Silver-plated reflecting film and preparation method thereof

A technology of reflective film and silver-plated type, applied in the field of silver-plated reflective film and its preparation, to achieve the effects of easy operation, excellent reflectivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

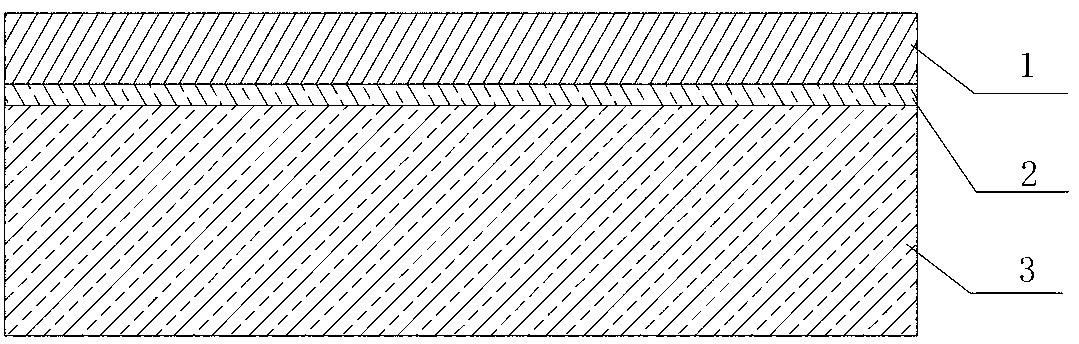

Image

Examples

preparation example Construction

[0028] The preparation method of the silver-plated composite reflection film provided by the invention comprises the steps:

[0029] (1) Prepare reflective polyester film layer;

[0030] (2) Place 99.99% silver in the target of the sputtering chamber, use Ar as the sputtering gas, and the vacuum degree is 10-1.0×10 -1 Pa, the working temperature is 850-1000°C, the film-forming speed is 0.01-5mm / min, a silver-plated layer is formed on the reflective polyester film layer, and annealing is performed at room temperature under nitrogen to accelerate the crystallization of the silver-plated layer;

[0031] (3) Using the dry coating method, using the pre-prepared protective layer film, through a 90°C heating channel and hot pressing, the protective layer film is composited on the silver-plated layer prepared in step (2), and wound up.

[0032] Prepare the silver-plated composite reflective film according to the above-mentioned method, and its various performance test methods are as ...

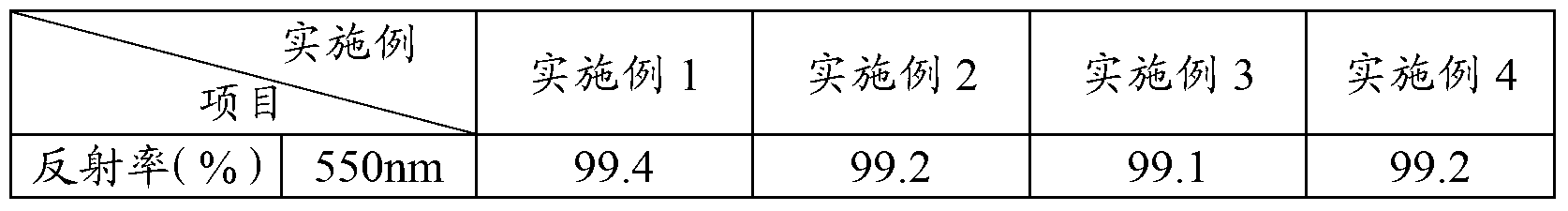

Embodiment 1

[0035] The silver-plated composite reflective film was prepared according to the above method, the thickness of the reflective polyester film layer was 50 μm, the thickness of the silver-plated layer was 1.5 μm, and the protective layer was a polyethylene film with a thickness of 20 μm. The relevant properties of the obtained composite reflective film are shown in Table 1.

Embodiment 2

[0037] The silver-plated composite reflective film was prepared according to the above method. The thickness of the reflective polyester film layer was 75 μm, the thickness of the silver-plated layer was 1.2 μm, and the protective layer was a polypropylene film with a thickness of 15 μm. The relevant properties of the obtained composite reflective film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com