Thick high-conductivity multilayer graphene film and RFID electronic label of impedance loaded shape

A multi-layer graphene, high-conductivity technology, applied in the field of antenna technology and radio frequency identification, can solve the problems of insufficient mechanical flexibility and corrosion resistance of metal antennas, complicated manufacturing process, and many antenna materials, and reduce the number of processes. The effect of manufacturing errors, reducing material consumption, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Polyimide, polyamide, and graphene oxide are formed into films by doctor blade method or screen printing method, and hot-pressed at 180°C to obtain a graphene film precursor;

[0030] 2) placing the obtained graphene film precursor in a high-temperature furnace in an inert gas or vacuum environment, first heat-treating at 500°C for 2 hours at a low temperature, then heat-treating at 1500°C for 3 hours and 2800°C for 3 hours;

[0031] 3) Repeat the heat treatment cycle described in step 2 for more than 3 times; then drop the temperature to room temperature at a constant rate of 4°C per minute; further roll forming at room temperature to obtain a high-conductivity multilayer graphene thick film.

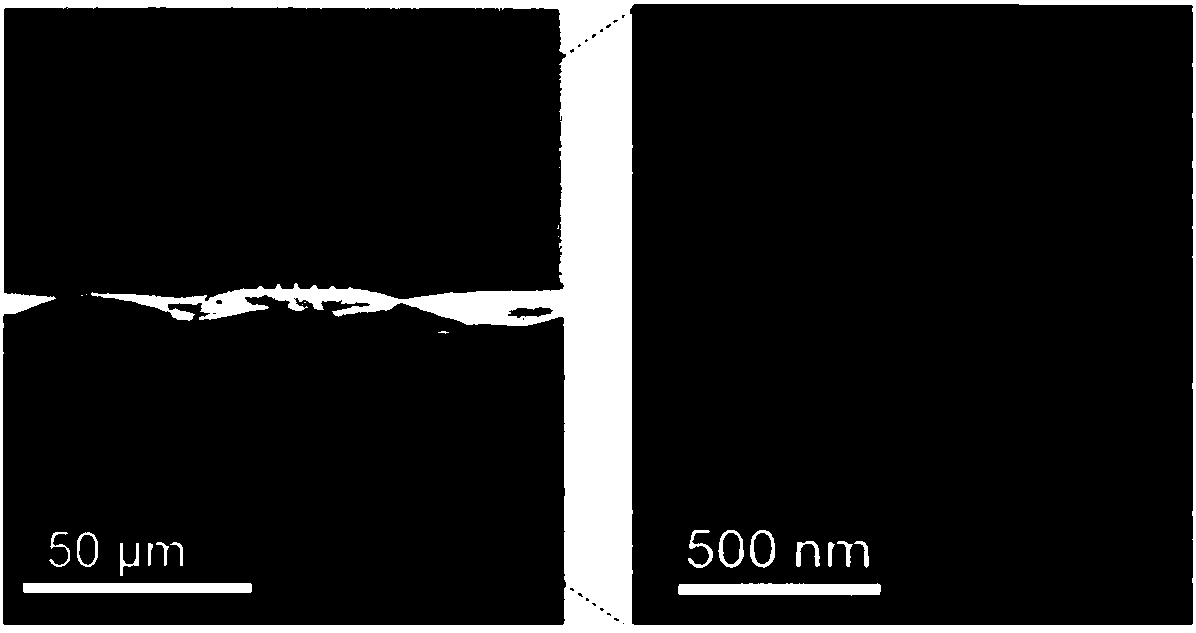

[0032] The microstructure and morphology of the graphene thick film were characterized by scanning electron microscope and transmission electron microscope: figure 1 It is the cross-section of the graphene thick film and the enlarged scanning electron microscope image, it can...

Embodiment 2

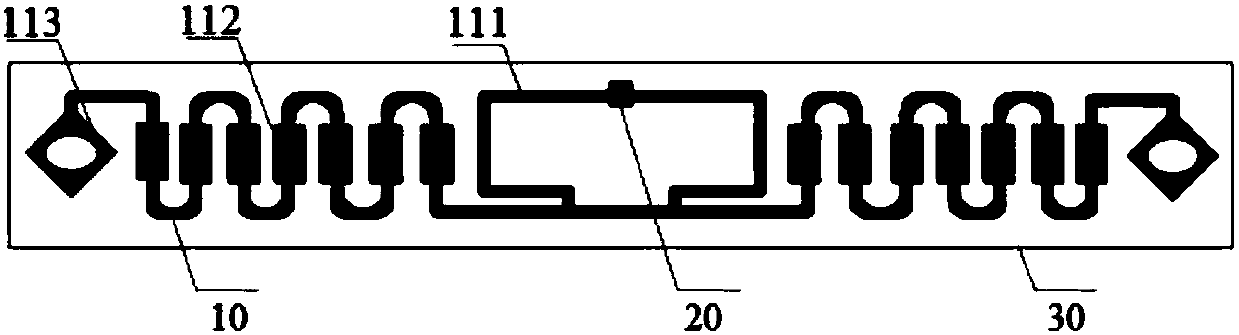

[0035] refer to Figure 4 In this embodiment, the high-conductivity multi-layer graphene thick film and the impedance-loaded high-frequency radio frequency electronic identification tag include an antenna 10, a chip 20, and a substrate 30, covering a frequency band of 13.56 MHz. Described antenna 10 comprises impedance loading shape coil 121, bridge 122 and via hole 123, and its material is high-conductivity multilayer graphene thick film, and thick film conductivity is 1×10 6 S / m, the number of layers is about 75,000 layers, which is formed by preparing a large thick film in the film forming step in Example 1 and then pressing it mechanically. The impedance-loaded coil is square, the coil width is 0.5 mm, and the number of coils is 8 turns. The chip model is NXPMFRC522. The substrate 30 is arranged in a rectangular shape, made of PVC, and its size range is 100mm in length, 90mm in width, and 0.2mm in thickness.

Embodiment 3

[0037] refer to Figure 5 In this embodiment, the high-conductivity multilayer graphene thick film and the impedance-loaded microwave-band radio frequency electronic identification tag include an antenna 10, a chip 20, and a substrate 30, covering a frequency band of 2.45 GHz. The material of the antenna 10 is a high-conductivity multilayer graphene thick film, and the conductivity of the thick film is 8×10 5 S / m, the number of layers is about 60,000, and it is directly prepared by the film-forming step in Example 1. The left arm of the dipole is an impedance-loaded linear dipole 131 with an arm length of 50 mm, and the right arm and the left arm are mirror images. The chip model is nRF2401. The substrate 30 is arranged in a rectangular shape, made of PET, and its size range is 120 mm in length, 20 mm in width, and 0.3 mm in thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com