A method and device for pre-lithiation of negative pole piece of lithium ion battery

A technology of lithium-ion batteries and negative pole pieces, which is applied in the field of lithium-ion batteries, can solve the problems of lithium metal safety hazards, low evaporation efficiency, and lack of promotion, and achieve the purpose of overcoming uneven pre-lithiation, low cost, and low lithium content. The effect of easy control of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

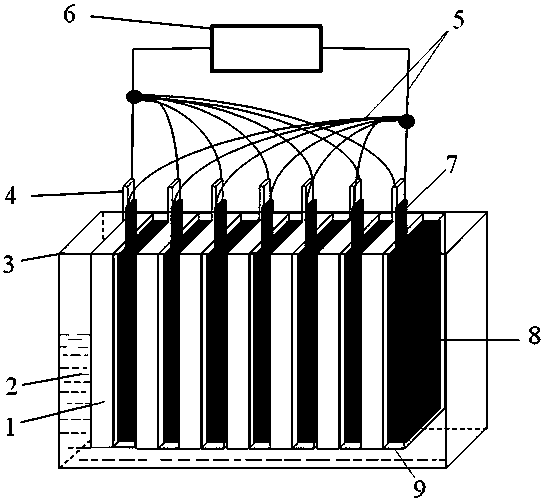

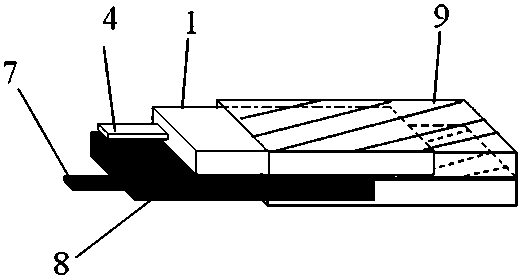

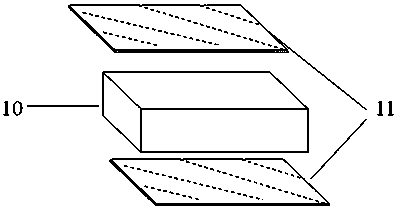

Embodiment 1

[0038]In an argon atmosphere, insert a 90mm*32mm graphite negative pole piece and one (or two) 95mm*35mm metal lithium pieces into the electrolyte so that the negative pole piece is opposite to but not in contact with the metal lithium piece. Connect the negative pole piece and the metal lithium piece to the positive and negative poles of the power supply respectively through wires, and use a 0.5C current to charge the negative pole piece for 6 minutes, so that the pre-lithiation amount in the graphite is 5% of the total capacity of the negative pole piece, and then Dry the negative electrode sheet to complete the pre-lithiation operation.

Embodiment 2

[0040] In an argon atmosphere, insert a 90mm*32mm silicon-graphite negative electrode sheet and one (or two) 95mm*35mm metal lithium sheets into the electrolyte so that the front faces of the electrode sheet and the metal lithium sheet are opposite but not in contact. Connect the negative pole piece and metal lithium piece to the positive and negative poles of the power supply respectively through wires, and charge the negative pole piece with a current of 0.5C for 12 minutes, so that the pre-lithiated amount in the silicon-graphite is 10% of the total capacity of the negative pole piece , and then dry the negative electrode sheet to complete the pre-lithiation operation.

Embodiment 3

[0042] In an argon atmosphere, insert a 90mm*32mm pure SiO negative pole piece and one (or two) 95mm*35mm metal lithium pieces into the electrolyte so that the positive side of the pole piece is opposite to but not in contact with the metal lithium piece. Connect the negative electrode sheet and metal lithium sheet to the positive and negative electrodes of the power supply through wires, and charge the negative electrode sheet with a current of 0.5C for 18 minutes, so that the pre-lithiated amount in pure SiO is 15% of the total capacity of the negative electrode sheet. Then dry the negative electrode sheet to complete the pre-lithiation operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com