Production method of low-alloy and high-strength thick plates

A low-alloy, high-strength, production method technology, applied in the field of metallurgy, can solve the problems of not being able to meet the requirements of thicker steel plates, Z-direction performance can not meet the requirements, loss of production costs, etc., to achieve large-scale production and use, good mechanical performance and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The production process of the present invention is: electric furnace smelting—outside furnace refining (LF+VD)—vacuum casting—billet cleaning—heating—rolling—stacking and slow cooling—heat treatment—flaw detection—sampling inspection—inspection—storage.

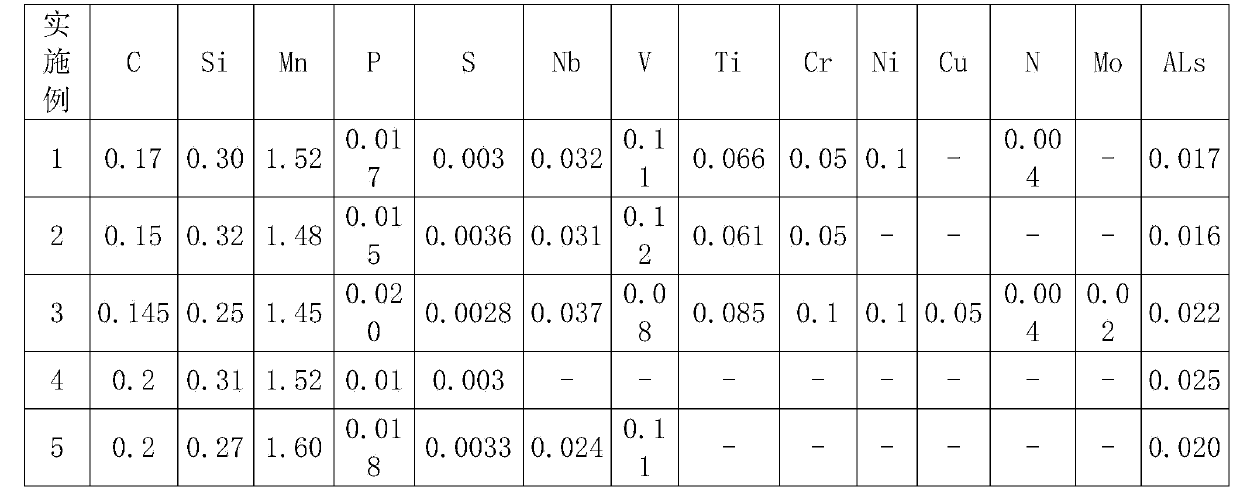

[0020] Embodiment chemical composition and Wt% content are as table 1:

[0021] Table 1 embodiment chemical composition wt% content table

[0022]

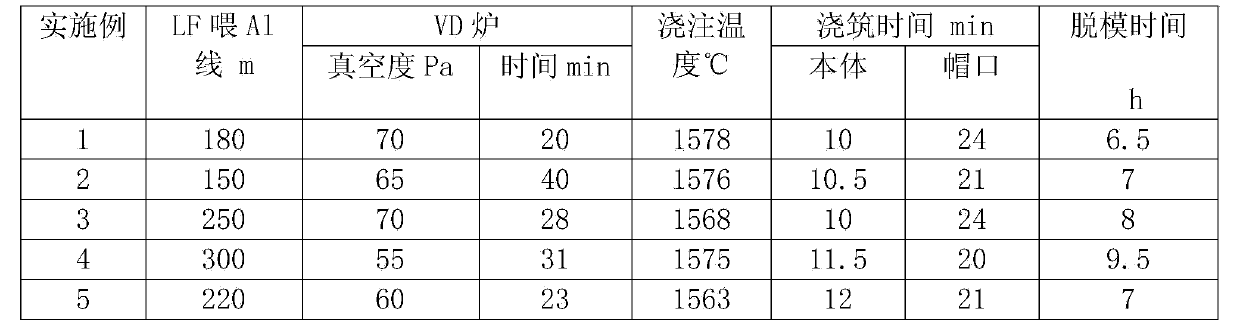

[0023] Embodiment smelting process parameters are shown in Table 2:

[0024] Table 2 Example smelting process parameter list

[0025]

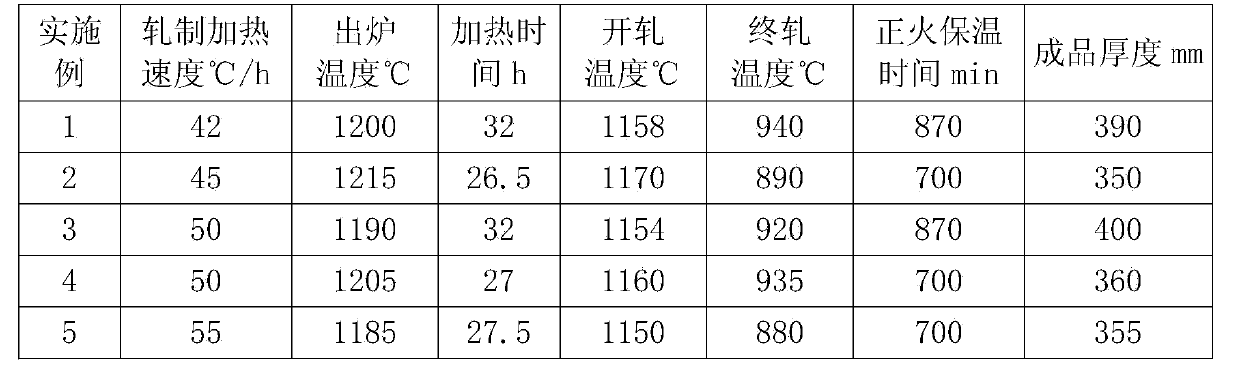

[0026] Embodiment rolling process parameter is shown in Table 3:

[0027] Table 3 embodiment rolling process parameter

[0028]

[0029] Embodiment performance index inspection result is shown in Table 4:

[0030] Table 4 embodiment performance index inspection result

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com