Manufacturing system for A2-level fireproof core board

A technology for processing systems and fireproof cores, applied in the direction of fireproofing, lamination systems, layered products, etc., can solve problems such as dragging down the working efficiency of composite systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings.

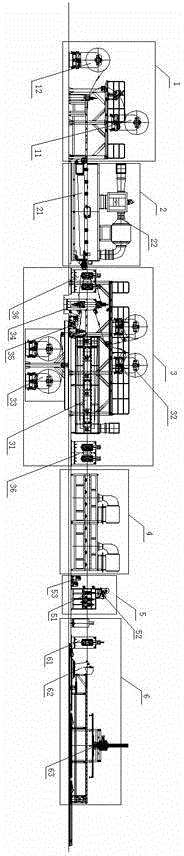

[0014] Such as figure 1 As shown, an A2 grade fireproof core board production and processing system is provided with unwinding device 1, heating device 2, composite device 3, cooling device 4, filming device 5, trimming and Shearing device 6, the total length of the composite system is 50-60m, which is half shorter than the original core board processing and composite system, and the occupied space is greatly reduced. The composite system system speed is 2-3m / min, which is traditional core board processing and composite 3 times of the system, greatly improving production efficiency. The unwinding device 1 includes an upper unwinder 11 and a lower unwinder 12, the heating device 2 is provided with a mesh belt synchronous chain conveyor 21, and a hot air circulating oven 22 is arranged above the mesh belt synchronous chain conveyor 21. The composite device 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com