Waterproof crack-resisting coating and preparation method thereof

A coating and water-reducing agent technology, applied in the field of coating materials, can solve the problems of destroying the decorative effect of the outer wall, the coating film is flowered, and the powder is dropped, and achieves the effects of good storage stability, improved service life, and good elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

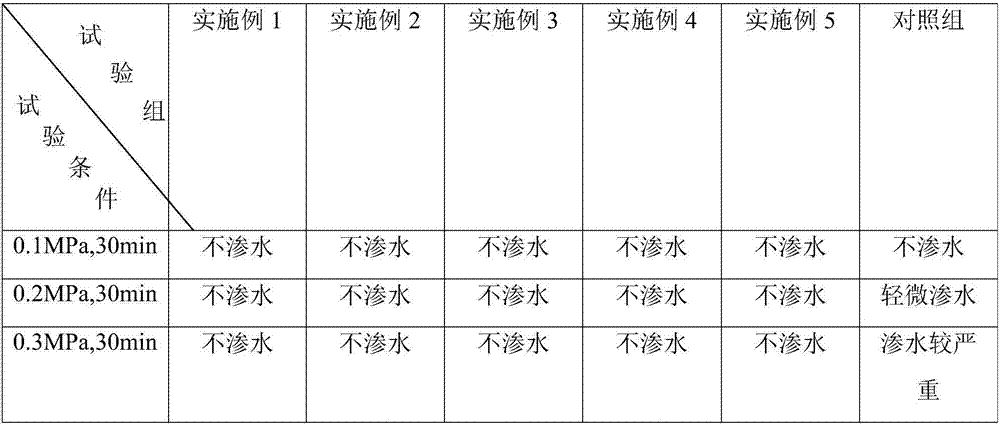

Examples

Embodiment 1~ Embodiment 5

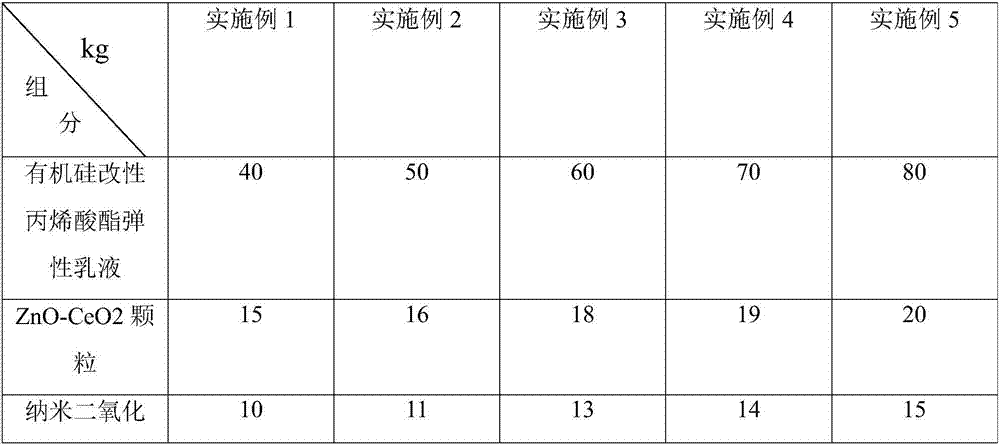

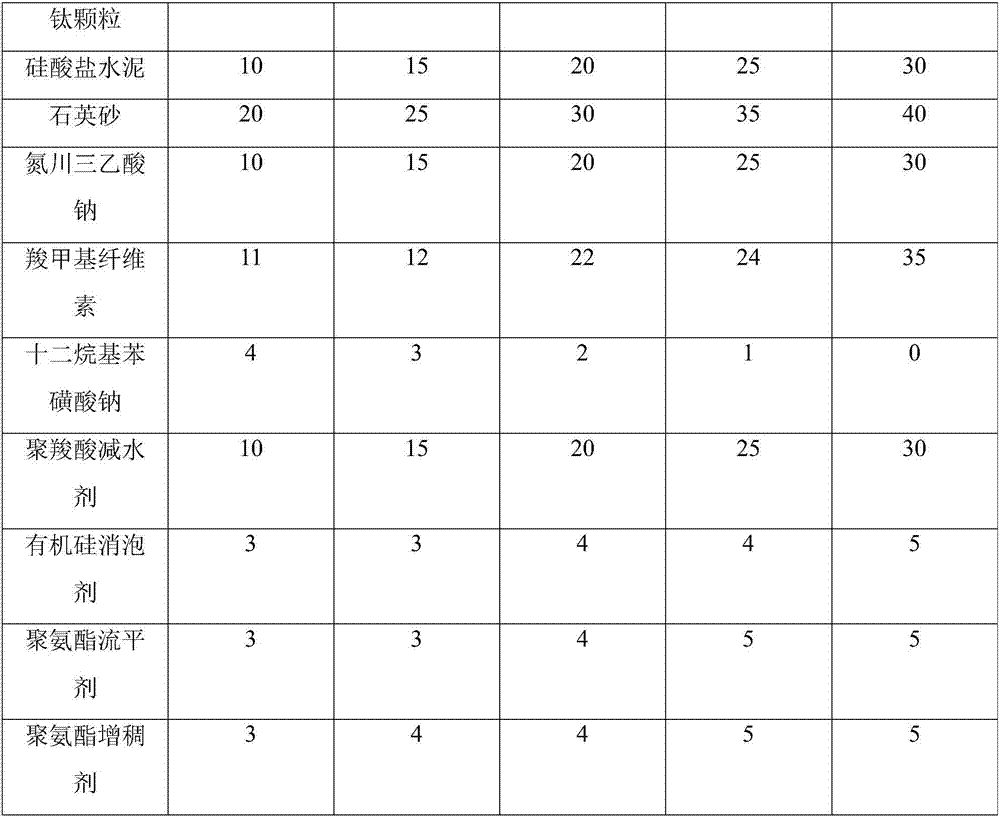

[0028] Table 1 Example 1 to Example 5 Parts by weight of each component raw material

[0029]

[0030]

[0031] Preparation of waterproof and anti-cracking paint:

[0032] Add 30kg of water to the reaction kettle, add carboxymethyl cellulose, polycarboxylic acid water reducer, silicone defoamer, polyurethane leveling thickener, 800~1200r / min high speed dispersion for 25~30min under stirring. Obtain the slurry; then add silicone modified acrylate elastic emulsion, ZnO-CeO 2 Blend of particles, nano-titanium dioxide particles, Portland cement, quartz sand, sodium triacetate, 1000~1200r / min for 15~20min; then use leveling thickener to adjust the viscosity, 300~500r / min for uniform mixing 40-60min; finally adjust the PH value with acid-base regulator, and stir evenly for 40-60min at 200-250r / min to obtain the finished waterproof and anti-cracking paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com