Milk flavor formula

A technology of milk essence and formula, which is applied in the field of food flavor, can solve the problems of insufficient natural feeling, limited application fields, poor aroma stability, etc., and achieve the effect of high aroma quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Take the production of 100KG milk essence as an example below to further describe the present invention:

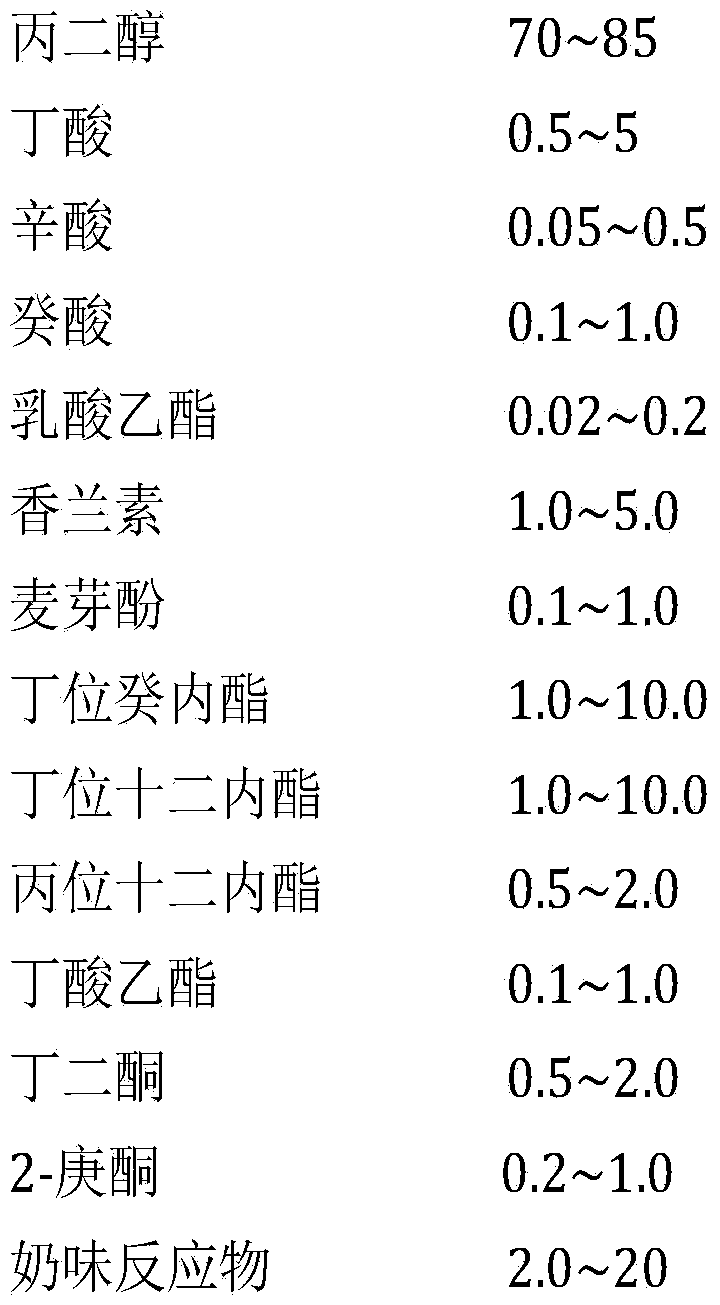

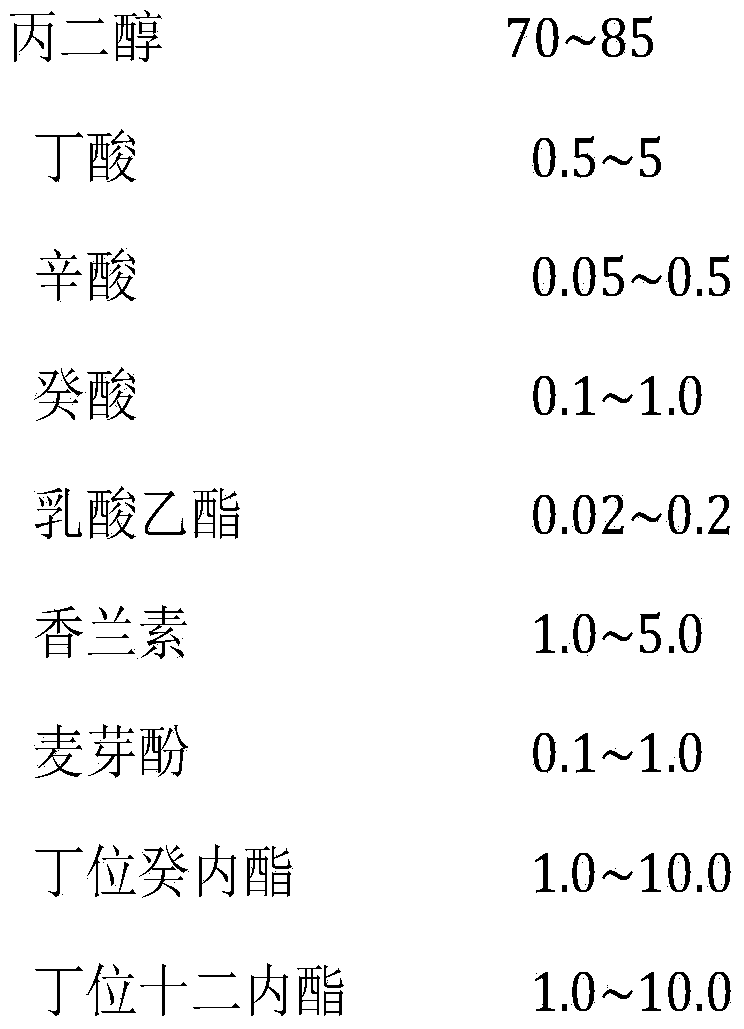

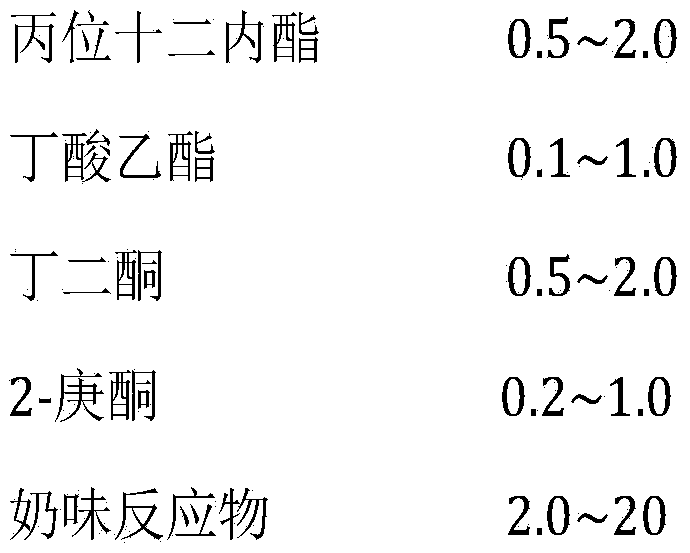

[0009] The ratio of producing 100KG milk essence is:

[0010]

[0011]

[0012] The production process is: propylene glycol 82.4KG, butyric acid 1.0KG, caprylic acid 0.1KG, capric acid 0.8KG, ethyl lactate 0.1KG, vanillin 2.5KG, maltol 0.5KG, butyl decanolactone 2.0KG, butyl lactone Add 3.0KG of laurolactone, 1.0KG of laurolactone, 0.5KG of ethyl butyrate, 0.6KG of diacetyl, 0.5KG of 2-heptanone, and 5.0KG of milk-flavored reactants. Stir in the interlayer tank under the heat preservation state at 5°C until it is completely dissolved, and fill it into the warehouse after sampling and testing pass the test. The milky reactant is prepared from natural source milk powder, reducing sugar and amino acid by Maillard reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com