Metal substrate long-lasting anticorrosive inter-coat and preparation method thereof

A long-term anti-corrosion, metal substrate technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of loss of anti-corrosion function, chemical bond breakage, short anti-corrosion period, etc., to achieve good metal anti-corrosion effect, The effect of promoting curing and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

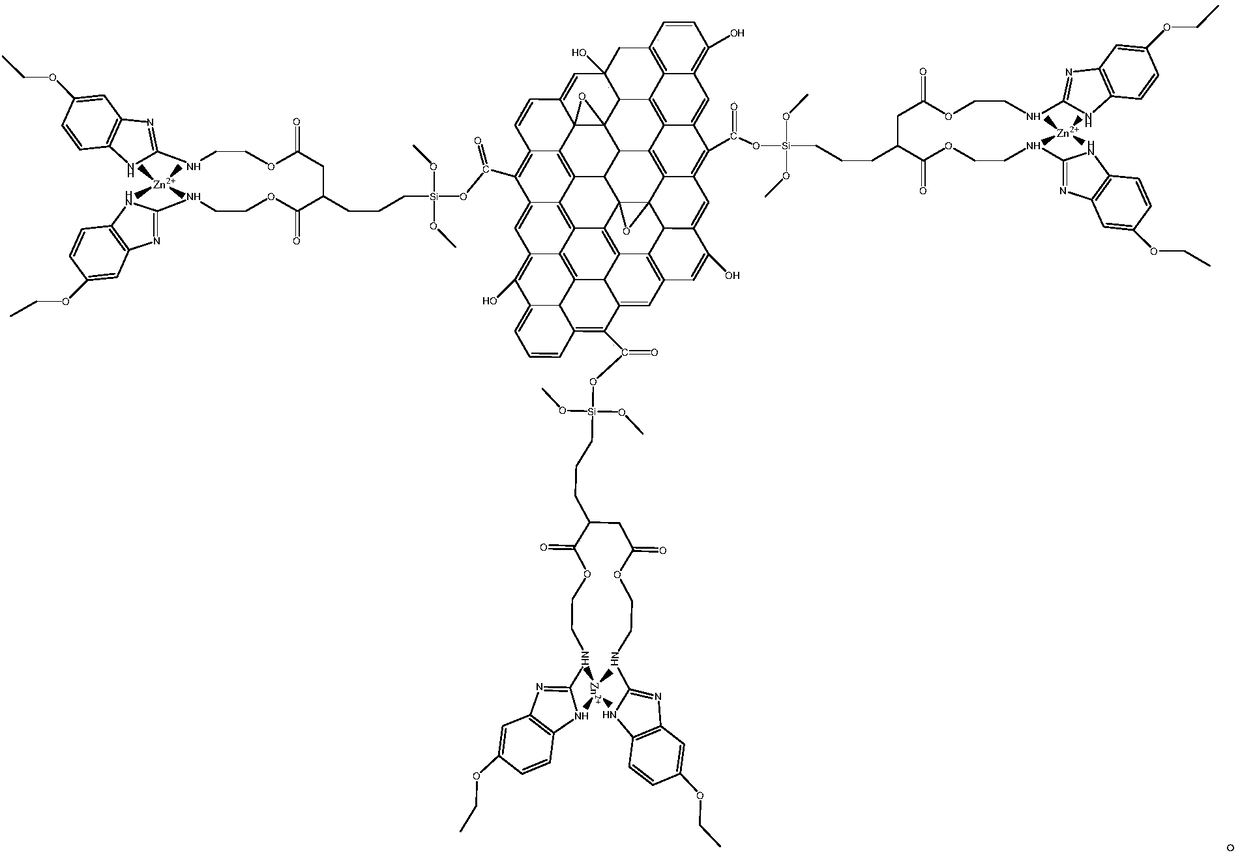

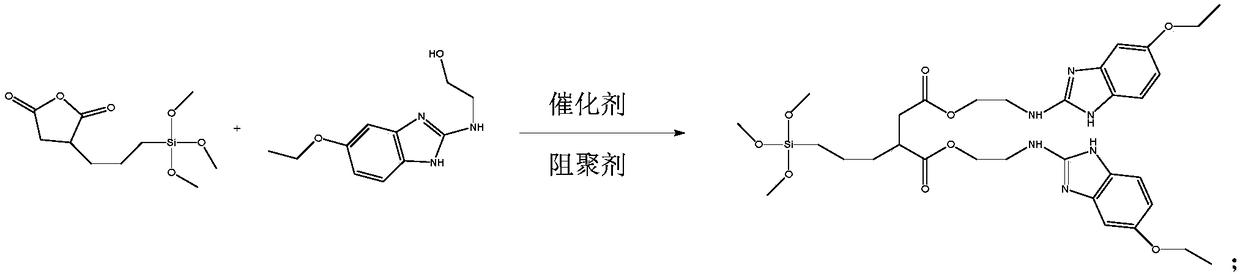

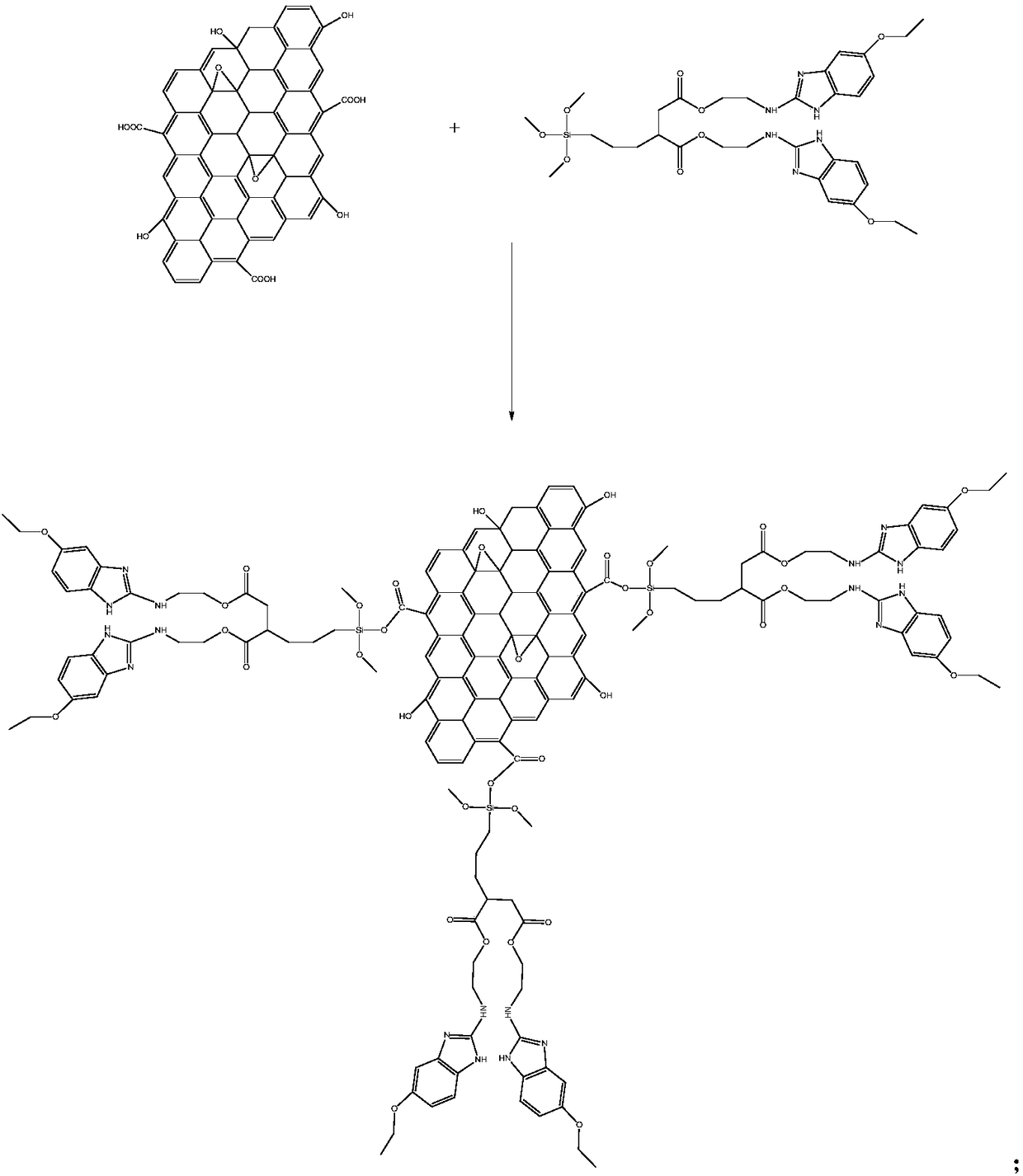

Image

Examples

Embodiment 1

[0050] A long-acting anti-corrosion medium coating for metal substrates, which is composed of A and B two components, and the weight ratio of the A component and the B component is 100:30;

[0051] Wherein, described component A is made up of following raw material by weight:

[0052] 55 parts of epoxy-silicone resin modified acrylic resin emulsion, 15 parts of functionalized modified graphene, 15 parts of talc powder with a particle size of 5um, 10 parts of ethylene glycol ether, 0.3 part of defoamer BYK066N, selected from BYK Chemical company, 1 part of leveling agent EFKA3777, selected from Ciba Company, 0.8 part of cobalt organic acid soap, 0.5 part of thickener R305, selected from Zhongwan Company, 1 part of wetting agent TEGO WET 260, selected from Tego Company , 35 parts of deionized water

[0053] Described B component is made up of following raw material by weight:

[0054] 45 parts of isocyanate curing agent, 15 parts of ethylene glycol ether;

[0055] The epoxy-s...

Embodiment 2

[0074] A long-acting anti-corrosion medium coating for metal substrates, which is composed of A and B two components, and the weight ratio of the A component and the B component is 100:25;

[0075] Wherein, described component A is made up of following raw material by weight:

[0076] 60 parts of epoxy-silicone resin modified acrylic resin emulsion, 12 parts of functionalized modified graphene, 10 parts of talc powder with a particle size of 1um, 8 parts of butanol, 0.1 part of defoamer BYK066N, selected from BYK Chemicals , 0.5 parts of leveling agent EFKA3777, selected from Ciba Company, 0.3 parts of cobalt organic acid soap, 0.3 parts of thickener R305, selected from Zhongwan Company, 0.5 parts of wetting agent TEGO WET260, selected from Tego Company, deionized 30 parts of water

[0077] Described B component is made up of following raw material by weight:

[0078] 40 parts of isocyanate curing agent, 10 parts of butanol;

[0079] The epoxy-silicone resin modified acryli...

Embodiment 3

[0098] A long-acting anti-corrosion medium paint for metal substrates, which is composed of A and B two components, and the weight ratio of the A component and the B component is 100:35;

[0099] Wherein, described component A is made up of following raw material by weight:

[0100] 50 parts of epoxy-silicone resin modified acrylic resin emulsion, 18 parts of functionalized modified graphene, 20 parts of talc powder with a particle size of 10um, 12 parts of isopropanol, 0.5 part of defoamer BYK066N, selected from BYK Company, leveling agent EFKA37770.8 parts, selected from Ciba Company, cobalt organic acid soap 0.5 parts, thickener R305 0.8 parts, selected from Zhongwan Company, wetting agent TEGOWET 260 0.8 parts, selected from Tego Company, 32 parts deionized water

[0101] Described B component is made up of following raw material by weight:

[0102] 50 parts of isocyanate curing agent, 20 parts of isopropanol;

[0103] The epoxy-silicone resin modified acrylic resin emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com