High-voltage-resistant low-cobalt ternary positive electrode material and preparation method thereof

A cathode material, high-voltage-resistant technology, applied in electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of no price advantage and high production cost, and achieve the effect of reducing cost, low internal resistance, and small internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The second aspect of the present invention is to provide a method for preparing the high-pressure resistant low-cobalt ternary positive electrode material described in the first aspect of the present invention, the method comprising the following steps:

[0043] Step 1, pretreating the precursor containing nickel, cobalt and manganese.

[0044] Among the present invention, described precursor containing nickel, cobalt, manganese is preferably the precursor of low cobalt content, more preferably has empirical formula (Ni 0.5 co 0.1 mn 0.4 )(OH) 2 precursors.

[0045] The invention adopts a one-time solid-phase sintering process to prepare a high-pressure-resistant and low-cobalt ternary positive electrode material. The preparation method has simple process, low cost, convenient operation, and is easy to realize large-scale industrial production.

[0046]In the present invention, the pretreatment of the precursor includes crushing and sieving. The precursor is pulver...

Embodiment 1

[0090] First weigh (Ni 0.5 co 0.1 mn 0.4 )(OH) 2 Precursor body 100g, take Lithium Retard 42.30g with excess 6% Li molar weight, then take by weighing neodymium oxide (Nd 2 o 3 ) additive 0.06g, tungsten oxide (WO 3 ) additive 0.038g;

[0091] Add the precursor, lithium carbonate, and neodymium oxide additives to a small high-mixer for mixing to ensure uniform mixing, and no white spots or lines are found in the mixed material;

[0092] The mixture is synthesized once in a muffle furnace, and the synthesis temperature is 500°C / 5h+850°C / 12h+930°C / 12h;

[0093] After the muffle furnace cools down naturally, the material is taken out and passed through a 300 molybdenum sieve to obtain the final product.

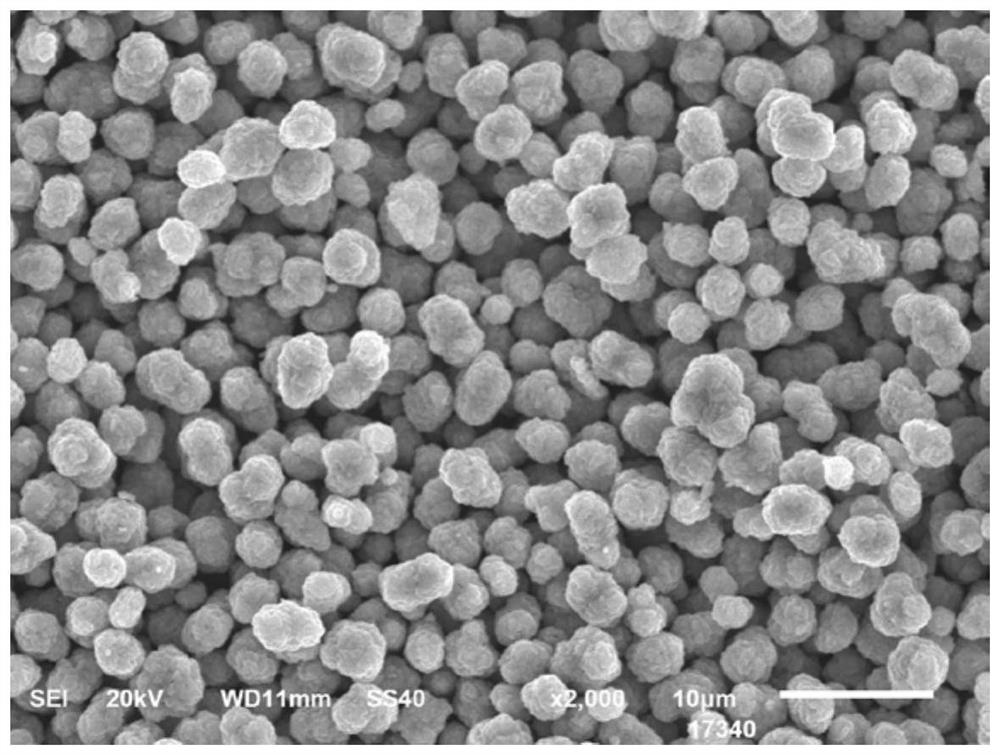

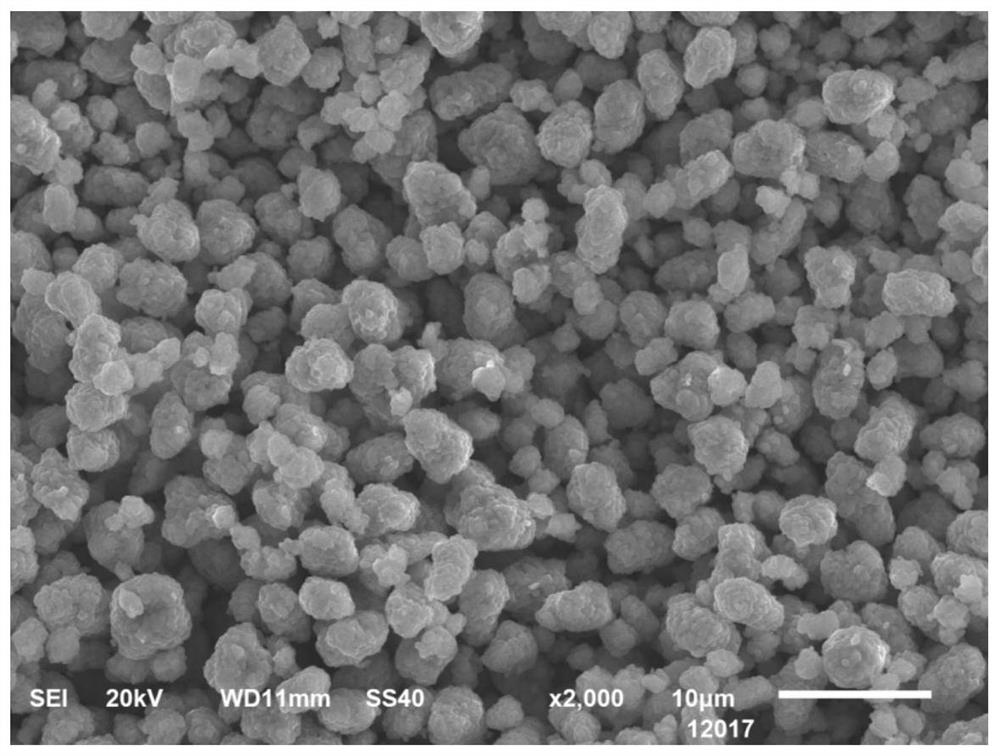

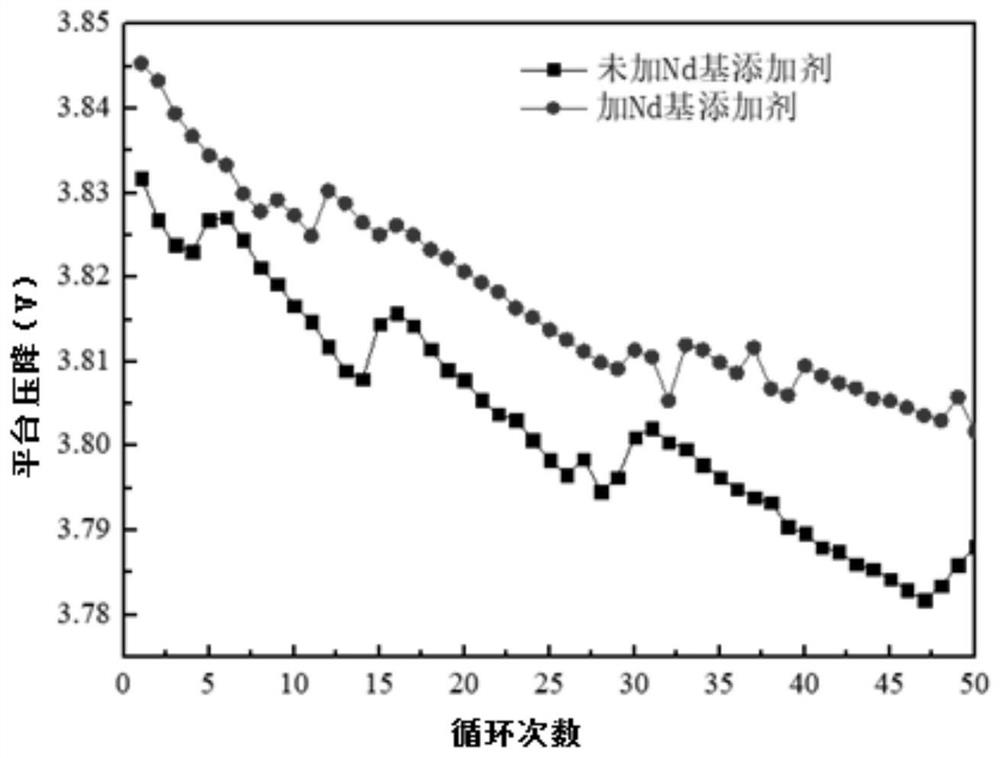

[0094] Scanning electron microscope test is carried out to the final product that makes, and the obtained result is as follows: figure 1 shown, from figure 1 It can be seen from the figure that the prepared particles are spherical, and the boundaries of each particle ar...

Embodiment 2

[0096] First weigh (Ni 0.5 co 0.1 mn 0.4 )(OH) 2 Precursor body 100g, take Lithium Retard 42.30g with excess 6% Li molar weight, then take by weighing neodymium oxide (Nd 2 o 3 ) additive 0.06g;

[0097] Add the precursor, lithium carbonate, and neodymium oxide additives to a small high-mixer for mixing to ensure uniform mixing, and no white spots or lines are found in the mixed material;

[0098] The mixture is synthesized once in a muffle furnace, and the synthesis temperature refers to 500°C / 5h+850°C / 12h+930°C / 12h;

[0099] After the muffle furnace is naturally cooled, the material is taken out and passed through a 300 molybdenum sieve to obtain the final product for testing and analysis;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com