Patents

Literature

120results about How to "Easy to use in mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

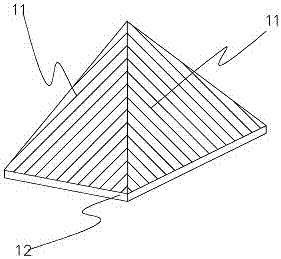

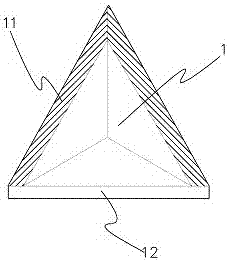

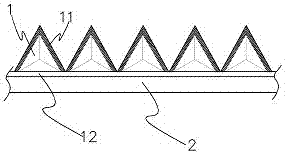

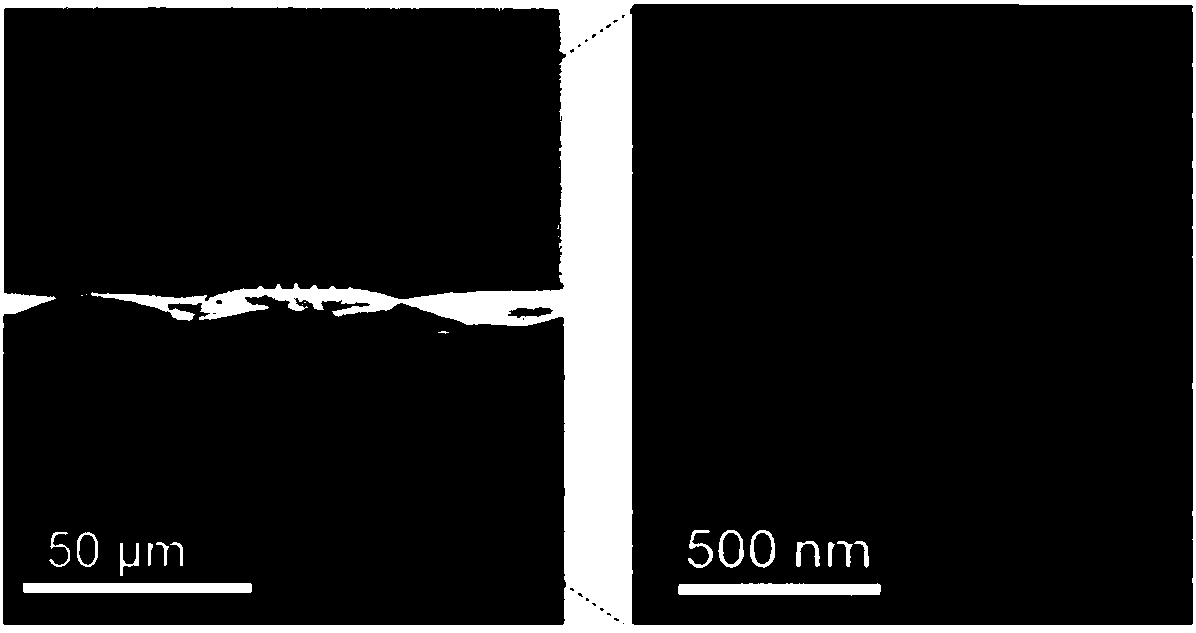

Micron order prism pyramid monomer and manufacturing method thereof

PendingCN107144903AAvoids the phenomenon of sedimentation at the bottom of the fluidImprove reflective effectOptical elementsMicron scalePolymer science

The invention relates to the light reflection material technology field and provides a micron order prism pyramid monomer and a manufacturing method thereof. The prism pyramid is capable of accommodating both the light flashing and light reflecting effects, and can exist independently without being attached to a carrier film. Only with adhesive glue, oil painting, hair glue and nail polishing oil and other colorless or colored transparent fluid or liquid media, it is possible to let the prism pyramid monomer to be attached on objects such as films, cloth, wires and plates requiring to be added with light or to realize light flash so that these materials can present the lighting effect. The monomer can be applied widely in great practical use, and the manufacturing method for the monomer is also simple and easy to implement. Therefore, with the method, batched monomer can be produced and used.

Owner:YEAGOOD INC

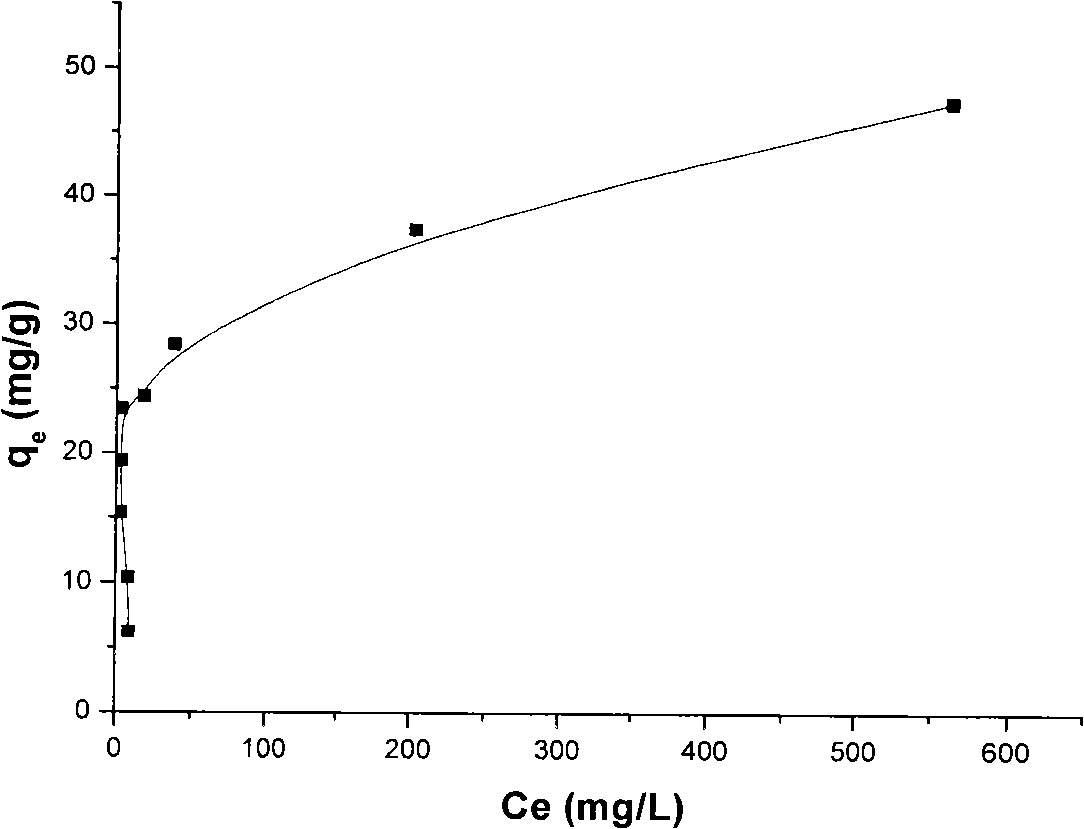

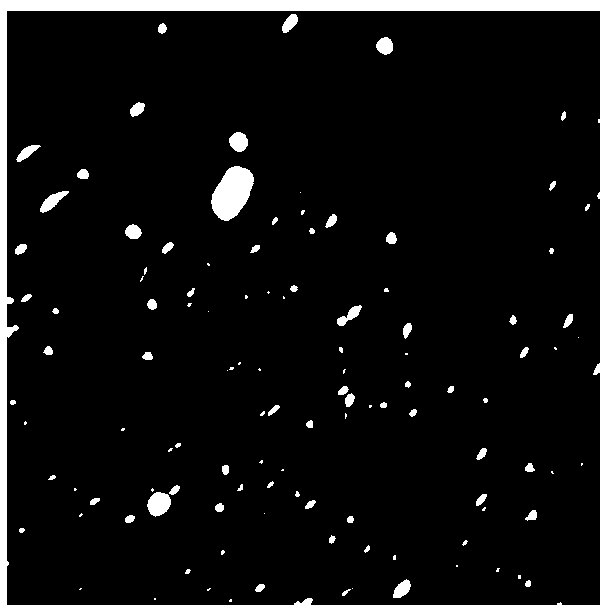

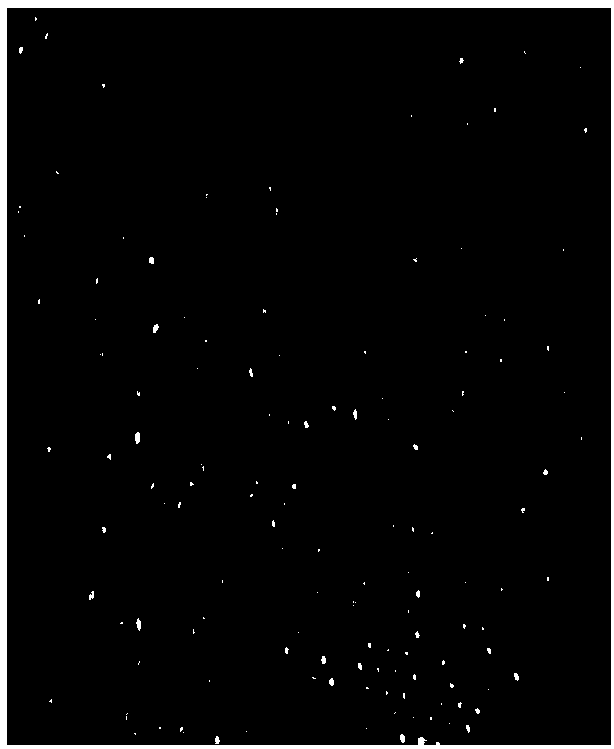

Novel method for fast removing cupric ion with magnetic sorbent

InactiveCN101279776AImprove adsorption capacityImprove regenerative abilityWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by sorptionAcetic acidSorbent

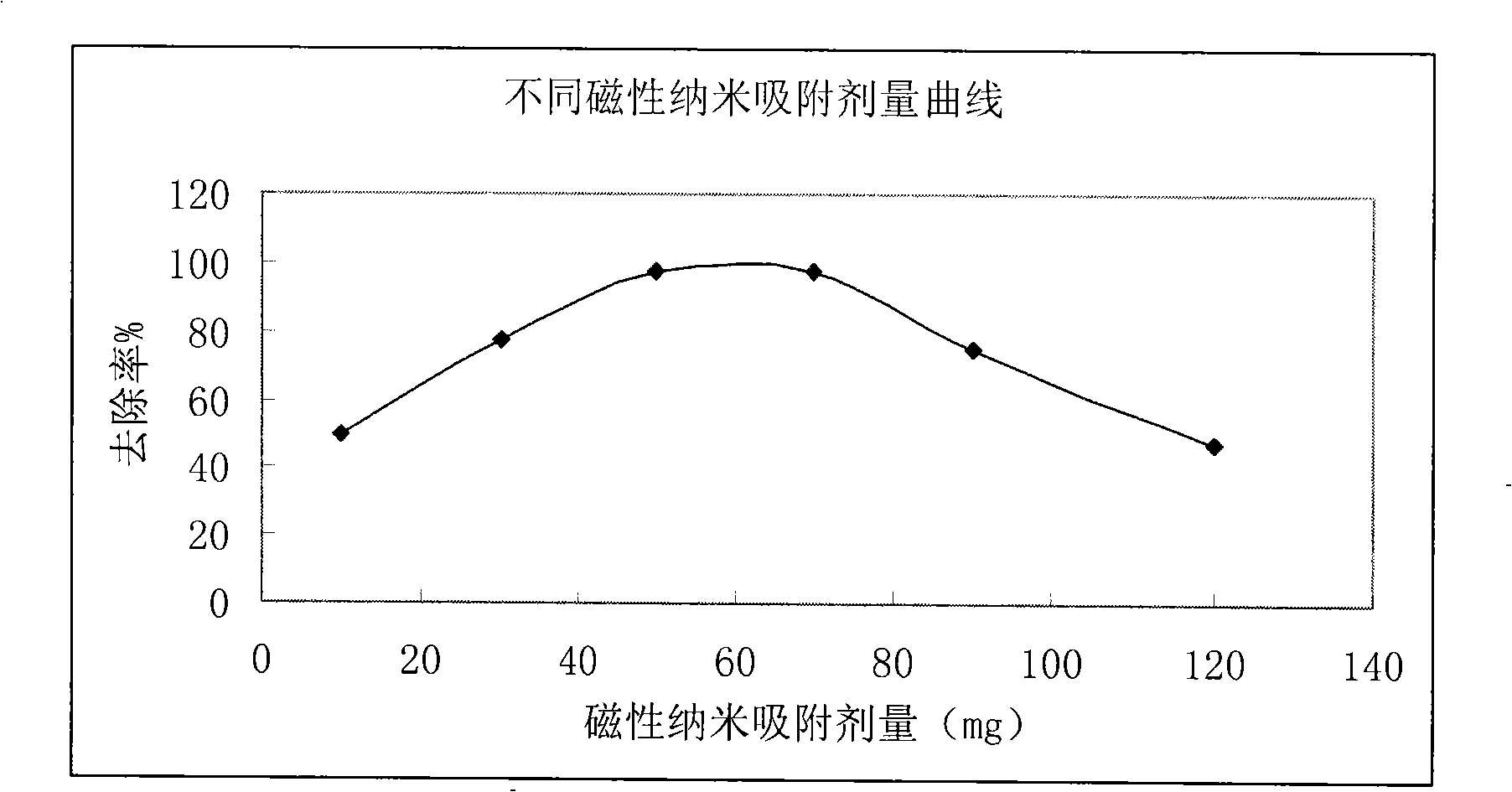

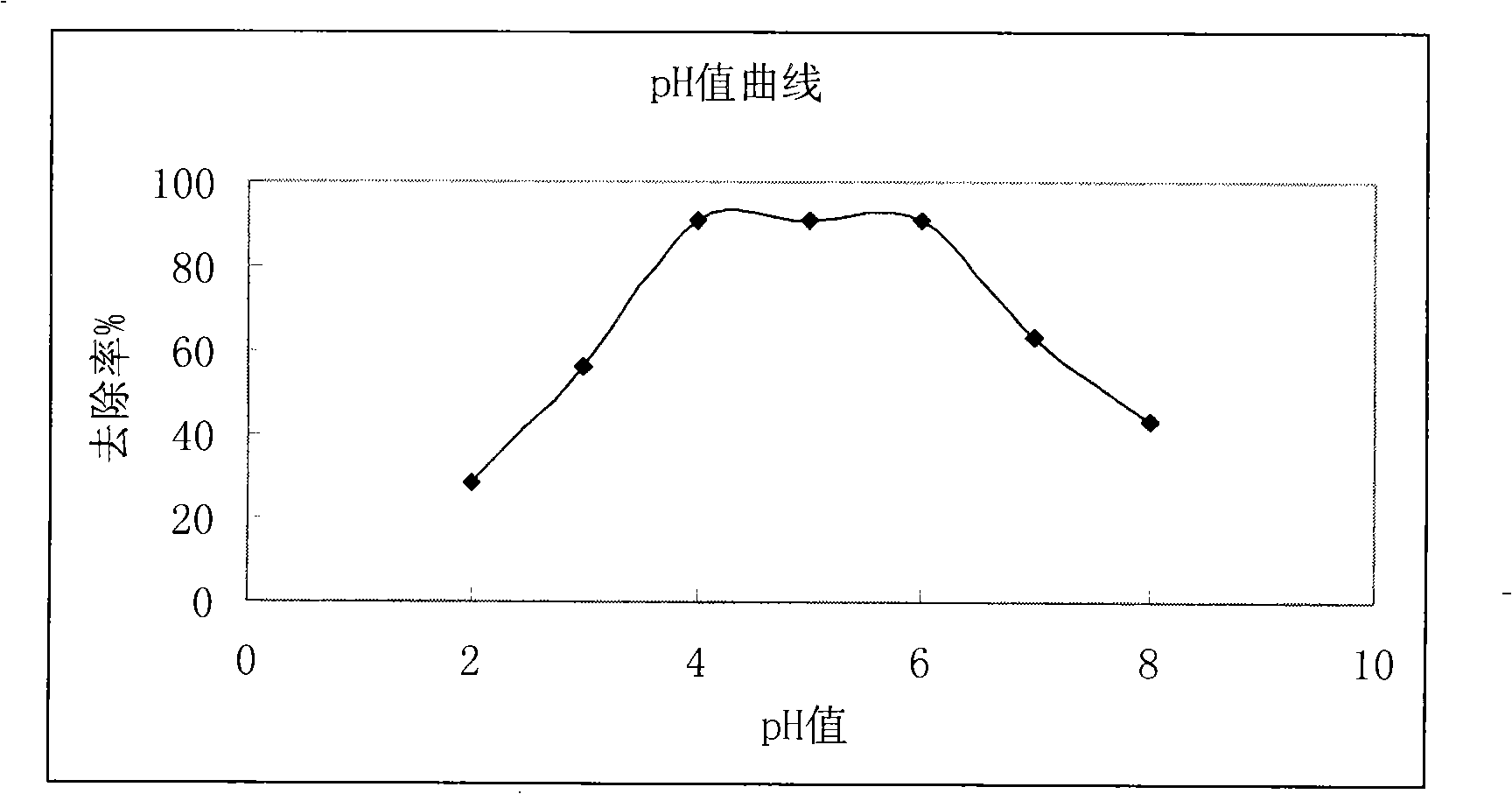

The invention relates to a method for fast removing metal copper ions in waste water by a magnetic adsorbent, which comprises steps that: (1) a chitosan solution with the mass fraction of 16 percent is used to wrap a Fe3O4 magnetic powder to prepare magnetic nanometer particles; (2) an acetic acid buffer solution with a pH value of 5.6 is used for swelling the magnetic nanometer particles and carrying out the surface chemical modification so as to prepare a novel magnetic adsorbent; (3) a magnetic nano-adsorber of 10-120mg is used for adsorbing a copper ion solution with the volume of 10ml and concentration of 40-800ppm at a temperature of 22 DEG C and a speed of 100rpm, and the solution undergoes the elution by an eluant with the volume of 20ml and concentration of 100mmol / L, thereby obtaining the regenerative magnetic nano-adsorber; and (4) the adsorption conditions of the magnetic nano-adsorber are optimized through adjusting the adsorption conditions. The method has advantages of simple and convenient operation, short time consumption, allowing fast feeding, convenient and rapid elution and strong regenerative power.

Owner:DONGHUA UNIV

Feedback adjustment spraying dispensing device and adjusting method thereof

PendingCN109332097AImprove regulation efficiencyGuaranteed reliabilityLiquid surface applicatorsCoatingsNozzleEngineering

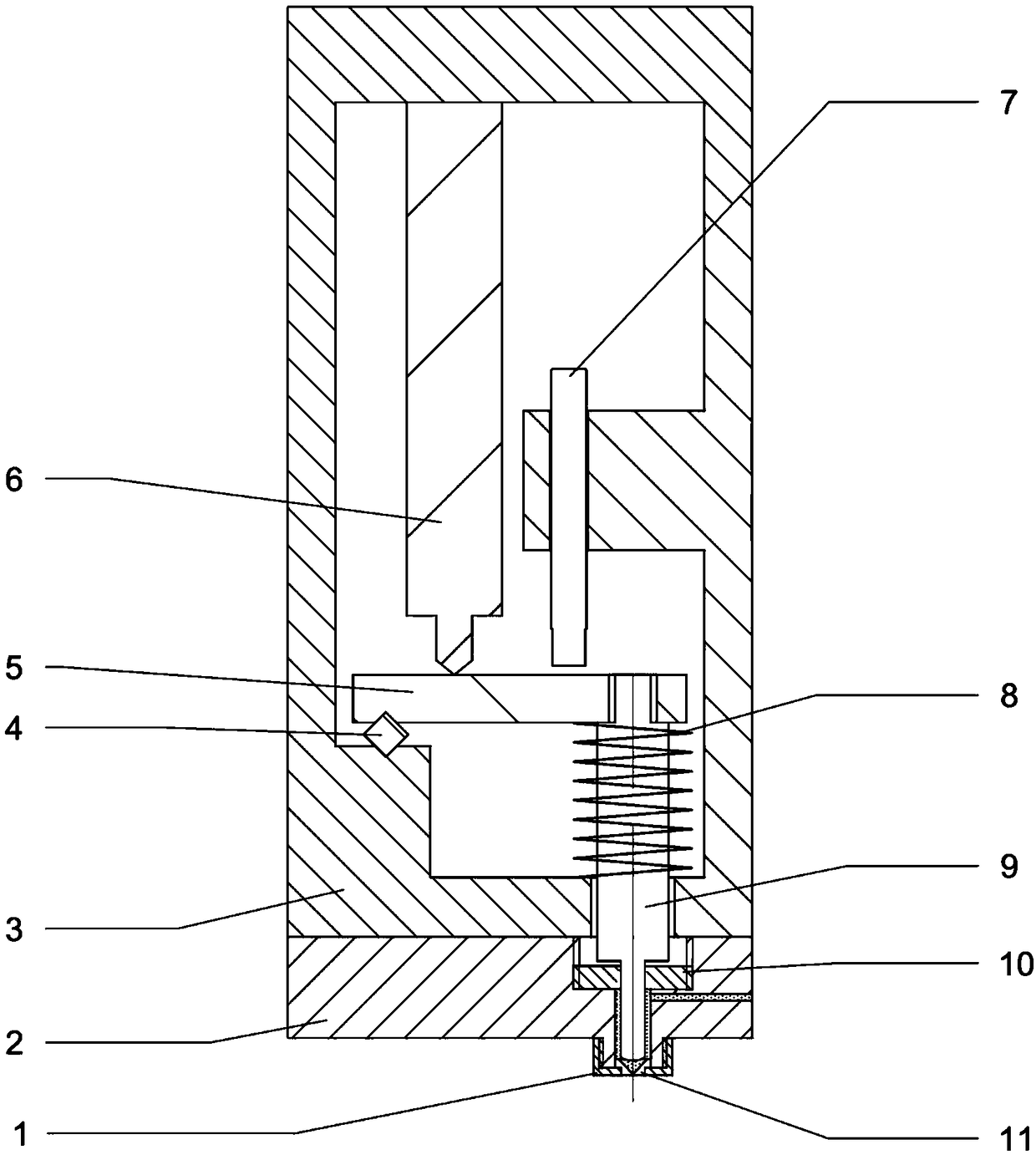

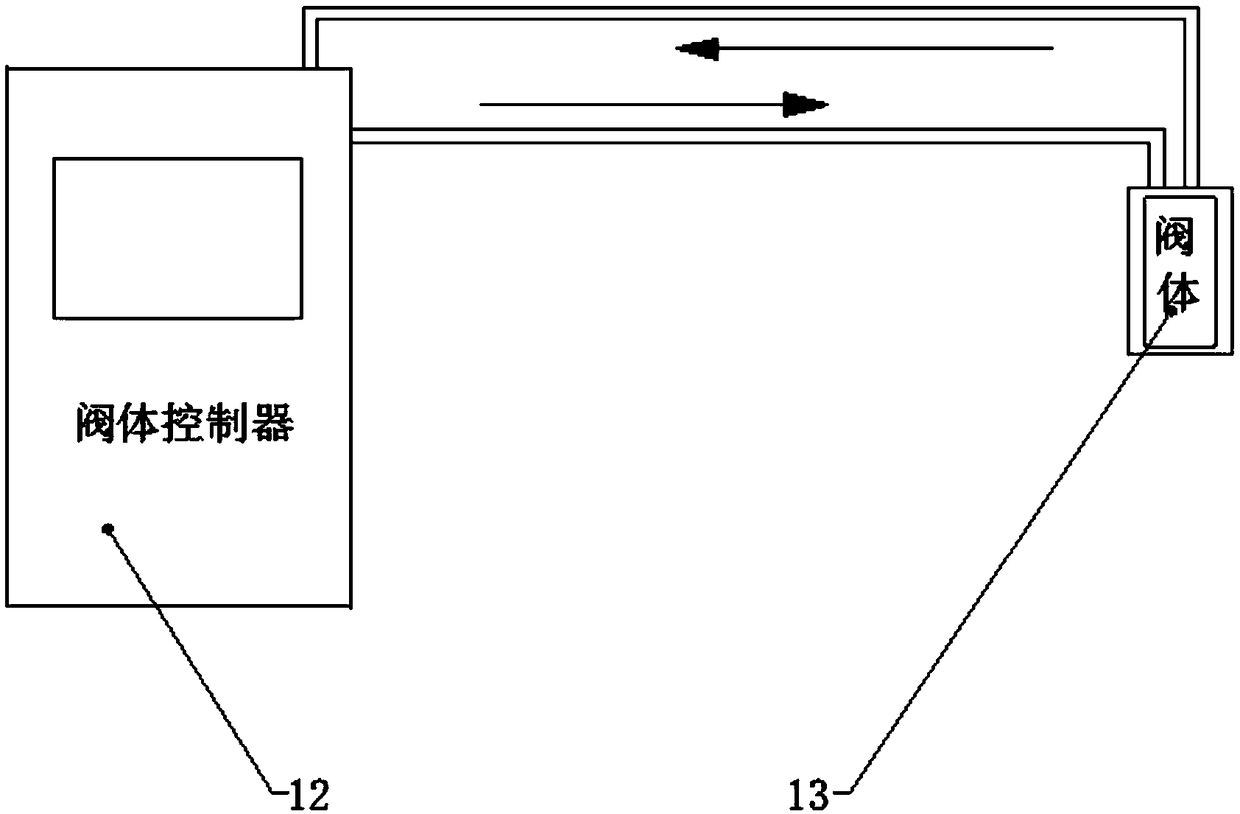

The invention relates to the technical field of dispensing, in particular to a feedback adjustment spraying dispensing device and an adjusting method thereof. A valve body is included and comprises avalve body upper shell and a valve body lower shell. The valve body lower shell is provided with a collision pin hole, and a collision pin is arranged in the collision pin hole in a sliding manner. The valve body lower shell is further provided with a glue inlet pipeline communicating with the collision pin hole. The outer portion of the lower shell is in threaded connection with a limiting threaded sleeve. A nozzle communicating with the collision pin hole is arranged at the bottom end of the limiting threaded sleeve. Glue spraying is achieved through collisions of the collision pin and the nozzle. A cavity is formed in the valve body upper shell, a lever is arranged in the valve body upper shell, a piezoelectric stack is fixed to the top end of the cavity, the collision pin upwards extends into the cavity, the piezoelectric stack abuts against the lever, the outer portion of the collision pin is sleeved with an elastic element, one end of the elastic element abuts against the lever,and the other end of the elastic element presses the valve body upper shell. The cavity is internally provided with a displacement sensor probe for detecting the lever moving distance. According to the feedback adjustment spraying dispensing device and the adjusting method thereof, the nozzle adjusting efficiency is high, and reliability is high.

Owner:CHANGZHOU GAO KAI PRECISION MACHINERY CO LTD

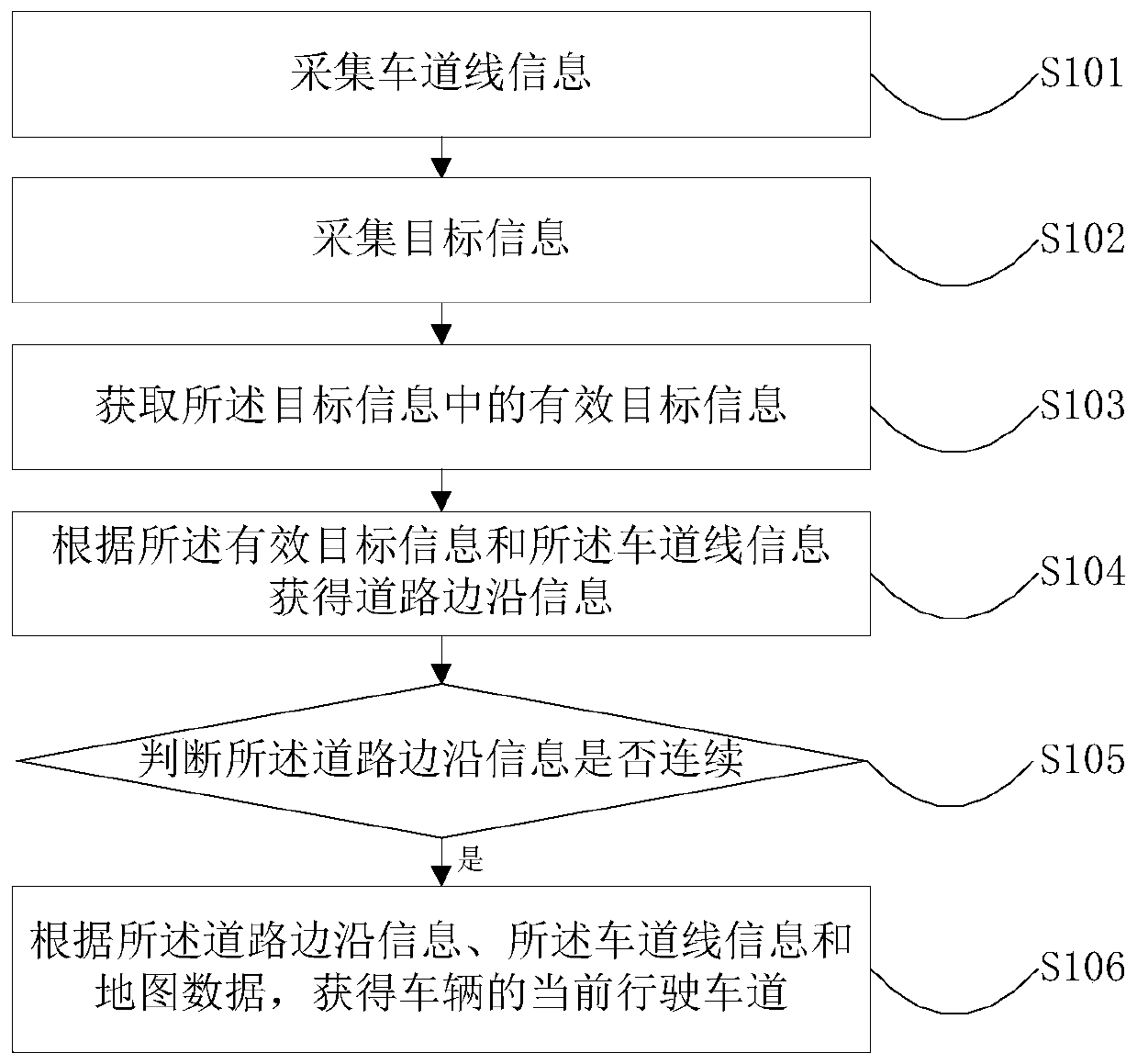

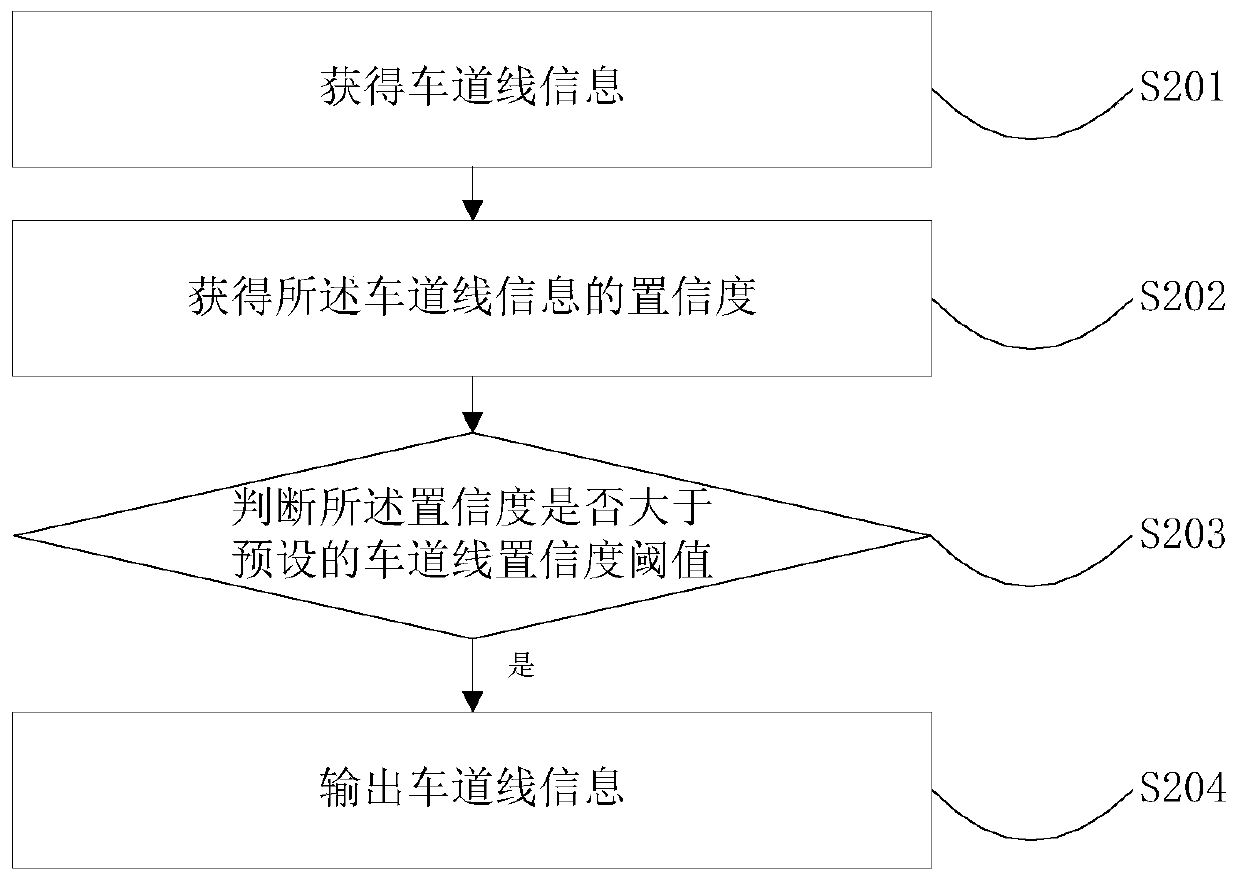

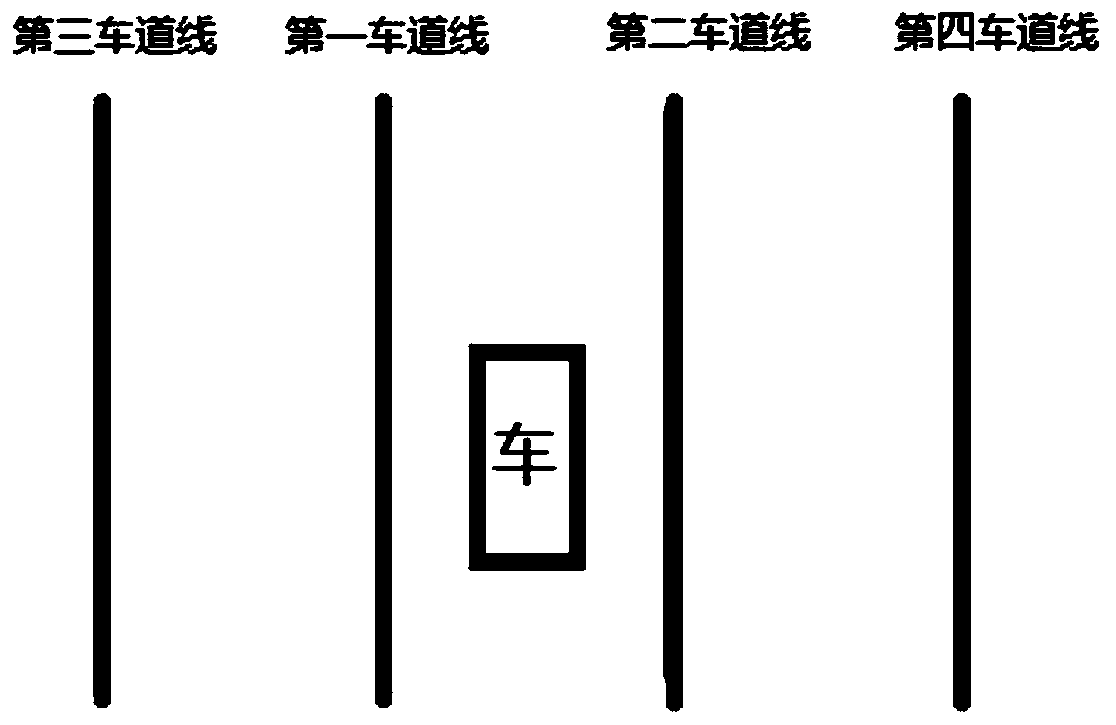

Vehicle running lane positioning method and device as well as terminal

PendingCN110174113ALow manufacturing costEasy to use in mass productionInstruments for road network navigationCurve fittingReal-time computing

The invention relates to map navigation, and provides a vehicle running lane positioning method and device as well as a terminal. The method comprises the following steps: acquiring lane line information; acquiring target information; acquiring effective target information in the target information; acquiring roadside information according to the effective target information and the lane line information; judging whether the roadside information is continuous or not; and if so, acquiring lane map information of a current vehicle running lane according to the roadside information, the lane lineinformation and map data. The roadside information is acquired through linear fitting or curved fitting, or by finding an offset boundary. Through adoption of the method, the vehicle lane can be determined on a low-accuracy navigation map under to the assistance of a visual sensor and a radar sensor; the accuracy of a lane-level map is achieved; the vehicle manufacturing cost is lowered; and convenience is brought to the volume production of vehicles.

Owner:福瑞泰克智能系统有限公司

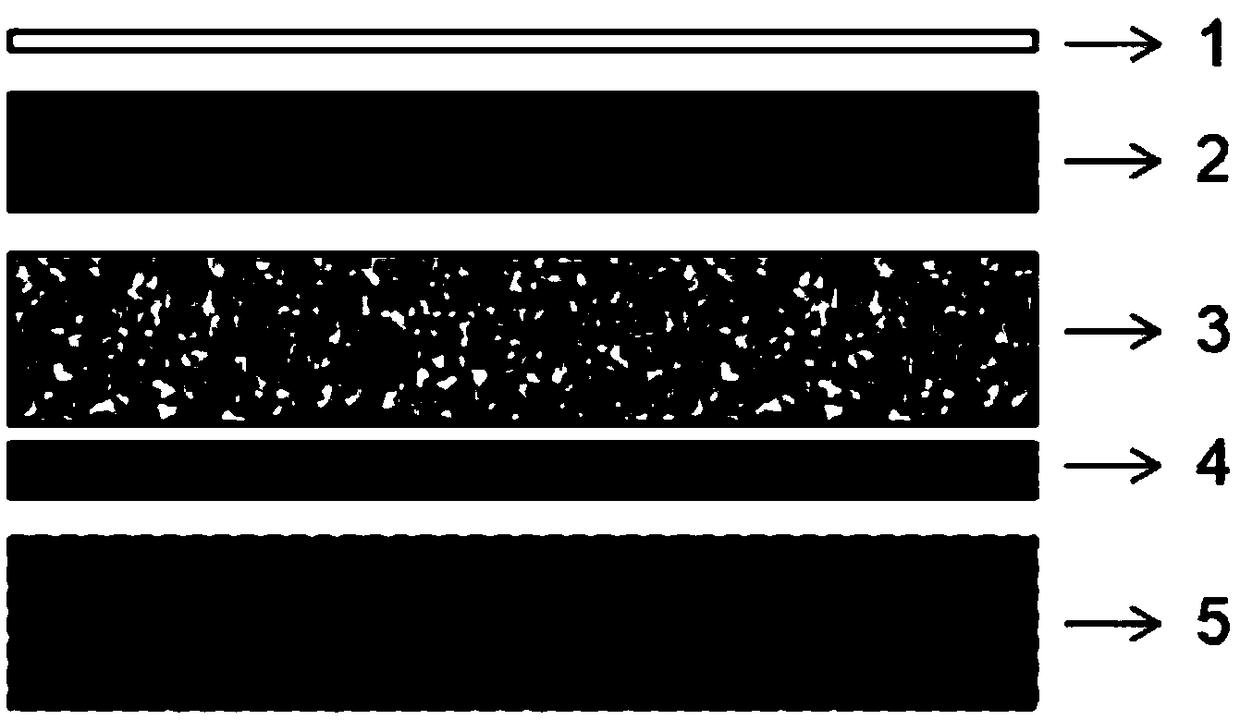

A2 level fireproof core board and manufacturing method thereof

The invention discloses an A2 level fireproof core board and a manufacturing method thereof. The core board consists of a fireproof core layer and a polymeric membrane bonding material, wherein the fireproof core board is of a sheet structure, and the sheet can be rolled into a roll. The method comprises the following steps: batching, discharging, baking, binding, cooling and rolling. The internal density of the core board is increased, so as to improve fireproof strength and enable combustion performance to meet the requirements of A2 level; the sheet can be rolled into the roll to be packed, other customers can machine the roll into a fireproof composite board according to self production requirements by combining with a metal plate as an aluminum plate, a copper plate or a stainless steel plate, as a result, the production cost is reduced, the sources are saved, and batch production is facilitated.

Owner:JIANGSU ALUMEIGE NEW MATERIALS

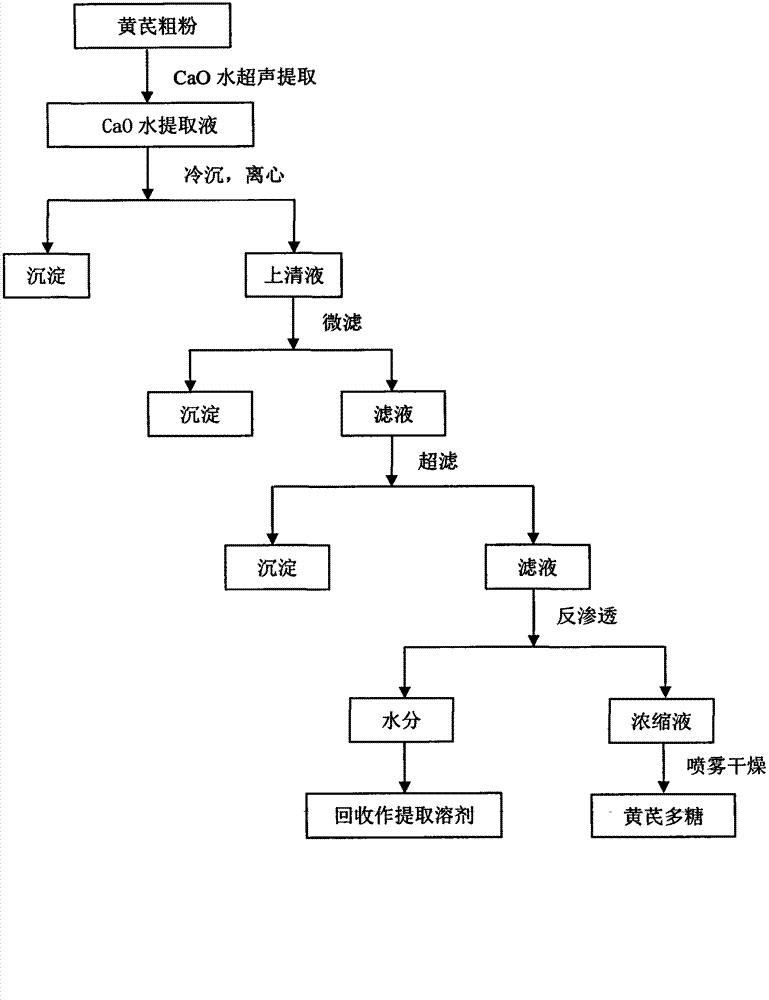

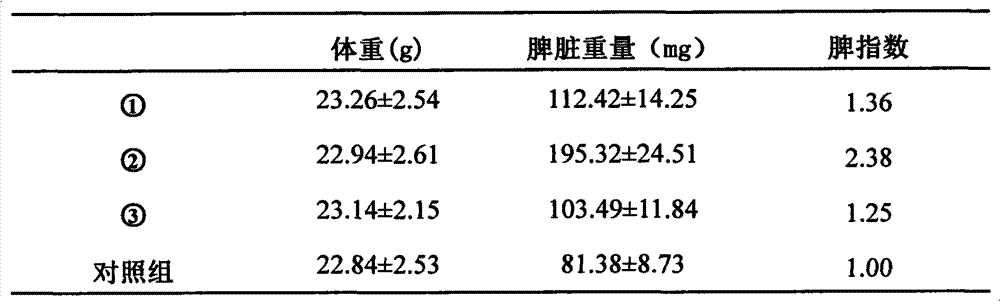

High-activity astragalus polysaccharide and preparation method of pharmaceutical composition of high-activity astragalus polysaccharide

ActiveCN102816251AShort active ingredient contentAvoid destructionOrganic active ingredientsImmunological disordersAstragalus polysaccharideCentrifugation

The invention discloses a preparation method of high-activity astragalus polysaccharide. Further, the invention relates to an astragalus polysaccharide containing pharmaceutical composition prepared from the astragalus polysaccharide. A preparation method of the astragalus polysaccharide comprises the following steps of: crushing Radix Astragali medicinal material, immersing it into a CaO aqueous solution, and successively carrying out ultrasonic extraction, cryoprecipitation, centrifugation, microfiltration, ultrafiltration, reverse osmosis and spray drying to obtain the astragalus polysaccharide. The extracted astragalus polysaccharide provided by the invention has high activity and high yield. In addition, the preparation method has a simple technology, is time-saving, energy-saving, highly efficient and simple, and is easy for popularization, development and application.

Owner:BEIJING CENT BIOLOGY

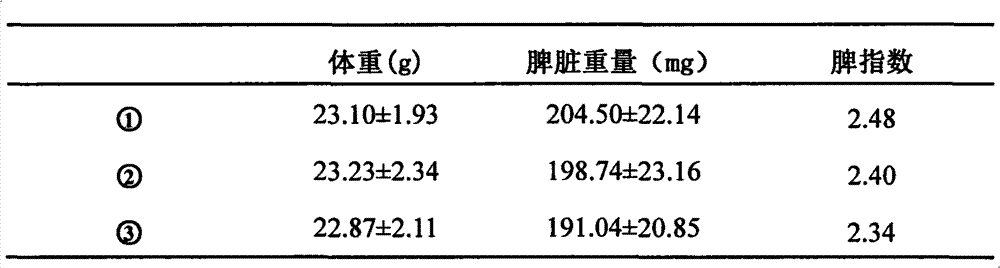

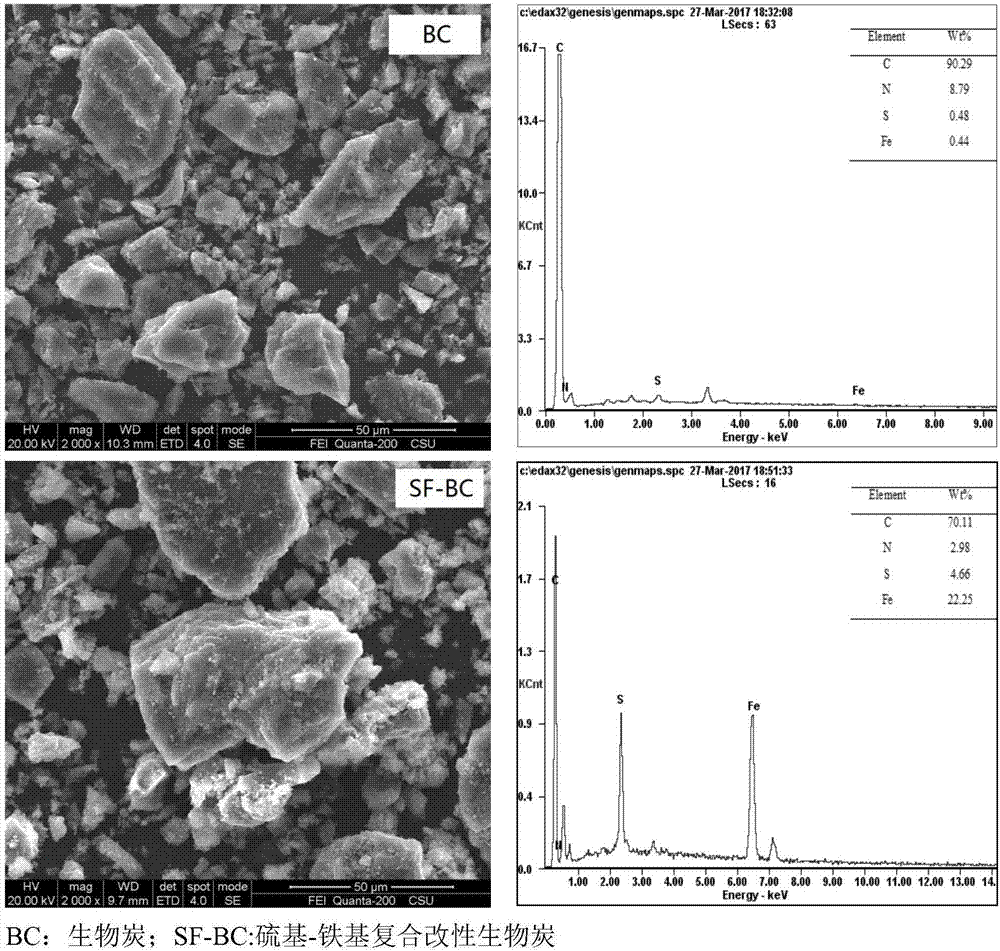

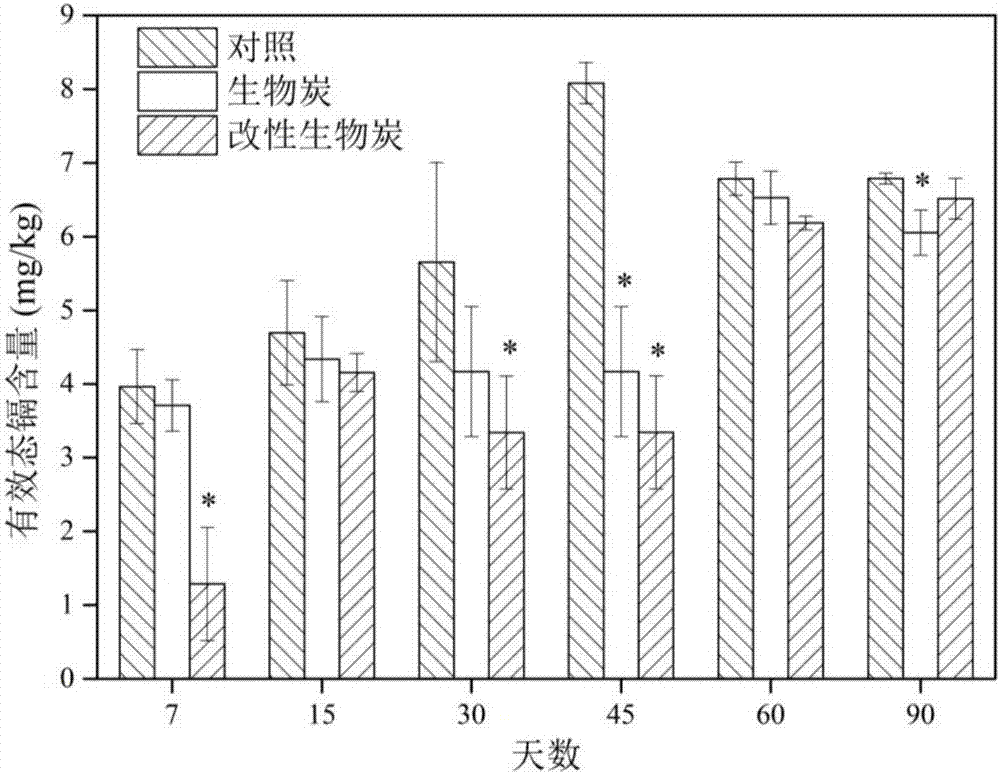

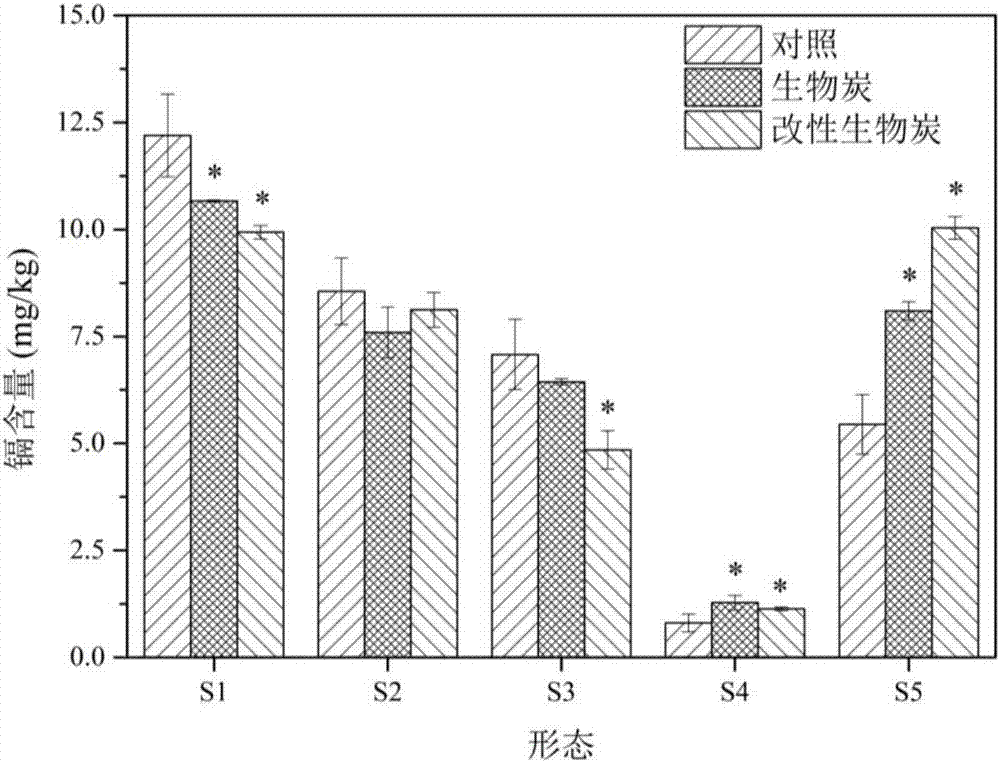

Method for preparing heavy metal cadmium stabilizer sulfenyl-ferrous composite modified charcoal and modified charcoal

ActiveCN107236545ALow priceNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil organic matterCoprecipitation

The invention discloses a method for preparing heavy metal cadmium stabilizer sulfenyl-ferrous composite modified charcoal and sulfenyl-ferrous composite modified charcoal prepared with the method. The method comprises the following steps: (1) preparing charcoal; (2) preparing a sulfenyl modification solution; (3) preparing a sulfenyl charcoal precursor; (4) preparing the sulfenyl-ferrous composite modified charcoal. The sulfenyl-ferrous composite modified charcoal prepared with the method is not only low in price and good in environmental-friendliness, but also simple in preparation process and easy in large-scale production and application; meanwhile, the content of organic matters in soil is remarkably increased, and the soil fertility is improved; relatively good adsorption, complexing and coprecipitation functions on exchangeable cadmium in soil are achieved, and effective cadmium in the soil can be remarkably immobilized.

Owner:CENT SOUTH UNIV

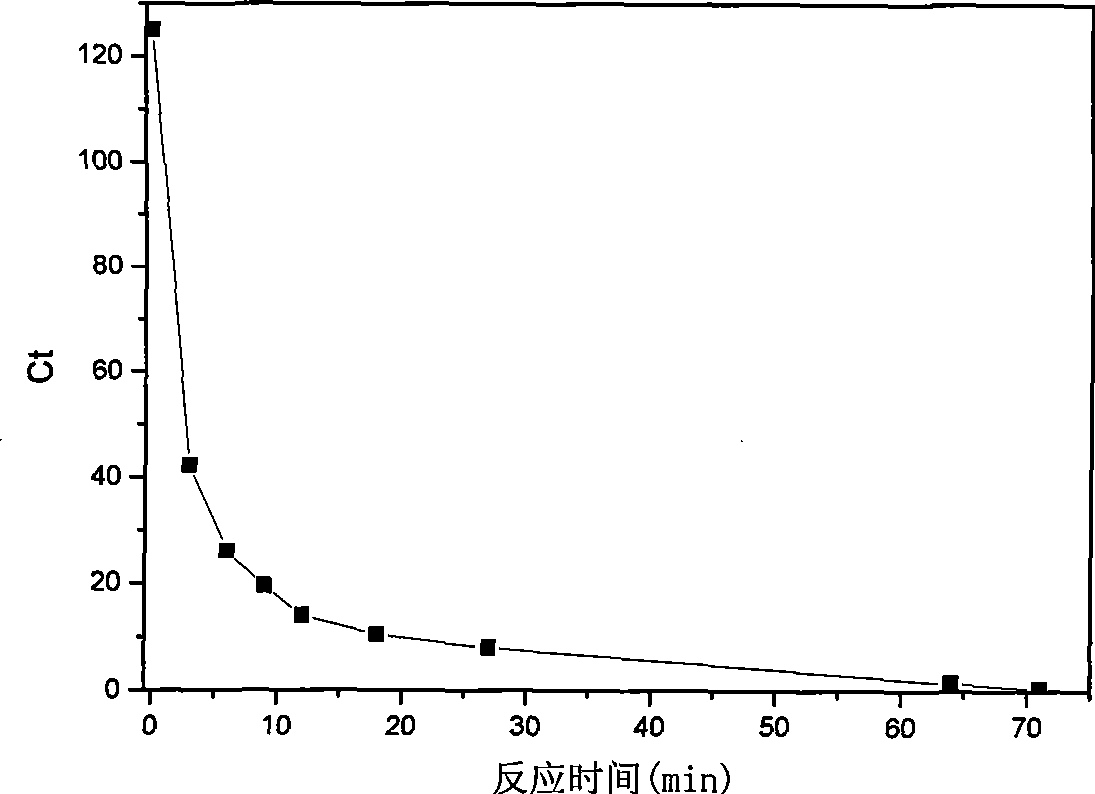

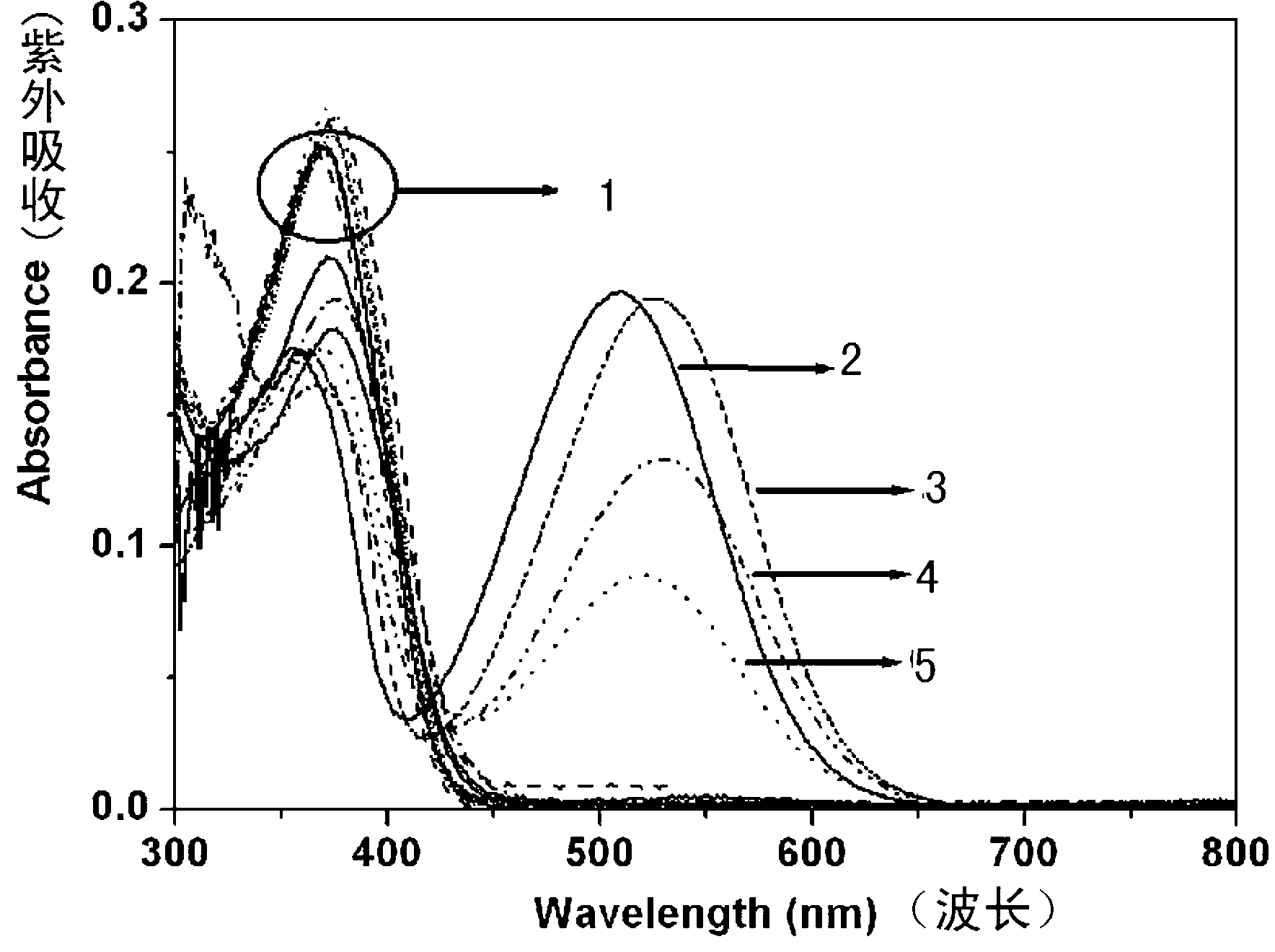

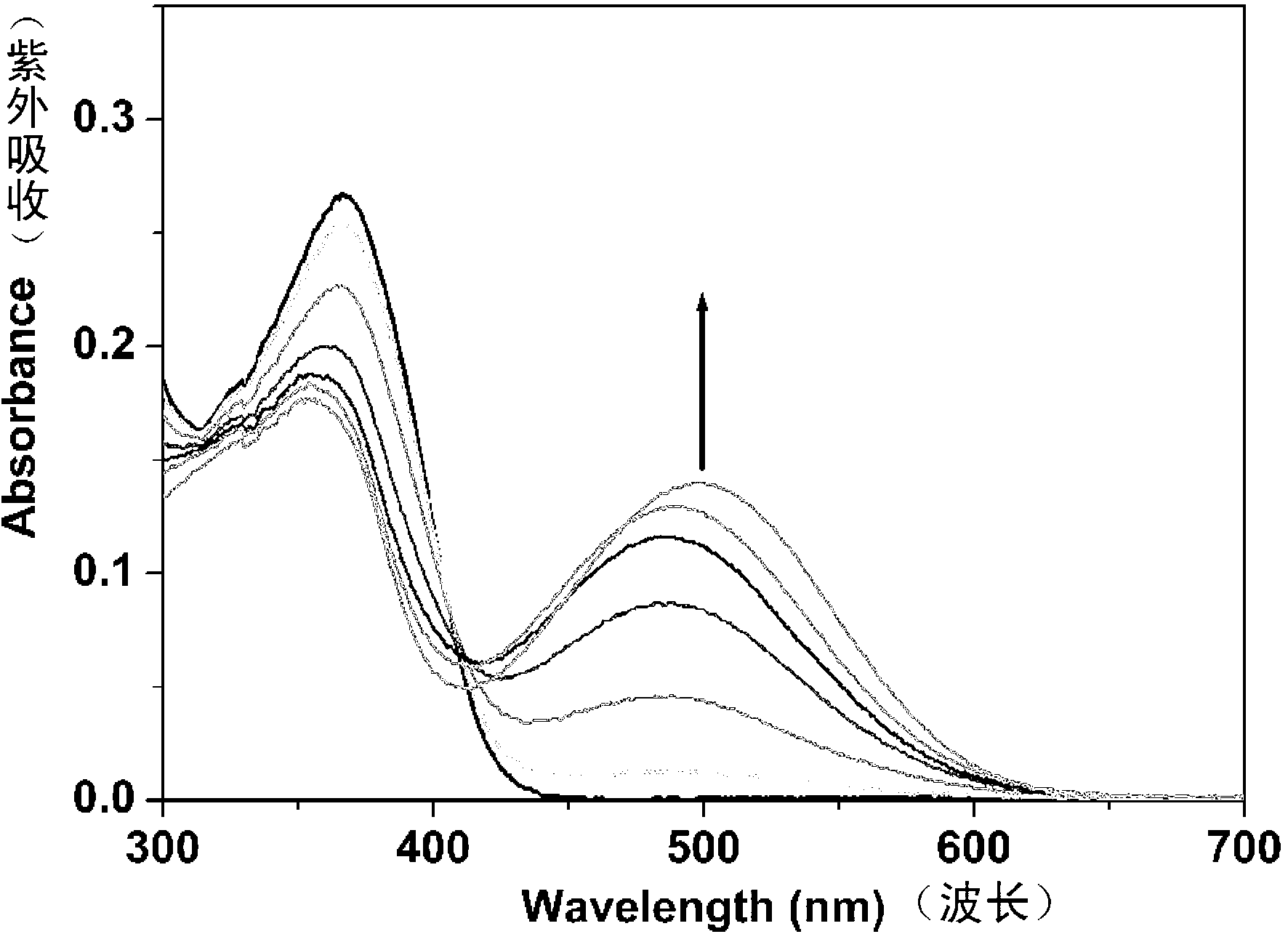

Application of sodium bismuthate in rapidly degrading organic dye waste water and degradation method

InactiveCN101519256AStrong oxidation abilityLow costWater/sewage treatment by irradiationWater contaminantsOrganic dyeCatalytic oxidation

The invention discloses application of sodium bismuthate in rapidly degrading organic dye waste water and a degradation method. The method comprises the following steps: removing impurities of the organic dye waste water by grates, standing and settling the waste water; and adjusting pH value to between 7 and 10; introducing the waste water into a reaction vessel, adding NaBiO3 into the reaction vessel, irradiating the mixture by visible light, reacting the mixture under stirring, and discharging the waste water after being processed; and when the concentration of the organic waste water exceeds 130 mg / L, diluting the waste water, wherein the selected sodium bismuthate is a commercial article and can be directly purchased; the adding concentration is 0.1 to 2 g / L economically; and when the adding concentration exceeds 3g / L, excessive solid particles disperse illumination to reduce the photolysis efficiency. The method has strong applicability to processing the dye waste water and can be performed at normal temperature. The catalytic oxidizer has strong oxidation capability, can oxidize most organic dyes, has high degradation speed, obviously reduced TOC and low cost, and is easy for mass production and use.

Owner:NANJING UNIV

3D (Three-dimensional) printer waste recovery system and recovery method thereof

InactiveCN107756805AReasonable designRealize detachable functionAdditive manufacturing apparatusPlastic recyclingRecovery methodInjection moulding

The invention relates to the technical field of 3D (Three-dimensional) printing, concretely relates to a 3D printer waste recovery system, and discloses a recovery method utilizing the recovery system. The recovery system comprises a waste storage device, a waste recovery device, a waste cooling device, a waste smashing device, a smashed waste conveying device and a re-injection molding device; and the recovery method comprises a waste storage process, a waste recovery process, a waste cooling process, a waste smashing process, a waste conveying process and an injection molding process. According to the 3D printer waste recovery system and the recovery method thereof provided by the invention, through the reasonable setting and the coordination and distribution of responsibilities of the processes, the 3D wastes are recovered through the system, and the cyclic utilization of the 3D printer wastes is realized.

Owner:HUNAN KUANGCHU TECH CO LTD

Bismuth ferrate-carbon nano tube, preparation method thereof and method for treating organic dye wastewater by utilizing bismuth ferrate-carbon nano tube

InactiveCN102489253AStrong applicabilityFast degradationOther chemical processesWater contaminantsProcess engineeringMicrowave oven

The invention discloses a bismuth ferrate-carbon nano tube, a preparation method thereof and a method for treating organic dye wastewater by utilizing the bismuth ferrate-carbon nano tube and belongs to the field of wastewater treatment. The preparation method of the bismuth ferrate-carbon nano tube comprises the following steps of: (1) dissolving ferric nitrate and bismuth nitrate in pure 2-methoxyethanol; (2) adding a nitric acid solution; (3) adding the carbon nano tube, citric acid and glycol; (4) rising the temperature for heating so as to form sol; (5) rising the temperature for evaporating a solvent so as to form gel; (6) calcining; and (7) rising temperature and calcining to obtain crystal. The method for treating the organic dye wastewater by utilizing the bismuth ferrate-carbon nano tube prepared by the preparation method comprises the following steps of: (A) settling the wastewater containing organic dyes and taking supernatant liquor; (B) adding the bismuth ferrate-carbon nano tube; (C) recovering the bismuth ferrate-carbon nano tube; and (D) heating the bismuth ferrate-carbon nano tube in a microwave oven, and putting the bismuth ferrate-carbon nano tube into use again. The material and the method for treating the organic dye wastewater are strong in applicability, fast and energy-saving and can be better combined with the existing process.

Owner:NANJING UNIV

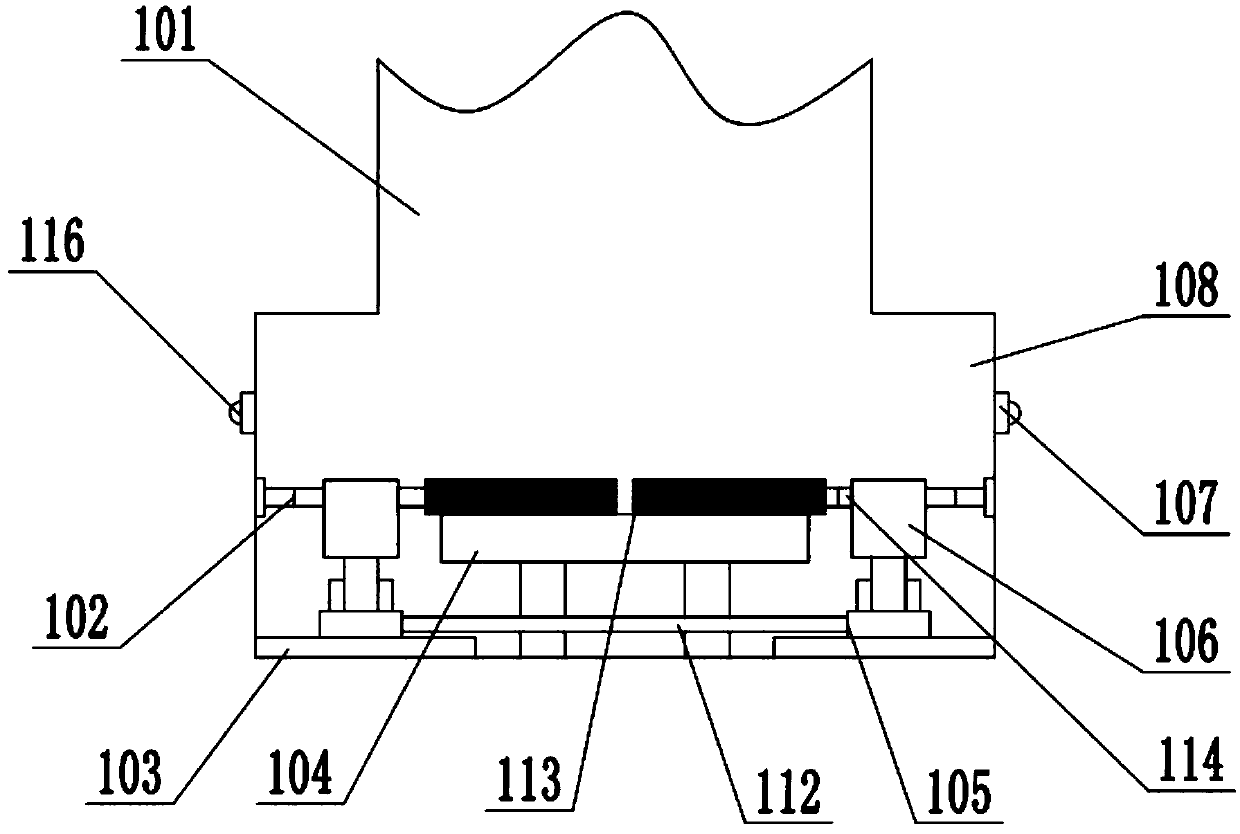

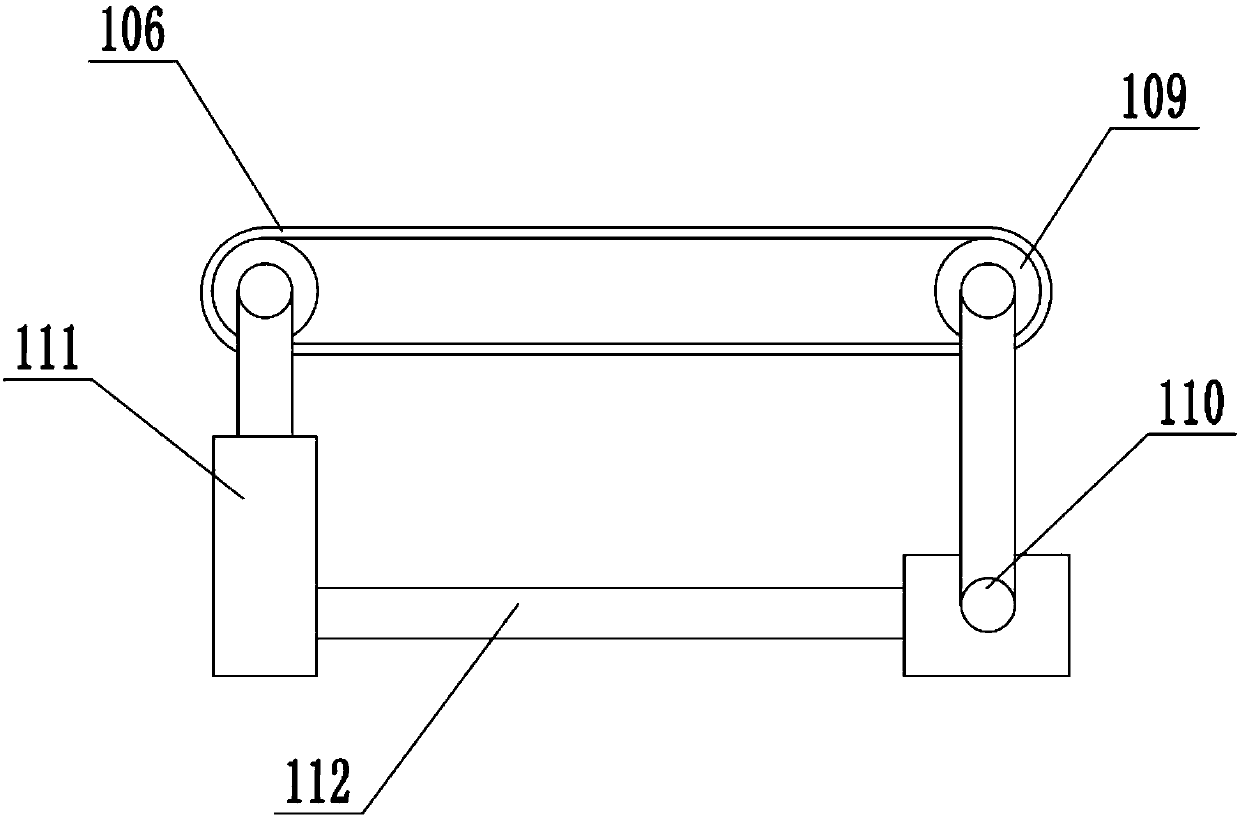

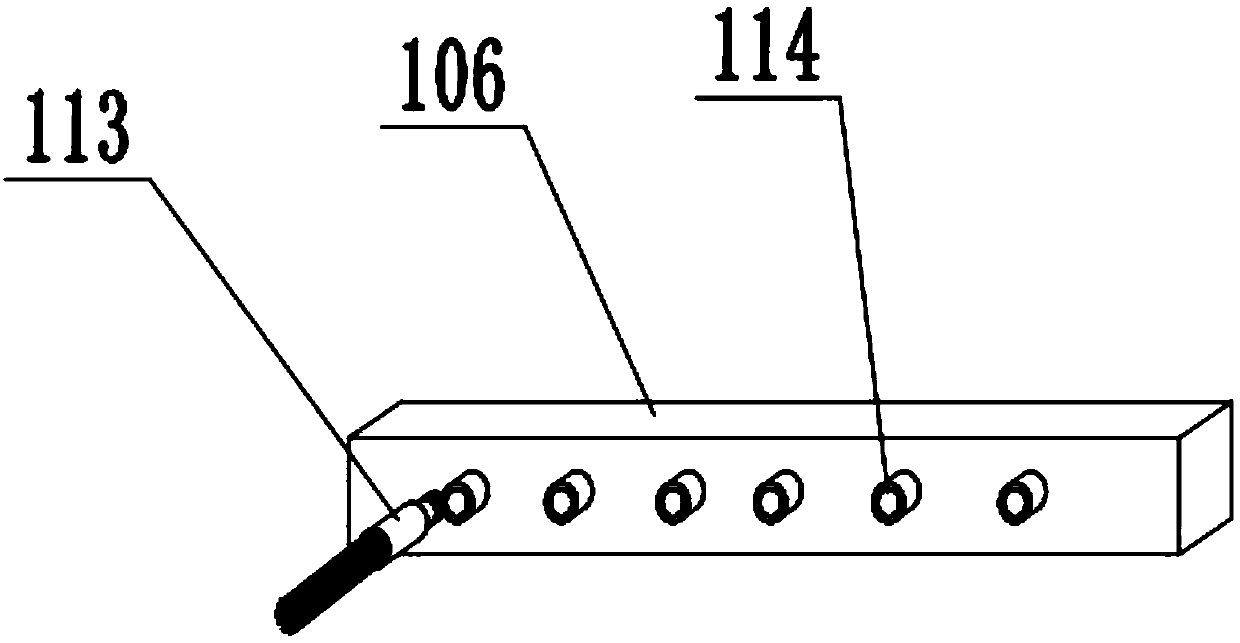

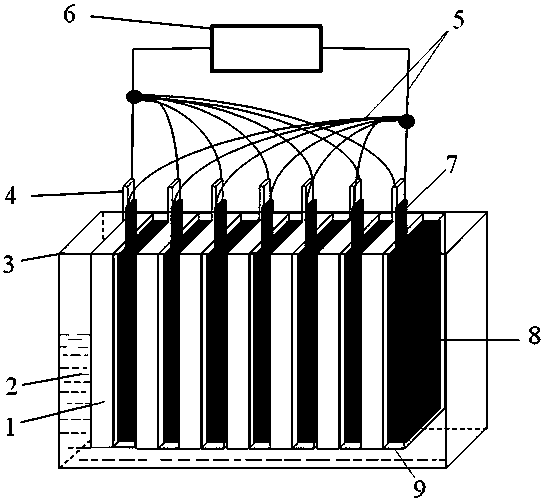

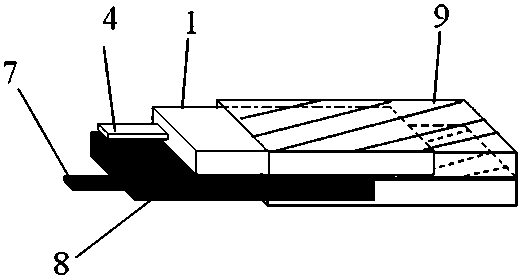

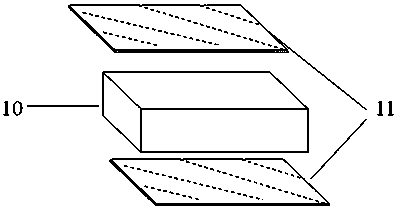

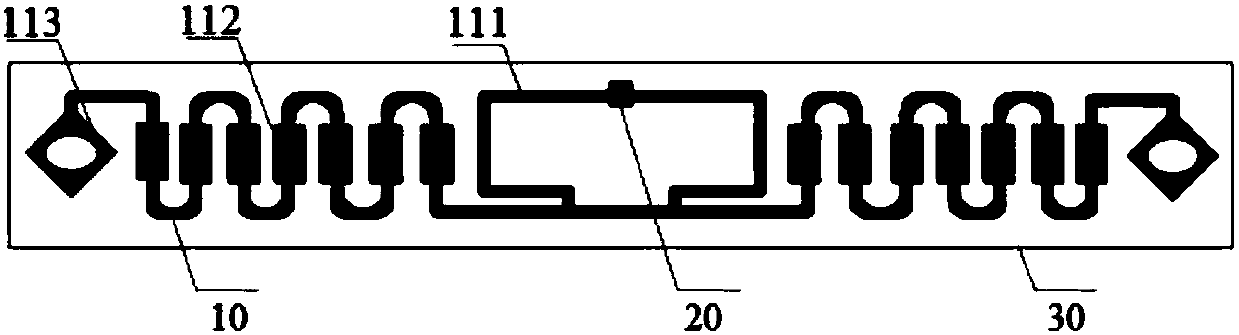

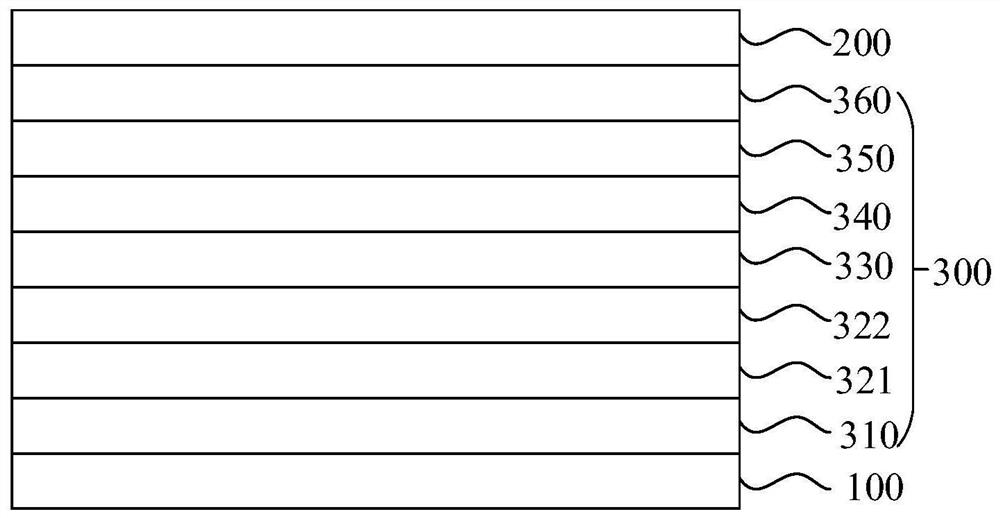

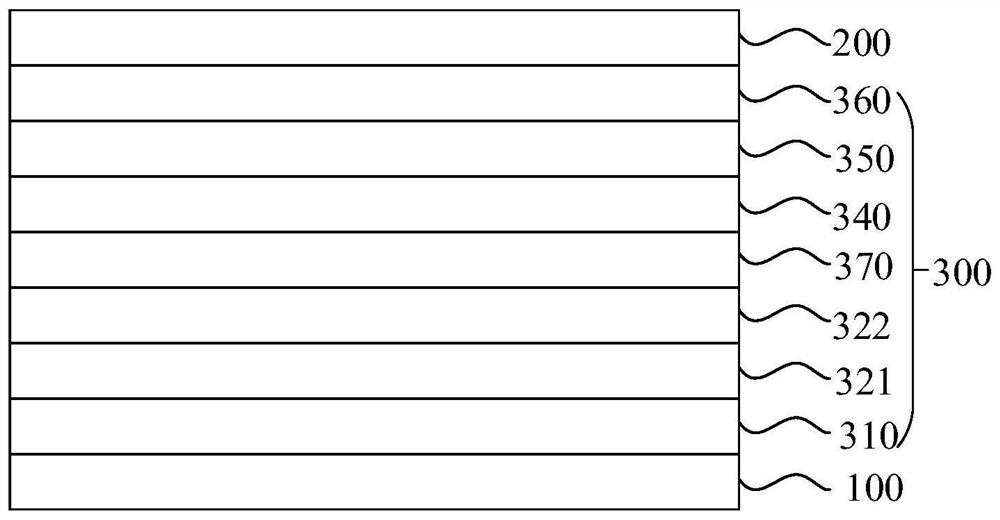

A method and device for pre-lithiation of negative pole piece of lithium ion battery

The invention provides a pre-lithiation method and device for negative pole pieces of a lithium-ion battery. The method comprises the steps as follows: firstly, the negative pole pieces and metal lithium pieces are sequentially immersed into an electrolyte at intervals in an inert atmosphere condition; the negative pole pieces correspond to the metal lithium pieces one by one but are not in contact with the metal lithium pieces; the negative pole pieces and the metal lithium pieces are connected with a positive electrode and a negative electrode of a power supply through leads respectively; the negative pole pieces are charged; the charging current is 0.05-2.0C; and the negative pole pieces are taken out and dried to obtain the pre-lithiated negative pole pieces. According to the pre-lithiation method and device, 'wet pre-lithiation' is adopted; the cost is low; the production security is high; the pole pieces can be evenly pre-lithiated; and the first efficiency and the energy density of the battery are improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Active carbon fiber-loaded NaBiO3-based composite oxide and preparation method thereof, and method for degrading organic dye waste water by using composite oxide

InactiveCN103623805ASimple equipment requirementsSimple requirementsWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsEpoxyFiber

The invention discloses an active carbon fiber-loaded NaBiO3-based composite oxide and a preparation method thereof and a method for degrading organic dye waste water by using the composite oxide. The preparation method comprises the following steps: successively cleaning an active carbon fiber with ammonia water, nitric acid, acetone and deionized water and drying the active carbon fiber for subsequent usage; synthesizing BSO from NaBiO3 and AgNO3 in a liquid phase and preparing a composite function material according to a mass ratio of BSO to NaBiO3 of 1: 1-3; and placing an epoxy resin and the composite function material according to a weight ratio of 1.5-2.5: 1 into a container containing acetone, carrying out high speed stirring, dipping the active carbon fiber 5 to 10 times of the mass of the composite oxide function material into an acetone solution for 2 h and successively subjecting the active carbon fiber to vacuum drying and then to heat treatment under the protection of N2 so as to obtain the composite oxide. The degradation method comprises the following steps: adding 2 to 5 g / L of the composite oxide into the organic dye waste water under irradiation by visible light; carrying out stirring at room temperature and normal pressure; and discharging waste water through centrifugation after basic decolouring of the waste water. The degradation method provided by the invention has the advantages of simple requirements on equipment, low energy consumption, convenient operation and capacity of achieving the purposes of decolouring, degradation and mineralization of the dye waste water in a short period of time.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

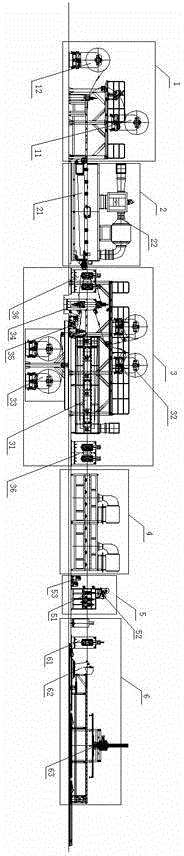

Manufacturing system for A2-level fireproof core board

ActiveCN104452998AHigh densitySmall footprintLamination plant layoutLaminationLiquid stateAdditive ingredient

The invention discloses a manufacturing system for an A2-level fireproof core board. An unreeling device, a heating device, a combining device, a cooling device, a film attaching device and a trimming and board shearing device are arranged in the forward moving direction of the core board of a combined system in sequence. The total length of the combined system ranges from 50 m to 60 m, and the system speed ranges from 2 m / min to 3 m / min. Compared with a traditional core board manufacturing and combining whole system, the occupied space is reduced by a half, the production efficiency is improved by two times, the ordering demands of different clients are met, more benefit is brought to a manufacturing enterprise, the whole manufacturing system is a whole, the A2-level fireproof core board can be rapidly manufactured, the processes of baking, stripping, rolling and cooling are conducted after materials are prepared, core materials which are liquid state ingredients are baked into a solid sheet shape, the internal density of the core board is increased, and therefore the fireproof strength is improved.

Owner:江苏协诚智能设备有限公司

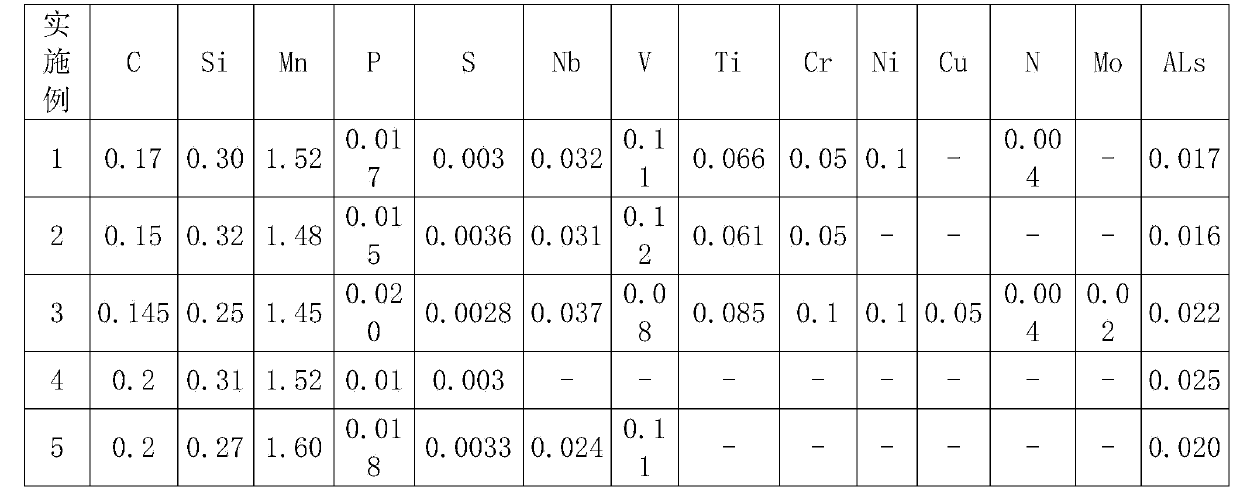

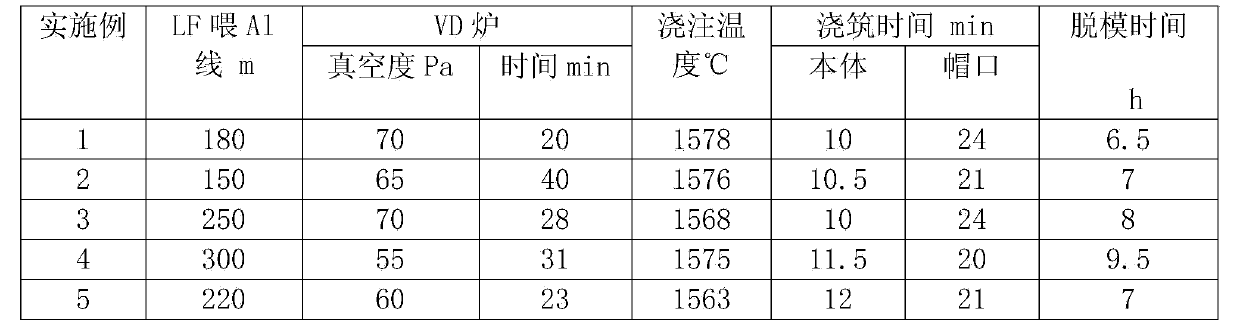

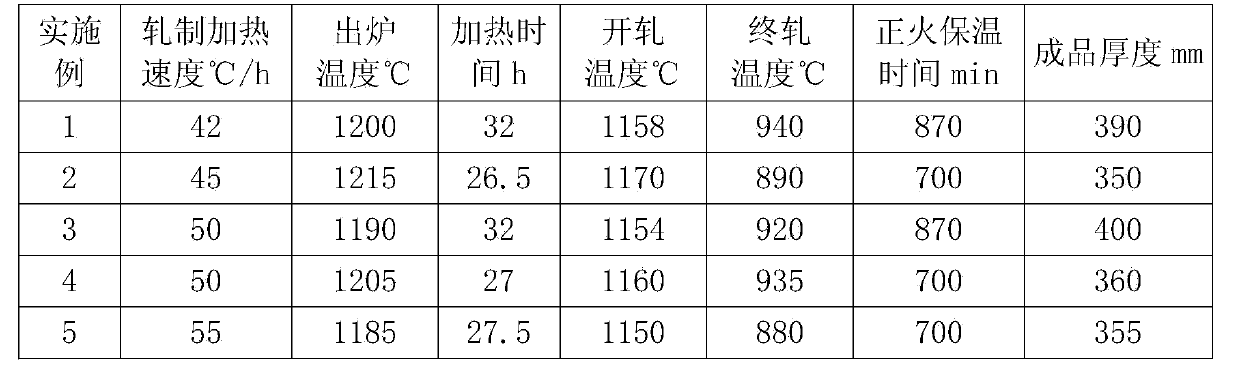

Production method of low-alloy and high-strength thick plates

ActiveCN103469099AImprove mechanical propertiesReduce manufacturing costFurnace temperatureSlow cooling

The invention provides a production method of low-alloy and high-strength thick plates, and the production method comprises the following steps: after electric furnace smelting is performed, carrying out LF (Ladle Furnace) refining and VD (Vacuum Degassing), controlling the casting temperature and casting time of a body and a cap, after steel ingots are cooled, quickly demoulding the steel ingots, carrying out heat preservation on the cap by using a heat-holding cover, and cooling the steel ingots in a cooling device; putting the steel ingots into a furnace when the furnace temperature is 600-700 DEG C, after tightly covering the steel ingots for 5-8 hours, heating the steel ingots to 1150 DEG C at a speed of 40-60 DEG C / h and carrying out heat preservation on the steel ingots, and freely heating the steel ingots to1180-1220 DEG C 5 hours before rolling; carrying out axial rolling on the steel ingot firstly so as to eliminate tapers, wherein the starting rolling temperature is greater than 1150 DEG C, the finish rolling temperature is 850-950 DEG C, the total reduction rate is greater than 50%, the slow cooling stacking temperature is not less than 500 DEG C, and the slow cooling time is not less than 48 hours; carrying out normalizing treatment on rolled steel plates at a temperature of 880-920 DEG C, and carrying out heat preservation on the steel plates at a speed of 1.9-2.25 mm / min. The mechanical properties, especially Z-direction properties, of super-thick steel plates produced by using the method disclosed by the invention completely meet the requirements, the yield strength Rel of the steel plate is greater than or equal to 300 MPa, the percentage reduction of cross sectional area Z is greater than to equal to 50%, the qualified rate of flaw detection is over 90%, and the production cost of the steel plate is low.

Owner:ANGANG STEEL CO LTD

Lightweight artificial leather with wear-resistant skin for vehicles and preparation method thereof

ActiveCN108797143AImprove dispersion uniformityImprove wear resistanceVehicle componentsCoatingsWear resistantPlasticizer

The invention discloses lightweight artificial leather with wear-resistant skin for vehicles applied to automotive trims. The lightweight artificial leather comprises a surface treatment agent layer,a wear-resistant skin layer, a foaming layer, a glue layer and a base fabric layer distributed in sequence from top to bottom; the wear-resistant skin layer comprises 80-100 parts of PVC (Polyvinyl Chloride) resin powder, 50-100 parts of a plasticizer, 1-20 parts of a heat stabilizer, 0.01-20 parts of a flatting agent, 0.01-20 parts of an anti-aging agent and 0.1-30 parts of an anti-wear agent. The anti-wear agent comprises 5-50 parts of hollow glass beads, 5-50 parts of hollow ceramic micro-beads, 80-100 parts of an o-benzene plasticizer and 30-90 parts of polyvinyl chloride powder. By addingthe hollow micro-beads and performing dispersing treatment on the hollow micro-beads in advance, the technical problem that the conventional PVC artificial leather is not wear-resistant and high in density is solved, and the PVC artificial leather with high wear resistance and the lightweight characteristic is obtained.

Owner:CANADIAN GENERAL TOWER CHANGSHU CO LTD

Lower alcohol detecting probe, preparation method and application thereof

InactiveCN103320116AGood choiceThe synthetic route is simpleOrganic chemistryAnalysis by material excitationAlcoholHydrogen atom

The invention discloses a lower alcohol detecting probe, and a preparation method and application of the detecting probe, and belongs to the technical field of analytical chemistry detection. The lower alcohol detecting probe has a general formula shown in the description, in which R1 represents a hydrogen atom, R2 represents a nitrogen atom or a group shown in the description and R3 represents a hydrogen atom or a methoxy group. Probe molecules of the lower alcohol detecting probe are made into a detecting plate, the detecting plate turns red or pink after being reacted with lower alcohol, and the phenomenon is obvious and can be recognized by naked eyes; the lower alcohol detecting probe is convenient for use and low in cost, can be directly used for detecting lower alcohol in a solution, can detect lower alcohol rapidly and in real time, is suitable for being used in large scale actual production, and has a good application prospect in the environmental protection field; and the lower alcohol detecting probe avoids the problem that professionals need to use professional tools and software for a long time to obtain results by means of large-scale equipment.

Owner:ZHENGZHOU UNIV

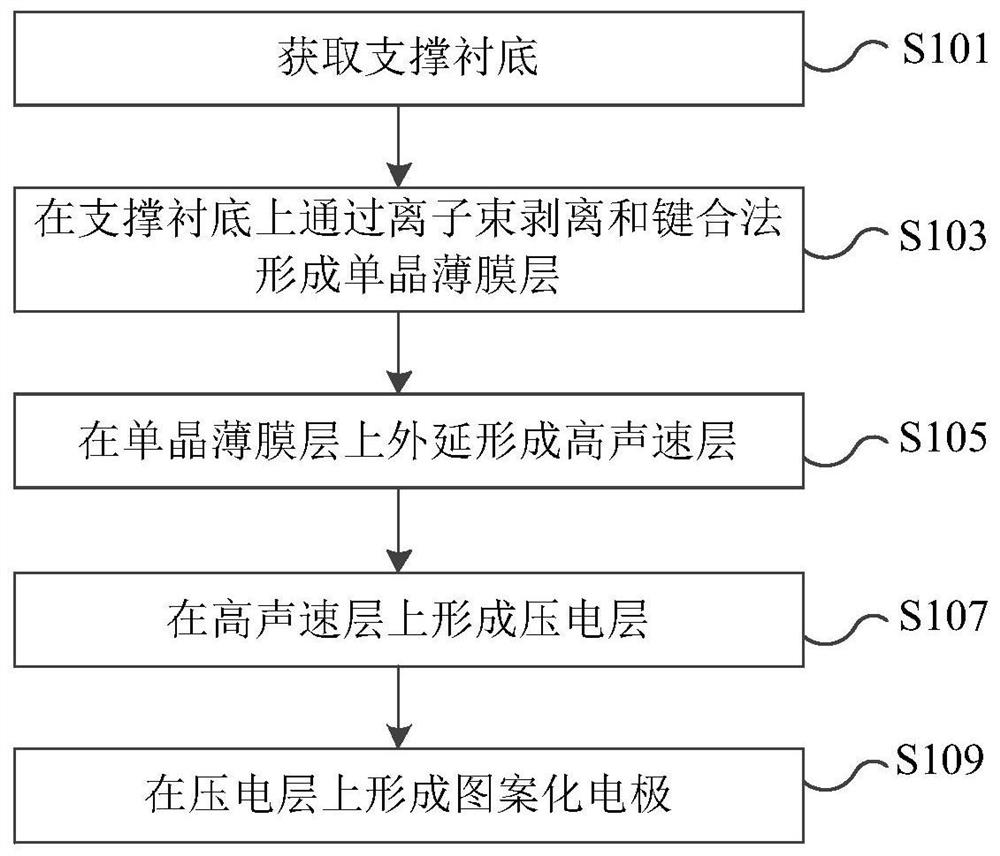

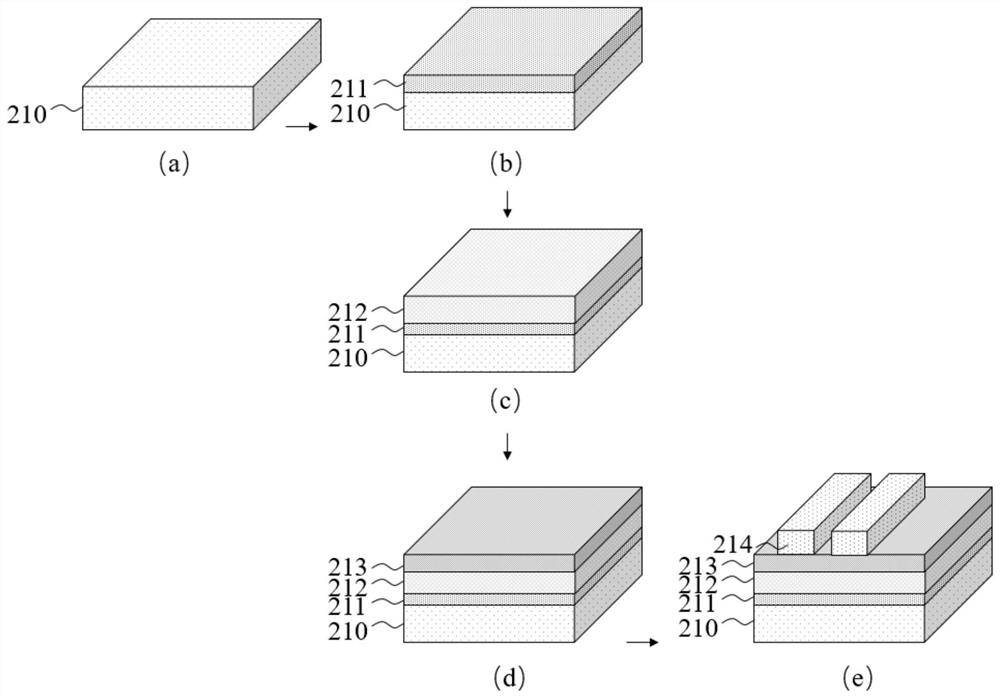

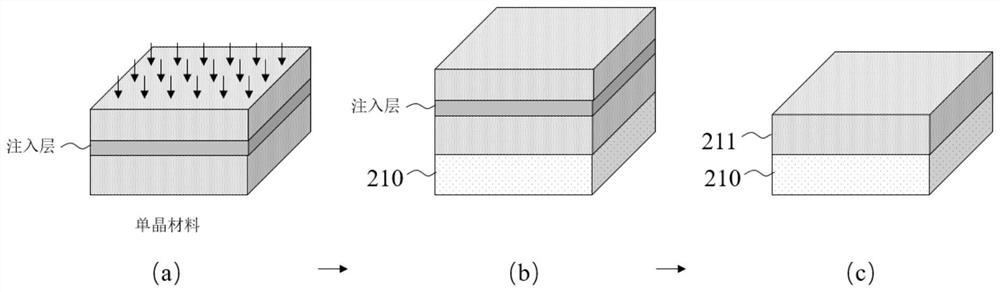

Acoustic resonator and preparation method thereof

The invention relates to an acoustic resonator and a preparation method thereof. The preparation method comprises the following steps of acquiring a support substrate; forming a single crystal thin film layer on the supporting substrate through an ion beam stripping and bonding method; epitaxially forming a high-sound-velocity layer on the single crystal thin film layer; forming a piezoelectric layer on the high sound velocity layer; forming a patterned electrode on the piezoelectric layer; wherein the sound velocity of the body wave propagated in the high sound velocity layer is greater thanthe sound velocity of the target elastic wave propagated in the piezoelectric layer. According to the preparation method, the high-sound-velocity layer is arranged below the piezoelectric layer, so the working frequency and the quality factor of the device can be effectively improved, the single crystal thin film layer which is expensive or cannot be directly obtained on the substrate in an epitaxial mode can be repeatedly transferred by utilizing an ion beam stripping and bonding technology, so preparation cost can be reduced, and meanwhile, the high-sound-velocity layer is deposited on the single crystal thin film layer by using an epitaxial technology to obtain the high-sound-velocity layer with the optimal thickness for constraining the sound wave energy, so the bandwidth and the quality factor of the sound wave resonator can be improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

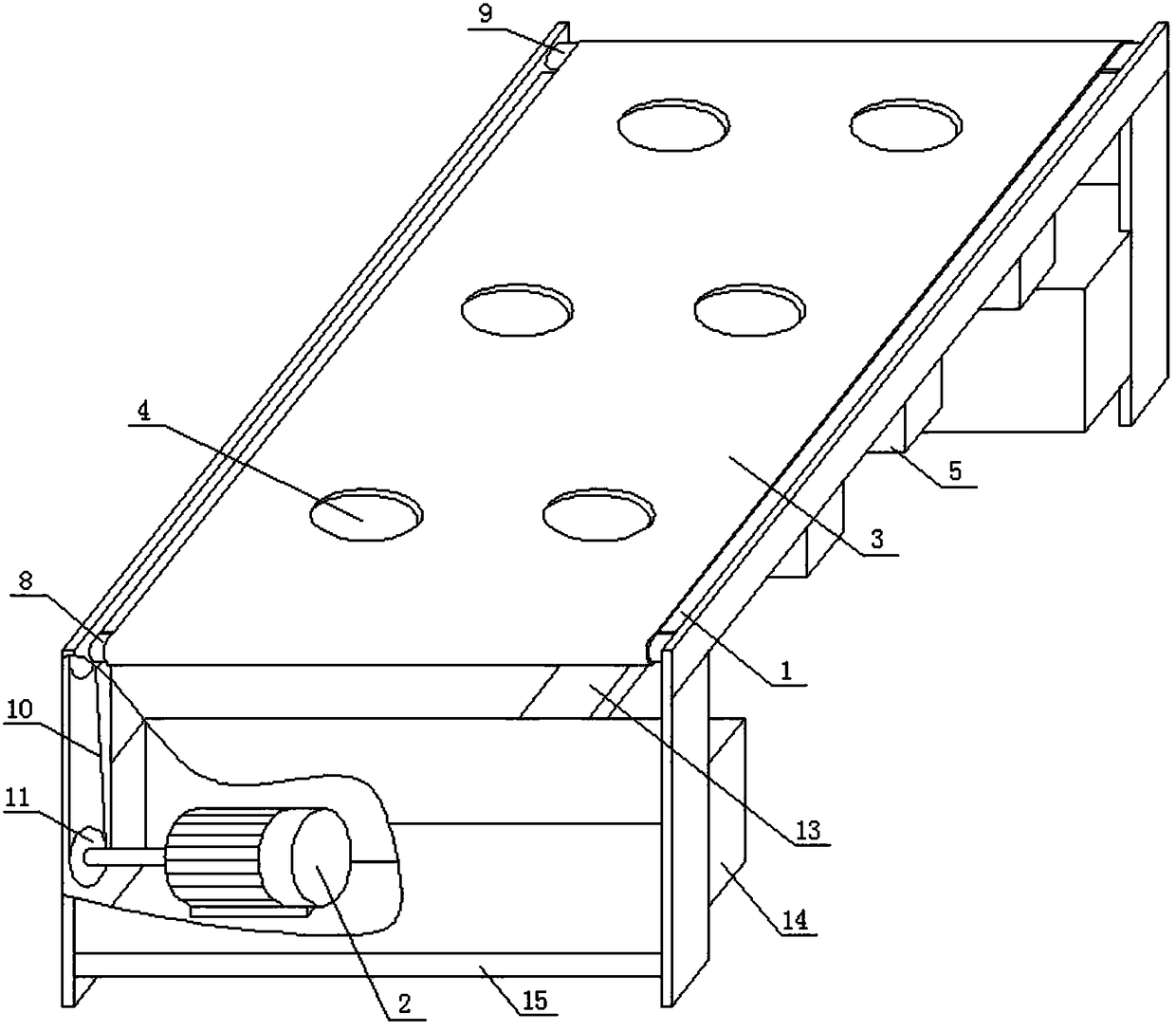

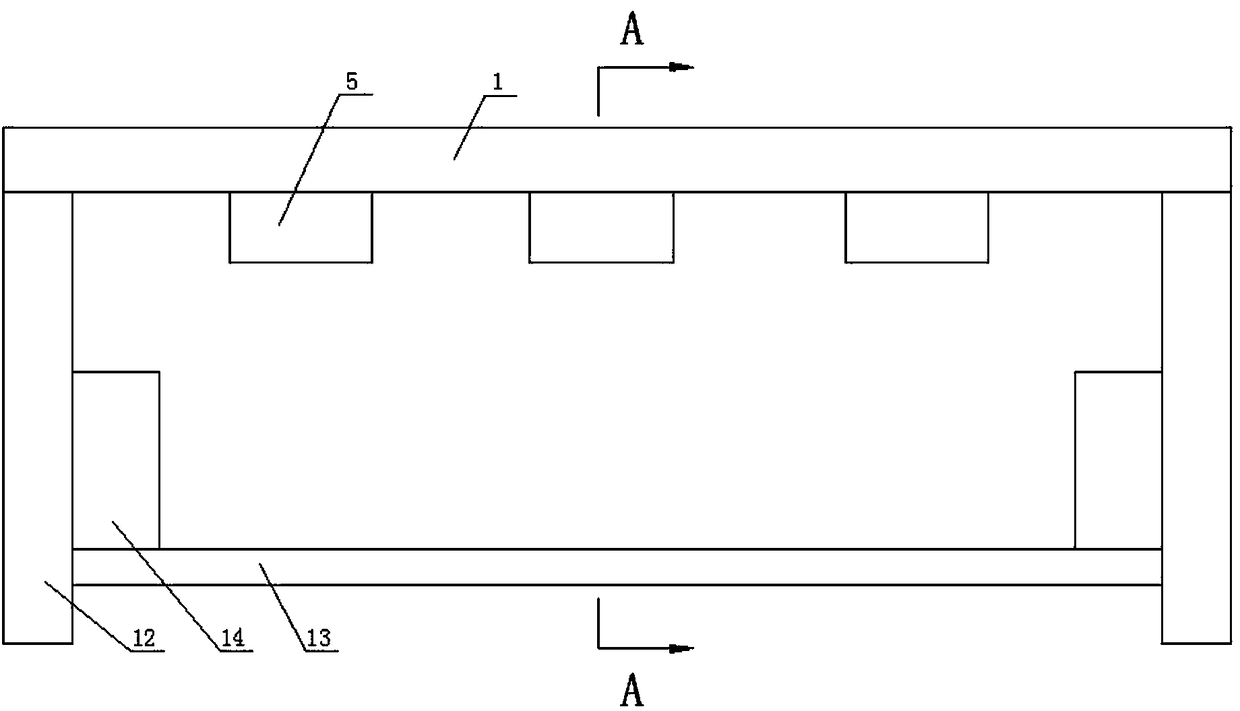

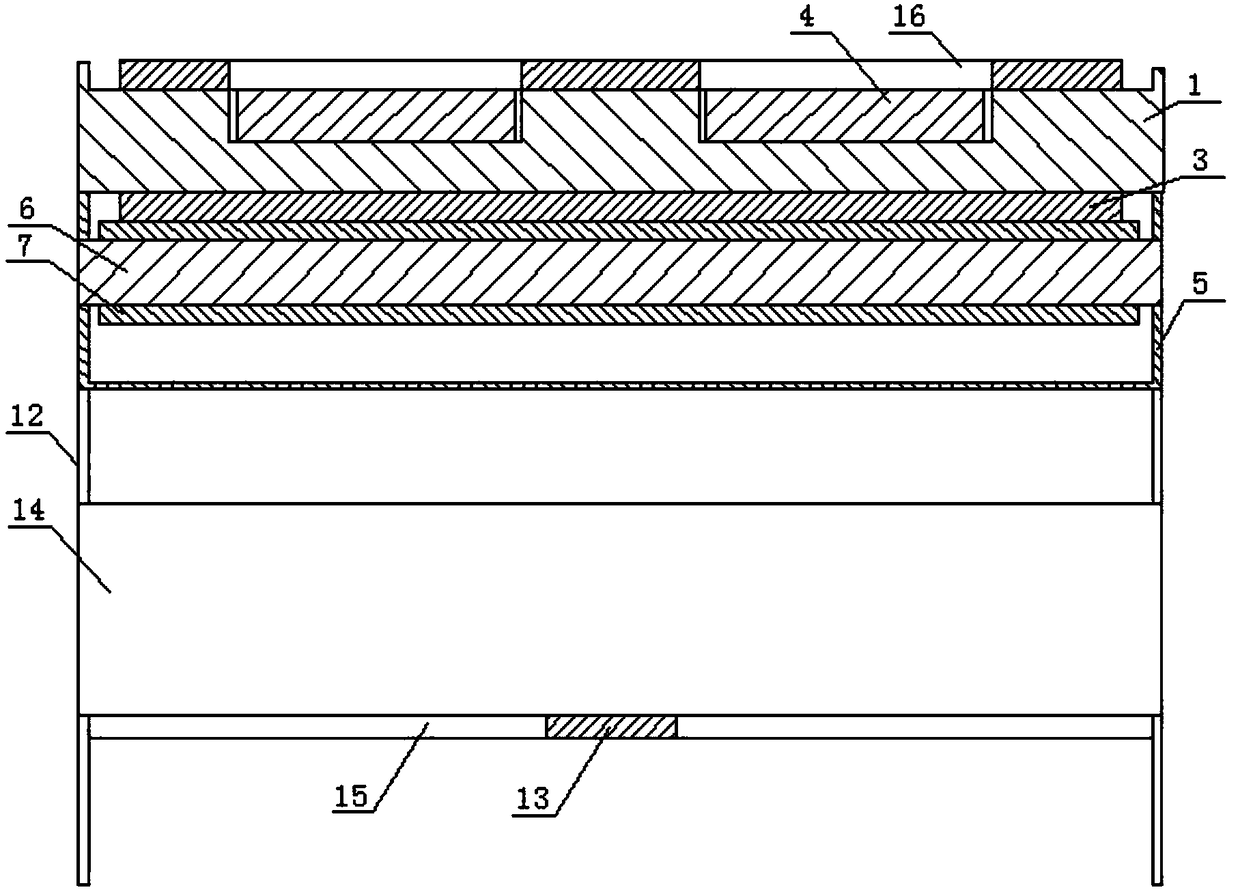

An intelligent dining table and an intelligent dining table system

PendingCN108158222AReduce waiting timeImprove cleaning efficiencyFurniture partsServing tablesControl systemLow demand

The invention relates to an intelligent dining table and an intelligent dining table system. The intelligent dining table comprises a table plate, a support, an annular table cloth sleeving the tableplate, a cleaning device and a control system, wherein the control system comprises a power source for supplying power, a relay, a magnetic proximity switch, a magnet used for changing the on-off state of the magnetic proximity switch and a motor. The intelligent dining table system comprises a bowl collection device, a tableware fetching stand and the intelligent dining table. The dining table can be cleaned wholly automatically to allow different groups of guests to have meals; the intelligent dining table and the intelligent dining table system have the advantages of simple structure, low demand for manual work, high cleaning efficiency and low production cost and can be put into production and use in batches.

Owner:伍贤勇

Thick high-conductivity multilayer graphene film and RFID electronic label of impedance loaded shape

InactiveCN107834169AShorten the lengthHigh bandwidthAntenna supports/mountingsRadiating elements structural formsMetallic materialsPolyamide

The invention discloses a thick high-conductivity multilayer graphene film and an RFID electronic label of an impedance loaded shape. A graphite film precursor including polyimides, polyamide and oxidized graphene forms a film in a scraping or screen printing method, and a graphene film precursor is prepared by hot press molding at the temperature of 50-180 DEG C; the graphene film precursor is placed in a high temperature furnace, heat treatment at the low temperature of 200-500 DEG C for 1-2 hours, heat treatment at 200-500 DEG C for 2-5 hours and heat treatment at 2000-2800 DEG C for 2-5 hours are carried out on the graphene film precursor successively in a cyclic way, and the graphene film precursor is then cooled for 12 hours slowly; and roll forming is carried out. Compared with a traditional metal material, the prepared RFID electronic label has similar functions, a signal transmission performance is ensured, the label can be produced in large scale to reduce the cost, and unique properties as high temperature resistance, corrosion resistance, flexibility and environmental protection of a graphene material are included.

Owner:WUHAN UNIV OF TECH

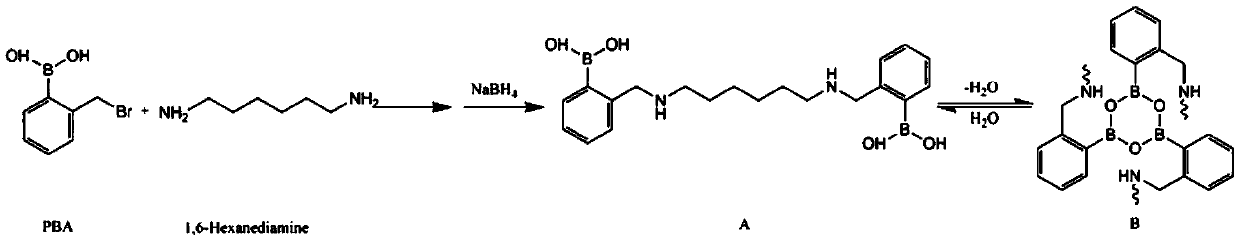

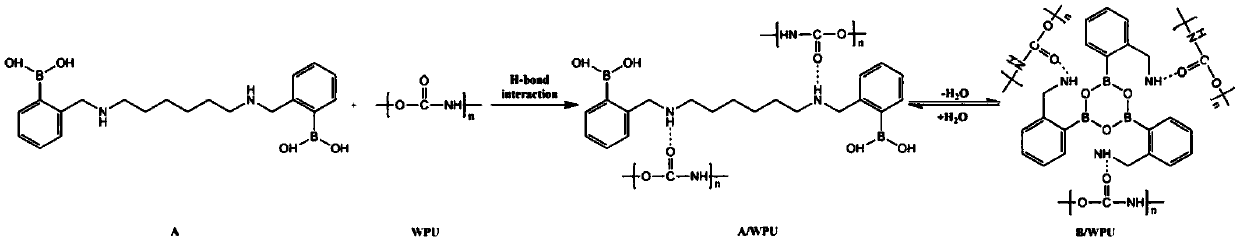

Self-repairing water-based polymer composite coating agent, and preparation method and application thereof

ActiveCN111548714AStrong self-healing efficiencyLow costGroup 3/13 element organic compoundsPolyurea/polyurethane coatingsPhenylboronic acidBoronic acid

The invention discloses a self-repairing water-based polymer composite coating, and a preparation method and application thereof, and belongs to the technical field of coating agent production. The preparation method comprises the following steps of: (1) reacting phenylboronic acid, a primary amine compound and NaBH4 to obtain a compound containing a boric acid bond, and performing dehydration, trimerizing and crosslinking to obtain a nitrogen coordination-containing boric acid ester bond compound; and (2) blending and compounding the nitrogen coordination-containing boric acid ester bond compound and a water-based polymer to obtain the self-repairing water-based polymer composite finishing agent. The preparation method disclosed by the invention has the advantages of simple and easily-controlled process, low cost, wide application range and the like, and is suitable for industrial production. The self-repairing water-based polymer composite coating agent prepared by the preparation method has a boron-oxygen six-membered ring and hydrogen bond dual self-repairing structure, can be quickly and efficiently self-repaired in an aqueous medium at room temperature, has the characteristics of good stability, excellent mechanical properties, obvious repairing effect and the like, and can be applied to various room-temperature self-repairing coatings.

Owner:SHAANXI UNIV OF SCI & TECH

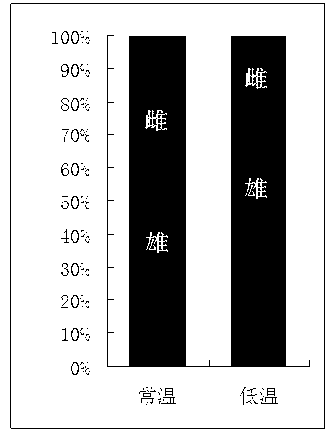

Method for inducing masculinization of fugu rubripes at low temperature

ActiveCN103210854AAvoid operating proceduresEasy to operateClimate change adaptationPisciculture and aquariaFugu rubripesInsemination

The invention discloses a method for inducing masculinization of fugu rubripes at a low temperature. The method comprises the following steps of: performing artificial induced spawning and insemination on healthy male and female fishes which are high in fatness and undergo good gonad development; hatching fertilized eggs under the water temperature condition of 20 DEG C for 45-75 days; and putting into water of 15-17 DEG C, and culturing for 35-65 days. Due to the adoption of the method, male fugu rubripes fries can be produced rapidly, the male rate in the fries is 65-80 percent, the average male rate is 75 percent, ultraviolet ray irradiation is not required, sex hormone is not fed, and complex operation processes are avoided; and the method is low in cost, is easy to operate, and has contribution to mass production.

Owner:DALIAN OCEAN UNIV +1

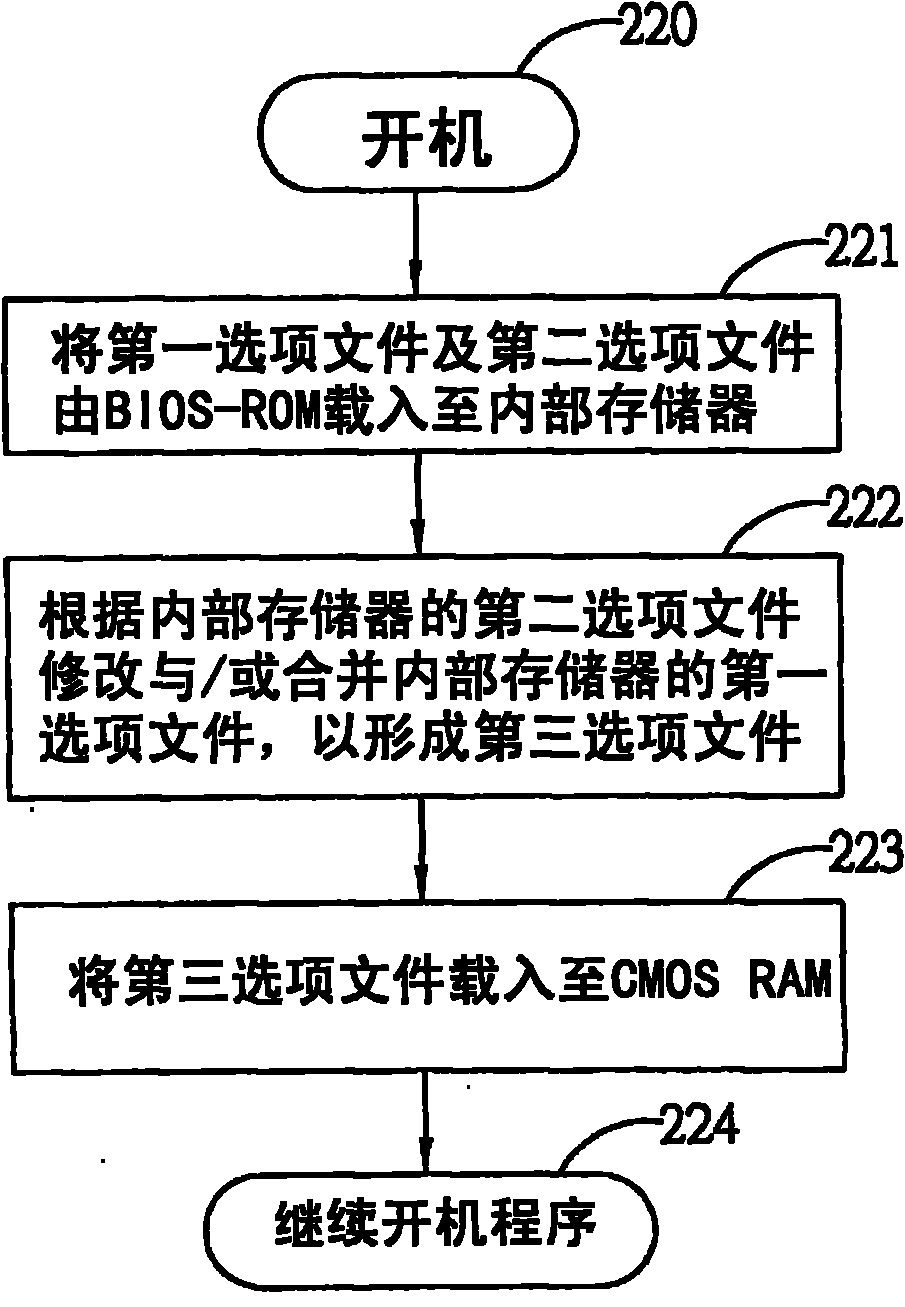

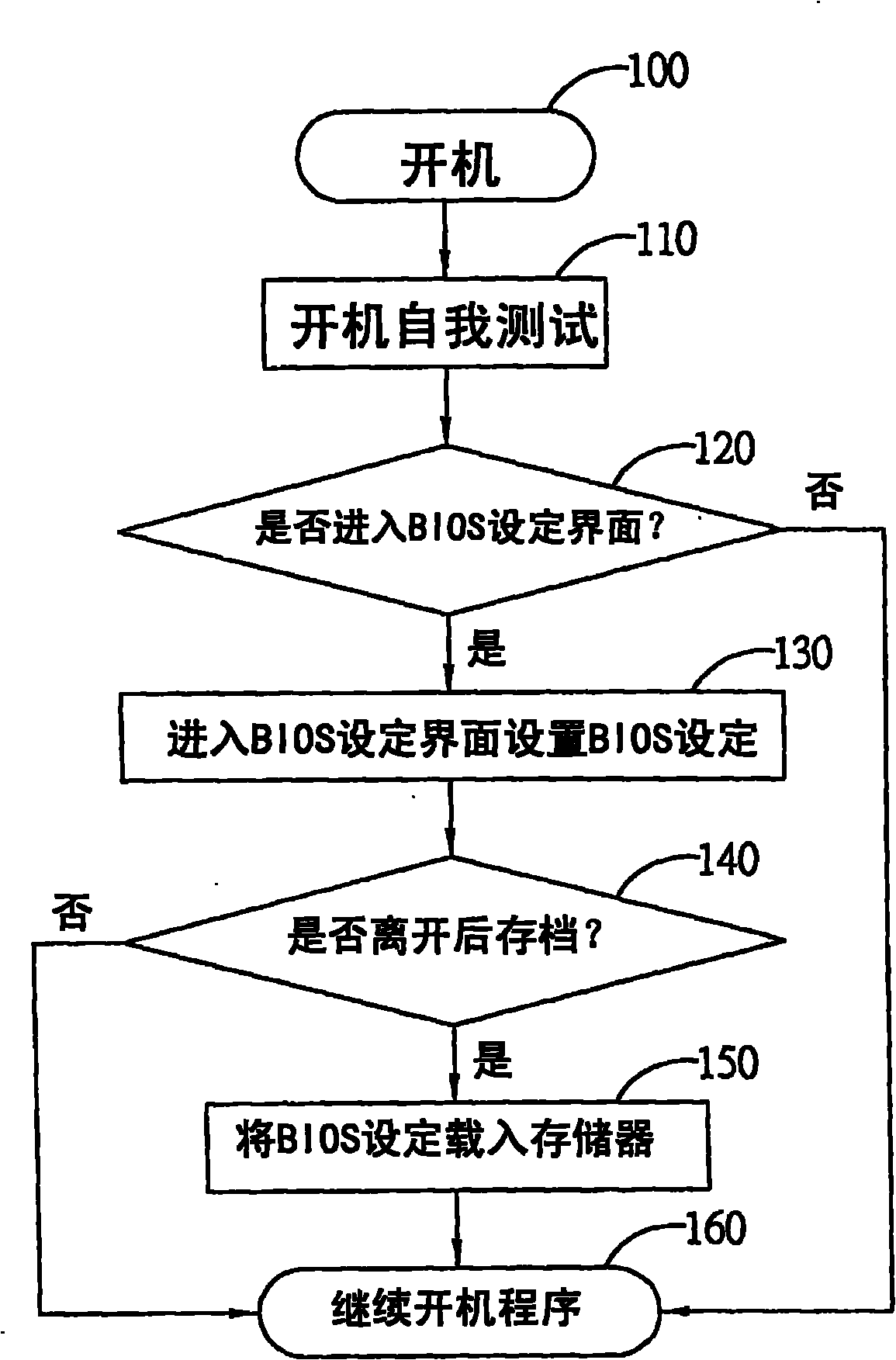

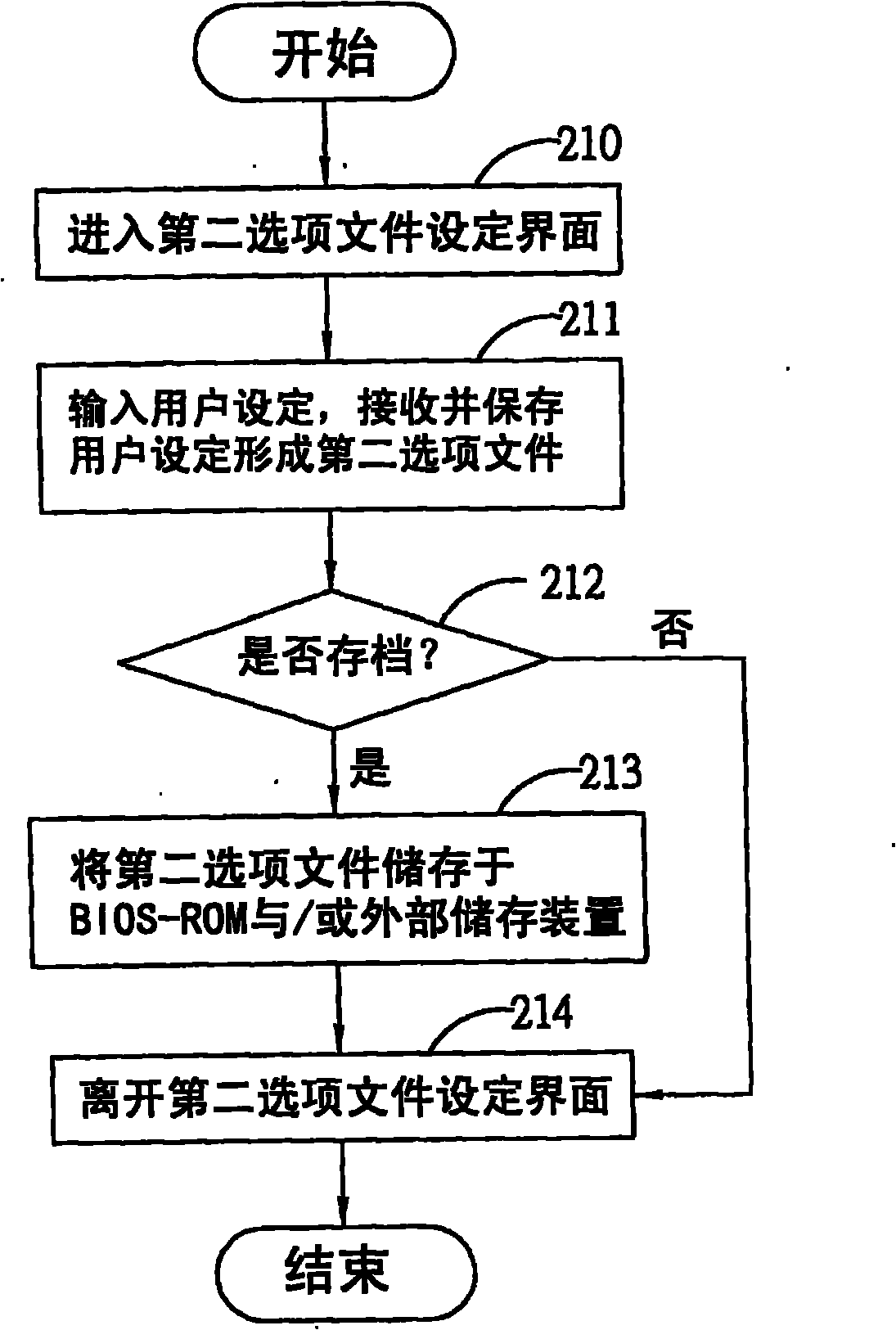

Setting method of basic input/output system

InactiveCN101814033AEliminate the inconvenience of setting one by oneEasy to use in mass productionProgram loading/initiatingInternal memoryCMOS

The invention relates to a setting method of a BIOS (Basic Input / Output System), which is applied to a computer with an internal memory, a CMOS RAM (Complementary Metal Oxide Semiconductor Random Access Memory) and a BIOS-ROM (Basic Input / Output System-Read Only Memory), wherein the BIOS-ROM is provided with a first option file. The setting method of the BIOS is characterized by comprising the following steps of: providing a setting interface of a second option file for setting the second option file; storing the second option file into the BIOS-ROM; and loading the first option file and the second option file into the internal memory in the original state of starting-up of the computer, amending and / or merging the first option file according to the second option file to form a third option file and loading the third option file to the CMOS RAM, therefore, the starting-up program is performed according to the third option file.

Owner:INVENTEC CORP

Comprehensive enzyme powder with lipolysis function and preparation method of comprehensive enzyme powder with lipolysis function

The invention relates to the technical field of enzyme preparation, in particular to comprehensive enzyme powder with a lipolysis function and a preparation method of the comprehensive enzyme powder with the lipolysis function. The comprehensive enzyme powder is prepared from, by weight, 1-5 parts of compound decomposition enzyme, 10-30 parts of natto, 50-70 parts of vegetables, 80-100 parts of fruits, 10-30 parts of edible fungi, 10-15 parts of medicinal and edible traditional Chinese medicine extracts, 5-10 parts of mushroom extracting liquid and 40-80 parts of pineapple powder by addition of enzyme strains. Compared with the prior art, the comprehensive enzyme powder with the lipolysis function has the advantages of diversity, balance and easiness in absorption. The preparation method has the advantages that fungal polysaccharides are extracted through combination of ultrasonic waves and an enzymolysis method, fungal cell wall crushing effects are enhanced by ultrasonic waves to increase polysaccharide dissolution rate, cell walls are subjected to further enzymolysis by the enzymolysis method to enable intercellular polysaccharides to be released sufficiently, and accordingly the preparation method is efficient, time saving, labor saving, higher in polysaccharide yield and purity and suitable for large-scale production and application.

Owner:上海世道健康科技有限公司

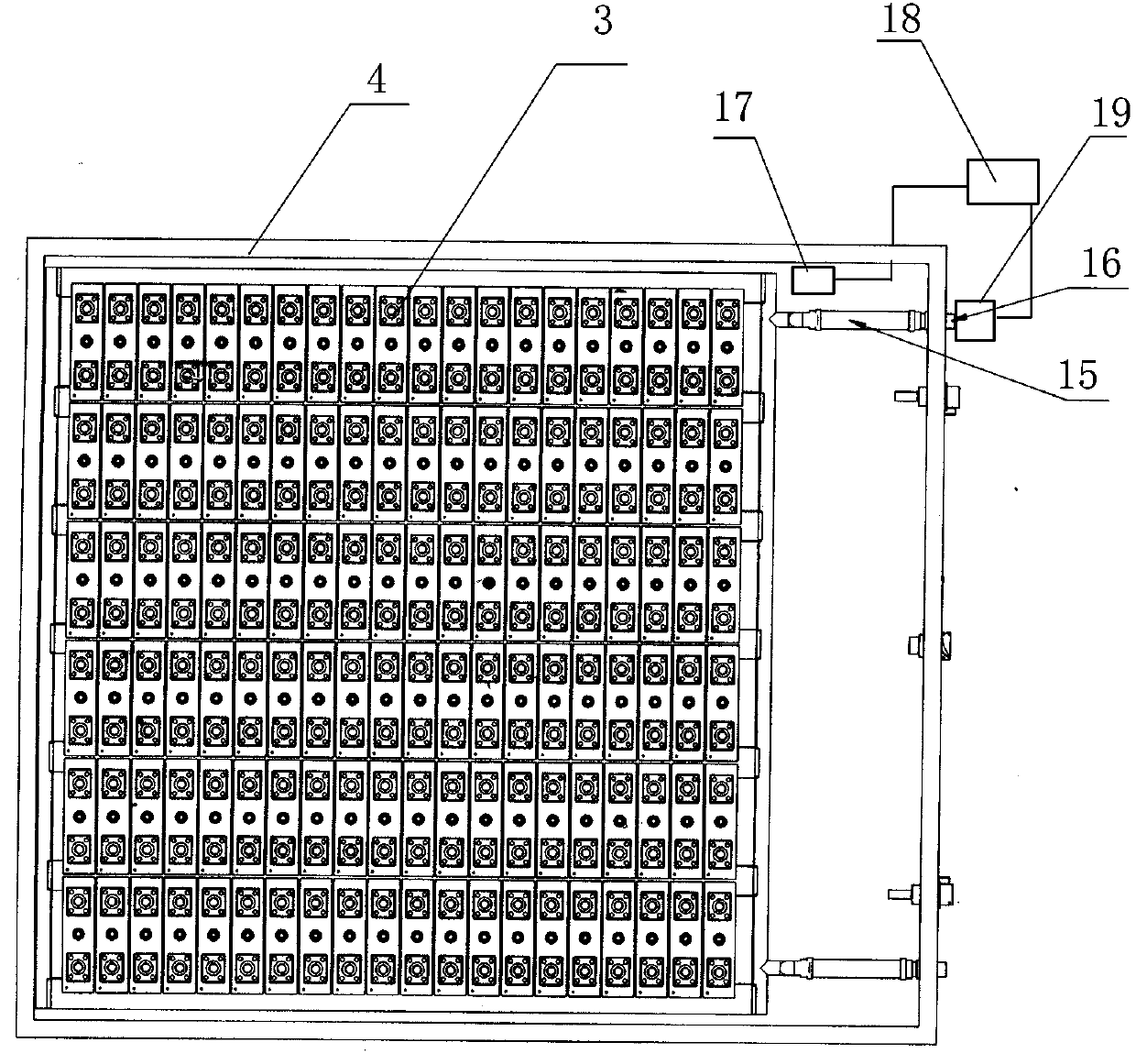

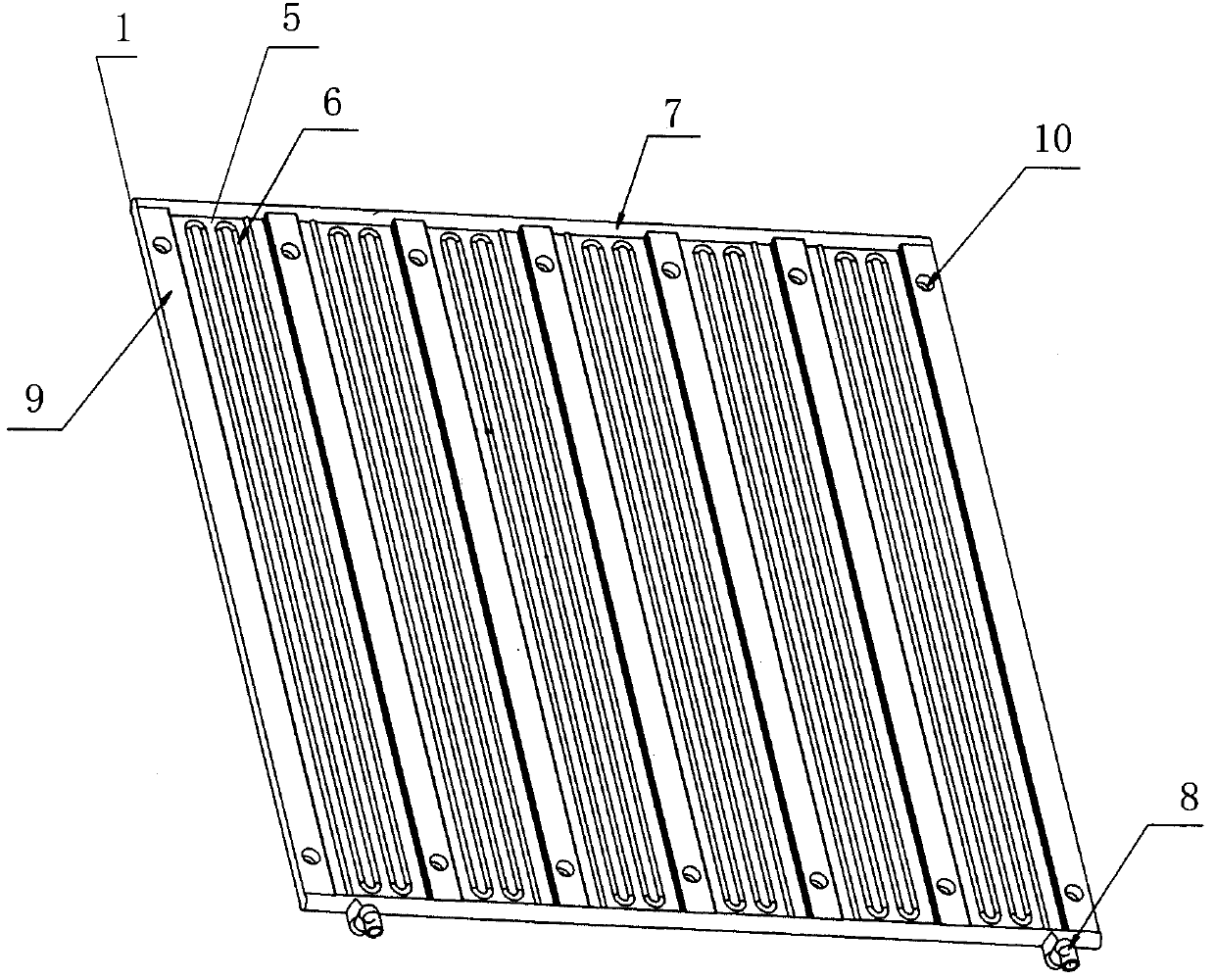

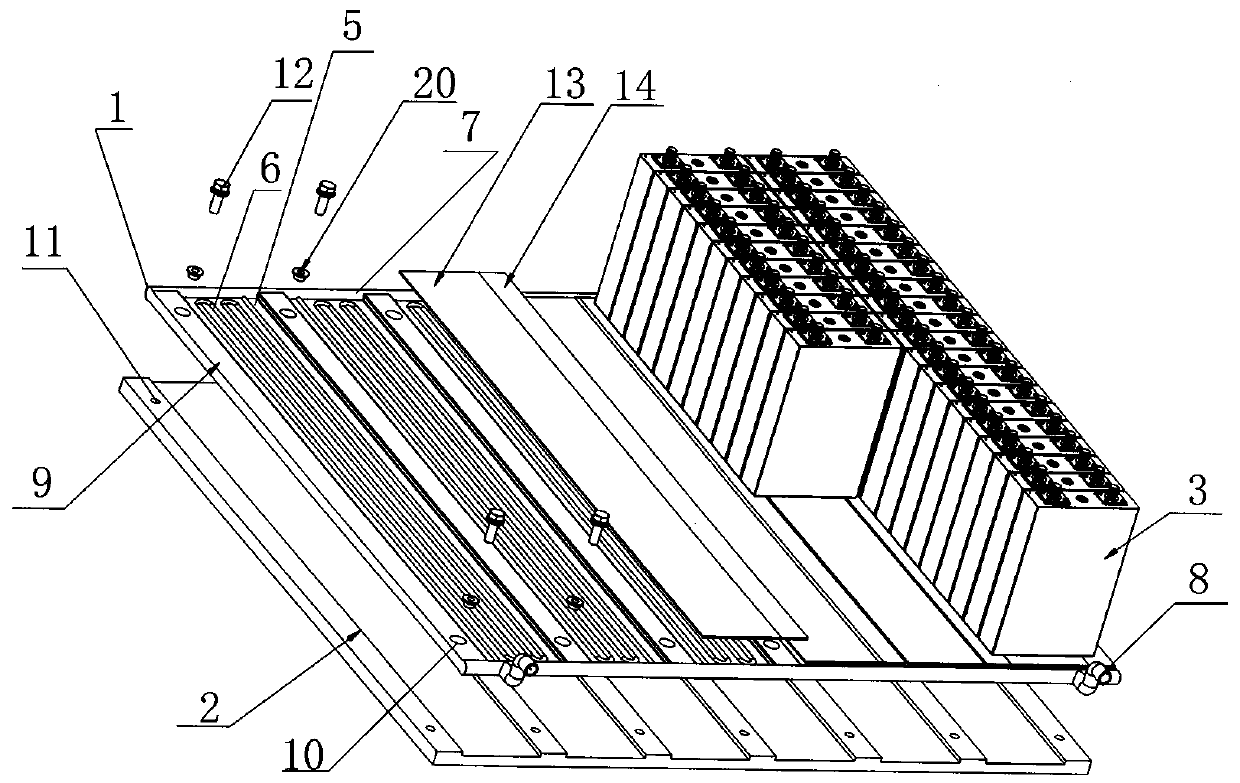

Rapid cooling device for power battery

The invention discloses a rapid cooling device for a power battery. A plurality of refrigerant tubes (6) are distributed on the surface of the battery mounting base (5) of a micro-channel heat exchanger (1), counter bores (10) are arranged, at two ends of a partition bar (9) between every two adjacent refrigerant tubes (6), at the left side and the right side of the battery mounting base (5), twoends of every refrigerant tube (6) respectively communicate with two busways (7), the front side busway (7) is connected with steam inlet and outlet tubes (8), a protection plate (2) is arranged at the bottom of the micro-channel heat exchanger (1), positioning holes (11) correspond to the counter bores (10), the protection plate (2) separates the bottom of the micro-channel heat exchanger (1) from the bottom of a battery box (4), a thermal conduction silicone pad (13) is arranged on every refrigerant tube (6), an insulating partition plate (14) is adhered to every partition bar (9), and a rubber hose (15) is connected to every steam inlet and outlet tube (8).

Owner:BAILE ELECTROTHERMIC ELECTRIC APPLIANCE JIANGSU

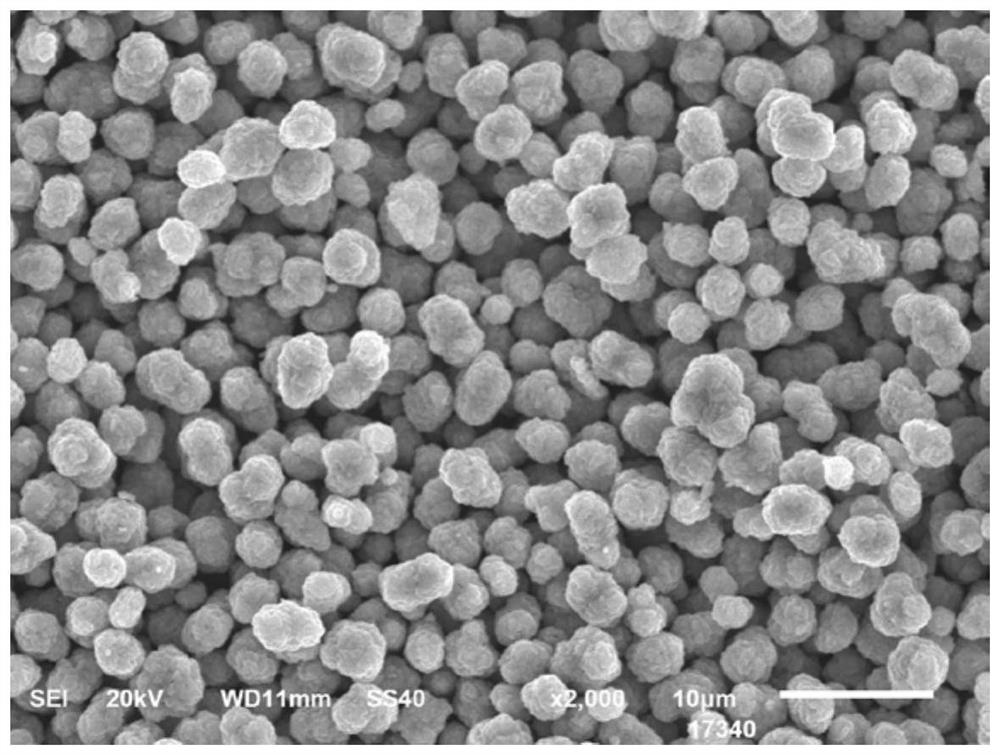

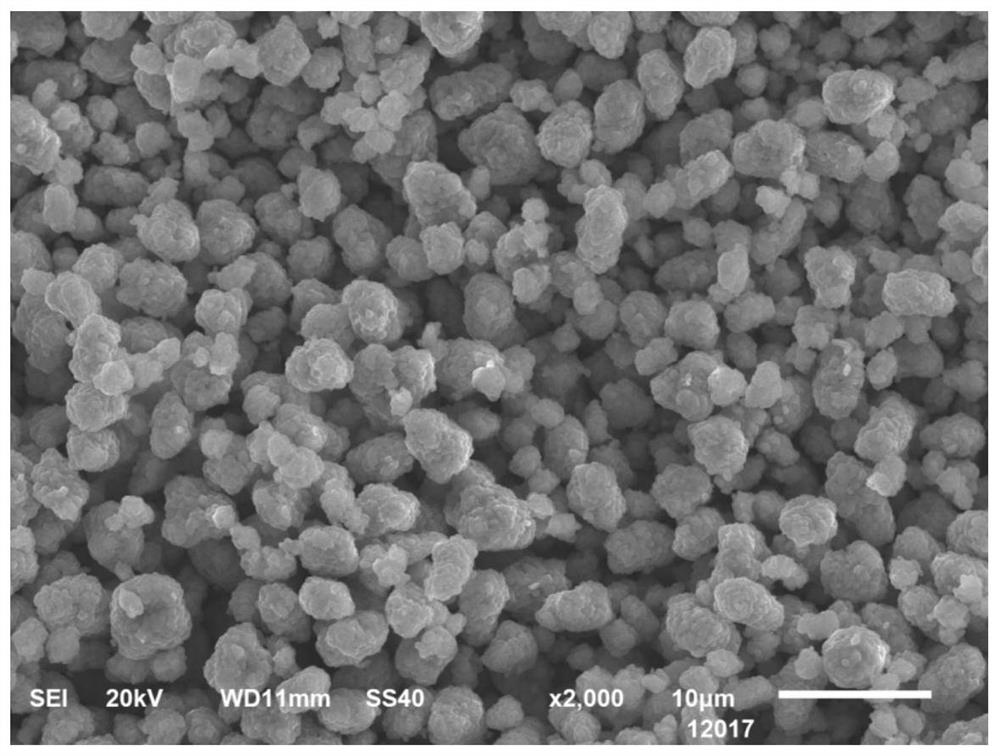

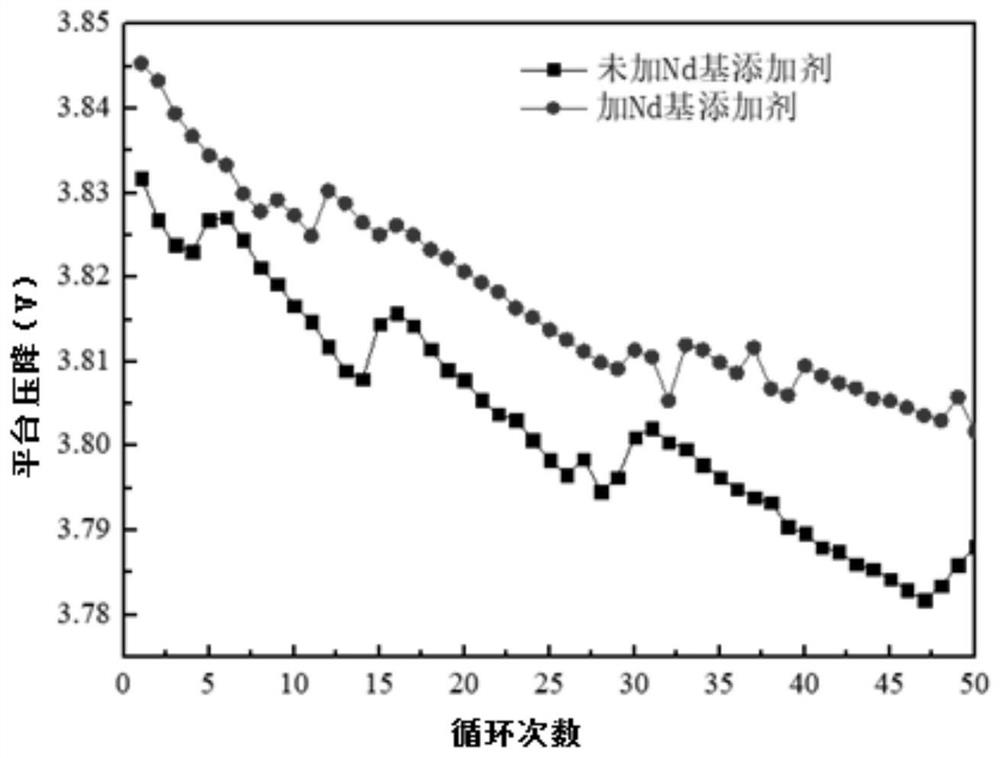

High-voltage-resistant low-cobalt ternary positive electrode material and preparation method thereof

InactiveCN112993239AEasy to prepareEasy to use in mass productionCell electrodesSecondary cellsInternal resistancePhysical chemistry

The invention discloses a high-voltage-resistant low-cobalt ternary positive electrode material which is prepared from a precursor containing nickel, cobalt and manganese, a lithium source and a small amount of an additive through the following steps: pretreating the precursor, then mixing the precursor, the lithium source and the additive, sintering, and carrying out post-processing to obtain the high-voltage-resistant low-cobalt ternary positive electrode material. The high-voltage-resistant low-cobalt ternary positive electrode material provided by the invention is relatively high in morphology regularity and uniform in particle size, and a lithium ion battery prepared from the positive electrode material still has relatively low internal resistance and excellent high-temperature cycle performance under high voltage.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

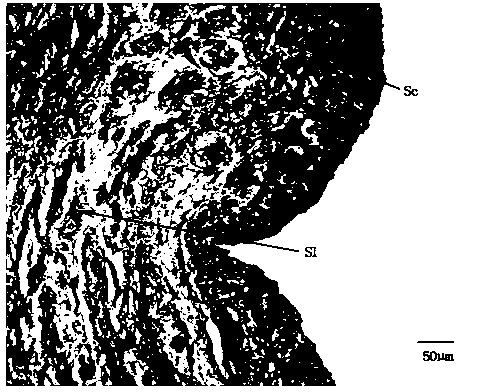

Method for inducing development of natural tetraploid loach male nucleus in cold shock way

InactiveCN102835338AFix damageRapid productionClimate change adaptationPisciculture and aquariaWeatherfishSemen

The invention discloses a method for inducing the development of natural tetraploid loach male nucleus in a cold shock way. The method has the advantages that the ovum inactivation and the chromosome doubling treatment are not needed, the male nucleus development diploid loach can be fast and efficiently produced, and in addition, the hatching rate is high. The method is sequentially implemented according to the following steps that the natural male tetraploid loach and female diploid loach are taken for hastening parturition, the semen of the male tetraploid loach and the ovum of the female diploid loach are respectively taken, the obtained semen is diluted by Kurokura's solution for 100 times for use, the diluted semen is mixed with the ovum to form fertilized ovum, and the fertilized ovum is placed into ice water being 3 DEG C to be soaked for 60 minutes and is then placed into normal temperature water for hatching.

Owner:DALIAN OCEAN UNIV +1

Organic compound, electronic element and electronic device

ActiveCN111662241AImprove mobilityIncrease polaritySolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsAryl

The invention provides an organic compound, and belongs to the technical field of organic materials. According to the compound disclosed by the invention, an electron-deficient nitrogen-containing heteroaryl group and a cyano group are connected to a structure formed by adamantane, so that the LUMO energy level is deepened, and the electron mobility is further improved. The invention also providesan electronic element comprising the organic compound, and an electronic device. The organic compound can improve the electron transport performance of the electronic element, and when the organic compound is used as an electron transport layer of an organic light-emitting electroluminescent device, the light-emitting efficiency and the service life of the device can be improved, and the workingvoltage can be reduced.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

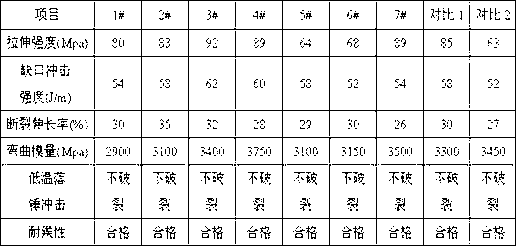

PMMA/MBS surface layer co-extrusion material and preparation method thereof

The invention discloses a PMMA / MBS surface layer co-extrusion material and a preparation method thereof, wherein using polymethyl methacrylate and polymethyl methacrylate-butadiene-styrol copolymer as main body materials, the PMMA / MBS surface layer co-extrusion material are prepared by through a double-stage double screw extruder. Compared with a traditional PMMA / ASA surface layer co-extrusion material, the stretching and impact performances of the PMMA / MBS surface layer co-extrusion material are greatly raised. Because the price of a main raw material of polymethyl methacrylate-butadiene-styrol copolymer is low, the cost of the co-extrusion material is greatly reduced. Simultaneously, a preparation technology is simple, and co-extrusion material is suitable for large scale production and usage.

Owner:GUANGDONG HUASHENG ELECTRICAL APPLIANCES

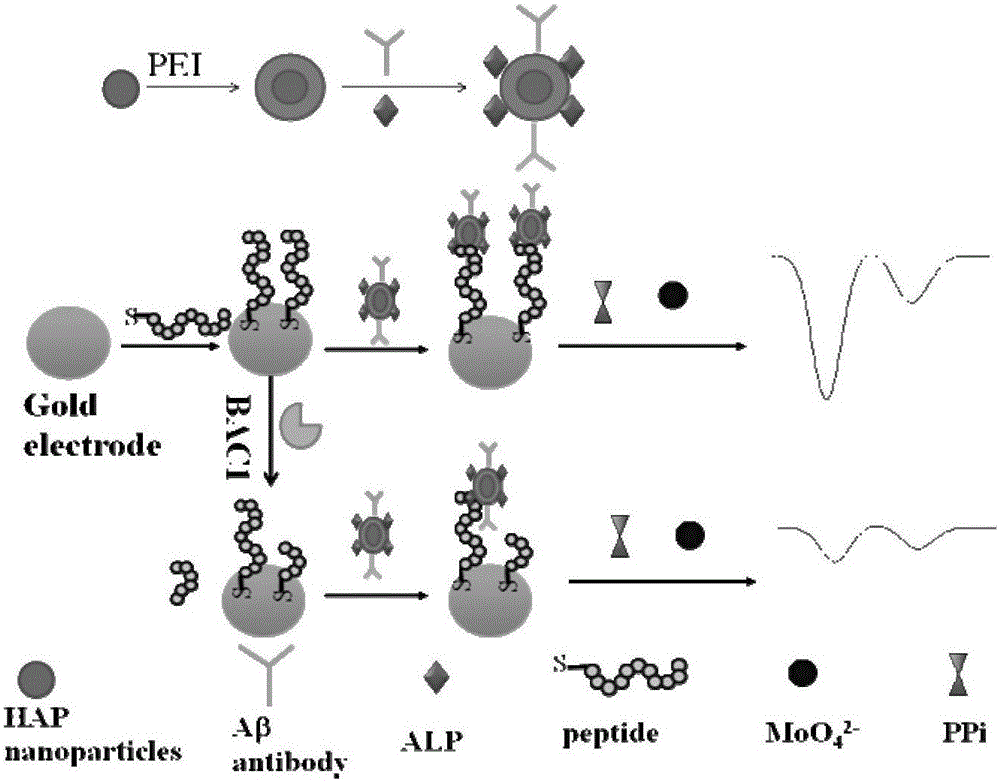

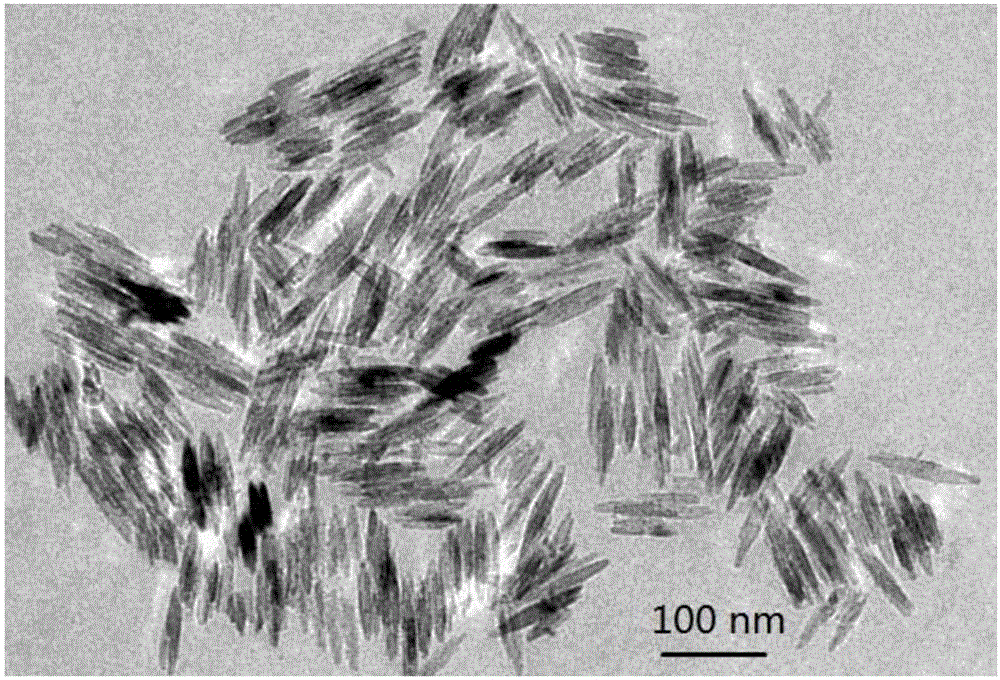

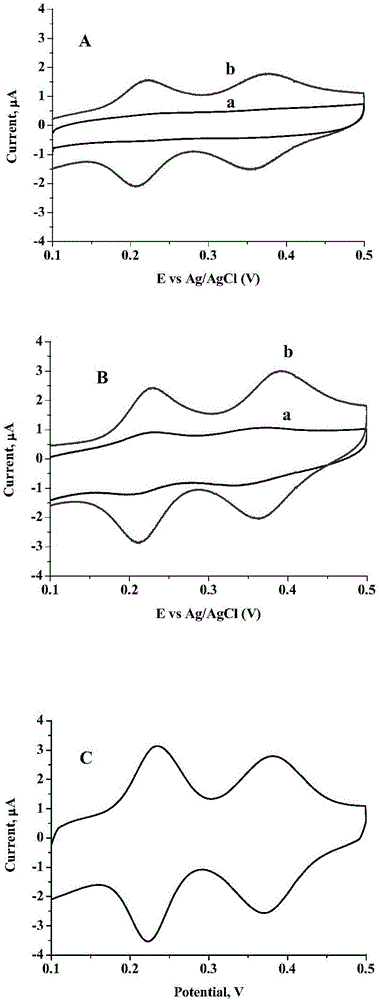

Hydroxyapatite-based electrochemical probe construction method and method for determining activity and inhibition property of BACE1

InactiveCN106093160AEnables sensitive detection of activitySimple and fast operationBiological testingMaterial electrochemical variablesAntibodyAbnormal alkaline phosphatase

The invention discloses a hydroxyapatite-based electrochemical probe and a construction method thereof, and a method for determining the activity and the inhibition property of BACE1. According to the present invention, an A[beta] antibody and alkaline phosphatase are co-modified on a hydroxyapatite matrix to form the hydroxyapatite-based electrochemical probe; the preparation method comprises: sequentially placing hydroxyapatite nanoparticles in a polyethylenimine solution and carrying out a reaction, placing in a glutaraldehyde solution and carrying out a reaction, and placing in a solution containing an A[beta] antibody and alkaline phosphatase and carrying out a reaction so as to obtain the probe; and the method for determining the activity and the inhibition property of BACE1 by using the hydroxyapatite-based electrochemical probe has advantages of simpleness, rapidness, high sensitivity and wide detection range, and can be widely promoted and applied.

Owner:CENT SOUTH UNIV

Sodium bismuthate/epoxy resin/glass fiber composite material, preparation method thereof, and application method for composite material in degradation of organic waste water

ActiveCN103623868AImprove stress shock resistancePromote absorptionWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyUltrasonic dispersion

The invention discloses a sodium bismuthate / epoxy resin / glass fiber composite material, a preparation method thereof and an application method for the composite material in degradation of organic waste water. The preparation method comprises the following steps: soaking sodium bismuthate powder in an aqueous solution of a silane coupling agent for treatment, then taking out the sodium bismuthate powder and drying the sodium bismuthate powder for subsequent usage; adding methyl tetrahydrophthalic anhydride into an epoxy resin and carrying out uniform mixing so as to obtain an epoxy resin glue solution; and mixing the treated sodium bismuthate with the epoxy resin glue solution, carrying out ultrasonic dispersion, coating an obtained mixture on glass fiber cloth, folding the glass fiber cloth three to five times in a die, carrying out curing, cooling and demolding and cutting the glass fiber cloth to a certain shape and a certain size. The application method comprises the following steps: uniformly putting the composite material with an appropriate shape and an appropriate size between jacket layers of a glass tube reactor and installing a visible light lamp at the center of an inner tube; allowing organic waste water to enter into a glass jacket, pass through the composite material and undergo a visible light catalytic degradation reaction with sodium bismuthate under irradiation by visible light. The preparation method has the advantages of low requirements on equipment, simple procedures, low energy consumption and convenience in operation; and the composite material is capable of degrading organic waste water in a short period of time.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com