Electroless copper plating activating solution and preparation method thereof

A technology of electroless copper plating and activation solution, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of palladium solution decomposition, catalytic failure, destruction, high operating cost of ionic palladium activation solution, etc., to achieve The surface is smooth, avoiding sedimentation, and ensuring the effect of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

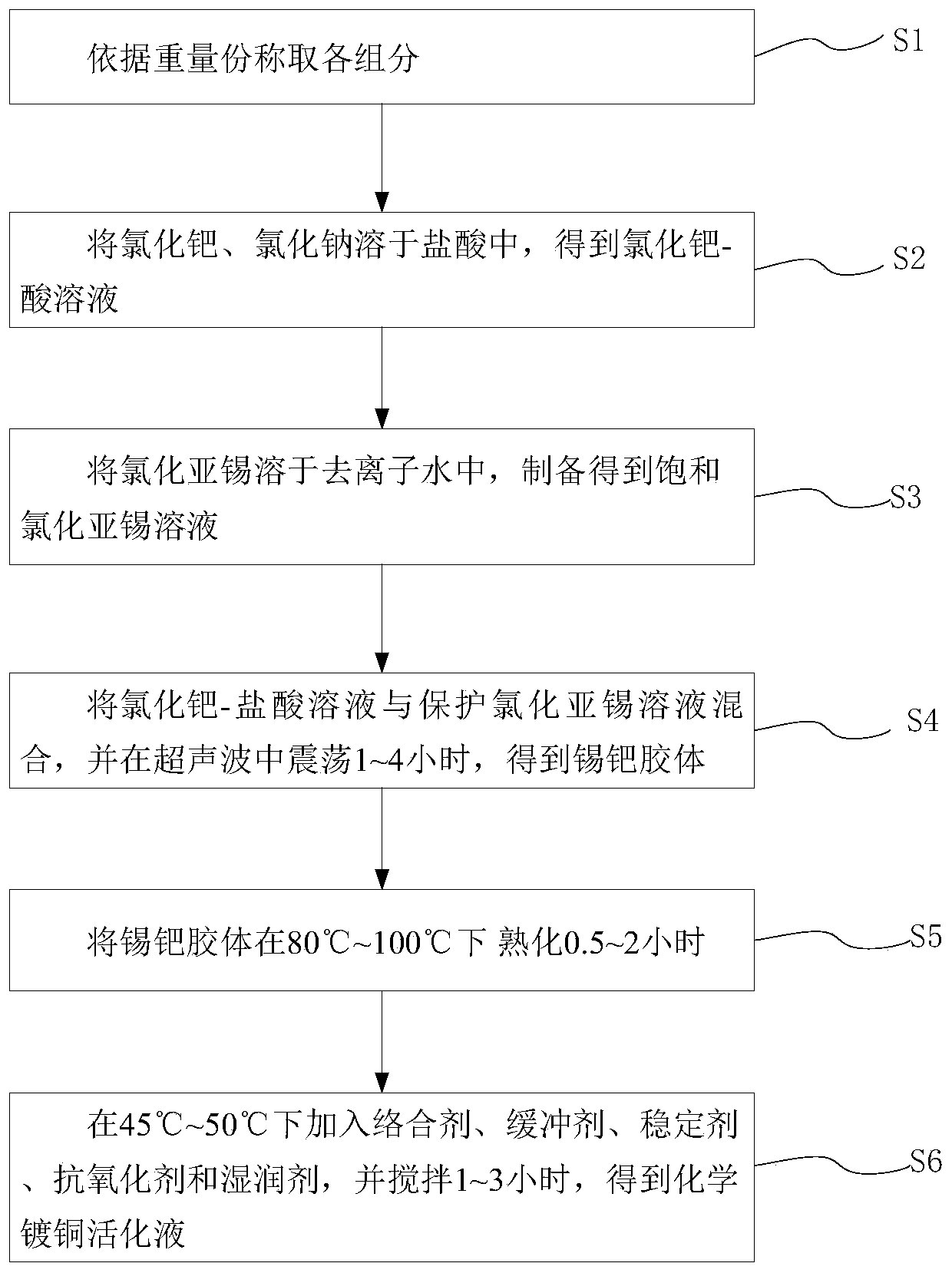

[0044] The preparation method of above-mentioned electroless copper plating activation solution is as follows:

[0045] Palladium chloride and sodium chloride are dissolved in hydrochloric acid to obtain a palladium chloride-hydrochloric acid solution;

[0046] Dissolving stannous chloride in deionized water prepares a saturated stannous chloride solution;

[0047] Mix palladium chloride-hydrochloric acid solution with saturated stannous chloride solution, and vibrate in ultrasonic to obtain tin palladium colloid;

[0048] Aging the tin palladium colloid;

[0049] Add complexing agent, buffering agent, stabilizer, antioxidant and wetting agent, and stir to obtain electroless copper plating activation solution.

[0050] Therefore, the electroless copper plating activation solution of the present application first prepares tin-palladium colloid, after aging the tin-palladium colloid to form a colloidal solution, add complexing agent and buffering agent, through complexing agent ...

Embodiment 1

[0055] Taking the preparation of 1Kg of electroless copper plating activation solution as an example, the components and contents are as follows:

[0056]

[0057]

[0058] The preparation method of the electroless copper plating activation solution of the present embodiment may further comprise the steps:

[0059] a1, take palladium chloride, sodium chloride and hydrochloric acid according to above-mentioned content, and palladium chloride, sodium chloride are dissolved in hydrochloric acid, obtain palladium chloride-hydrochloric acid solution;

[0060] a2, take stannous chloride by weighing, and dissolve in deionized water, prepare saturated stannous chloride solution;

[0061] a3, mixing palladium chloride-hydrochloric acid solution with saturated stannous chloride solution, and vibrating in 500KHz ultrasonic waves for 1 hour to obtain tin palladium colloid;

[0062] a4, aging the tin-palladium colloid at 80°C for 2 hours;

[0063] a5, add complexing agent, bufferin...

Embodiment 2

[0065] Taking the preparation of 1Kg of electroless copper plating activation solution as an example, the components and contents are as follows:

[0066]

[0067] The preparation method of the electroless copper plating activation solution of the present embodiment may further comprise the steps:

[0068] b1, take palladium chloride, sodium chloride and hydrochloric acid according to the above-mentioned content, and dissolve palladium chloride and sodium chloride in hydrochloric acid to obtain palladium chloride-hydrochloric acid solution;

[0069] b2, take stannous chloride by weighing, and dissolve in deionized water, prepare saturated stannous chloride solution;

[0070] b3, mixing palladium chloride-hydrochloric acid solution with saturated stannous chloride solution, and vibrating in 100KHz ultrasonic waves for 4 hours to obtain tin palladium colloid;

[0071] b4, aging the tin-palladium colloid at 100°C for 0.5 hours;

[0072] b5, add complexing agent, buffering ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com