Lightweight artificial leather with wear-resistant skin for vehicles and preparation method thereof

A lightweight and artificial leather technology, which is applied to vehicle parts, textiles, papermaking, coatings, etc., can solve the problems that PVC artificial leather cannot be realized, and the wear resistance of PVC artificial leather cannot be fundamentally improved, so as to achieve lightweight and improve Abrasion resistance, effect of improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

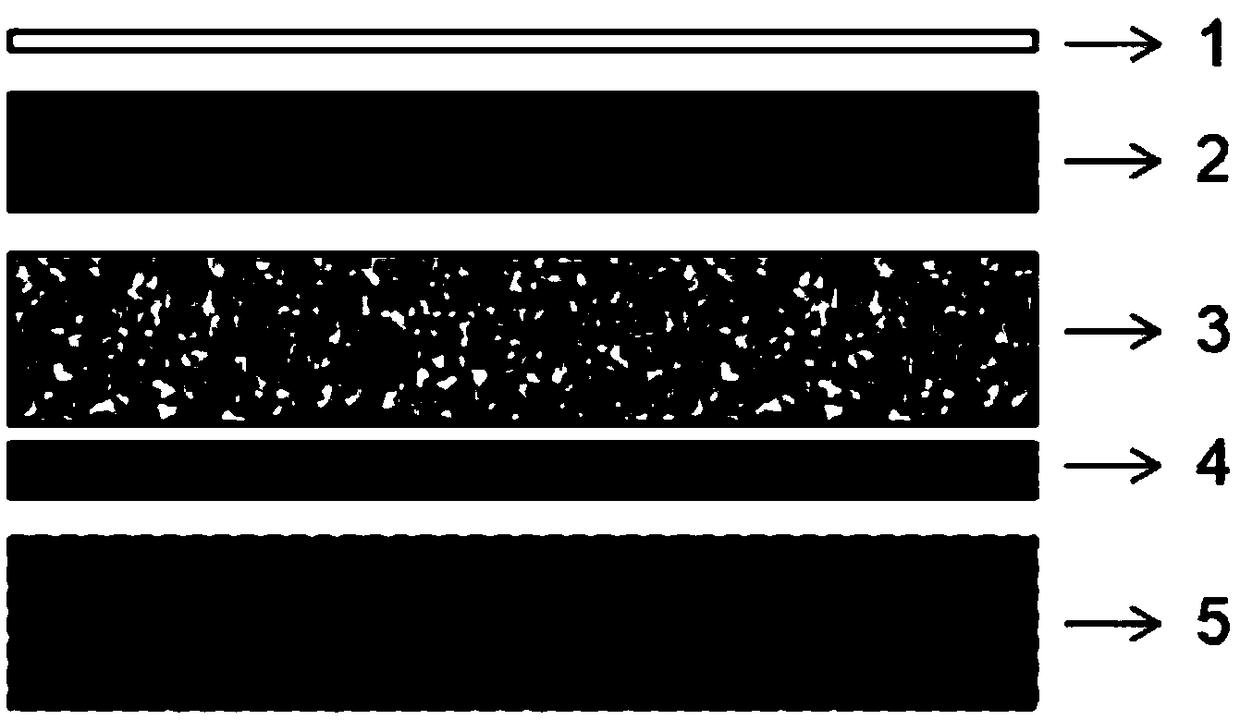

[0043] A lightweight artificial leather for vehicles with a wear-resistant skin and a preparation process thereof, comprising the following steps:

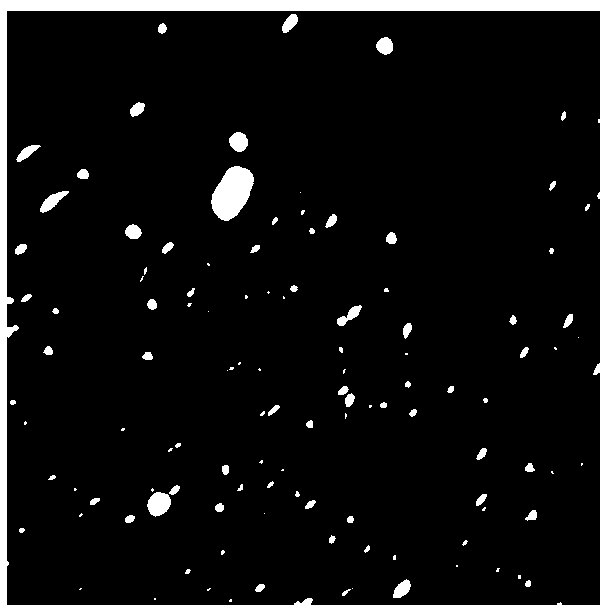

[0044] (1) Preparation of anti-wear agent: get 30 parts of hollow glass microspheres, 10 parts of hollow ceramic microspheres, 80 parts of dimethyl phthalate, 30 parts of polyvinyl chloride powder, mix, and disperse and stir under the condition of 1500rpm 1.5h; vacuum defoaming and stirring the stirred slurry at -0.09MPa and 300rpm for 30min; filter the defoamed slurry through a 150-mesh screen to obtain the wear-resistant agent;

[0045] (2) Preparation of wear-resistant skin layer slurry: Take 100 parts of PVC resin powder, 70 parts of plasticizer dioctyl phthalate, 1 part of heat stabilizer calcium stearate, and leveling agent polydimethylsilane 0.1 part, 0.01 part of anti-aging agent 2-hydroxyl-4-methoxybenzophenone, 20 parts of anti-wear agent obtained in step (1), mix, and disperse and stir for 20min under the condition of 5...

Embodiment 2

[0048] (1) Preparation of anti-wear agent: get 20 parts of hollow glass microspheres, 20 parts of hollow ceramic microspheres, 100 parts of n-butyl phthalate, 90 parts of polyvinyl chloride powder, mix, and disperse and stir under the condition of 1000rpm 1h; vacuum defoaming and stirring the stirred slurry at -0.15MPa and 200rpm for 40min; filter the defoamed slurry through a 150-mesh screen to obtain the wear-resistant agent;

[0049] (2) Preparation of wear-resistant skin layer slurry: Take 80 parts of PVC resin powder, 90 parts of plasticizer succinate, 1 part of heat stabilizer zinc stearate, and leveling agent polymethylphenylsiloxane 1 part, 1 part of anti-aging agent 2-hydroxyl-4-dodecyloxybenzophenone, 10 parts of anti-wear agent obtained in step (1), mix, and disperse and stir for 30min under the condition of 300rpm; Disperse and stir for 40 minutes under the same conditions; then disperse and stir for 35 minutes at 2600rpm; vacuum defoam and stir the stirred slurry ...

Embodiment 3

[0052] (1) Preparation of anti-wear agent: take 10 parts of hollow glass microspheres, 30 parts of hollow ceramic microspheres, 90 parts of diethyl phthalate, 60 parts of polyvinyl chloride powder, mix, and disperse and stir under the condition of 1500rpm 1.5h; vacuum defoaming and stirring the stirred slurry at -0.09MPa and 300rpm for 30min; filter the defoamed slurry through a 150-mesh screen to obtain the wear-resistant agent;

[0053] (2) Preparation of wear-resistant skin layer slurry: Take 100 parts of PVC resin powder, 80 parts of plasticizer epoxy butyl oleate, 3 parts of heat stabilizer castor oil calcium, leveling agent polyether polyester modified organic 0.01 part of siloxane, 0.1 part of anti-aging agent 2-(2'-hydroxyl-5'-tertoctylphenyl) benzotriazole, 1 part of anti-wear agent obtained in step (1), mixed, at 500rpm disperse and stir for 20min; then disperse and stir for 30min at 1000rpm; then disperse and stir for 30min at 2500rpm; vacuum defoam and stir the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com