Micron order prism pyramid monomer and manufacturing method thereof

A production method and prism angle technology, which are applied in optical components, optics, instruments, etc., can solve the problems of poor medium suspension effect, easy color loss, faded light perception, etc., and achieve the effect of bending resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

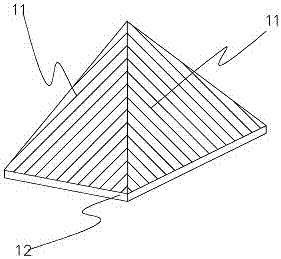

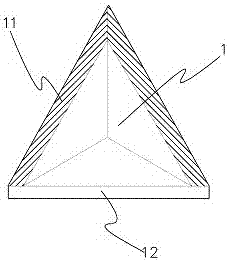

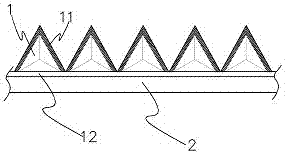

[0032] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that a micron-scale prism pyramid monomer includes a prism pyramid monomer 1, the vertical height from the apex of the prism pyramid monomer to the bottom surface is 65um to 70um, and the prism angle The thickness from the pyramid apex of the cone monomer 1 to the carrier film 2 is 70um~80um; the three sides of the prism pyramid monomer are respectively provided with a silver mirror metal layer 11, and the silver mirror metal layer 11 is vacuum evaporated. Inorganic metal materials such as metallized aluminum or zinc or chromium or silver, the thickness of the silver mirror metal layer 11 is 1um to 5um, and the surface smoothness of the silver mirror metal layer 11 is within 50nm; the bottom surface of the prism corner cone monomer 1 Also covered with a peelabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com