Alkyd resin modified polymer electrolyte as well as preparation method and application thereof

An alkyd resin and polymer technology, applied in the directions of graft polymer adhesives, amide/imide polymer adhesives, polyether adhesives, etc., can solve the problem of inability to prepare high lithium conductivity and good Mechanical properties of polymer electrolytes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In one embodiment, a method for preparing an alkyd resin modified polymer electrolyte, comprising:

[0043] Alkyd resin with acrylamide, methacrylamide, acrylonitrile, methyl acrylate, methyl methacrylate, monofunctional or multifunctional polyethylene glycol acrylate, monofunctional or multifunctional poly One or more monomers in ethylene glycol methacrylate are copolymerized in an organic solvent under the action of a thermal initiator or a photoinitiator, and then an electrolyte, a plasticizer, an ion non-conductive or Ion-conductive inorganic nanoparticles or nanofibers are uniformly mixed, coated on the surface of the substrate or electrode sheet, and finally heated and cured in the air to obtain an alkyd resin-modified polymer electrolyte;

[0044] Alternatively, dissolve the alkyd resin and the ion-conducting polymer in an organic solvent, add electrolytes, plasticizers, ionically non-conductive or ion-conductive inorganic nanoparticles or nanofibers for blending...

example 1

[0061] A kind of polymer electrolyte modified by alkyd resin, prepared by the method of copolymerization:

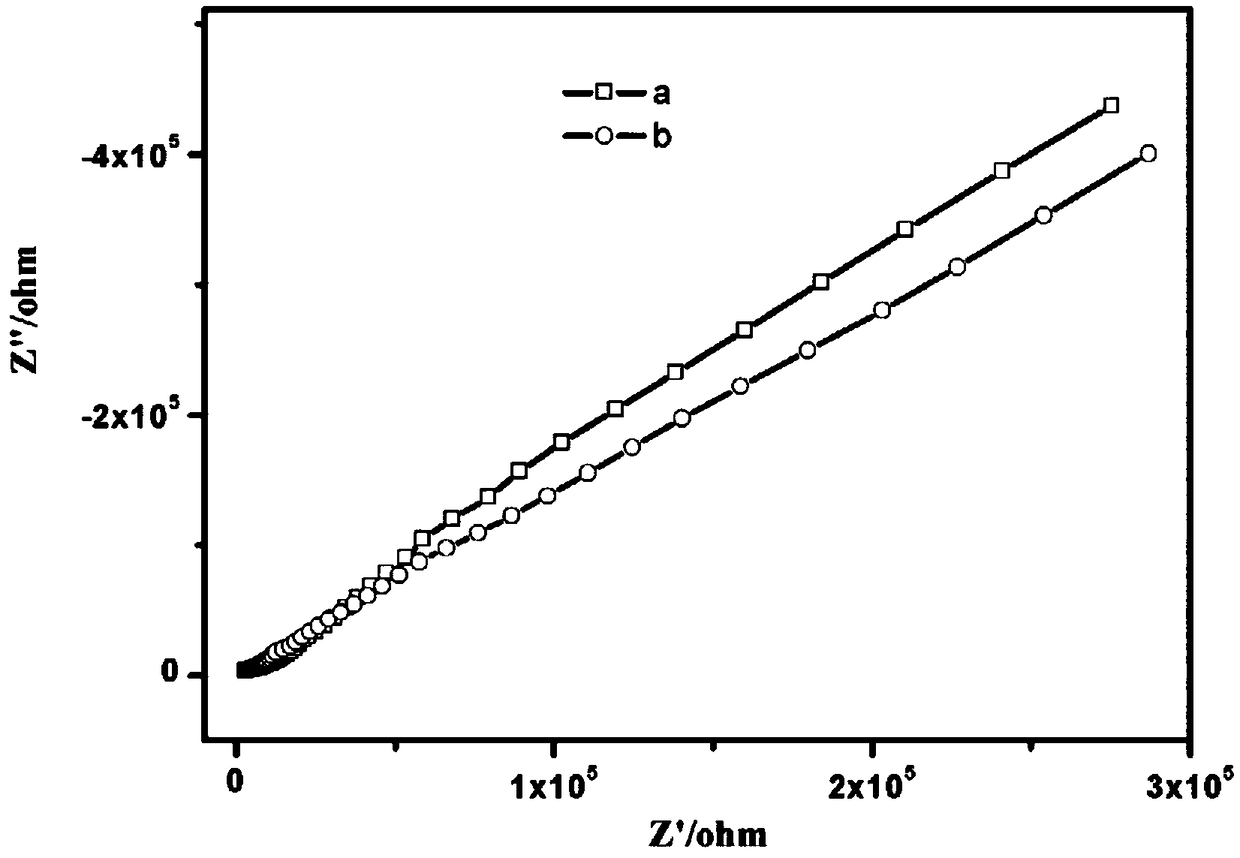

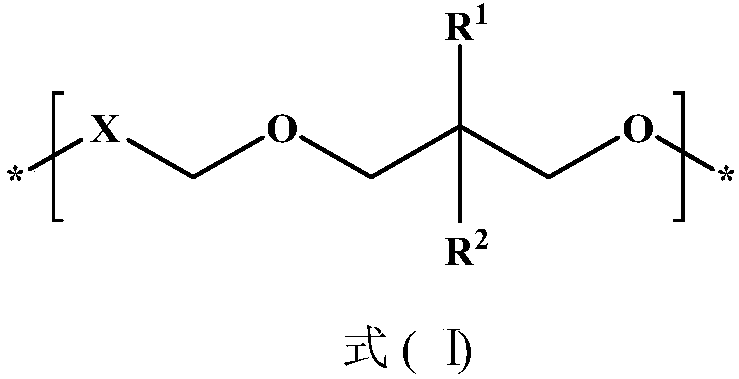

[0062] According to the weight ratio, 20 parts of alkyd resin (purchased from Jining Tainuo Chemical Co., Ltd., which is equivalent to X in formula (I) comes from phthalic acid, R 1 is an acrylate group, R 2 α-linolenic acid), 20 parts of methoxy polyethylene glycol acrylate (purchased from Arkema Co., Ltd.) and 1 part of azobisisobutyronitrile initiator were dissolved in 20 parts of tetrahydrofuran, at 60 ° C under nitrogen Reaction in the air for 10h. After cooling to room temperature, add 5 parts of LiClO to the copolymer solution 4 , 4 parts of dioctyl phthalate plasticizer and 30 parts of 200nm silicon dioxide, stirred evenly, scraped and coated on a polytetrafluoroethylene board, cured at 80°C for 5h, and prepared a self-supporting alcohol with a thickness of 100μm Acid resin modified polymer electrolyte. The prepared polymer electrolyte membrane is used in lit...

example 2

[0071] A kind of polymer electrolyte modified by alkyd resin, prepared by the method of copolymerization:

[0072] According to the weight ratio, 15 parts of alkyd resin (purchased from Jining Tainuo Chemical Co., Ltd., which is equivalent to X in formula (I) comes from phthalic acid, R 1 is a methacrylate group, R 2 α-linolenic acid), 30 parts of acrylonitrile (purchased from Arkema Co., Ltd.) and 2 parts of tert-butyl peroxybenzoate initiator were dissolved in 20 parts of acetonitrile, and reacted at 70° C. for 5 h in a nitrogen atmosphere. After cooling to room temperature, add 10 parts of LiClO to the copolymer solution 4, 8 parts of diisodecyl phthalate plasticizer and 20 parts of 50nm zinc oxide, stirred evenly and then scraped onto a polytetrafluoroethylene board, cured at 90 ° C for 8 hours to prepare a self-supporting alcohol with a thickness of 100 μm Acid resin modified polymer electrolyte. The prepared polymer electrolyte membrane is used in lithium ion batterie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com