High-activity astragalus polysaccharide and preparation method of pharmaceutical composition of high-activity astragalus polysaccharide

A technology of astragalus polysaccharide and composition, which is applied in the field of pharmaceutical compositions containing astragalus polysaccharide, can solve the problems of low yield and biological activity of astragalus polysaccharide, high requirements on method, equipment and environment, unfavorable promotion, development and application, etc. Conducive to continuous operation, beneficial to large-scale production use, the effect of improving productivity and biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

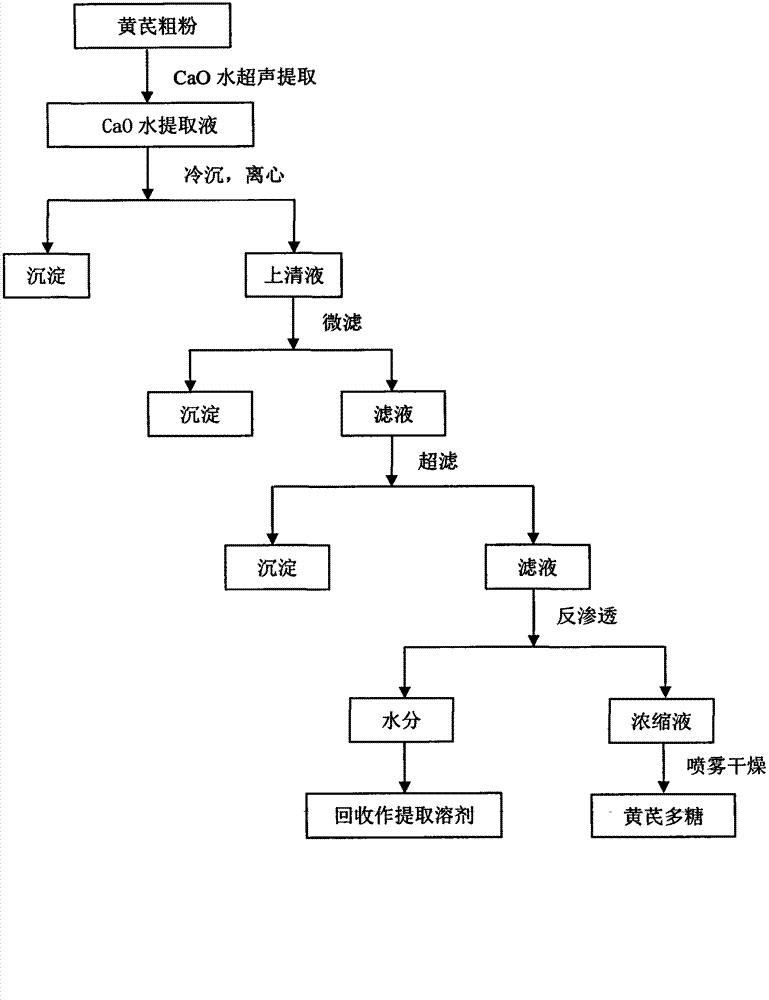

Method used

Image

Examples

Embodiment 1

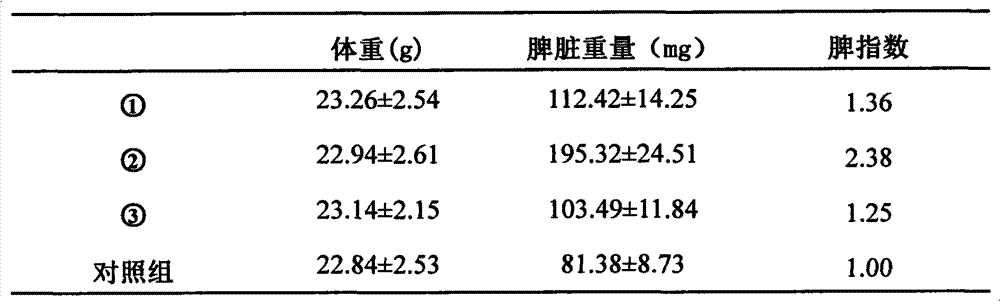

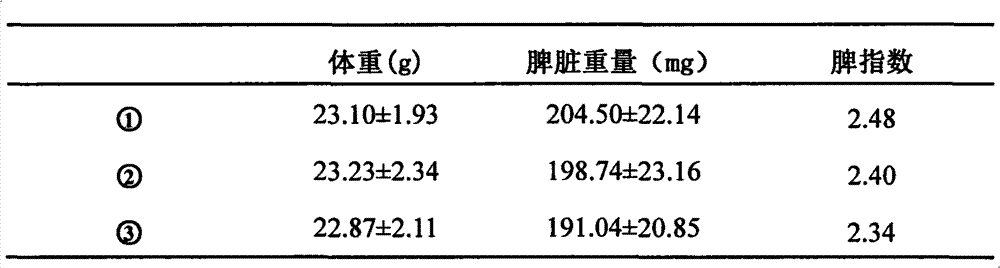

[0035]Weigh 10g of Radix Astragali, crush it into a coarse powder with a diameter of 300 μm, add 10 times the amount of 1% CaO aqueous solution and soak for 60 minutes; ultrasonically extract 3 times (power 60Kw, temperature 60°C), 30 minutes each time, combine the extracts, and quickly cool to At room temperature, centrifuge at 12000rpm, the centrifugate passes through a 0.22μm microporous membrane, the pressure of the membrane is 0.3MPa, the membrane is continuously washed with warm water, the amount of water added is 3 times that of the astragalus polysaccharide centrifugate, and the filtrate passes through the molecular weight cut-off It is a 200,000 Dalton ultrafiltration membrane, and the ultrafiltrate is then concentrated through a reverse osmosis membrane at a pressure of 10MPa (collecting the outflowing water and returning to the extraction tank for reuse), and then spray-dried (the inlet air temperature of spray drying is 160°C , the air outlet temperature is 80° C., ...

Embodiment 2

[0037] Weigh 5 g of Radix Astragali, crush it into a coarse powder with a diameter of 200 μm, add 8 times the amount of 1% CaO aqueous solution and soak for 30 min; ultrasonically extract twice (power 20Kw, temperature 40°C), each time for 60 min, combine the extracts, and quickly cool to Centrifuge at room temperature at 10000rpm, the centrifugate passes through a 0.45μm microporous membrane, the pressure of the membrane is 0.2MPa, the membrane is continuously washed with warm water, the amount of water added is twice that of the astragalus polysaccharide centrifugate, and the filtrate passes through the molecular weight cut-off It is an ultrafiltration membrane of 100,000 Daltons, and the ultrafiltrate is then concentrated through a reverse osmosis membrane at a pressure of 15 MPa (collecting the outflowing water, returning to the extraction tank for reuse), and spray drying (the inlet air temperature of the spray drying is 180°C , the air outlet temperature is 90° C., and th...

Embodiment 3

[0039] Weigh 20g of Astragalus medicinal decoction pieces, crush them into a coarse powder with a diameter of 500μm, add 5 times the amount of 1% CaO aqueous solution and soak for 40min; ultrasonically extract once (power 40Kw, temperature 80°C), each time for 90min, combine the extracts, and cool rapidly to room temperature, centrifuged at 8000rpm, the centrifugate passed through a 0.75μm microporous membrane, the pressure of the membrane was 0.1MPa, the membrane was continuously washed with warm water, and the amount of water added was 1 times that of the astragalus polysaccharide centrifugate, and the filtrate was cut off Ultrafiltration membrane with a molecular weight of 50,000 Daltons, and the ultrafiltrate is then concentrated through a reverse osmosis membrane at a pressure of 20 MPa (collecting the outflowing water, returning to the extraction tank for reuse), and spray-dried (the inlet air temperature for spray drying is 140 °C, the air outlet temperature is 70 °C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com