nm to 500nm. The prepared all-solid-state polymer electrolyte membrane is good in heat stability and high in room-temperature conductivity and lithium ion transference number. By virtue of the dry-state polymer electrolyte, the phenomenon that an ordinary liquid battery is likely to burn and explode and the like can be avoided, and the safety reliability of the battery can be improved.

Owner:DONGFANG ELECTRIC CORP LTD

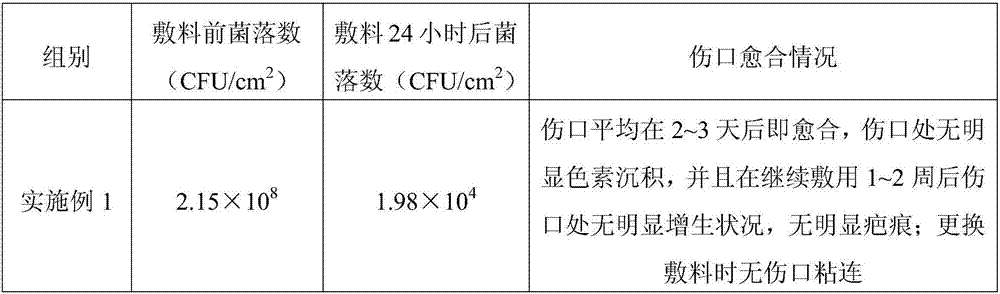

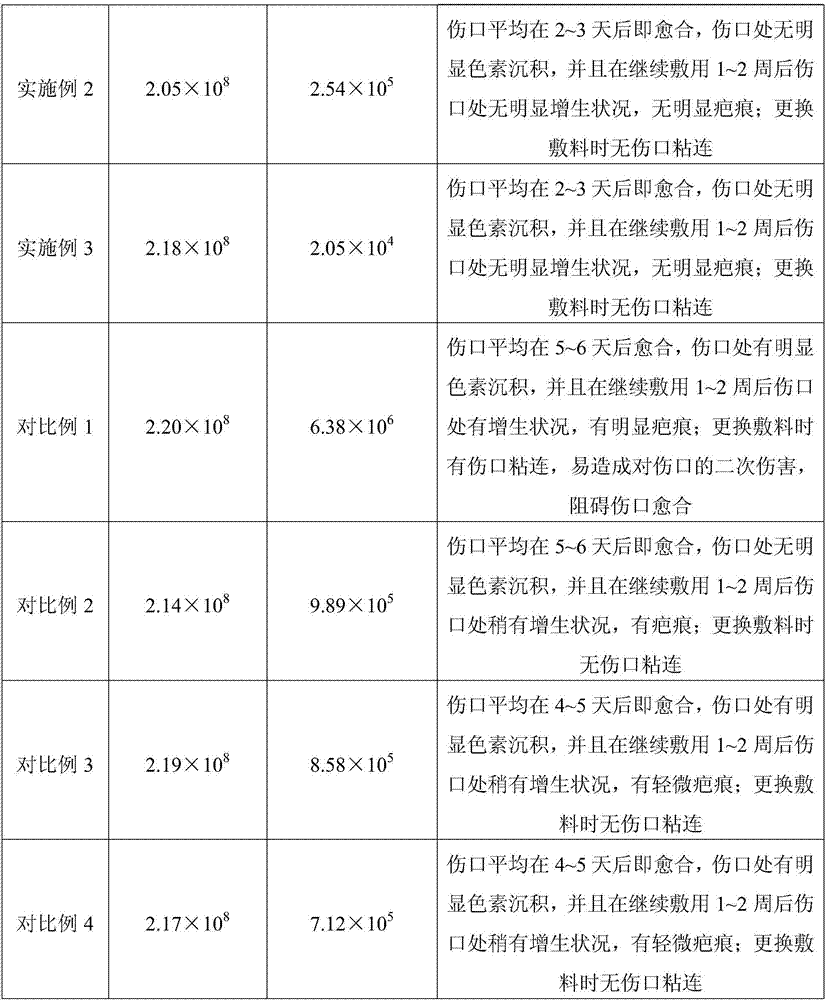

Alginate medical dressing and preparation method thereof

ActiveCN107029272AGood moisturizing effectAvoid stickingPharmaceutical delivery mechanismAbsorbent padsSodium carboxymethylcelluloseAloin

The invention relates to the technical field of medical articles, in particular to alginate medical dressing and a preparation method thereof. The medical dressing is prepared by soaking alginate fibers in a functional soaking solution, wherein the functional soaking solution is prepared from, by weight, 2-4% of carboxymethyl chitosan, 1-2% of oligochitosan, 3-6% of chitosan hydrochloride, 1-2% of hyaluronic acid chitosan, 0.03-0.05% of antibacterial agent, 0.5-5% of sodium carboxymethyl cellulose, 1-6 % of calcium chloride, 0.005-0.05% of epidermal growth factor, 0.02-0.05% of aloe extracts and the balance water. The chitosan substances, the antibacterial agent, carboxymethyl cellulose, calcium chloride, the epidermal growth factor and the aloe extracts are loaded in the alginate fibers, so that the medical dress is endowed with the remarkable effects of preventing bacteria, stopping bleeding, promoting healing, preventing wound adherence and preventing scars.

Owner:HENAN HUIBO MEDICAL CO LTD

Tobacco material preparing method for heated non-combustion tobacco products

ActiveCN103462213AEfficient releaseStrong sense of satisfactionTobacco treatmentBiotechnologyFreeze-drying

A tobacco material preparing method for heated non-combustion tobacco products is characterized by sequentially comprising the following steps of (1) performing digestion on tobacco raw materials with an ethanol solution and preparing a tobacco extract; (2) after the digestion, separating the solution from the tobacco to obtain a tobacco extracting solution, evaporating the extracting solution under a decompressing condition to remove ethanol, and freezing and drying to obtain a solid tobacco extract; (3) mixing the solid tobacco extract with metal hydroxide particles with a flame retarding function, adding a solvent to disperse and form a thick mixture, drying the obtained thick mixture with a roller drying method, and crushing the dried materials to obtain the tobacco material suitable for the heated non-combustion tobacco products. Smoke released due to heating at 200 DEG C to 400 DEG C from the tobacco material prepared according to the method has good satisfying feeling in both concentration and strength, and the flavor quality and sense comfort are good, and a good flame retarding action is realized.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

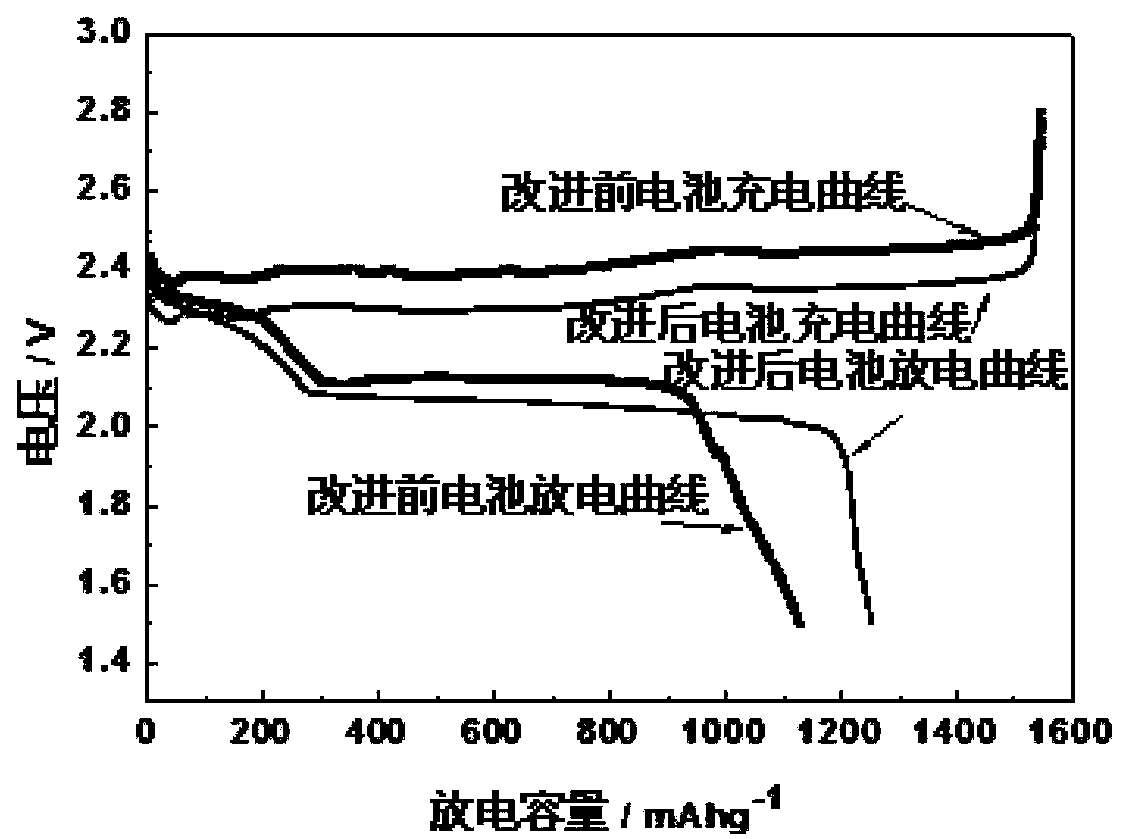

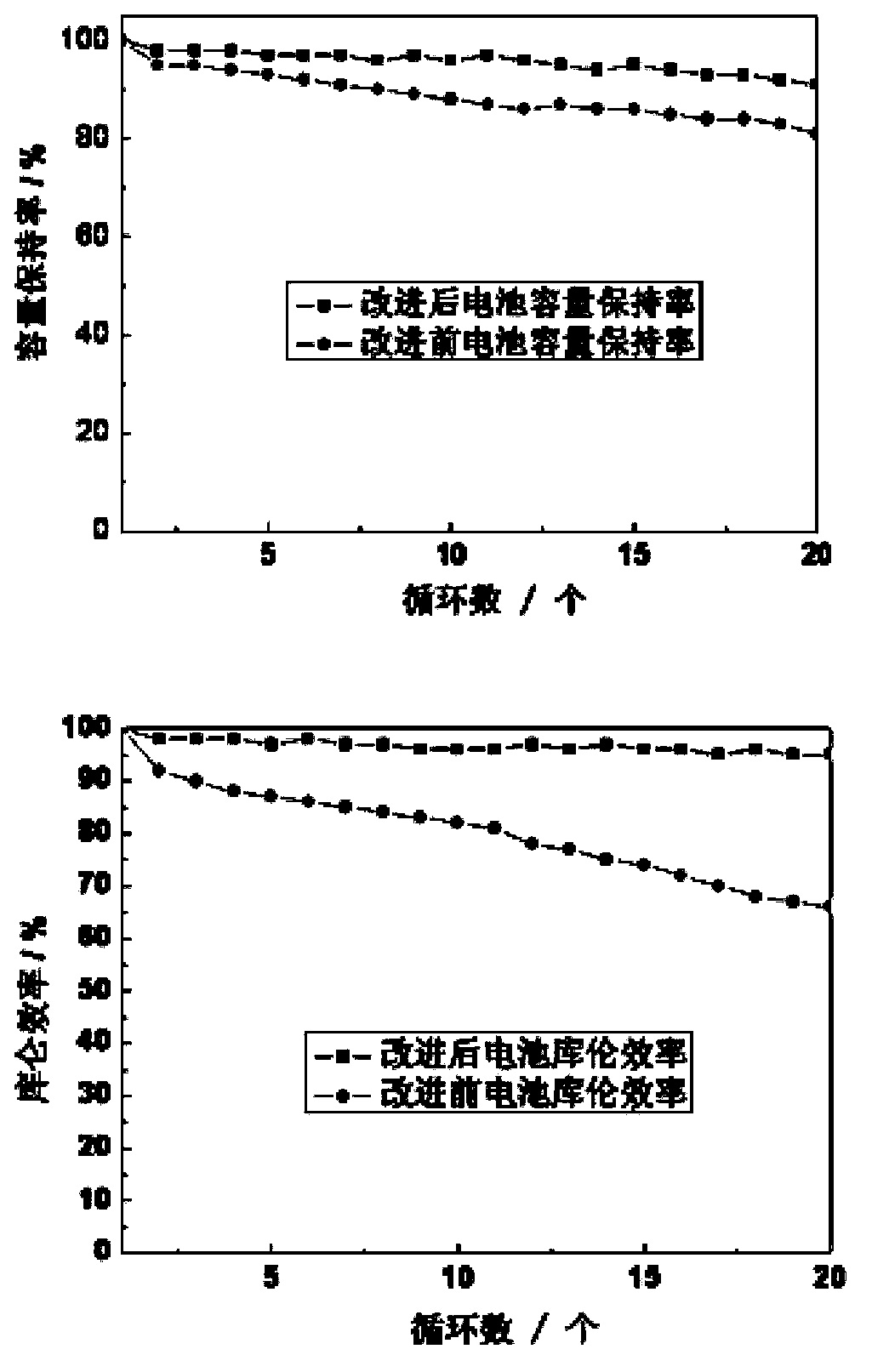

Positive electrode for lithium sulfur battery

ActiveCN104300112AImprove cycle stabilityLow costNon-aqueous electrolyte accumulator electrodesConductive polymer compositeOxide composite

The invention relates to a positive electrode for a lithium sulfur battery. The material of the positive electrode is a one or two or above two of a carbon-sulfur composite material, a sulfur-conductive polymer composite material and a sulfur-metal oxide composite material, and the content of sulfur in the positive electrode material is 10-95%; the positive electrode material also contains nano-gold or / and nano-silver particles; and a ratio of the total addition of the nano-gold or / and silver to the mass of the positive electrode material is 1:(0.01-1). The electronic orbital effect of the nano-gold or / and silver is used to complex polysulfide in order to make products in the discharge process maximally fixed in a positive electrode region, so the self discharge phenomenon caused by the dissolution of the polysulfide is effectively inhibited, thereby the coulomb efficiency and the cycle stability of the lithium sulfur battery are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

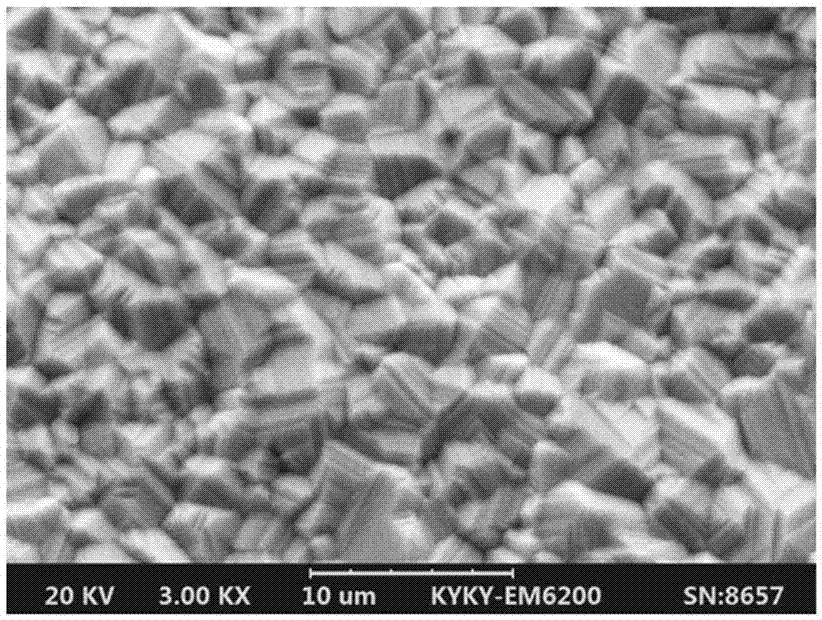

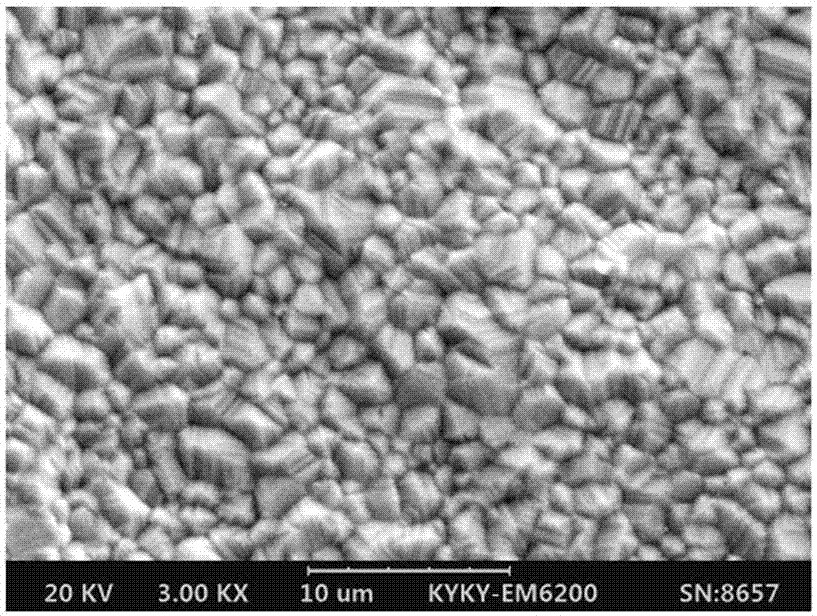

Aluminium alloy trivalent chromium passivation solution as well as preparation method and passivation technology thereof

ActiveCN102912338AStrong complexationAdjust the PH value wellMetallic material coating processesOrganic acidCorrosion

The invention relates to an aluminium alloy trivalent chromium passivation solution as well as a preparation method and a passivation technology thereof. The aluminium alloy trivalent chromium passivation solution mainly contains chromic nitrate, complexing agents and a film forming accelerant, wherein the complexing agents contain a group of organic acid complexing agent and a group of polyhydroxy-alcohol complexing agent. The preparation method thereof comprises the steps of weighing raw materials in proportion, adding right amount of water for dissolution, adding the organic acid complexing agent and the polyhydroxy-alcohol complexing agent, preserving warm for two hours after heating the mixture to be at the temperature of 50-70 DEG C, finally adding the film forming accelerant, stirring and keeping still. The passivation technology comprises oil removing, hot water washing, activation, double washing, passivation, washing, hot water washing and drying. When the aluminium alloy trivalent chromium passivation solution disclosed by the invention is applied to the surface anticorrosive treatment of casting aluminum alloy parts, the corrosion resistance of the aluminium alloy is remarkably improved, the corrosion resistance time is over 480 hours, the price is reduced, and the production cost is significantly reduced.

Owner:翊鹏(湖北)实业有限公司

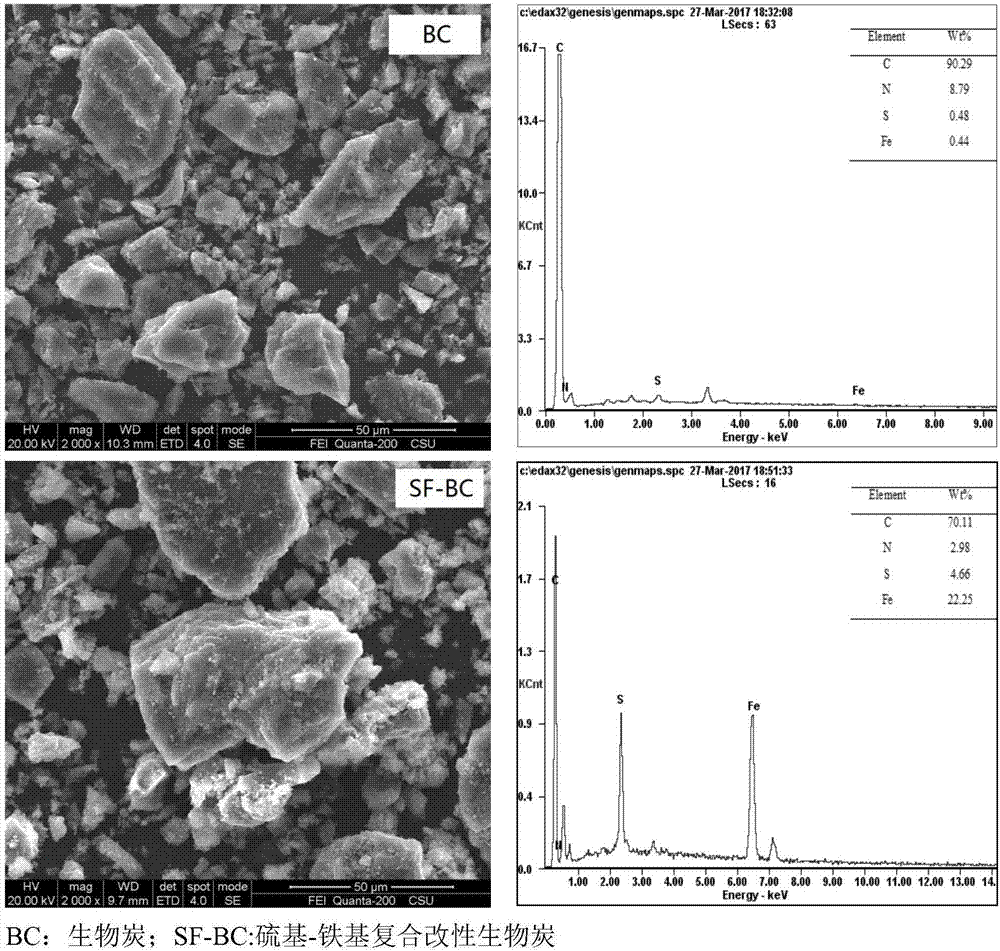

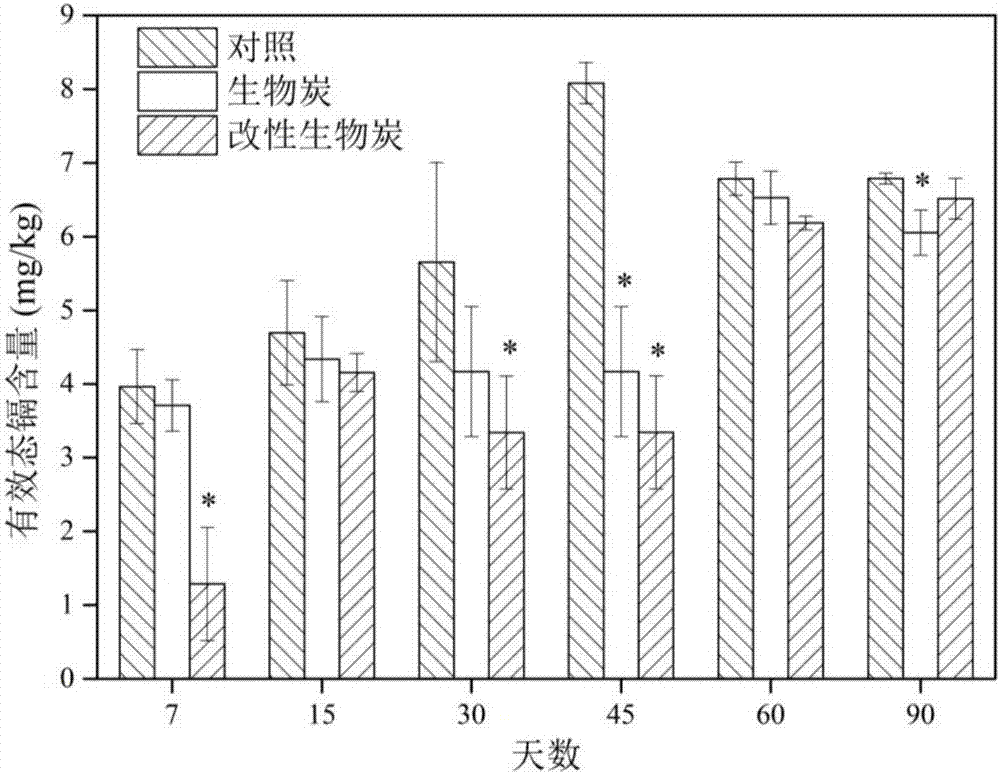

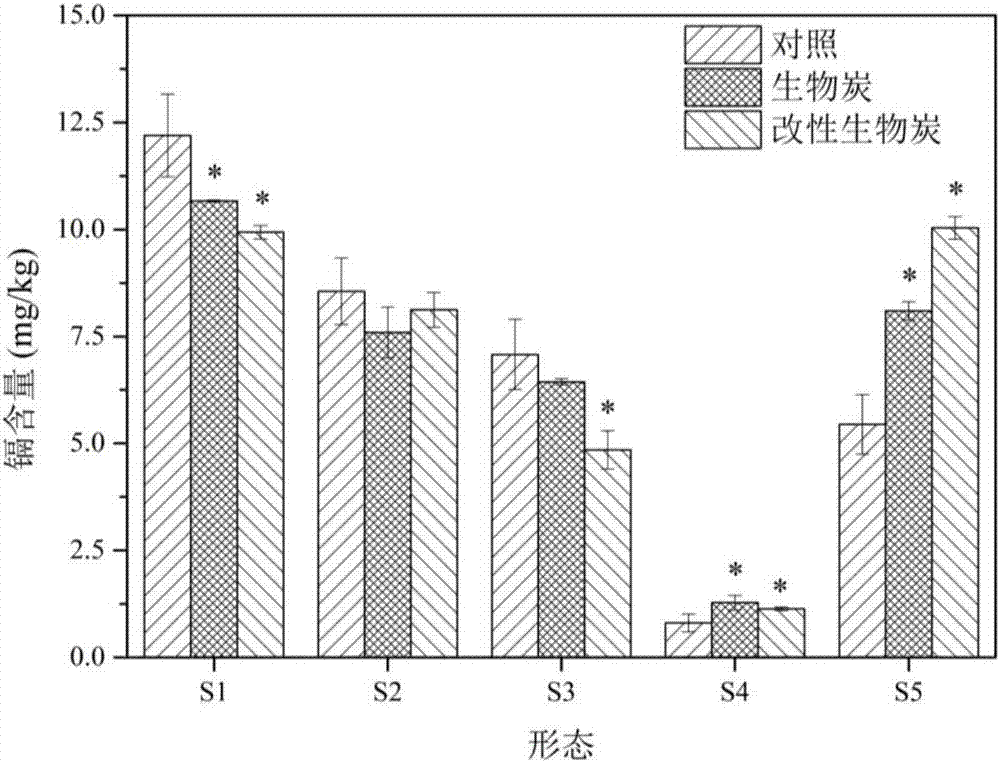

Method for preparing heavy metal cadmium stabilizer sulfenyl-ferrous composite modified charcoal and modified charcoal

ActiveCN107236545ALow priceNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil organic matterCoprecipitation

The invention discloses a method for preparing heavy metal cadmium stabilizer sulfenyl-ferrous composite modified charcoal and sulfenyl-ferrous composite modified charcoal prepared with the method. The method comprises the following steps: (1) preparing charcoal; (2) preparing a sulfenyl modification solution; (3) preparing a sulfenyl charcoal precursor; (4) preparing the sulfenyl-ferrous composite modified charcoal. The sulfenyl-ferrous composite modified charcoal prepared with the method is not only low in price and good in environmental-friendliness, but also simple in preparation process and easy in large-scale production and application; meanwhile, the content of organic matters in soil is remarkably increased, and the soil fertility is improved; relatively good adsorption, complexing and coprecipitation functions on exchangeable cadmium in soil are achieved, and effective cadmium in the soil can be remarkably immobilized.

Owner:CENT SOUTH UNIV

Composite anti-salt agent and applications thereof

ActiveCN107699209AImprove solubilityStrong complexationPipeline systemsDrilling compositionSolubilityFerrocyanide

The invention discloses a composite anti-salt agent, which mainly comprises a ferrocyanide solubilizer A and a complexone B, and can further comprise a polymer lattice modifier C and / or water. According to the present invention, the composite anti-salt agent has a synergistic effect, wherein the ferrocyanide solubilizer A in the composite anti-salt agent can substantially increase the solubility of the salt, and provides the main effect of the composite anti-salt agent, the complexone B in the composite anti-salt agent has good complexation effects on metal ions and can change the metal ion concentration of the salt crystal so as to reduce the solubility product of the salt crystal, and the polymer lattice modifier C can change the compact structure of the salt into the loose structure soas to make the salt be easily carried away by the flowing of the solution. According to the present invention, the composite anti-salt agent can provide excellent salt crystallization prevention effect on salt solutions with highly mineralized sodium chloride, and further can provide good salt release effects on salt solutions with highly mineralized sodium chloride, calcium chloride and magnesiumchloride.

Owner:CHINA PETROLEUM & CHEM CORP +1

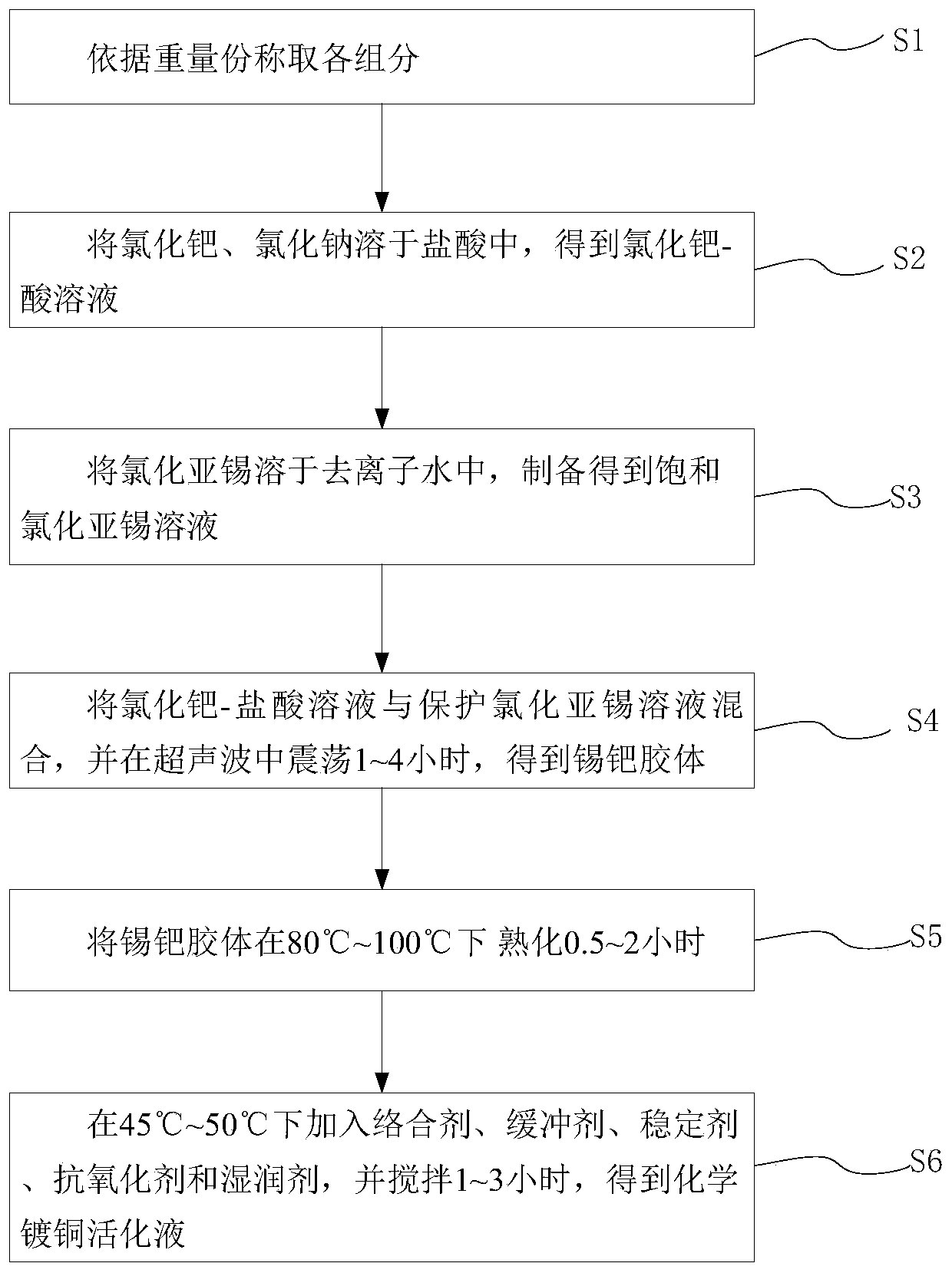

Electroless copper plating activating solution and preparation method thereof

ActiveCN110670050AImprove stabilityStrong complexationLiquid/solution decomposition chemical coatingPropanoic acidDiethylenetriamine

The invention provides an electroless copper plating activating solution and a preparation method thereof. The electroless copper plating activating solution is prepared from, by weight part, 1-10 parts of palladium chloride, 100-400 parts of stannous chloride, 50-200 parts of sodium chloride, 10-100 parts of sodium chloride, 0.1-50 parts of a complexing agent, 1-200 parts of a buffering agent, 0.1-10 parts of a stabilizing agent, 0.05-10 parts of an antioxidant and 0.1-10 parts of a wetting agent. The complexing agent is one or more of ethidene diamine, trimethyl amine, triethylanmine, diethylenetriamine, triethylenetetramine and tetraethylenepentamine. The buffering agent is one or more of ethylenediamine tetraacetic acid, glycine, propionic acid, malic acid and 2-(cyclohexylamino)ethanesulfonic acid. The electroless copper plating activating solution is high in stability and can adapt to intense circulating stirring in a horizontal electroless copper plating process.

Owner:SHENZHEN CYPRESS IND DEV CO LTD

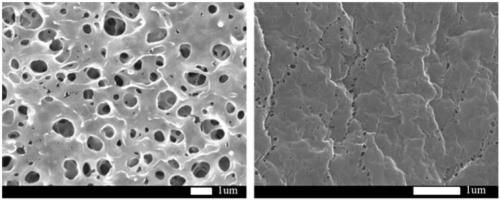

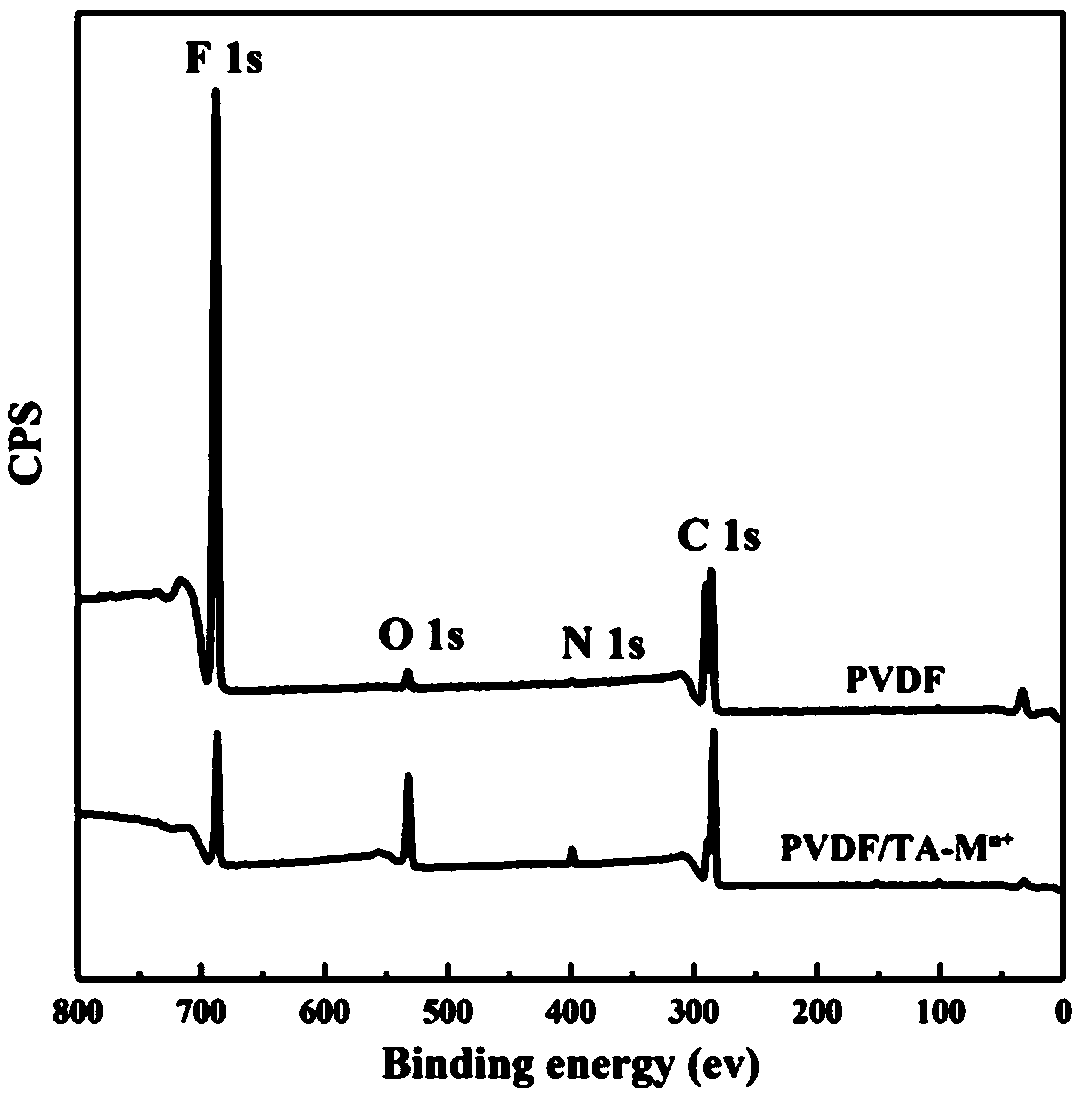

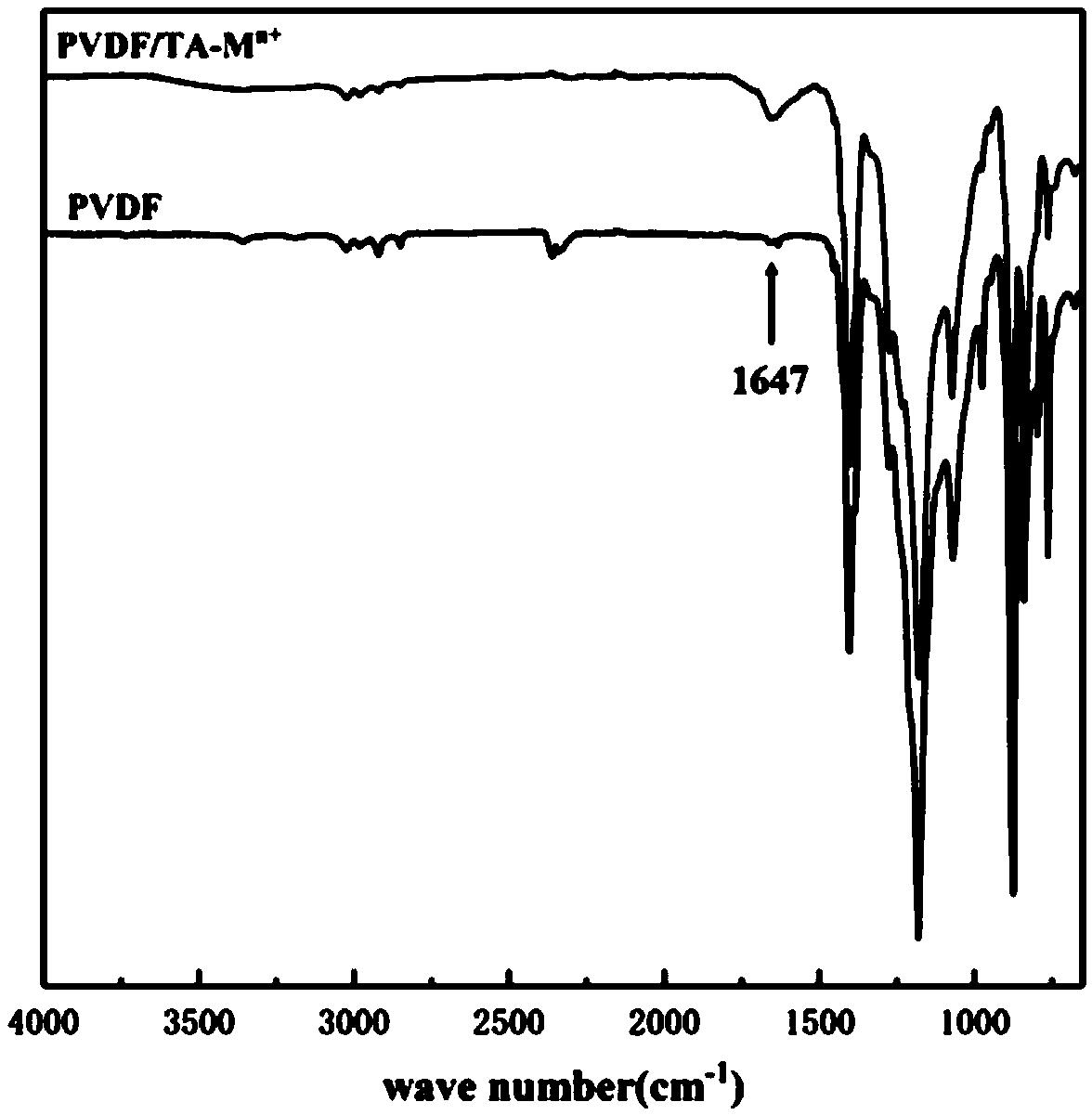

Hydrophilic modification method of high-flux PVDF porous membrane

ActiveCN109621739AHigh throughputGood hydrophilicitySemi-permeable membranesMembranesPorous membraneIon

The invention relates to a hydrophilic modification method of a high-flux PVDF porous membrane. The method comprises the following steps that PVDF powders, tannic acid and PVP are used as raw materials, firstly the PVDF porous membrane is prepared by adopting a phase inversion method, a metal ion solution is used as coagulation bath, by means of the strong complexing capacity of tannic acid with metal ions, a relatively stable molecular chain interpenetrating network structure is formed on the surface of the membrane and inside the membrane, thereby effectively complexing with tannic acid containing a plurality of hydrophilic groups, and the tannic acid has good complexation with PVP, so that more PVP is fixed, and finally a composite hydrophilic channel of tannic acid-PVP-metal ion is formed inside the membrane, so that a PVDF modified membrane with high flux and better hydrophilicity is prepared. The preparation method has the advantages of being wide in raw material source, low in preparation cost and simple in processing technology, and being beneficial for bulk production and marketization application and popularization, and meeting green environmental protection requirements.

Owner:WUHAN UNIV OF TECH

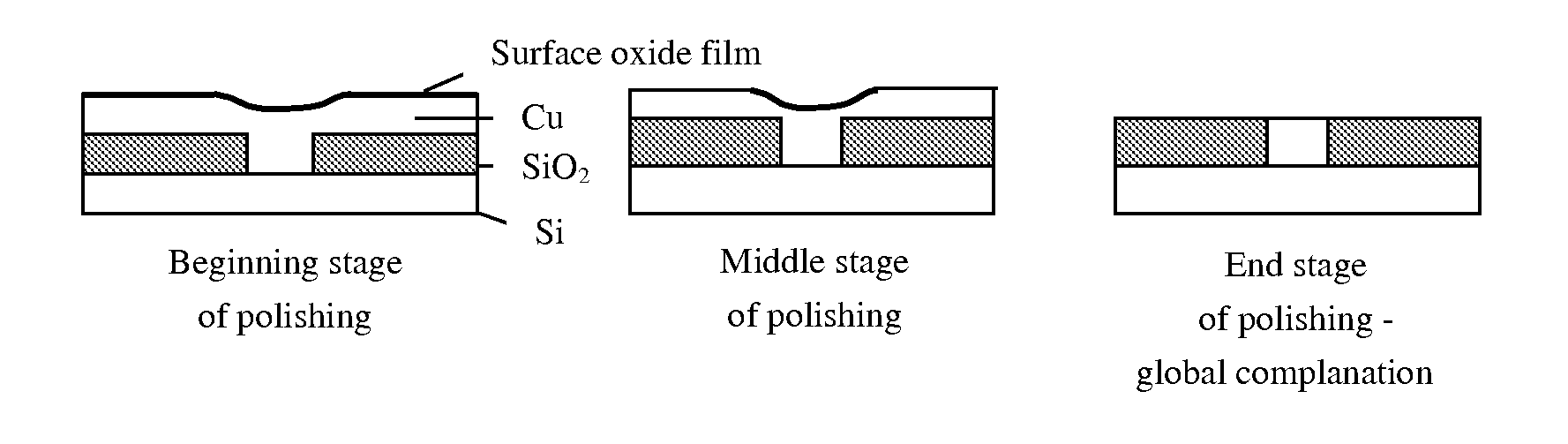

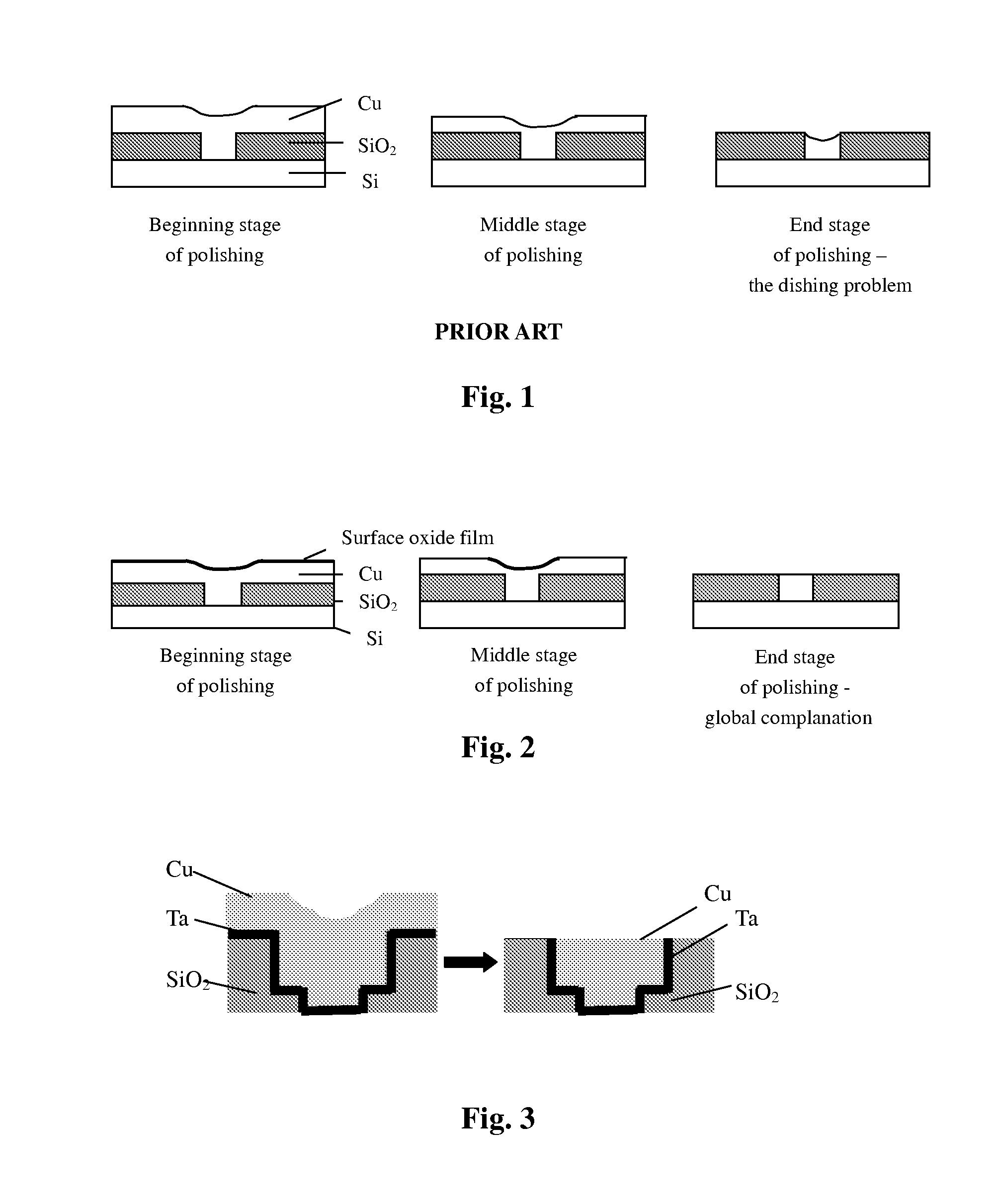

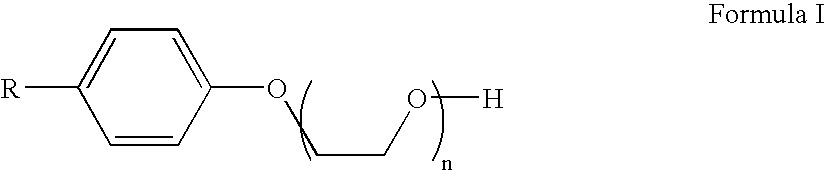

Method for controlling the dishing problem associated with chemical-mechanical planarization (CMP) during manufacture of copper multilayer interconnection structures in ultra large-scale integrated circuits (ULSI)

InactiveUS20080032606A1Good effectStrong complexationOther chemical processesSemiconductor/solid-state device manufacturingVery large scale integrated circuitsSlurry

Provided is a method of chemical-mechanical planarization of copper multilayer interconnection structures and of controlling the dishing problem associated therewith comprising: (a) preparing a slurry by (i) diluting SiO2 hydrosol with deionized water; (ii) admixing a chelating agent and adjusting the pH to between 9.5 to 11.5; and (iii) admixing nonionic surfactant(s) and oxidant(s); (b) applying said slurry to said copper multilayer interconnection structures; and (c) polishing said copper multilayer interconnection structures with polishing pad(s). The flow speed is 200-5000 ml / min, the temperature is 20-40° C., the rotation speed is 60-120 rpm, the pressure is 100-250 g / cm2, and the polishing speed can be 200-1100 nm / min. The process involves 1-5 min for polishing the copper and then 30-60 sec for polishing the copper, the barrier layer, and the dielectric layer. Consistent polishing speeds for the copper, the barrier layer, and the dielectric layer are achieved, which effectively reduces the dishing problem. At the same time, the method reduces the contamination of the surface with metal ions.

Owner:LIU YULING +5

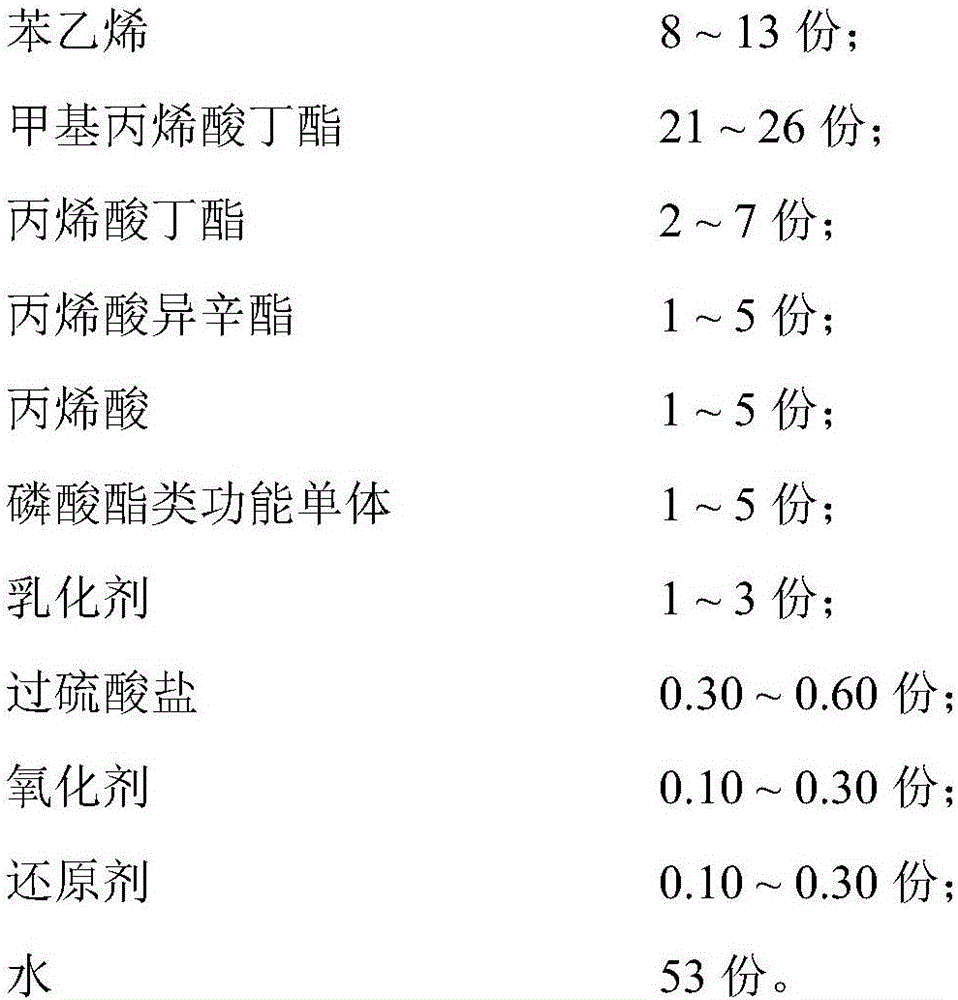

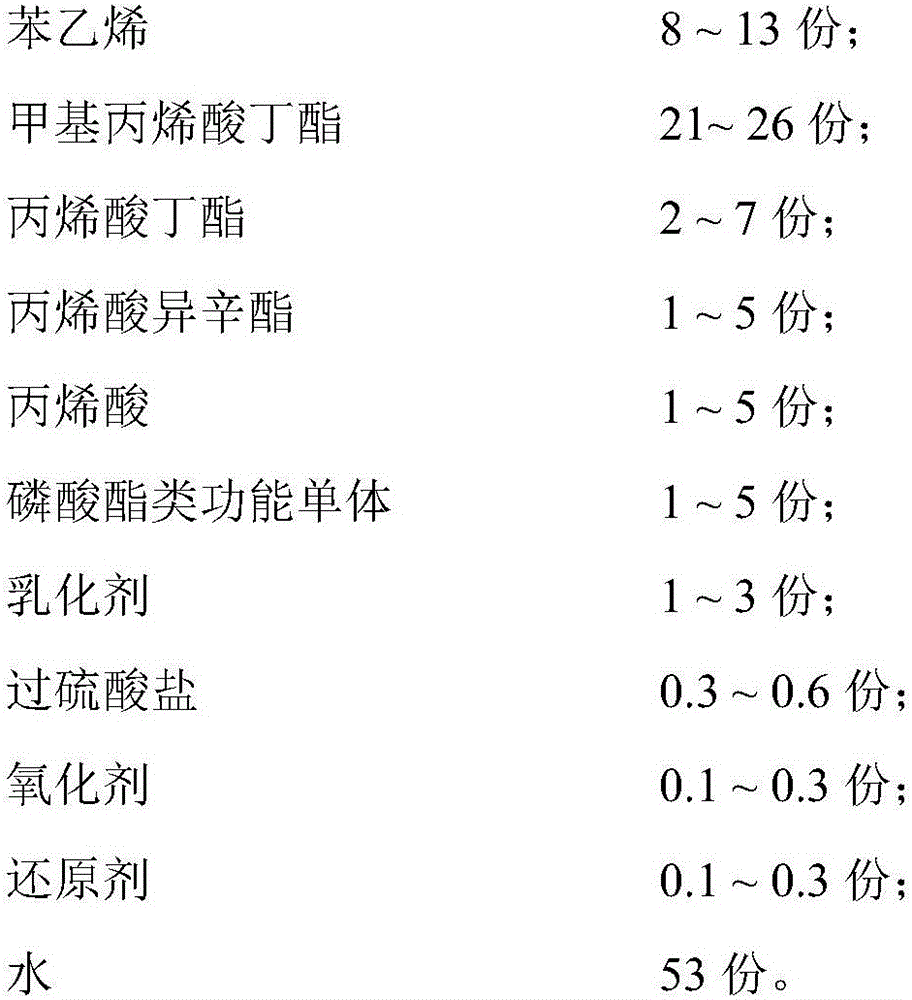

Water-based styrene-acrylic emulsion for primer and topcoat integrated metallic paint and preparation method of water-based styrene-acrylic emulsion

ActiveCN106565893AImprove water resistanceGood resistance to salt waterAnti-corrosive paintsIsooctyl acrylateWater based

The invention discloses water-based styrene-acrylic emulsion for primer and topcoat integrated metallic paint and a preparation method of the water-based styrene-acrylic emulsion. The raw material of the water-based styrene-acrylic emulsion is composed of the following components of, by weight, 8-13 parts of styrene, 21-26 parts of butyl methacrylate, 2-7 parts of butyl acrylate, 1-5 parts of iso-octyl acrylate, 1-5 parts of acrylic acid, 1-3 parts of phosphate ester functional monomers, 1-3 parts of emulgators, 0.3-0.6 part of persulfate, 01-0.3 part of oxidizing agent, 0.10-0.3 part of reducing agent, and 53 parts of water. The phosphate ester functional monomers are grafted into acrylic based emulsion particles through polymerization reaction, so that the prepared metallic paint and metallic ions have good complexation, and a quite compact protective film is formed; meanwhile, a gloss controllable technology is adopted, and not only are the good water resistance, salt water resistance, salt fog resistance and other corrosion resistance ensured, but also the good glossiness and hardness are achieved. The paint is directly sprayed or brushed on the surface of metal after being prepared, a compact, flat and smooth paint film is formed, and the water-based styrene-acrylic emulsion for the metallic paint combined with the performance requirements of primer and topcoat is obtained.

Owner:成都巴德富科技有限公司

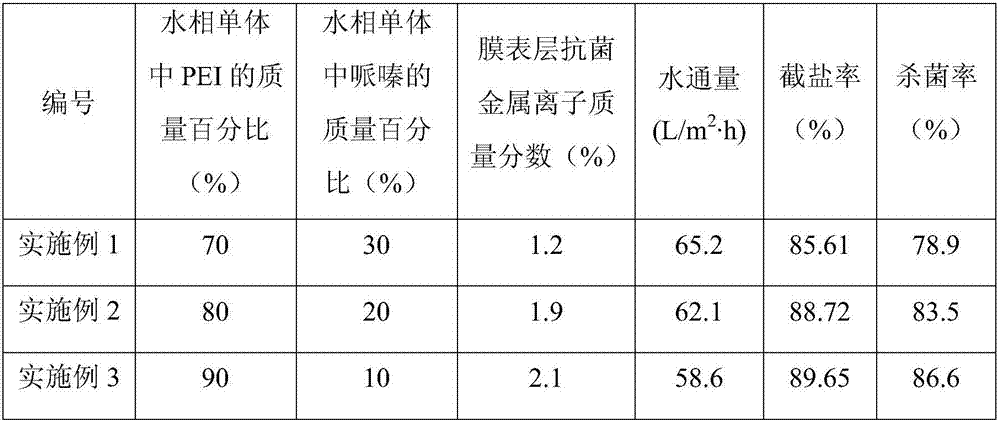

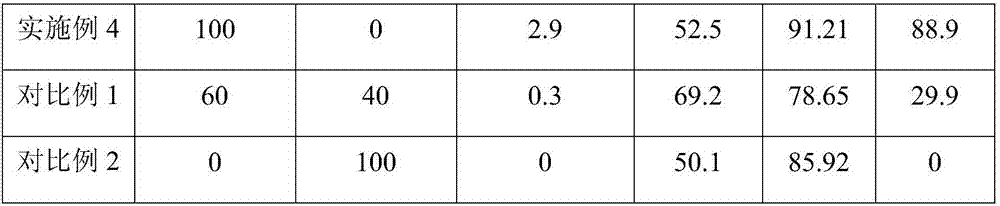

Antibacterial composite nanofiltration membrane and preparation method thereof

ActiveCN107983158AImprove antibacterial propertiesExtended service lifeMembranesSemi-permeable membranesSurface layerMicrobial pollution

The invention provides an antibacterial composite nanofiltration membrane. The antibacterial composite nanofiltration membrane comprises a porous support membrane bottom layer and an antibacterial surface layer complexed with antibacterial metal ions on the surface. The preparation method of the antibacterial composite nanofiltration membrane comprises the steps as follows: the bottom layer is impregnated with an aqueous phase solution containing aqueous phase monomers, and a bottom layer coated with the aqueous phase monomers is obtained; the bottom layer coated with the aqueous phase monomers is impregnated with an oil phase solution containing oil phase monomers, and a bottom layer coated with the aqueous phase monomers and the oil phase monomers is obtained; the bottom layer coated with the aqueous phase monomers and the oil phase monomers is subjected to thermal treatment, and a composite nanofiltration membrane with a polyamide functional layer is prepared; the composite nanofiltration membrane is impregnated with a metal salt solution containing antibacterial metal ions and the antibacterial composite nanofiltration membrane is obtained, wherein the aqueous phase monomers comprise polyethyleneimine. The antibacterial performance, particularly the microbial pollution resistance, of the antibacterial composite nanofiltration membrane is improved while the high permeabilityis kept; the antibacterial composite nanofiltration membrane has lasting antibacterial performance, long service life and good application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

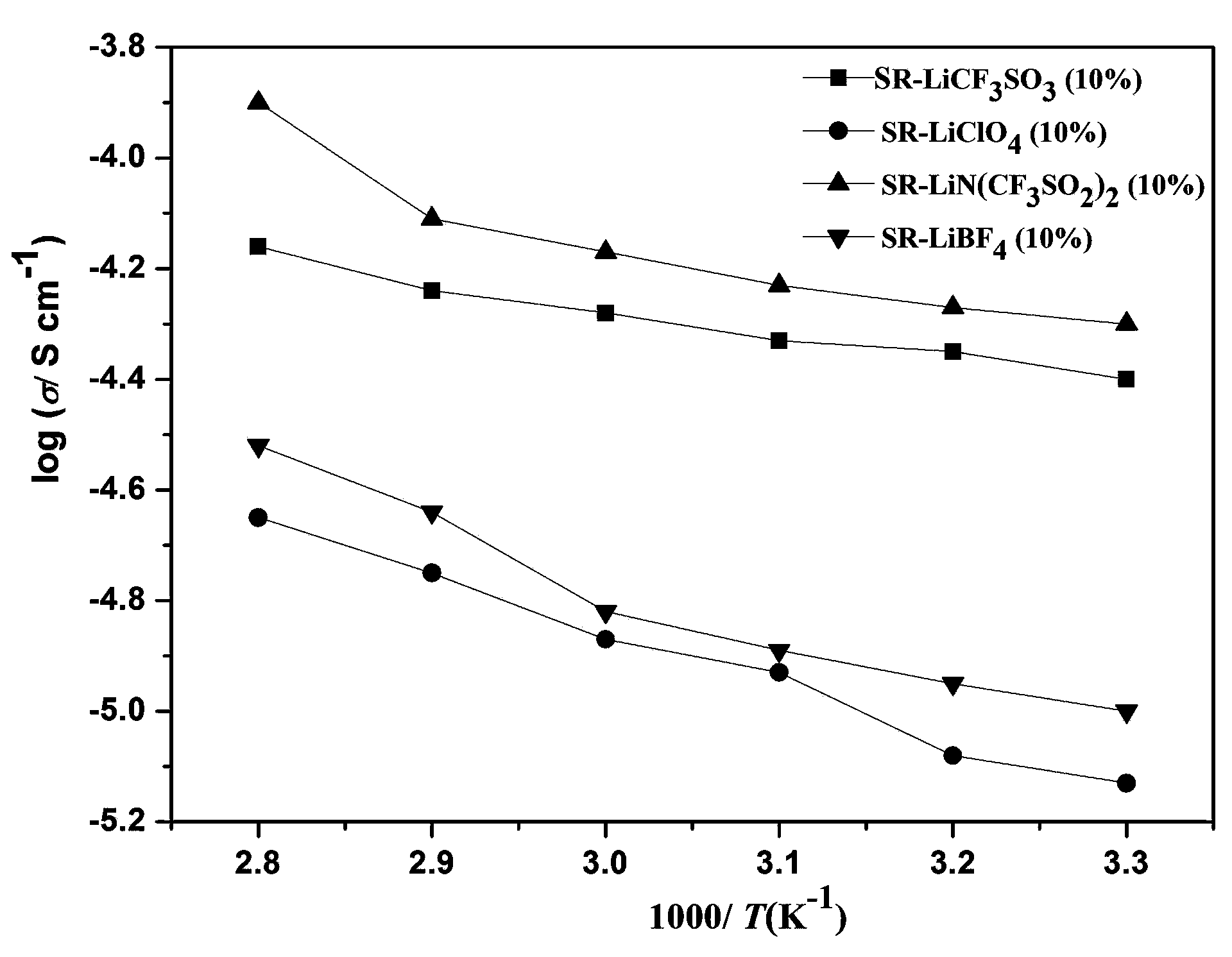

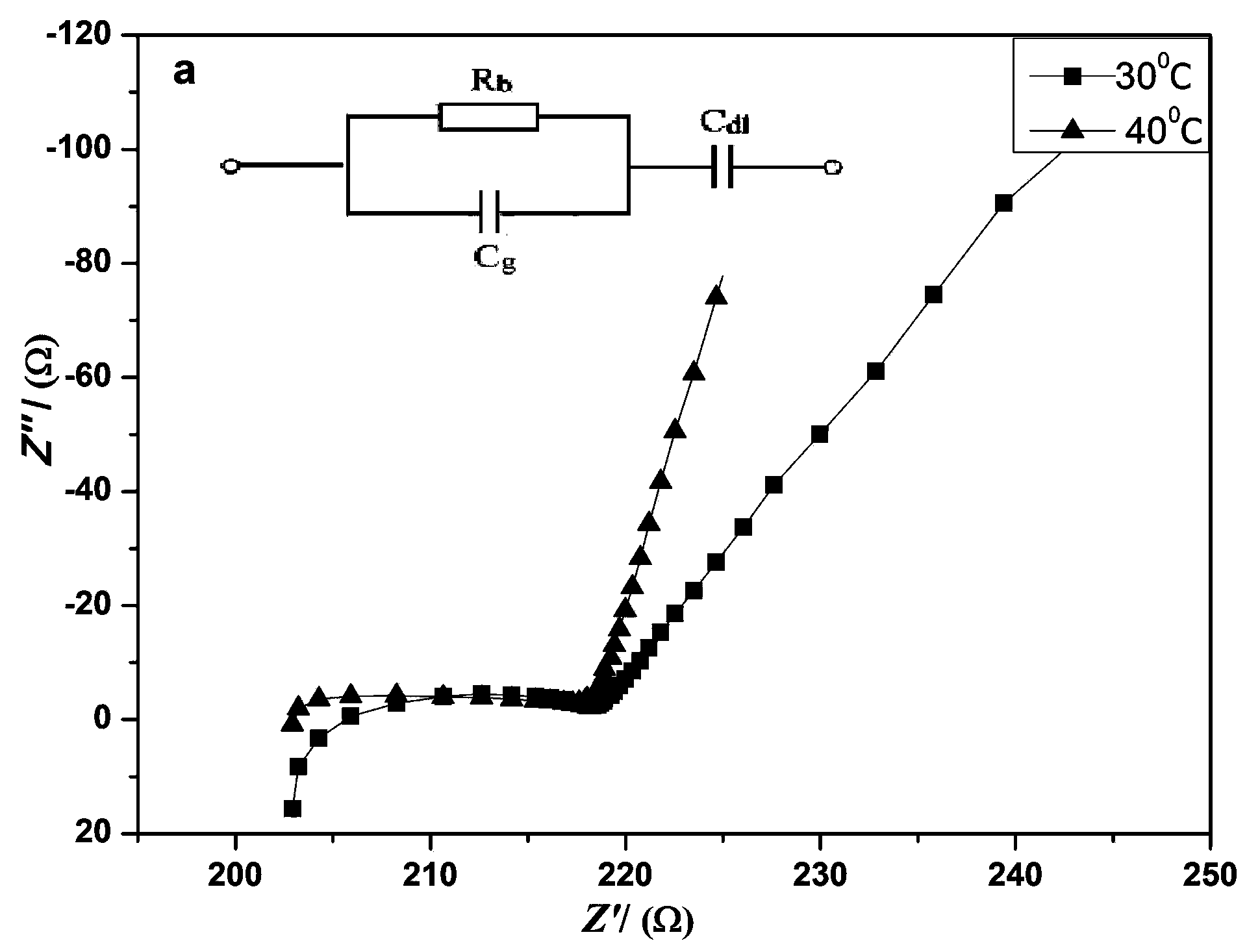

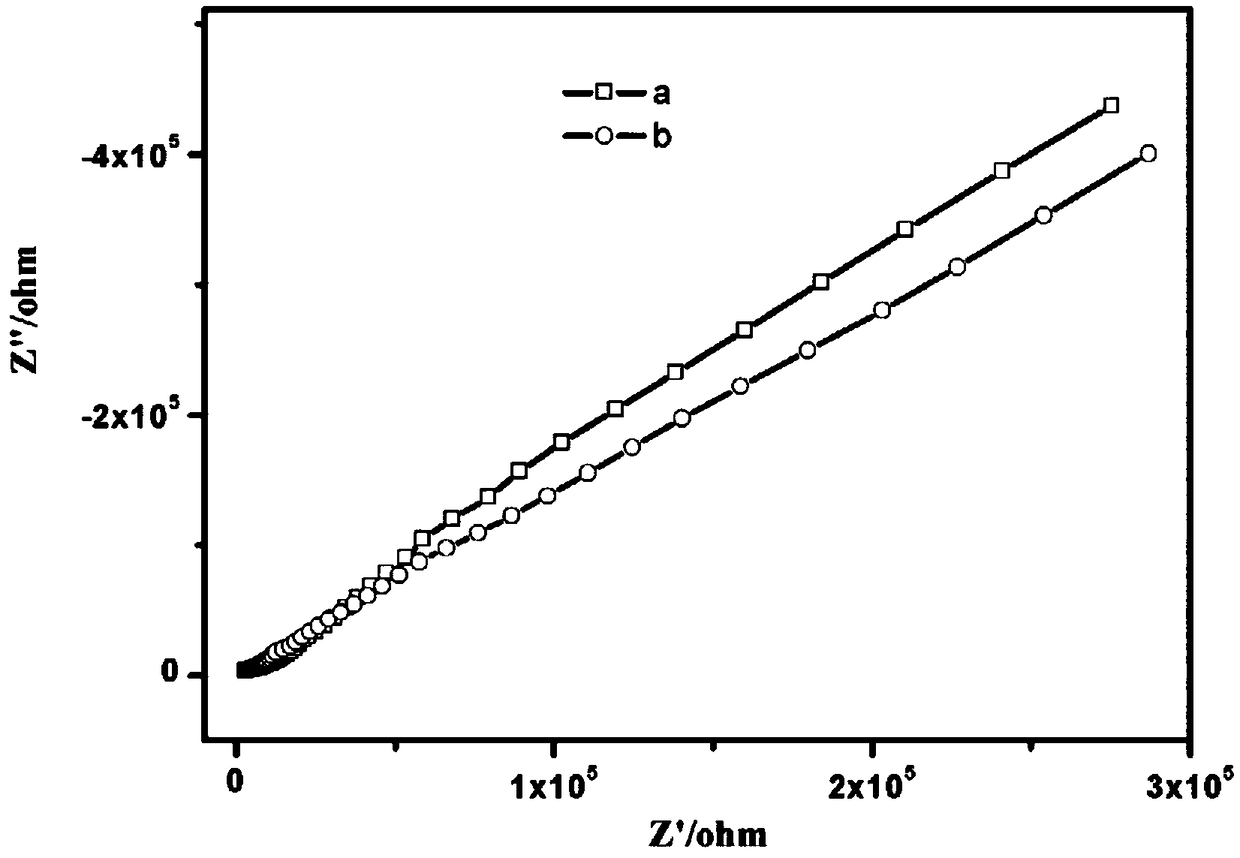

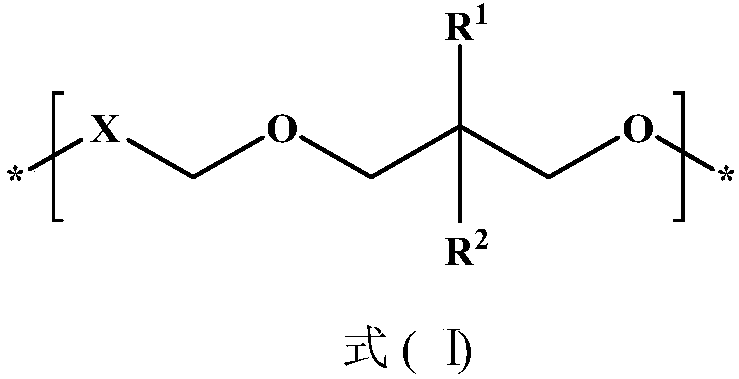

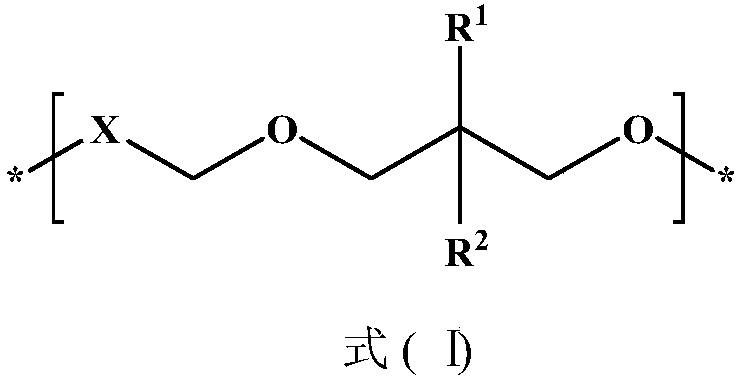

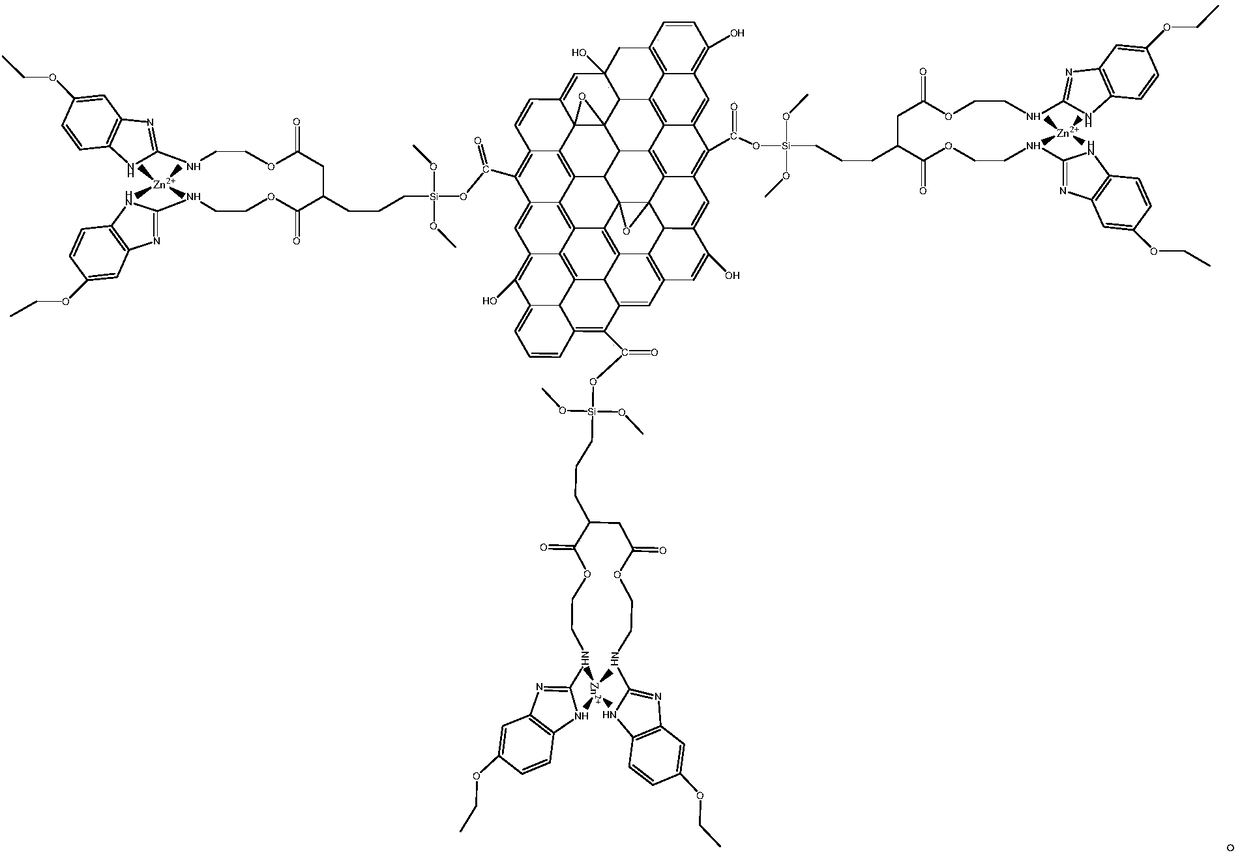

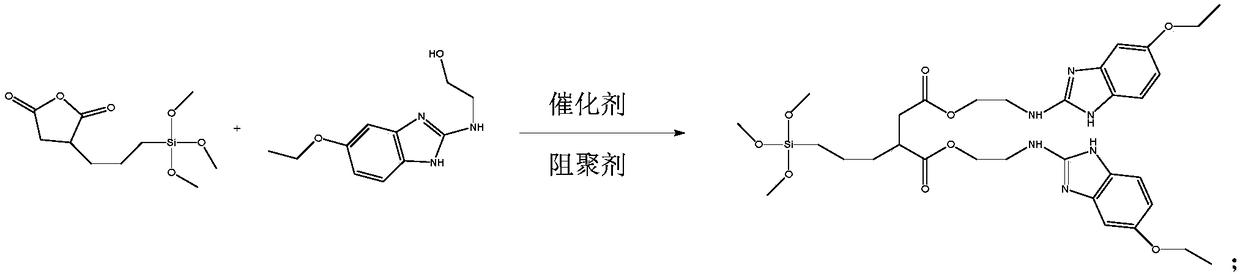

Alkyd resin modified polymer electrolyte as well as preparation method and application thereof

ActiveCN109401693AImprove flexibilityHigh mechanical strengthNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolymer science

The invention relates to an alkyd resin modified polymer electrolyte as well as a preparation method and application thereof. The preparation method comprises the following steps that alkyd resin andone or more monomers of acrylamide, methacrylamide, acrylonitrile, methyl acrylate, methyl methacrylate and monofunctional or polyfunctional polyethylene glycol acrylate / polyethylene glycol methacrylate are subjected to copolymerization in an organic solvent under the action of an initiator, then an electrolyte body, a plasticizer and ionic non-conductive or ionic conductive inorganic nano-particles or nano-fibers are added into a copolymer, and uniform mixing is carried out so as to obtain the alkyd resin modified polymer electrolyte; or the alkyd resin and an ionic conductive polymer are dissolved in the organic solvent, the electrolyte body, the plasticizer and the ionic non-conductive or ionic conductive inorganic nano-particles or the nano-fibers are added to perform blending, and uniform mixing is carried out so as to obtain the alkyd resin modified polymer electrolyte. The invention provides the novel high-performance polymer electrolyte and the preparation method thereof.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

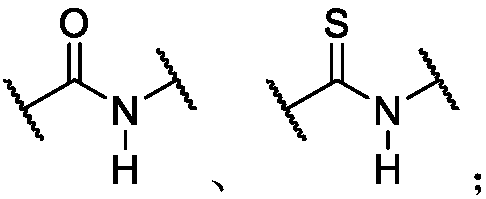

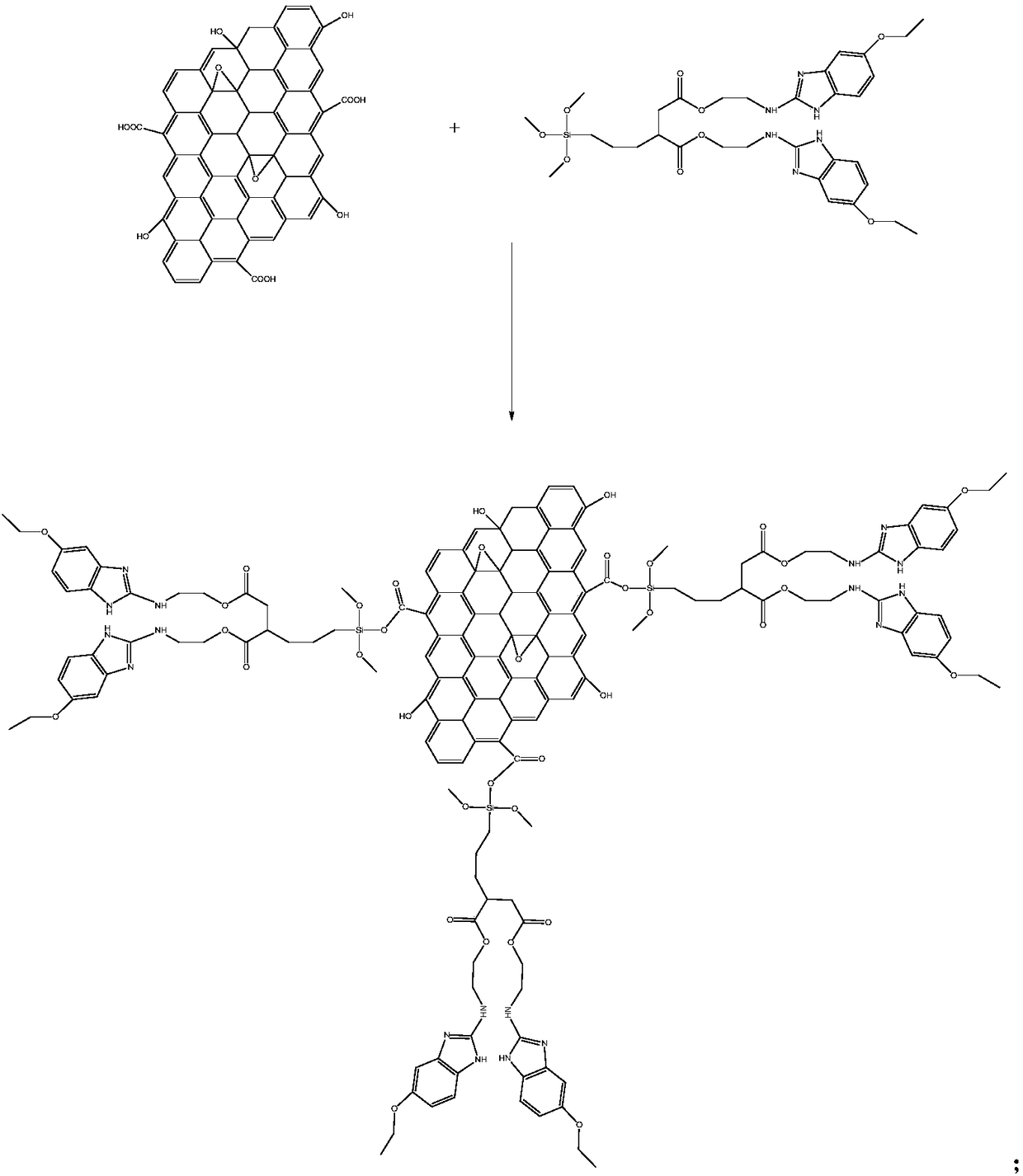

Hybrid crosslinked dynamic polymer

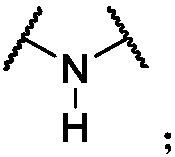

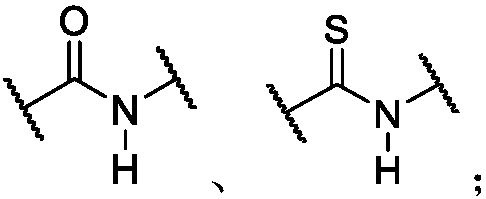

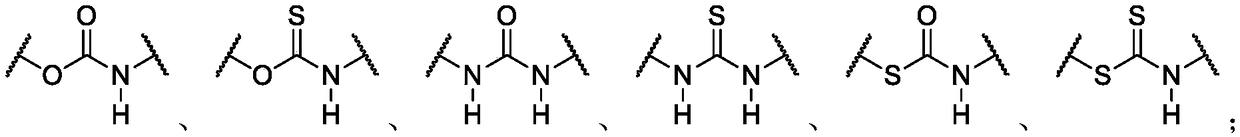

InactiveCN109206576ASimple structureImprove performanceEster polymer adhesivesIonCation–pi interaction

The invention relates to a hybrid crosslinked dynamic polymer, which contains host-guest interaction, covalent bond formed covalent crosslinking and optional other supramolecular interactions. Specifically, covalent crosslinking reaches the gel point of covalent crosslinking or above in at least one crosslinked network, and the other supramolecular interactions are at least selected from ion interaction, metallophilic interaction, dipole-dipole interaction, hydrogen bond interaction, cation-pi interaction, anion-pi interaction, benzene-fluorobenzene interaction, pi-pi stacking interaction, ionhydrogen bond interaction, hydrogen bond interaction, metal-ligand interaction, and radical cation dimerization. As host-guest interaction has the advantages of molecular recognition, stable action effect and the like, the dynamic polymer has self-repairability and good toughness, and covalent crosslinking endows the polymer with certain strength and stability. The dynamic polymer can be used formaking self-repair materials, sealing materials, tough materials, adhesives, shape memory materials and force sensor materials.

Owner:厦门天策材料科技有限公司

Preparation method of electromagnetic shielding fabric

InactiveCN104695212ALow costNo pollution in the processPhysical treatmentLiquid/solution decomposition chemical coatingChemical platingEngineering

The invention discloses a preparation method of an electromagnetic shielding fabric. The preparation method comprises the following specific operation steps: roughening; sensitizing; activating; performing chemical plating; cleaning; drying. The preparation method is easy and feasible, no pollution is caused in the preparation process, the preparation cost is low, and the prepared electromagnetic shielding fabric has the advantages of light weight, durability, wide shielding frequency, good comprehensive performance and the like.

Owner:SUZHOU CHENHENG WEAVING

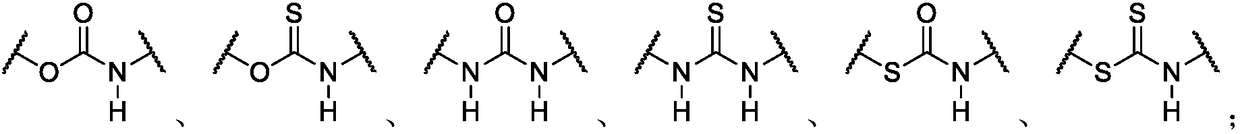

Multistage countercurrent reaction integration technology and device for synchronous removal of a plurality of heavy metal ions

ActiveCN104326595AHigh reducing activityQuick responseWater treatment compoundsWater contaminantsWastewaterHeavy metals

The invention relates to an integration technology for synchronous removal of a plurality of heavy metal ions by use of structure state iron; pretreated heavy metal wastewater is introduced into a structure state iron-vertical multistage reaction system, the suitable reactor stage is adopted according to properties of the wastewater and kinds and concentrations of heavy metals in the wastewater; a medicament and the wastewater are fully contacted and mixed for reaction in a mixing reaction pool in the manner of countercurrent mixing, then the solution enters into a sedimentation tank of a reactor of the stage to achieve solid-liquid separation; after separation, the supernatant is detected, until the supernatant achieves discharge standard, the effluent is discharged; if the effluent does not achieve the discharge standard, the effluent continues to enter into a reactor of next stage for repeated wastewater treatment, until the effluent achieves the discharge standard; the medicament is the structure state iron. The structure state iron-vertical multistage reaction system includes a rapid mixing pool, a slow mixing pool, a pretreatment sedimentation tank and a multistage pretreatment reactor, has the advantages of simple operation, capability of continuously performing multi-stage reaction, small occupation area, high treatment efficiency, and short reaction time, can simultaneously remove the heavy metals, reduces the application cost, and has promotion and application prospect.

Owner:TONGJI UNIV

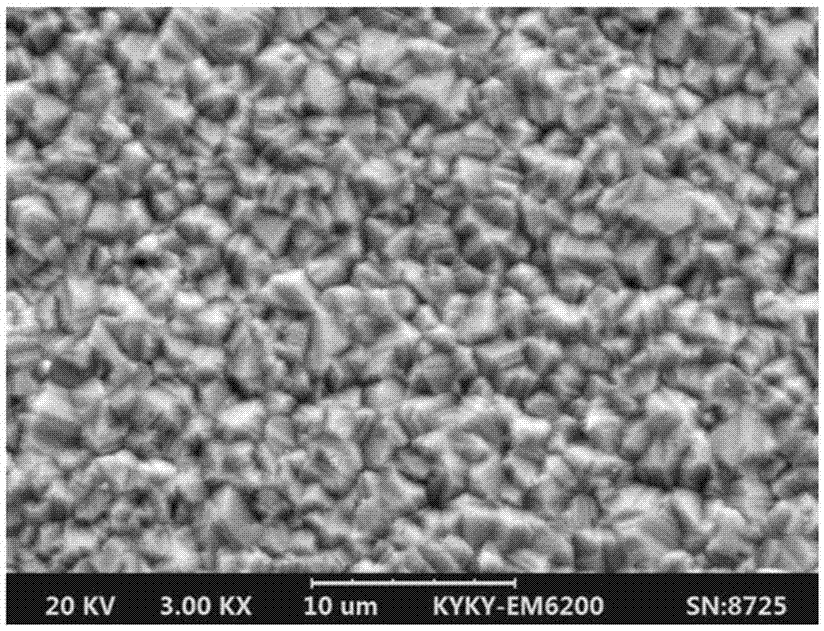

Electroless tin plating formula for printed circuit board

ActiveCN106939417AComplexation effectiveStrong complexationLiquid/solution decomposition chemical coatingThioureaTin plating

The invention discloses an electroless tin plating formula for a printed circuit board. The formula comprises the following components with the following concentrations: 10-30g / L of stannous ions, 70-130g / L of thiourea, 30-70g / L of methanesulfonic acid, 30-60g / L of citric acid, 20-50g / L of tetrasodium iminodisuccinate, 10-30g / L of carbohydrazide, 10-50mg / L of interfacial agent, 0.05-0.15g / L of bismuth acetate and 20-40g / L of polyamino polyether methylene phosphonate, wherein the component solutions are uniformly mixed and then prepared into an electroless tin plating solution; and the electroless tin plating solution has the following characteristics: tin is stable in tin deposition rate, bivalent tin is not liable to be oxidized into tetravalent tin, and the solution is high in stability. The formula disclosed by the invention contains many complexing agents, the stannous ions are not liable to be oxidized into tetravalent tin, the oxidization of oxygen dissolved in the plating solution can be cancelled by virtue of a reducing agent, the plating solution contains bismuth acetate, a plating layer is a tin-bismuth alloy, and the alloyed plating layer is not liable to grow tin whiskers; and moreover, the electroless tin plating solution has the following characteristics: tin is stable in tin deposition rate, bivalent tin is not liable to be oxidized into tetravalent tin, and the solution is high in stability.

Owner:SHENZHEN CHENGGONG CHEM

Metal substrate long-lasting anticorrosive inter-coat and preparation method thereof

ActiveCN108997916AHigh mechanical strengthImprove dispersion uniformityAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention belongs to the technical field of anticorrosive coating, and in particular, relates to a metal substrate long-lasting anticorrosive inter-coat and a preparation method thereof, wherein the inter-coat is composed of a component A and a component B, and the component A is composed of the following raw materials in parts by weight: 50-60 parts of an epoxy-organosilicone resin modified acrylic resin emulsion, 12-18 parts of functionalized modified graphene, 10-20 parts of a filler, 8-15 parts of a cosolvent, 0.1-0.5 part of a defoamer, 0.5-1 part of a leveling agent, 0.3-0.8 part ofa water-based drier, 0.3-0.8 part of a thickener, 0.5-1 part of a wetting agent, and 30-35 parts of deionized water; the component B is composed of the components in parts by weight: 40-50 parts of anisocyanate curing agent, and 10-20 parts of a cosolvent. The inter-coat has the advantages of long-term excellent anticorrosive performance, strong adhesion force of the substrate, high mechanical strength, excellent friction resistance, excellent salt spray resistance, good water resistance, chemical resistance, oil resistance and impact resistance, high construction adaptability and the like.

Owner:惠州市湾厦表面处理技术有限公司

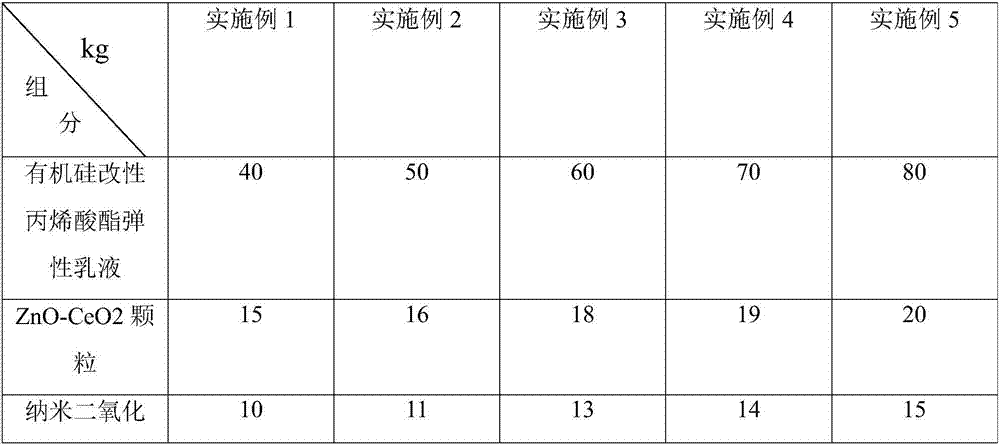

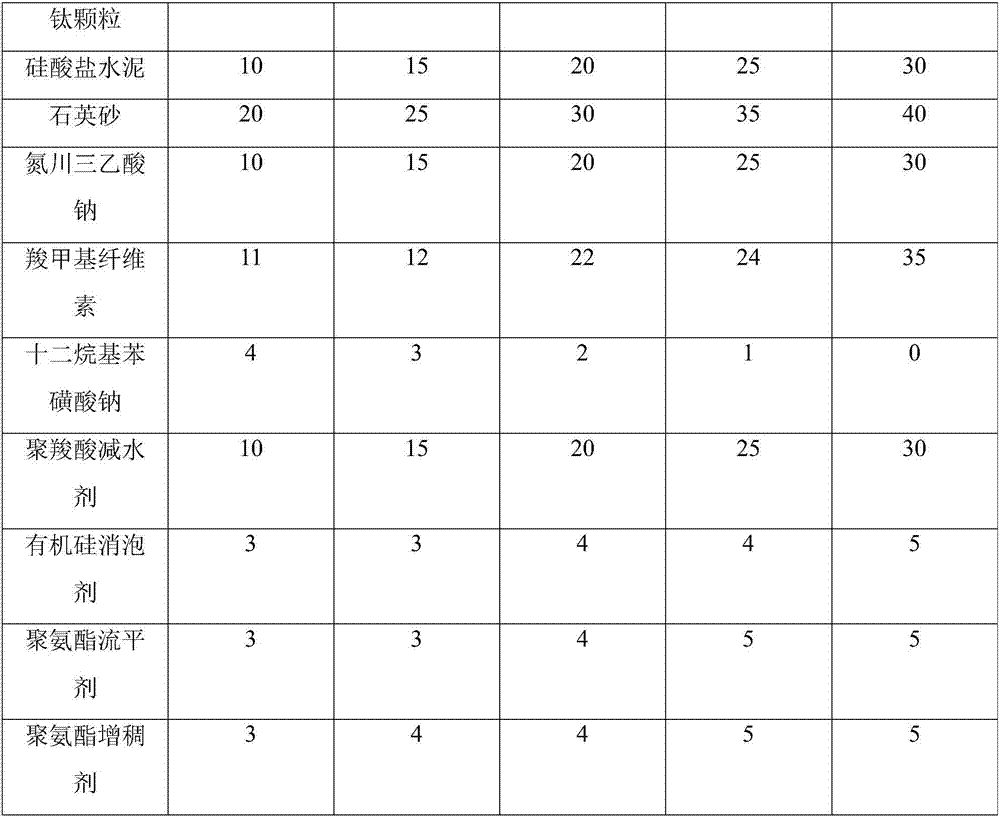

Waterproof crack-resisting coating and preparation method thereof

InactiveCN107987647AHigh elongationResponsiveAntifouling/underwater paintsPaints with biocidesCelluloseCrack resistance

The invention discloses a waterproof crack-resisting coating and a preparation method thereof, and relates to the field of coating materials. The waterproof crack-resisting coating is prepared from the following components in parts by weight: 40 to 80 parts of elastic emulsion, 15 to 20 parts of ZnO-CeO2 particles, 10 to 30 parts of Portland cement, 20 to 40 parts of quartz sand, 10 to 30 parts ofcomplexing agent, 10 to 30 parts of cellulose, 10 to 30 parts of water reducing agent, 3 to 5 parts of defoaming agent, 3 to 5 parts of dispersing agent, 3 to 5 parts of leveling agent and 3 to 5 parts of thickening agent. The waterproof crack-resisting coating provided by the invention has the advantages of excellent waterproof and crack resistance, scrubbing resistance, pulverization resistance, stain resistance, weather fastness, good aging resistance, storage stability, low cost, greenness and environment friendliness.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Dynamic crosslinked polymer containing combination supramolecular interaction

PendingCN109422836AStrong complexationAdaptableEster polymer adhesivesPharmaceutical non-active ingredientsRestorative materialCrosslinked polymers

A dynamic crosslinked polymer containing a combination supramolecular interaction is disclosed. The polymer contains at least two supramolecular interactions and the degree of crosslinking of at leastone of the supramolecular interactions is above its crosslinked gel point, wherein at least one of the supramolecular interactions is a subject-object interaction, and the dynamic crosslinked polymercan prepare polymer materials with strong reversibility, rich structure and various properties through introduction of the supramolecular interactions with different dynamicity. The difference between different kinds of supramolecular interactions in the dynamic crosslinked polymer makes the polymer exhibit a hierarchical dynamic reversible effect; and the dynamic crosslinked polymer can be usedas a self-repair material, a toughness material, a sealing material, a force transducer material, and the like, thereby being widely applied.

Owner:厦门天策材料科技有限公司

Nutritive xanthohumic acid solution for soilless cultivation and its preparing process

InactiveCN1381429AStrong complexationImprove solubilityAgriculture gas emission reductionCultivating equipmentsRoot systemChemistry

A nutritive Xanthohumic acid solution for soilless cultivation its prepared from water (67-80 wt.%), ash (6-15), active xanthohumic acid (2-8) and nutritive elements through heating active xanthohumic acid to 40-80 deg.c, adding the precursors of N, P, K, Fe, Mn, Cu, Zn, Mo and B and water, reaction at 40-80 deg.C for 0.5-2 hr, and cooling to obtain the product. It can increase the resistance of plant to drought, cold and disease, and decrease the poisoning of nitrite or vegetables.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Veterinary medicine composition for preventing and treating mycotoxin pathopoiesia

InactiveCN102716214AEliminate damageEnhance detoxification abilityAntimycoticsInanimate material medical ingredientsAdditive ingredientGLYCYRRHIZA EXTRACT

The invention relates to a veterinary medicine composition for preventing and treating mycotoxin pathopoiesia. The veterinary medicine composition is prepared from the follow ingredients in parts by weight: 5 to 25 parts of mildew preventive, 5 to 25 parts of sodium humate, 5 to 25 parts of montmorillonite, 5 to 25 parts of rheum officinale, 5 to 25 parts of scutellaria baicalensis, 5 to 25 parts of coptis chinensis, 5 to 15 parts of liquorice and 5 to 25 parts of radix isatidis. The veterinary medicine composition has the advantages that the specific adsorption capacity is realized, various mycotoxins can be directionally and effectively eliminated, the veterinary medicine composition effectively aims at zearalenone, vomitoxin, aflatoxin, ochratoxin, fumitremorgin, T-2 toxin and the like, the detoxification capability of the liver per se on the toxin can be improved, and the toxin injury to animal bodies is eliminated.

Owner:河南中亚神鹏医药科技有限公司

Leather cleaning agent

InactiveCN101012412ABright and stable colorDo not cause harmNon-ionic surface-active compoundsOrganic detergent compounding agentsGleditsia triacanthosCleansing Agents

The invention discloses an environment-protective leather abluent, which comprises the following parts: 90-97.5% Chinese honey locust and peppertree extract liquid, 1-5% acetate triethanolamine, 1-3% carbowax 6000 and 0.5-2% pingpingjia. The invention makes color fresh on the leather, which protects leather effectively.

Owner:TAIYUAN NORMAL UNIV

Novel reverse-osmosis scale inhibitor

ActiveCN104906961AHigh anti-scaling efficiencyReduce dosageSemi-permeable membranesScale removal and water softeningHexamethylenetetramineRoom temperature

The invention discloses a novel reverse-osmosis scale inhibitor which comprises the following raw materials in parts by weight: 2-8 parts of sodium citrate, 33-45 parts of hydrolytic polymaleic anhydride, 28-37 parts of polyepoxysuccinic acid salt, 9-15 parts of urotropine, 13-20 parts of polylactic acid, and 40-50 parts of water. A preparation method comprises the following steps: adding sodium citrate, hydrolytic polymaleic anhydride, polyepoxysuccinic acid salt, urotropine and half of water into a reaction kettle, heating to 40-50 DEG C, and stirring for uniformly dissolving; dissolving polylactic acid with the rest water to obtain a polylactic acid solution; heating the materials in the reaction kettle to 70-75 DEG C, dropwise adding the polylactic acid solution, and keeping the temperature for 3-4h after the dropwise adding is finished; and cooling to room temperature so as to obtain the novel reverse-osmosis scale inhibitor. The novel reverse-osmosis scale inhibitor disclosed by the invention has the scale inhibition rate being up to 95%, is small in adding amount, environmentally friendly, stable in property, and long in storage period, and can be used for solving the problems that existing reverse-osmosis inhibitors mainly are foreign products and are limited in treatment capacity, complex in synthesis, relatively high in production cost, and the like in the prior art.

Owner:浙江川宁环保科技有限公司

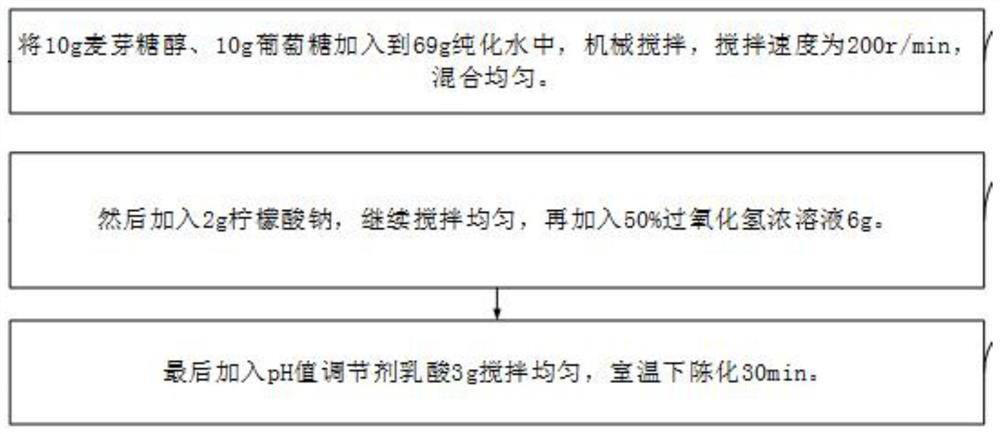

Hydrogen peroxide disinfectant and preparation method thereof

InactiveCN111838174AImprove stabilityReduce decompositionBiocideDisinfectantsPhysical chemistryH2O2 - Hydrogen peroxide

The invention provides a hydrogen peroxide disinfectant and a preparation method thereof, and belongs to the technical field of disinfectants. The hydrogen peroxide disinfectant provided by the invention comprises 10-30 wt% of a photo-thermal stabilizer, 1-5 wt% of a metal ion chelating agent, 3-8 wt% of a pH value regulator, 2.5-3.5 wt% of hydrogen peroxide and the balance of water, the metal ionchelating agent can complex metal ions in the solution, reduces the decomposition effect of the metal ions on the hydrogen peroxide, and still has excellent complexing ability under acidic conditions; the photo-thermal stabilizer can reduce decomposition of the hydrogen peroxide by light and heat, so that the hydrogen peroxide disinfectant shows better stability under higher temperature and illumination; the pH value regulator is used for regulating the pH value of the system, the stability of the hydrogen peroxide disinfectant is further improved, and after the hydrogen peroxide disinfectantis stored in an oven at 37 DEG C for 90 days, the reduction rate of the content of hydrogen peroxide is less than 5%, so that the requirement on the stability of the disinfectant in Technical Specification for Disinfection (2002 edition) is met.

Owner:重庆市普康消毒用品有限公司

Polyamidoxime-based chelating resin for extracting uranium from seawater and preparation method thereof

ActiveCN111171208ASimple and fast manufacturing methodEasy to operateOther chemical processesSeawater treatmentPolymer adsorbentChelating resin

The invention relates to polyamidoxime-based chelating resin for extracting uranium from seawater and a preparation method thereof, and is characterized in that the polymer chelating resin is preparedby adopting a solvothermal method, and a chelating group is amidoxime; amidoxime styrene and ethylene glycol dimethacrylate are copolymerized under a solvothermal condition, and high-concentration amidoxime is immobilized on a polymer skeleton, so that the amidoxime chelating resin adsorbing material is prepared, and the amidoxime chelating resin adsorbing material is applied as a polymer adsorbent for separating and enriching uranium from seawater. The preparation route of the synthesized polyamidoxime-based chelating resin is simple and easy to operate. Meanwhile, the adsorbent has the advantages of being high in adsorption capacity, large in adsorption capacity, high in adsorption speed and the like when used for separating and enriching uranyl ions in seawater, is easy to separate from an aqueous solution, and can effectively adsorb and recover uranyl ions in the seawater solution.

Owner:EAST CHINA UNIV OF TECH

Method for improving color depth and fastness of natural brown baffeta

The invention discloses a method for improving color depth and fastness of natural brown baffeta. The method comprises the following steps of (1) preparing a color-increased solution; (2) preparing a fixation solution; (3) pretreating; (4) carrying out color-increased treatment; (5) carrying out fixation treatment. By adopting the method provided by the invention, the color depth of the natural brown baffeta can be remarkably improved, the soaping fastness and the color fastness to sunlight are also remarkably improved, and the color depth, the soaping fastness and the color fastness to sunlight commonly reach to 4 to 5 grades so as to fully meet the commercial application requirement.

Owner:南通市富贵源印花有限公司

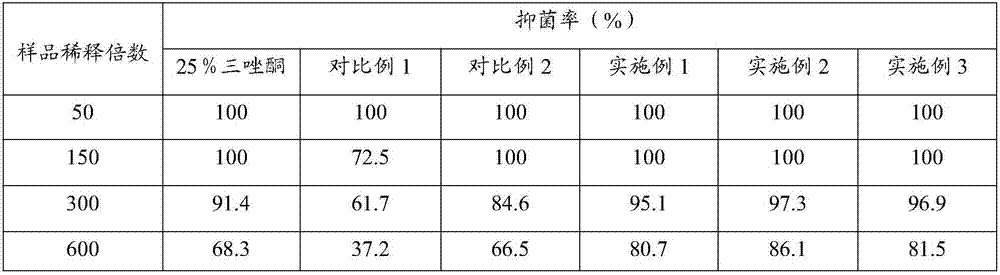

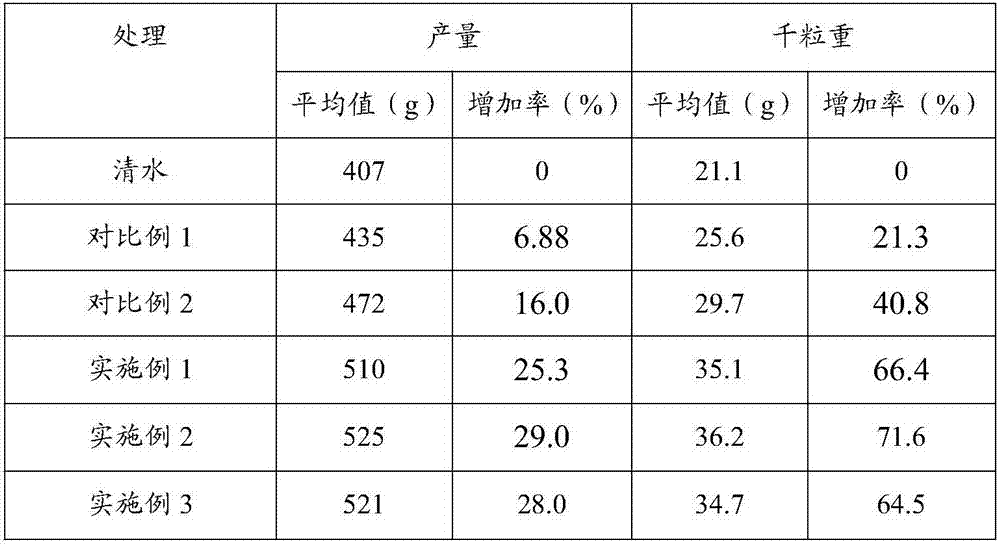

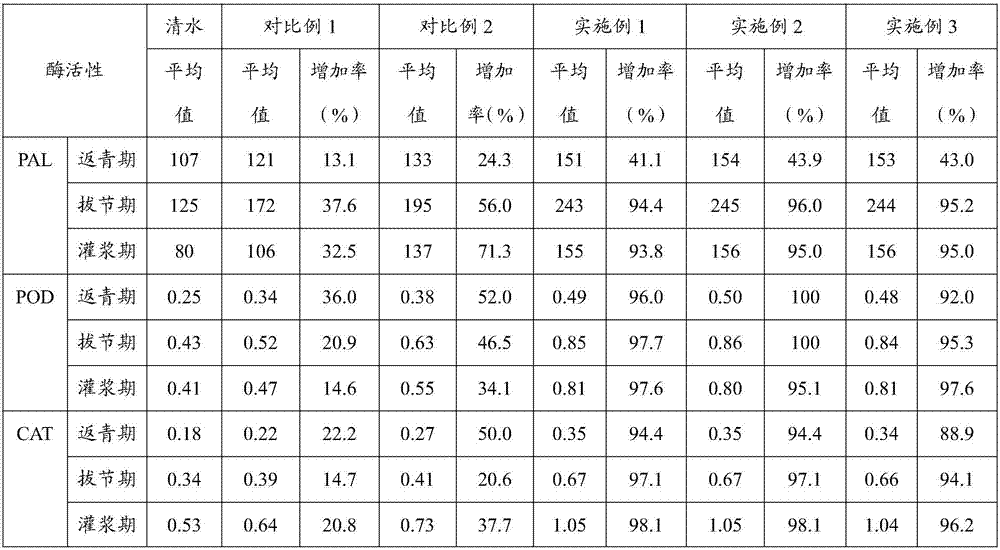

Foliar fertilizer for improving wheat powdery mildew resistance and preparation method thereof

InactiveCN107324922AGeneration of restrictionsControl spreadAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium bicarbonateSucrose

The invention relates to foliar fertilizer for improving wheat powdery mildew resistance and a preparation method thereof. The foliar fertilizer is prepared from sodium bicarbonate, dipotassium hydrogenphosphate, potassium silicate, riboflavin, sucrose, fulvic acid, chitin, phytosterol, trace elements, a chelating agent, a wetting agent, a dispersant and water. The preparation method comprises adding water into a reactor, heating the water to 50-80 DEG C, adding trace elements and a chelating agent into the water, stirring the mixture for a reaction to obtain a solution A, cooling the solution to 40-50 DEG C, adding sodium bicarbonate, dipotassium hydrogenphosphate, potassium silicate, fulvic acid and a wetting agent into the solution, stirring the solution for a reaction to obtain a solution B, cooling the solution to 30-40 DEG C, adding remaining materials into the solution, stirring the materials for a reaction to obtain a solution C, cooling the solution C to the room temperature, filtering the solution and collecting the filtrate to obtain the foliar fertilizer. The foliar fertilizer can improve wheat resistance to powdery mildew, has good permeability, water-absorbing quality, water-retaining property, strong complexation and chelation ability and surface adsorption ability, improves a fertilizer utilization rate and promotes wheat growth.

Owner:FOSHAN SANSHUI JIAXIN AGRI TECH RES INST GENERAL PARTNERSHIP

Spinning and dyeing pretreatment auxiliary agent and preparation method and application thereof

The invention relates to a spinning and dyeing pretreatment auxiliary agent, which is prepared by adopting the following raw material components: 30 to 50 parts by weight of desizing agent, 5 to 20 parts by weight of alkali-resisting penetrant, and 4 to 10 parts by weight of complexing agent; the desizing agent is multi-alkyl amine salt; the alkali-resisting penetrant is an alkali-resisting nonionic surfactant; the complexing agent is hydroxy carboxylate. Further, the adopted raw material components also include 1 to 10 parts by weight of hydrogen peroxide stabilizer; the hydrogen peroxide stabilizer is organic phosphonate. The spinning and dyeing pretreatment auxiliary agent can be obtained through the preparation of successively mixing the raw material components, and the spinning and dyeing pretreatment auxiliary agent can be applied to a cold-batch method or open-width scouring-bleaching method spinning and dyeing pretreatment process. The spinning and dyeing pretreatment auxiliary agent can shorten the flow of the conventional spinning and dyeing pretreatment process, can reduce the energy consumption and material consumption in the pretreatment process, and can reduce the effluent volume; an obtained intermediate product of textile fabrics has good whiteness, capillary effect and desizing percentage.

Owner:青岛先达精细化工有限公司

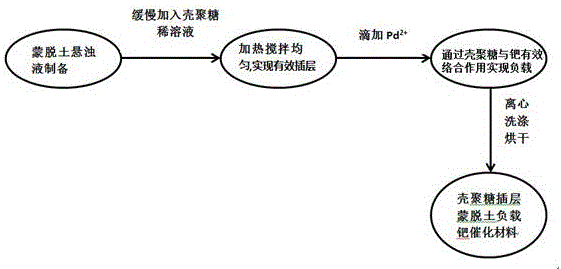

Method for preparing palladium catalytic materials supported by chitosan-modified montmorillonite

InactiveCN106345529ASimple preparation processLow equipment requirementsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMechanical stabilityMontmorillonite

The invention relates to a method for preparing palladium catalytic materials supported by chitosan-modified montmorillonite. The palladium catalytic materials are used for catalyzing organic reaction. The method has the advantages that chitosan can be fed into spaces among layers of cationic montmorillonite in acid solution by the aid of ion exchange processes, accordingly, spacing of the layers of the montmorillonite can be enlarged, transition metal can be supported by means of sufficient complexation on the dropwise added transition metal and the chitosan, and the palladium catalytic materials supported by the chitosan-intercalated montmorillonite can be obtained by means of centrifuging, washing and drying and are excellent in comprehensive performance; the specific surface areas of the palladium catalytic materials are enlarged by 10-20 times as compared with original montmorillonite, and the palladium catalytic materials are high in heat stability and mechanical stability and are excellent in catalytic activity and reuse stability when applied to organic coupling reaction.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com