Method for preparing heavy metal cadmium stabilizer sulfenyl-ferrous composite modified charcoal and modified charcoal

A compound modification and biochar technology, which is applied in the direction of fertilizer mixtures, chemical instruments and methods, organic fertilizers, etc., can solve the problems of complex process, high cost of modified biochar preparation, long cycle, etc., and achieve simple and remarkable preparation process. Curing effect, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

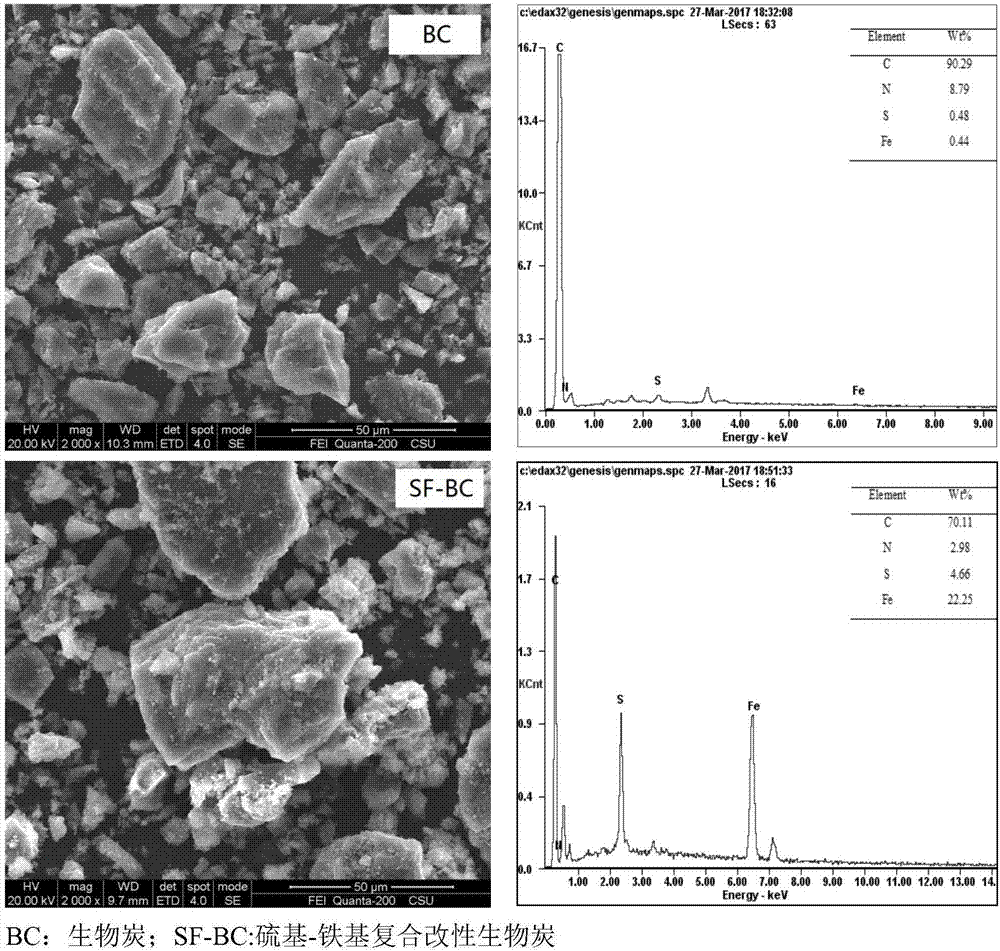

[0028] The preparation method 1 of sulfur-based-iron-based composite modified biochar comprises the following steps:

[0029] (1) Grind the biochar into powder, pass through a 100-mesh sieve, and set aside;

[0030] (2) Mix 0.30mol / L sodium hydroxide solution and carbon disulfide solution according to the volume ratio of 1:0.5, stir at room temperature for 5h, and apply ultrasonication for 1.5h to prepare the mixed solution;

[0031] (3) Mix the biochar prepared in step (1) with the mixed liquid obtained in step (2) at a solid-to-liquid ratio of 1:3, keep stirring at 40°C for 6 hours, filter with suction, and dry the solid matter at 45°C Finally, it is ground into powder and passed through a 100-mesh sieve to obtain sulfur-based biochar;

[0032] (4) Mix the sulfur-based biochar obtained from step (3) with 0.8mol / L ferrous sulfate solution at a solid-to-liquid ratio of 1:4, keep stirring at 35°C for 12 hours, ultrasonically disperse for 2 hours, and filter to obtain a solid ...

Embodiment 2

[0036] The preparation method 2 of sulfur-based-iron-based composite modified biochar comprises the following steps:

[0037] (1) Grinding the biochar into powder, passing through an 80-mesh sieve, for use;

[0038] (2) Mix 0.80 mol / L sodium hydroxide solution and carbon disulfide solution at a volume ratio of 1:1, stir at room temperature for 6 hours, and apply ultrasonication for 2 hours to prepare a mixed solution;

[0039] (3) Mix the biochar prepared in step (1) with the mixed liquid obtained in step (2) at a solid-to-liquid ratio of 1:4, keep stirring at 45°C for 8 hours, filter with suction, and dry the solid matter at 45°C Finally, it is ground into powder and passed through a 100-mesh sieve to obtain sulfur-based biochar;

[0040] (4) Mix the sulfur-based biochar worth in step (3) with 1.5mol / L ferrous sulfate solution at a solid-to-liquid ratio of 1:6, keep stirring at 35°C for 16 hours, ultrasonically disperse for 2 hours, and filter to obtain a solid material, an...

Embodiment 3

[0042] The preparation method 3 of sulfur-based-iron-based composite modified biochar comprises the following steps:

[0043] (1) Grinding the biochar into powder, passing through a 60-mesh sieve, for use;

[0044] (2) Mix 0.50 mol / L sodium hydroxide solution and carbon disulfide solution according to the volume ratio of 1:1.5, stir at room temperature for 4 hours, and use ultrasonication for 2 hours to prepare a mixed solution;

[0045] (3) Mix the biochar prepared above with the mixed liquid obtained in step (2) according to the solid-to-liquid ratio of 1:5, keep stirring at 40°C for 6 hours, then filter with suction, separate the solid from the liquid, and dry the solid matter at 45°C Finally, it is ground into powder and passed through a 100-mesh sieve to obtain sulfur-based biochar;

[0046] (4) Mix the sulfur-based biochar worth in step (3) with 1.2mol / L ferric sulfate solution at a solid-to-liquid ratio of 1:5, keep stirring at 35°C for 10h, ultrasonically disperse for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com