Rapid cooling device for power battery

A power battery and rapid cooling technology, applied in secondary batteries, battery temperature control, circuits, etc., can solve the problems of shortening the service life of the power system, uneven temperature, battery failure, etc. Cooling, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

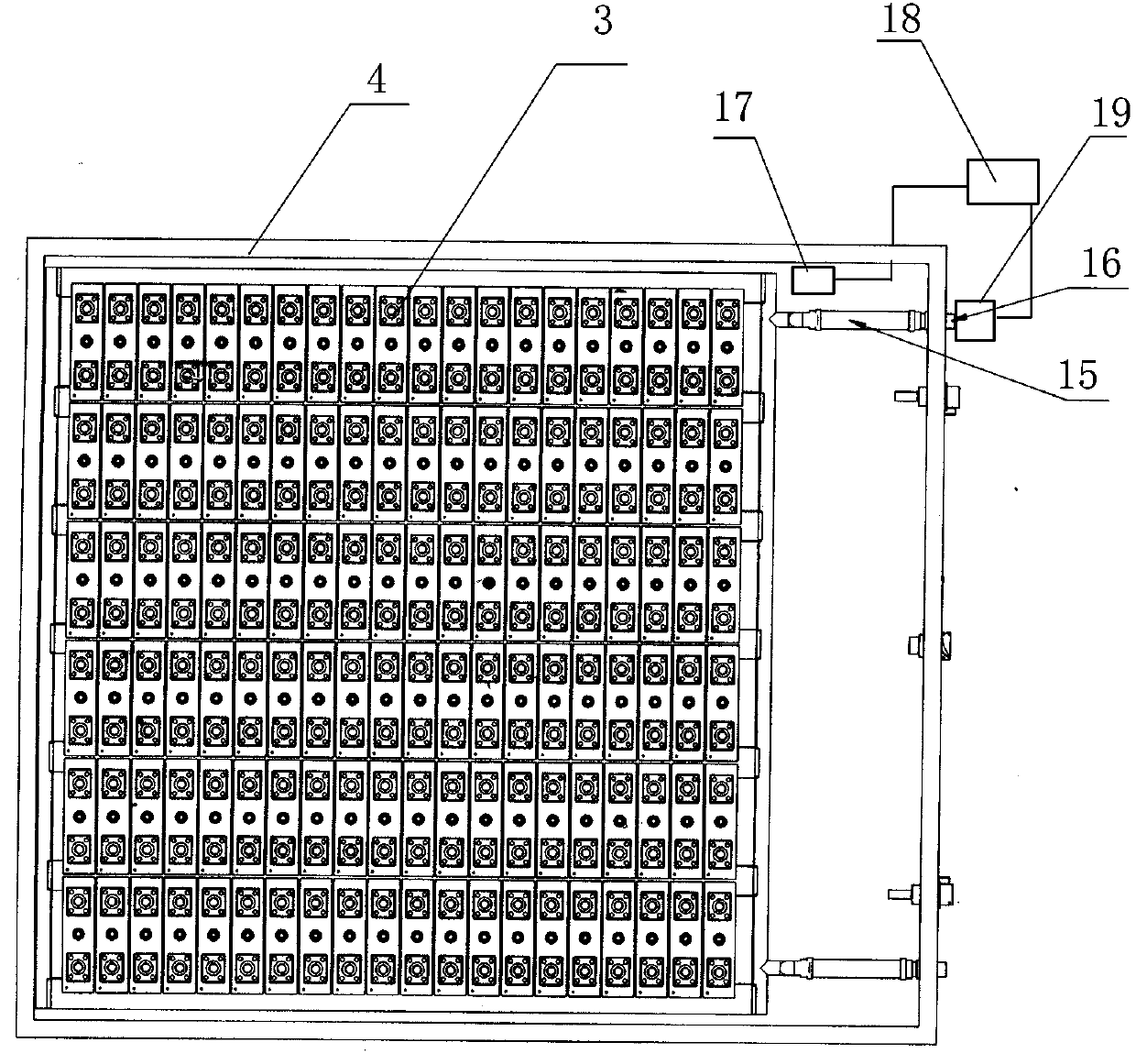

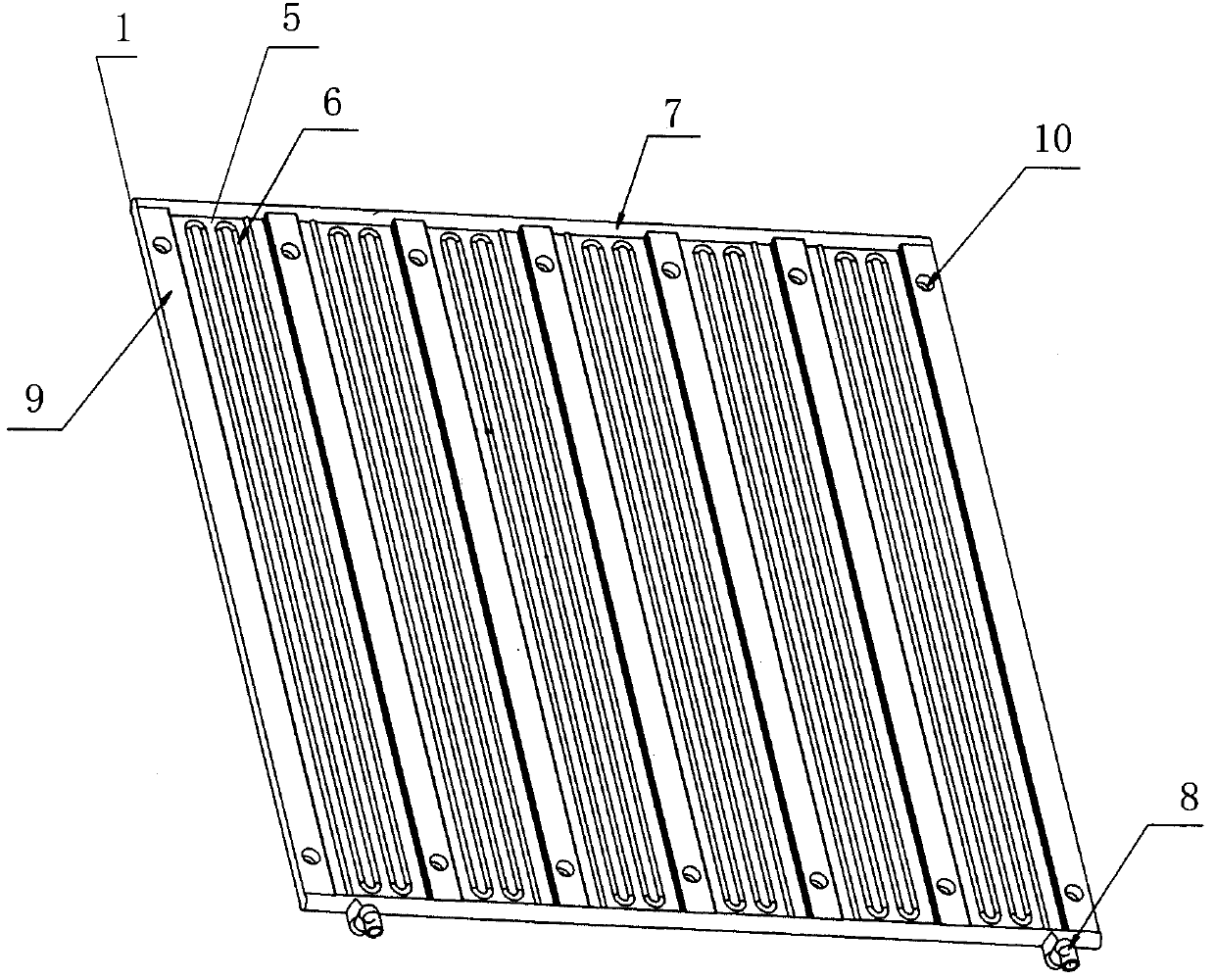

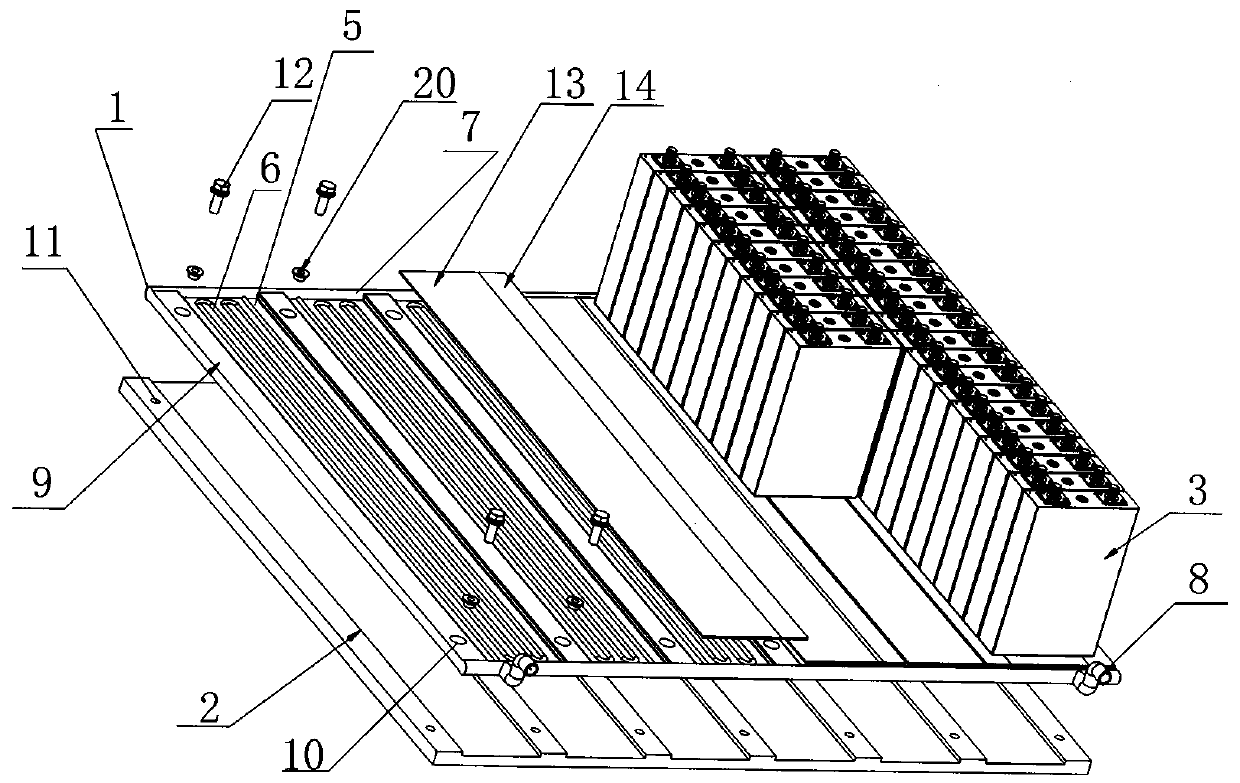

[0010] exist figure 1 , figure 2 and image 3 Among them, the present invention provides a rapid cooling device for a power battery, which is mainly composed of a microchannel heat exchanger 1, a protection plate 2, a power battery 3 and a battery box 4, the microchannel heat exchanger 1, a protection plate 2 and a power The batteries 3 are all placed in the battery box 4, the protective plate 2 is a high-strength insulating foamed plastic, and the microchannel heat exchanger 1 is composed of a battery mounting base 5, a refrigerant pipe 6, a confluence pipe 7 and a steam inlet and outlet. tubes 8, and several groups of refrigerant tubes 6 are distributed on the surface of the battery mounting base 5. Six groups of refrigerant tubes 6 are distributed on the surface of the battery mounting base 5 in this embodiment, and the refrigerant tubes 6 are row pipes. The tubes 6 are evenly distributed on the surface of the battery mounting base 5, spacers 9 are arranged on the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com