Antibacterial composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and antibacterial metal ion technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problem of poor antibacterial persistence of composite nanofiltration membrane, poor permeability of antibacterial composite nanofiltration membrane, and loss of antibacterial particles and other problems, to achieve the effect of stable complexation, improved antibacterial performance, and improved antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

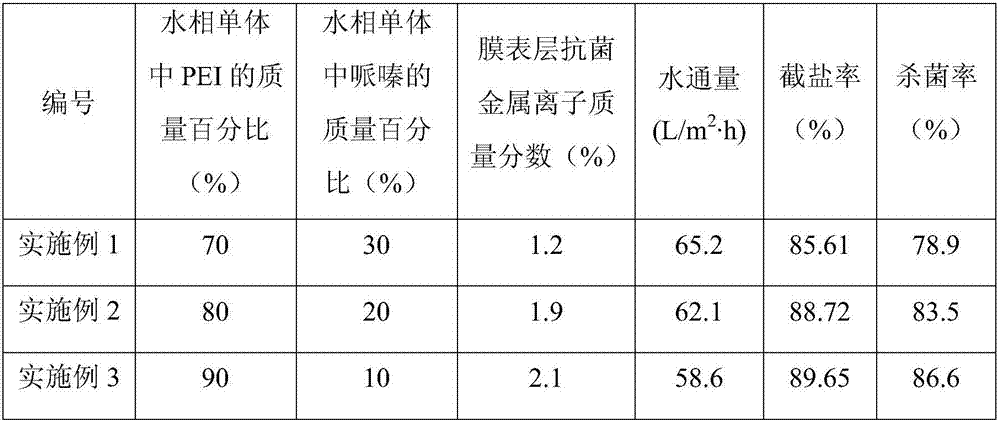

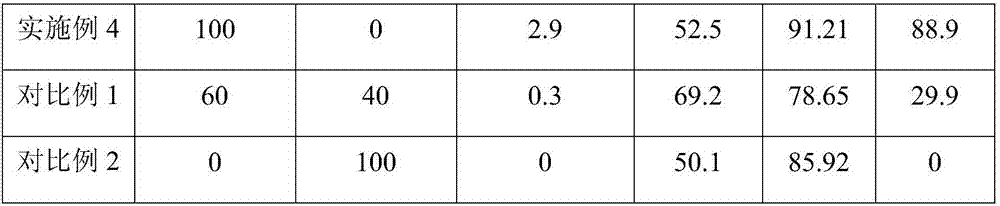

[0055] Prepare the water phase solution that the water phase monomer concentration is 5g / L, wherein, the water phase monomer is PEI and piperazine, the percentage of PEI accounting for the total mass of the water phase monomer is 70%, and the number average molecular weight of PEI is 2000; A polyethersulfone porous support membrane with a molecular weight cut-off of 30,000-50,000 is soaked in the aqueous phase solution for 10 seconds, and the excess aqueous phase solution is poured off to prepare a porous support membrane coated with the aqueous phase monomer, and then cleaned with Roll the surface of the membrane dry with a rubber roller; place the porous support membrane coated with the aqueous phase monomer in ISOPAR E solvent oil solution of trimesoyl chloride with a concentration of 1g / L for immersion treatment for 10s, and pour off the excess oil phase solution, then dried in the air, and then placed in a 70°C oven for drying treatment for 1.5min, and a composite nanofilt...

Embodiment 2

[0057] In this embodiment, except that the mass percentage of PEI in the aqueous phase monomer is 80%, and the number average molecular weight of PEI is 5000, the steps for preparing the antibacterial composite nanofiltration membrane are the same as in Example 1. The prepared nanofiltration composite membrane was tested and characterized according to the test methods of separation performance, antibacterial performance and antibacterial metal ion content of the aforementioned composite nanofiltration membrane, and the obtained test results are listed in Table 1.

Embodiment 3

[0059] In this embodiment, except that the mass percentage of PEI in the aqueous phase monomer is 90%, and the number average molecular weight of PEI is 10,000, the steps for preparing the antibacterial composite nanofiltration membrane are the same as in Example 1. The prepared nanofiltration composite membrane was tested and characterized according to the test methods of separation performance, antibacterial performance and antibacterial metal ion content of the aforementioned composite nanofiltration membrane, and the obtained test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com