Preparation method of electronic tobacco tar for microwave pyrolysis-molecular distillation combination

A molecular distillation and electronic cigarette oil technology, applied in the field of electronic cigarettes, to achieve the effect of improving sensory quality, reducing tar and other harmful substances, and having elegant and delicate aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

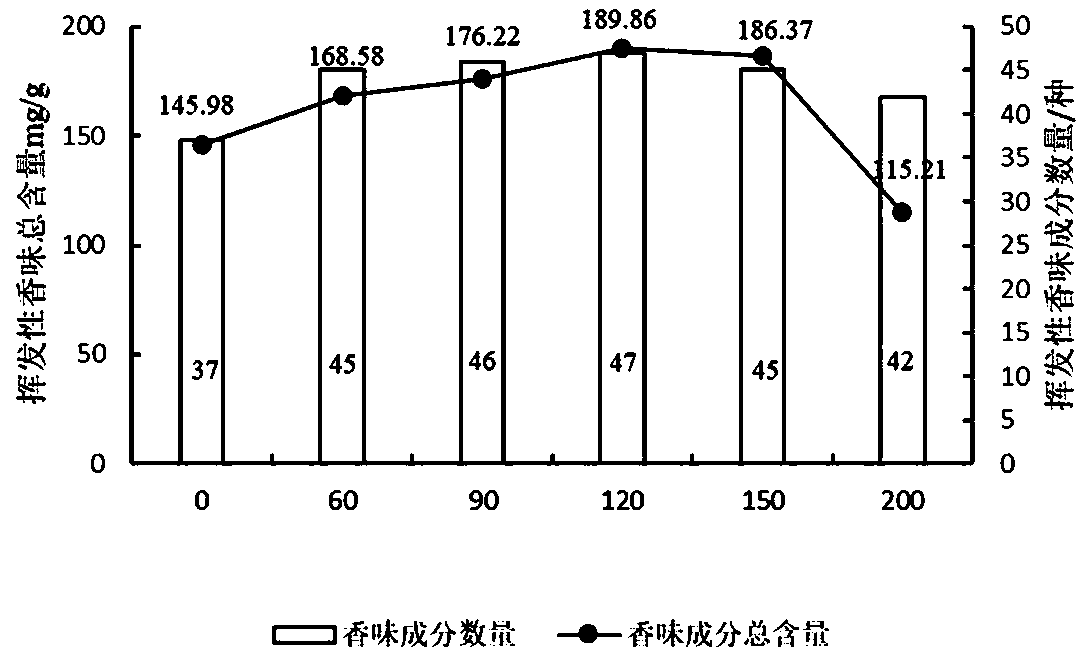

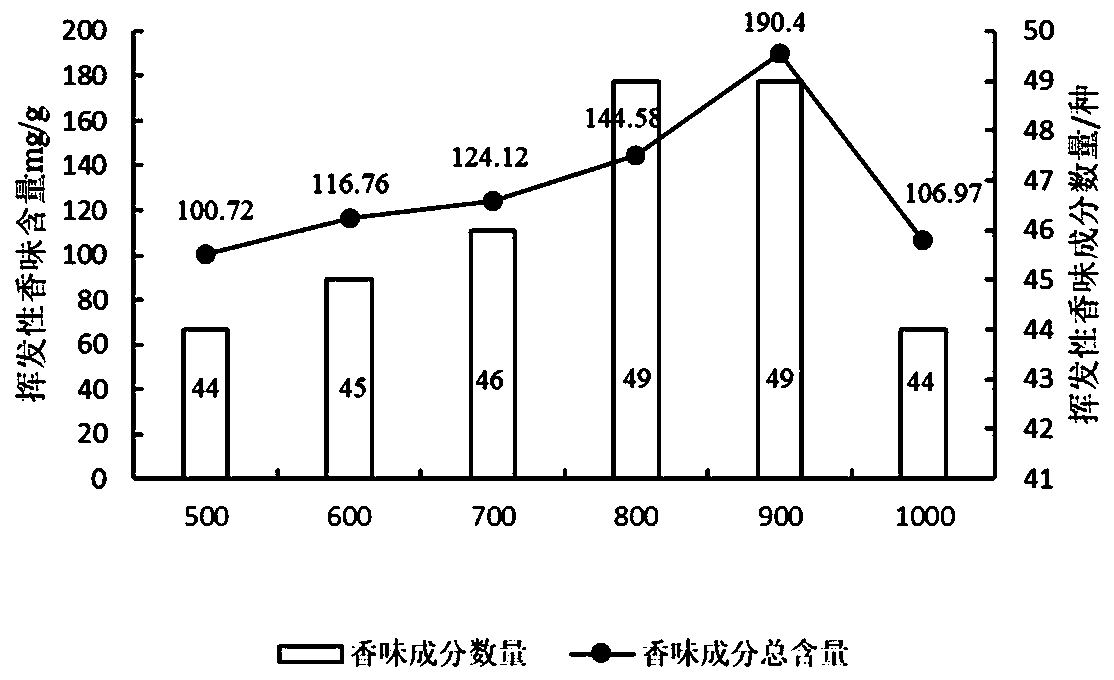

Image

Examples

Embodiment 1

[0041] In this example, taking B011 flue-cured tobacco leaves in Xuchang, Henan as an example, electronic cigarette oil was specifically prepared, and the specific process is briefly described as follows.

[0043] Shred the flue-cured tobacco leaves of Xuchang, Henan Province B011, and place them in a constant temperature and humidity box to balance for 24 hours, so that the moisture content reaches 12%-14%. Take 100g of shredded tobacco and place it in a quartz reaction bottle, and place the quartz reaction bottle in the cracking furnace chamber In the center, microwave cracking is carried out; for specific cracking, the power of microwave cracking is 900W, and the cracking time is 120s.

[0044] (2) Extraction

[0045] The pyrolysis product produced after microwave pyrolysis in step (1) was extracted with 200 mL of absolute ethanol, and the ultrasonic extraction power was 40%. After the extraction was completed for 30 minutes, it was concentr...

Embodiment 2~3

[0067] In Example 2 and Example 3, taking C076 flue-cured tobacco leaves of Henan Xuchang and Hubei Enshi B1F tobacco leaves of Burley tobacco as examples, e-liquid and e-liquid were prepared, and the specific preparation process was the same as that of Example 1.

[0068] The changes in the content of some components in the e-liquid prepared in Examples 1 to 3 above are summarized in Table 2 below.

[0069] Table 2 Comparison results of the main aroma components of cut tobacco pyrolysis products after molecular distillation and without molecular distillation

[0070] .

[0071] It can be seen from the above table that after further molecular distillation of the pyrolysis products of shredded tobacco, the content of important tobacco aroma components in e-liquid is significantly higher than that in e-liquid without molecular distillation (due to nicotine and cigarette strength related, and its content is far greater than the content of other aroma substances, so it is exclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com