All-solid-state electrolyte membrane of lithium ion battery and preparation method thereof

A technology of lithium ion battery and electrolyte membrane, applied in the field of all-solid-state lithium battery manufacturing, can solve the problems of low room temperature conductivity, etc., and achieve the effects of high room temperature conductivity, good compatibility and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] a. Preparation of polymer electrolyte colloidal emulsion

[0038] First, dissolve EVA in an organic solvent, add acrylonitrile monomer to the EVA solution and raise the temperature to 70-80°C; then dropwise add the solution containing the initiator benzoyl peroxide to polymerize for 2-5 hours, add VEC to further Polymer colloid liquid is obtained after polymerization for 6-24 hours. Dissolve an appropriate amount of lithium salt ultrasonically in diethyl carbonate (DEC) or a mixed solution of DEC / EC, add the completely dissolved lithium salt solution into the polymer colloidal emulsion and stir for 1-6 h.

[0039] b. Preparation of composite polymer electrolyte emulsion modified by inorganic nanofillers

[0040] The polymer colloid liquid obtained in step a is mechanically stirred and mixed with the polymer colloid liquid of uniformly dispersed nano-inorganic fillers by ball milling for 2-8 hours to obtain a modified inorganic / organic composite electrolyte emulsion.

...

Embodiment 1

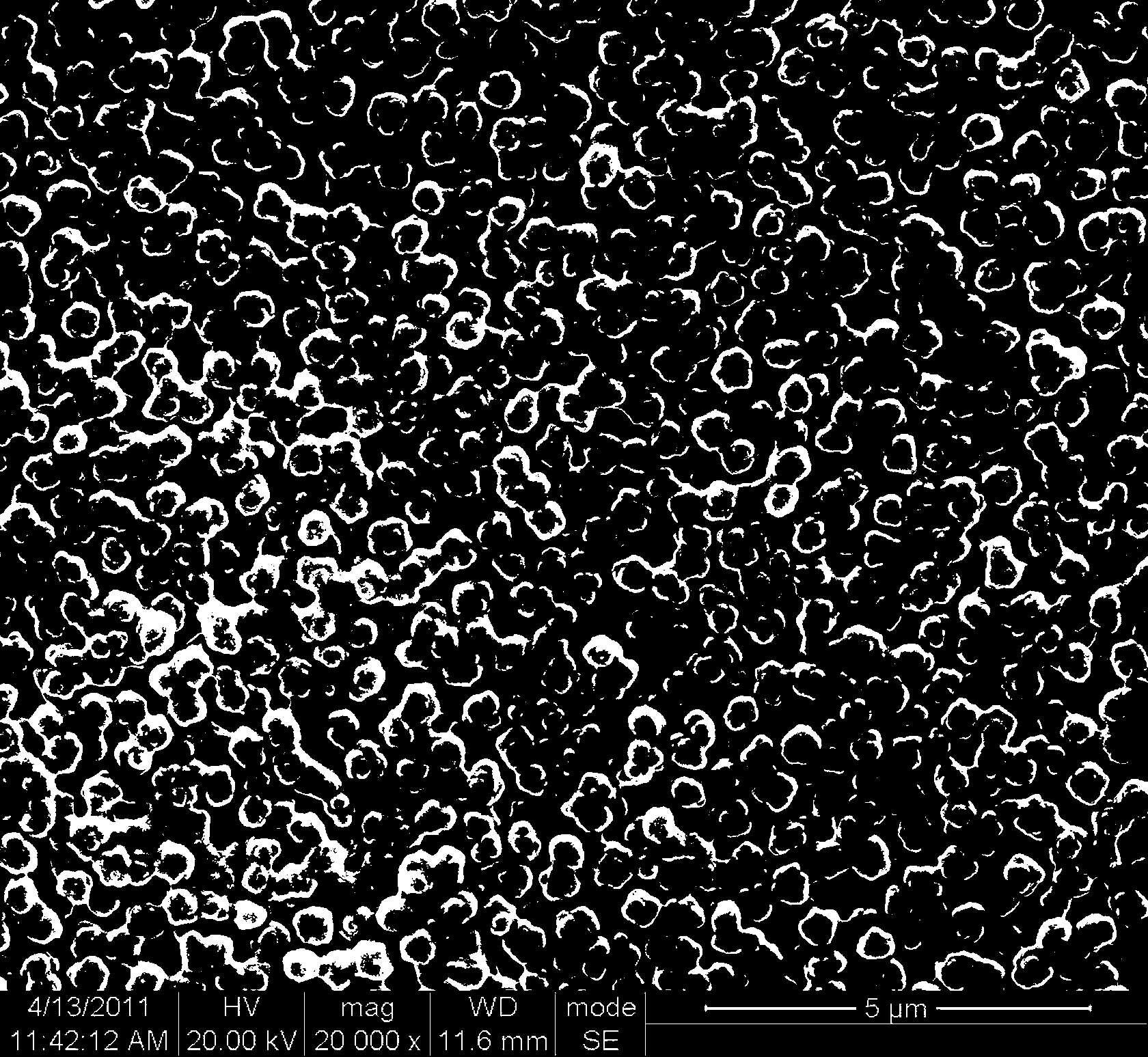

[0044] Add an organic mixed solvent of ethyl acetate and 1,4-dioxane (400 g) and 23.4 g of ethylene-vinyl acetate copolymer (EVA, Sumitate KC-10, 28wt% vinyl acetate), the mixture was heated to 70 °C and completely dissolved in the solvent under mechanical stirring, and then 93.6 g of acrylonitrile (AN) monomer was added dropwise, and nitrogen gas was introduced for 30 minutes , and then slowly drop 0.49 g of benzoyl peroxide dissolved in 30 mL of toluene solution into the reaction system. After the dropwise addition, react for about 1 hour, and then add vinyl ethylene acetate (VEC, 46.8g) dropwise after the reactant turns into a light yellow emulsion. After 8 hours of reaction, P(AN -co- VEC) / EVA polymer emulsion. In this reaction system, the conversion rate of AN is above 85%, the solid content is about 20 wt.%, the particle size of the polymer microspheres is 100-500nm, and the particle size of the latex is controlled by the polymerization reaction conditions. The obtaine...

Embodiment 2

[0047] Add an organic mixed solvent of ethyl acetate and 1,4-dioxane (400 g) and 23.4 g of ethylene-vinyl acetate copolymer (EVA, Sumitate KC-10, 28wt% vinyl acetate), the mixture was heated to 70 ℃ and completely dissolved in the solvent under mechanical stirring, and then 187.2g of acrylonitrile (AN) monomer was added dropwise, and nitrogen gas was introduced for 30 minutes , and then slowly drop 0.49 g of benzoyl peroxide dissolved in 30 mL of toluene solution into the reaction system. After the dropwise addition, react for about 1 hour, and then add vinyl ethylene acetate (VEC, 50.4g) dropwise after the reactant turns into a light yellow emulsion. After 8 hours of reaction, P(AN -co- VEC) / EVA polymer emulsion. In this reaction system, the conversion rate of AN is above 85%, the solid content is about 20 wt.%, the particle size of the polymer microspheres is 100-200nm, and the particle size of the latex is controlled by the polymerization reaction conditions. The obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com