A method for preparing cigarettes with colored smoke beads

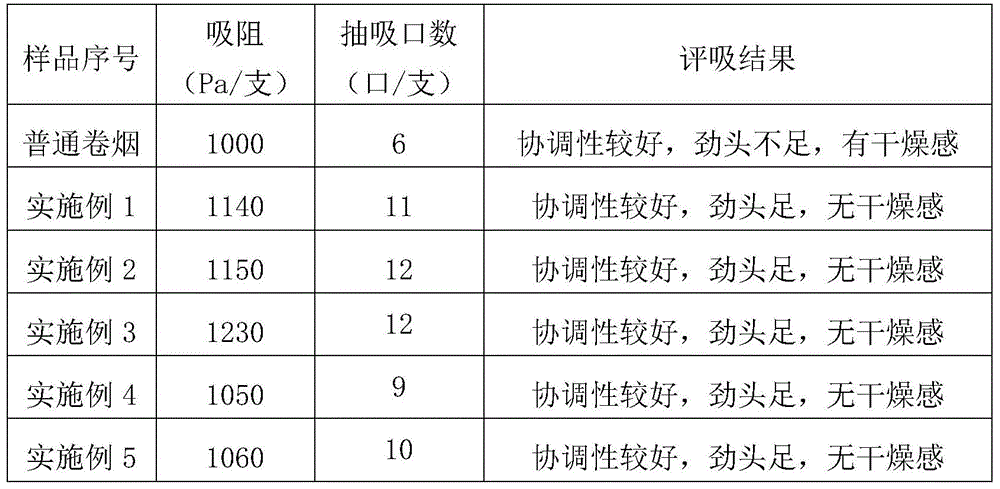

A technology for tobacco beads and cigarettes, applied in the field of cigarettes, can solve the problems of difficulty in ensuring the distribution of cut tobacco, unable to guarantee the formula of cut tobacco, short smoking time of cigarettes, etc., and achieves the effects of uniform cigarette formula, increased number of puffs, and good coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing cigarettes, comprising the steps of:

[0030] 1) Puree 1Kg of cigarette leaf powder into 80-mesh fine powder (referring to the fine powder that can pass through the 80-mesh sieve), take 5g of hydroxypropyl methylcellulose, dissolve it in 400ml of water, add it to the above-mentioned fine powder, and stir evenly And make soft material, then extrude the soft material on the spheronizer, extrude it into slender strips through the extruder, then spheronize it through the spheronizer, and dry it on the fluidized bed to obtain a particle size range of 0.8- 1.5mm, smoke beads with a bulk density of 1.5g / ml;

[0031] 2) pack a colored film coat on the surface of the smoke beads, and the colored film coat accounts for 1% of the weight of the smoke beads;

[0032] 3) Add 0.5% carrageenan powder by weight to the coated cigarette beads, mix evenly, put it into a mold and feed steam at 120°C, and apply 1.2Kg / cm2 at the same time 2 Press the smoke beads into ...

Embodiment 2

[0035] A method for preparing cigarettes, comprising the steps of:

[0036] 1) Purify 1Kg of cigarette leaf powder into 60-mesh fine powder (referring to fine powder that can pass through a 60-mesh sieve), take 8g of povidone, dissolve it in 500ml of water, add it to the above-mentioned fine powder, stir evenly and make soft Then extrude the soft material on the spheronizer, extrude it into slender strips through the extruder, then spheronize it through the spheronizer, and dry it on the fluidized bed to obtain a particle size range of 1-2mm, bulk density Smoke beads of 1.6g / ml;

[0037] 2) pack a colored film coat on the surface of the smoke beads, and the colored film coat accounts for 2% of the weight of the smoke beads;

[0038] 3) Add 1% xanthan gum powder to the coated cigarette beads, mix evenly, put it into a mold and feed steam at 140°C, and apply 1Kg / cm2 at the same time 2 Press the smoke beads into smoke sticks;

[0039] 4) Wrap the cigarette stick with tipping p...

Embodiment 3

[0041] A method for preparing cigarettes, comprising the steps of:

[0042] 1) Powder 1Kg of cigarette leaves into fine powder of 100 mesh, take 10g of carboxymethyl cellulose, dissolve it with 400ml of water, add it to the above fine powder, stir evenly and make soft material, then squeeze out the soft material- Spheronizing machine, first extruded into slender strips through the extruder, then spheronized by the spheronizer, dried on the fluidized bed to obtain smoke beads with a particle size range of 0.5-1.2mm and a bulk density of 1.8g / ml;

[0043] 2) pack a colored film coat on the surface of the bead, and the colored film coat accounts for 0.5% of the weight of the bead;

[0044] 3) Add 0.2% gelatin powder to the coated smoke beads, mix evenly, put it into a mold and feed steam at 110°C, and apply 1.5Kg / cm2 at the same time 2 Press the smoke beads into smoke sticks;

[0045] 4) Wrap the cigarette stick with tipping paper, connect it with a filter, and make a cigarette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com