Acoustic resonator and preparation method thereof

An acoustic wave resonator, a legitimate technology, applied in electrical components, impedance networks, etc., can solve the problem of low operating frequency of surface acoustic wave filters, and achieve the effects of large-scale production and use, high performance, and increased operating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

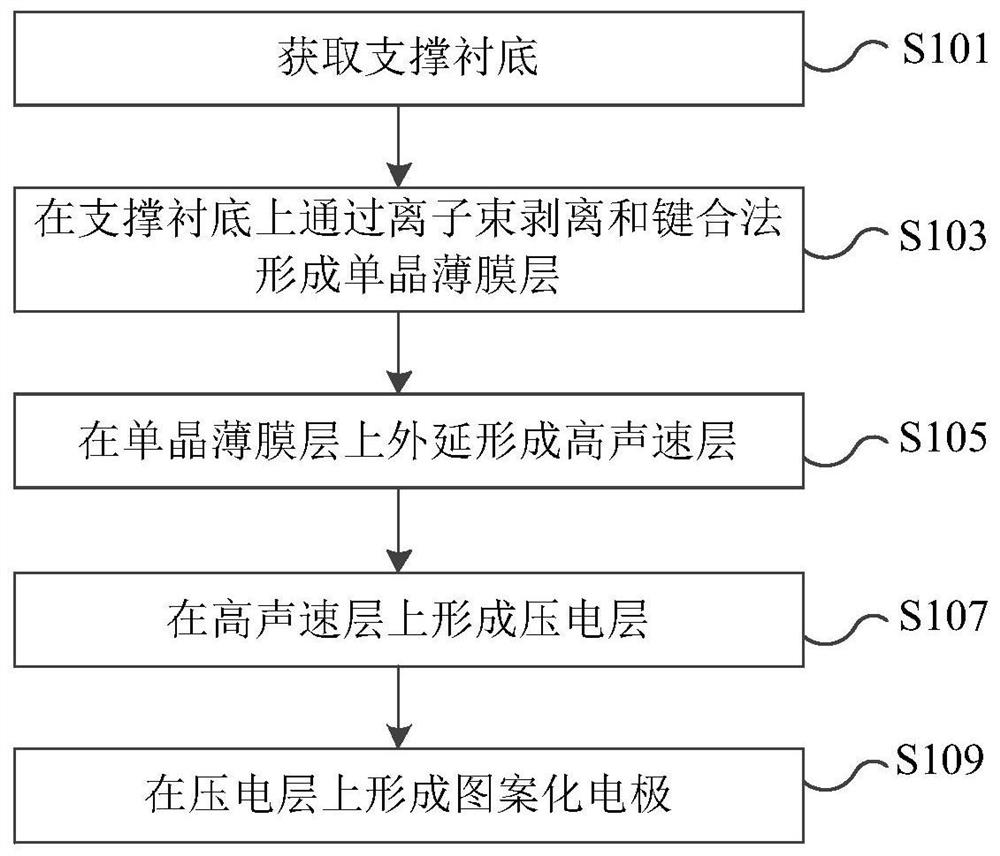

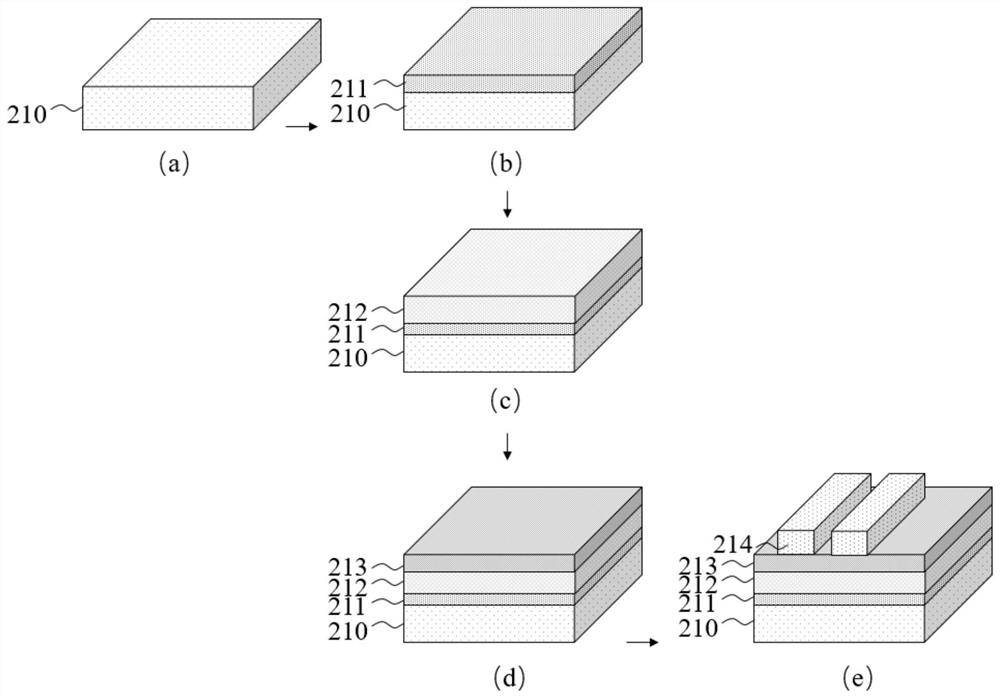

[0035] In view of the shortcomings of the prior art described above, the embodiment of the present application provides a method for manufacturing an acoustic wave resonator. see figure 1 and figure 2 , figure 1 is a schematic flow chart of a method for preparing an acoustic wave resonator provided in an embodiment of the present application, figure 2 It is a schematic diagram of the preparation process of an acoustic wave resonator provided in the embodiment of the present application, including:

[0036] S101: Obtain a supporting substrate 210 .

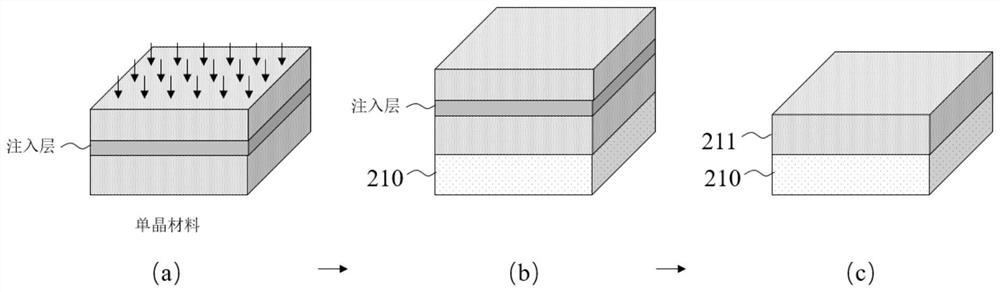

[0037] S103: Forming a single crystal thin film layer 211 on the supporting substrate 210 by ion beam stripping and bonding.

[0038]S105 : Epitaxially forming a high-sonic layer 212 on the single crystal thin film layer 211 .

[0039] S107 : forming the piezoelectric layer 213 on the high-sonic layer 212 .

[0040] S109 : forming a patterned electrode 214 on the piezoelectric layer 213 .

[0041] Optionally, based on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com