Application of sodium bismuthate in rapidly degrading organic dye waste water and degradation method

An organic dye and rapid degradation technology, which is applied in energy wastewater treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve the problems of high cost and long treatment time, and achieve strong applicability, low operating cost and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

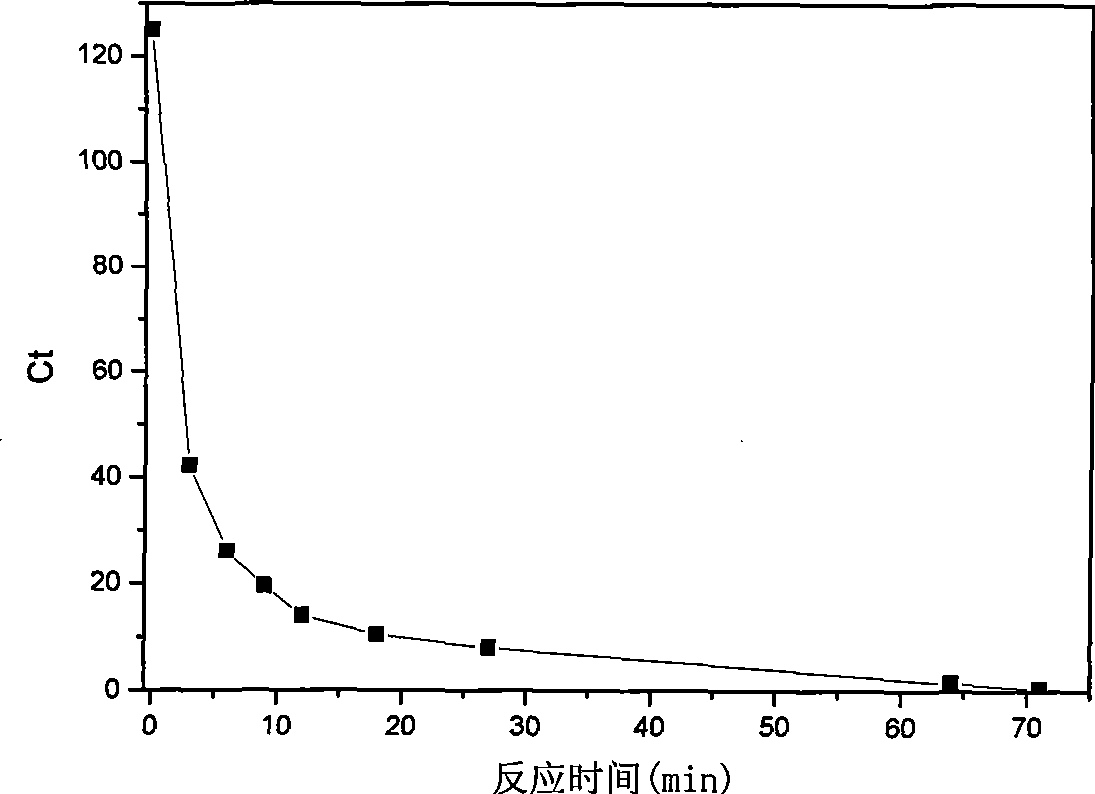

Embodiment 1

[0018] Prepare 62.5mg / L saffron red aqueous solution to simulate dye wastewater, and measure 80mL of dye solution into the reactor. A stirring bar is placed in it, and the solution is stirred under the action of the stirrer. The reactor is protected by water cooling, and circulating condensed water can keep the whole reaction at room temperature during the reaction. Weigh 130mg NaBiO 3 Add the above solution, mix well under the action of stirring, and then irradiate with visible light to decolorize the dye solution. Subsequently, the change of saffron red with the reaction time and the change of TOC were measured. The experimental results showed that the concentration of saffron red decreased by 98.7% and the TOC decreased by 79% within 14 minutes.

Embodiment 2

[0020] Prepare 57 mg / L methyl violet aqueous solution to simulate dye wastewater, and measure 70 mL of dye solution into the reactor. A stirring bar is placed in it, and the solution is stirred under the action of the stirrer. The reactor is protected by water cooling, and circulating condensed water can keep the whole reaction at room temperature during the reaction. Weigh 100mg NaBiO 3 Add the above solution, mix well under the action of stirring, and then irradiate with visible light to decolorize the dye solution. Subsequently, the change of the concentration of methyl violet with the reaction time and the change of TOC were measured. The experimental results showed that the concentration of methyl violet decreased by 99% and the TOC decreased by 67% within 9 minutes.

Embodiment 3

[0022] Prepare 100 mg / L basic fuchsin aqueous solution to simulate dye wastewater, and measure 80 mL of dye solution into the reactor. A stirring bar is placed in it, and the solution is stirred under the action of the stirrer. The reactor is protected by water cooling, and circulating condensed water can keep the whole reaction at room temperature during the reaction. Weigh 120mg NaBiO 3 Add the above solution, mix well under the action of stirring, and then irradiate with visible light to decolorize the dye solution. Subsequently, the variation of the concentration of basic fuchsin with the reaction time and the variation of TOC were measured. The experimental results showed that the concentration of basic fuchsin decreased by 99% and the TOC decreased by 87% within 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com