Method for preparing palladium catalytic materials supported by chitosan-modified montmorillonite

A chitosan modification and catalytic material technology, which is applied in the preparation of organic compounds, chemical instruments and methods, catalysts, etc., can solve the problems of too fast loss of transition metals, easy aging degradation, poor reusability, etc. Achieve the effects of good complexation ability, excellent comprehensive performance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

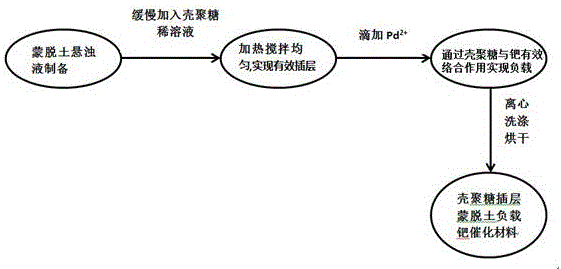

[0026] Such as figure 2 Shown, the preparation method of chitosan modified montmorillonite supported palladium catalytic material of the present invention comprises the following steps:

[0027] (1) Preparation of dilute chitosan solution: Take 0.5g of pharmaceutical grade chitosan powder (molecular weight: 100,000, degree of deacetylation: 95%), dissolve in 50ml of 2% acetic acid solution to form a mixed solution, and keep stirring for 2 hours to form Homogeneous solution, let it defoam for 2h.

[0028] (2) Preparation of palladium ion solution: Weigh 0.3g palladium chloride, add 100ml distilled water, add 5g sodium chloride in a conical flask, heat and stir to completely dissolve to form Na 2 PdCl 4 solution.

[0029] (3) Preparation of chitosan-modified montmorillonite-loaded palladium catalytic material: take 2g montmorillonite, add 50ml distilled water, heat in a water bath at 50-60°C, stir evenly, pour chitosan solution into montmorillonite to suspend Stirring was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com