PMMA/MBS surface layer co-extrusion material and preparation method thereof

A surface layer and raw material technology is applied in the field of PMMA/MBS surface layer co-extrusion material and its preparation, which can solve the problems of high cost and high price of co-extrusion material, and achieve the effects of cost reduction, low price and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

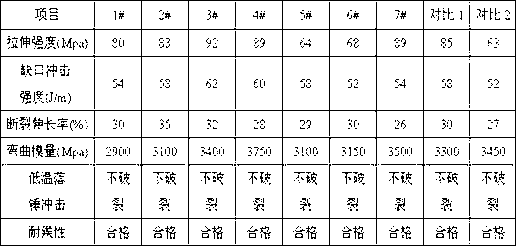

Examples

preparation example Construction

[0053] A kind of preparation method of PMMA / MBS surface layer co-extrusion material, its steps are as follows:

[0054]1) Grind polymethyl methacrylate to 50-300 mesh, then stir and mix with other raw materials;

[0055] 2) Put the mixed material into the feeding hopper of the double-stage twin-screw extruder, after the first-stage twin-screw shears and melts, it enters the second-stage single-screw, is sheared by the single-screw, extruded, and granulated , dried to obtain PMMA / MBS component-type surface layer co-extrusion material;

[0056] Among them, the temperature settings are as follows: the first-stage twin-screw first zone is 170-180°C, the second-stage temperature is 185-200°C, the third-stage temperature is 170-180°C, and the second-stage single-screw temperature is 195-210°C;

[0057] Wherein, the raw materials used are as described above.

[0058] Preferably, in step 1), the stirring speed is 100-500 rpm.

Embodiment

[0062] Co-extrusion material 1# is made of the following raw materials in parts by weight:

[0063] 60 parts of PMMA,

[0064] MBS 35 copies,

[0065] 7.0 parts of light calcium carbonate,

[0066] Polyethylene wax 0.5 part,

[0067] Antioxidant 0.5 part,

[0068] 0.4 part of ultraviolet absorber,

[0069] Pigment 0.4 parts.

[0070] Co-extrusion material 2# is made of the following raw materials in parts by weight:

[0071] 65 parts of PMMA,

[0072] MBS 30 copies,

[0073] 5.0 parts of heavy calcium carbonate,

[0074] 0.6 parts of stearic acid,

[0075] Antioxidant 0.8 part,

[0076] 0.8 part of ultraviolet absorber,

[0077] Pigment 0.4 parts.

[0078] Co-extrusion material 3# is made of the following raw materials in parts by weight:

[0079] PMMA 70 parts,

[0080] MBS 25 copies,

[0081] 3.0 parts of talcum powder,

[0082] Zinc stearate 0.5 parts,

[0083] Antioxidant 0.2 part,

[0084] 0.4 part of ultraviolet absorber,

[0085] Pigment 0.4 parts.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com